High-solid, low-viscosity and quick-drying odor removal alkyd resin, method for preparing same and application of high-solid, low-viscosity and quick-drying odor removal alkyd resin

A clean-odor alkyd resin, high-solid and low-viscosity technology, applied in coatings, polyester coatings, etc., can solve problems that affect the health of construction workers in the coating site environment, can not give people pleasure, and olfactory sensory stimulation, etc. Achieve the effect of smooth, even, plump and clean paint film, improve convenience and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

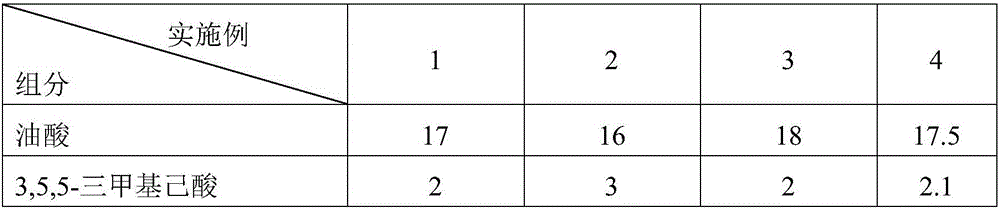

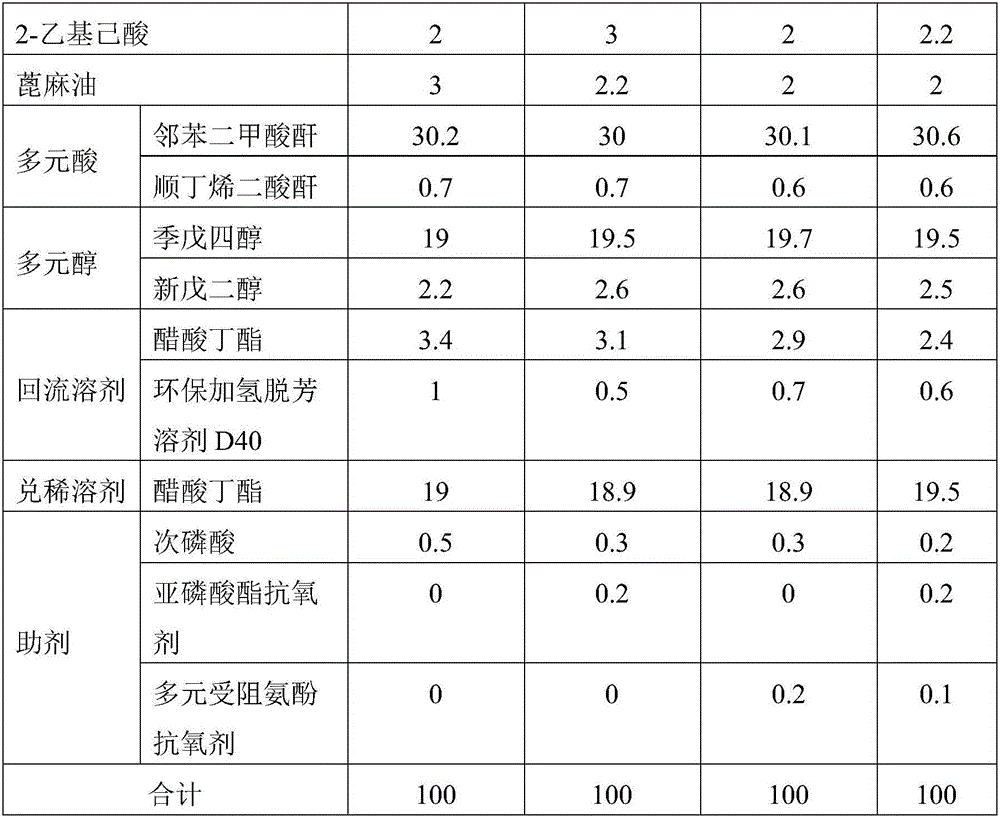

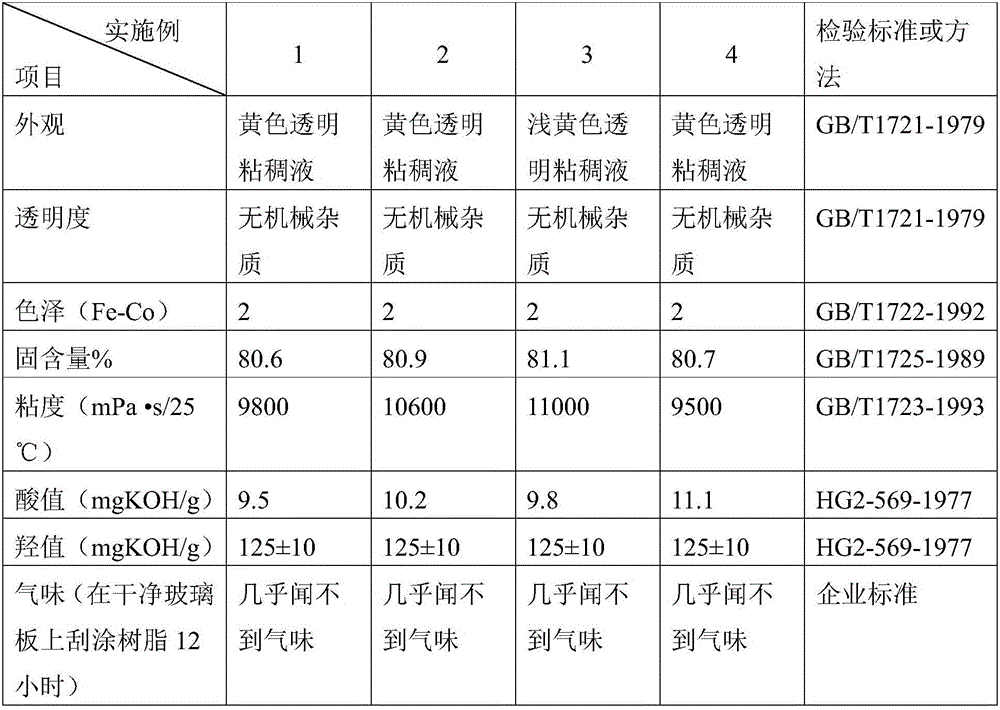

[0033] The raw material components and weight formulations (unit: kg) of Examples 1 to 4 are shown in Table 1.

[0034] Table 1: (unit: kg)

[0035]

[0036]

[0037] 2. Preparation method of high-solid, low-viscosity, quick-drying and net-taste alkyd resin

[0038] The preparation method of the high-solid, low-viscosity, quick-drying and clean-flavor alkyd resin described in Examples 1 to 4 comprises the following steps:

[0039] Step 1: Weigh each raw material component according to the formula of Examples 1-4.

[0040] Step 2: In the reaction kettle, add the oleic acid, 3,5,5-trimethylhexanoic acid, 2-ethylhexanoic acid, castor oil, phthalic anhydride, maleic acid, Acid anhydride, pentaerythritol, neopentyl glycol, reflux solvent, additives, heat up to 150-160°C under nitrogen gas, after reflux, heat up to 200-210°C at a rate of 8-12°C / h and keep warm until the acid value and viscosity qualified.

[0041] Step 3: Raise the temperature to 200-210°C and start sampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com