Rotating shaft of automobile generator

A technology for automotive generators and rotating shafts, applied in shafts, shafts, bearings, mechanical equipment, etc., can solve the problems of poor positioning of rotating shafts, low efficiency of press-fitting work, and easy deformation of shaft heads, and improve installation efficiency and quality , Reduce the probability of deformation and reduce the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

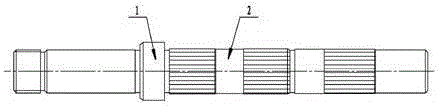

[0012] Examples, see attached figure 1 , a rotating shaft of an automobile generator, comprising a step 1 and a body 2, the left end of the body 2 is processed with an external thread, the body 2 is provided with a step 1, the body 2 is provided with a spline groove and is located on the right side of the step 1 On the side, there are three spline grooves, and the optical axis is between adjacent spline grooves.

[0013] Preferably, chamfers are provided on the left and right end surfaces of the body 2 .

[0014] Preferably, an undercut groove is provided on the right side of the thread at the left end of the body 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com