Amino acid cleansing cream and preparation method thereof

A production method and technology of cleansing cream, applied in the field of amino acid cleansing cream and its production, can solve the problems of easy allergies, weak neutralization ability, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

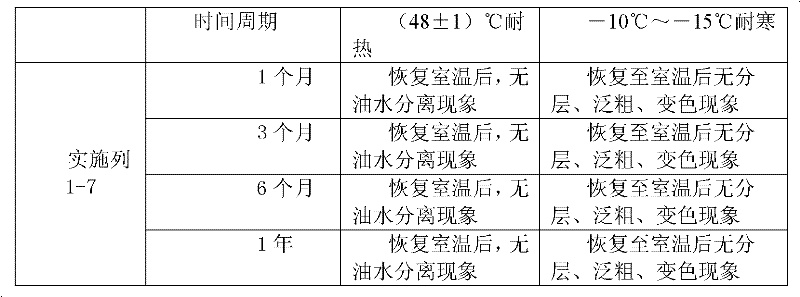

Examples

Embodiment 1

[0089] The total amount of raw materials is 100 kg. Among them, the material of phase A: 5 kg of glycerin, 0.08 kg of hydroxyethyl cellulose. Phase B materials: 10 kg of propylene glycol, 28 kg of lauroyl glutamate, and 7 kg of sodium cocoyl glutamate. Phase C material: 0.8 kg of cetearyl-octadecane mixed fatty alcohol, 0.35 kg of cetearyl alcohol ether (20), 0.68 kg of cocoaminopropyl dimethyl betaine, cetearyl alcohol ether-60 myristyl Ethylene glycol 0.5 kg. Phase D material: 1.5 kg of acrylate / polyoxyethylene-20 stearyl ether methacrylate copolymer. Phase E material: 0.6 kg of citric acid. Phase F materials: 0.15 kg of bis-imidazolidinyl urea, 0.10 kg of methyl p-hydroxybenzoate, 0.05 kg of propyl p-hydroxybenzoate; the balance is deionized water.

[0090] Craftsmanship:

[0091] (1) After mixing the components of Phase A evenly, add them together with deionized water into the emulsification pot, stir and heat to 60°C, stir and dissolve, then cool down to 30°C.

[00...

Embodiment 2

[0101] The total amount of raw materials is 100 kg. Among them, the material of phase A: 3 kg of glycerin, 0.05 kg of hydroxyethyl cellulose, and 0.2 kg of D-panthenol. Phase B materials: 10 kg of propylene glycol, 25 kg of lauroyl glutamate, and 6 kg of sodium cocoyl glutamate. C-phase material: 0.8 kg of cetearyl-octadecane mixed fatty alcohol, 1.2 kg of ethylene glycol distearate, 0.35 kg of cetearyl alcohol ether (20), 0.68 kg of cocoaminopropyl dimethyl betaine, Ceteareth-60 myristyl glycol 0.5 kg. Phase D material: 1.5 kg of acrylate / polyoxyethylene-20 stearyl ether methacrylate copolymer. Phase E material: 0.6 kg of citric acid. Phase F materials: sodium hyaluronate 0.05 kg, willow bark extract 0.7 kg, aloe vera juice 2.0 kg, vitamin C 0.8 kg, essence 0.08 kg, diazolidinyl urea 0.15 kg, methyl paraben 0.10 kg , 0.05 kg of propyl p-hydroxybenzoate; the balance is deionized water.

[0102] Manufacturing process is the same as embodiment 1.

Embodiment 3

[0104] The total amount of raw materials is 100 kg. Among them, the material of phase A: 5 kg of glycerin, 0.08 kg of hydroxyethyl cellulose, and 0.4 kg of D-panthenol. Phase B materials: 8 kg of propylene glycol, 27 kg of lauroyl glutamate, and 6 kg of sodium cocoyl glutamate. Phase C material: 0.5 kg of cetearyl-octadecane mixed fatty alcohol, 1 kg of ethylene glycol distearate, 0.4 kg of cetearyl alcohol ether (20), 0.5 kg of cocoaminopropyl dimethyl betaine, Ceteareth-60 myristyl glycol 0.63 kg. Phase D material: 1.7 kg of acrylate / polyoxyethylene-20 stearyl ether methacrylate copolymer. Phase E material: 0.45 kg of citric acid. Phase F materials: sodium hyaluronate 0.06 kg, willow bark extract 0.9 kg, aloe vera juice 1.0 kg, vitamin C 0.5 kg, essence 0.08 kg, diazolidinyl urea 0.15 kg, methyl paraben 0.10 kg , 0.05 kg of propyl p-hydroxybenzoate; the balance is deionized water.

[0105] Manufacturing process is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com