Ultra-low emission energy-saving biomass circulating fluidized bed boiler

A circulating fluidized bed, energy-saving technology, applied in fluidized bed combustion equipment, steam boilers, combustion types, etc. Combustion effect is poor and other problems, to achieve good self-cleaning characteristics, stable steam parameters, and prevent alkali metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

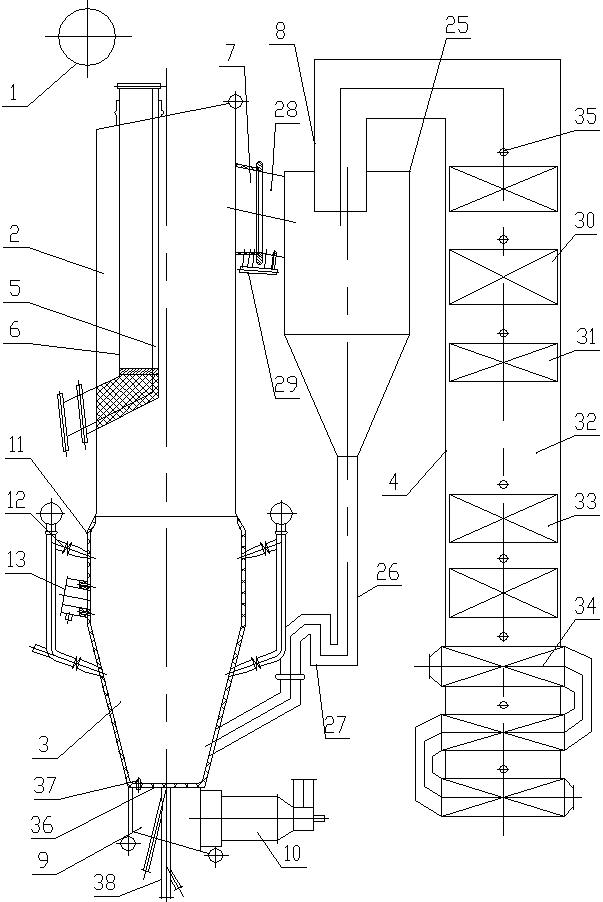

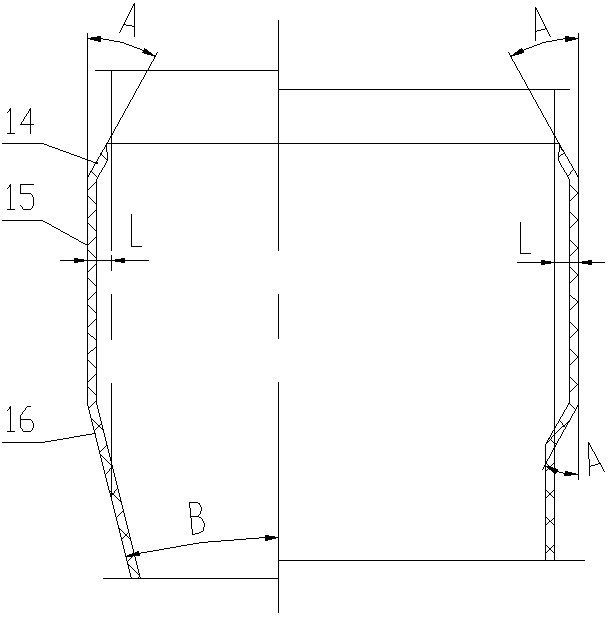

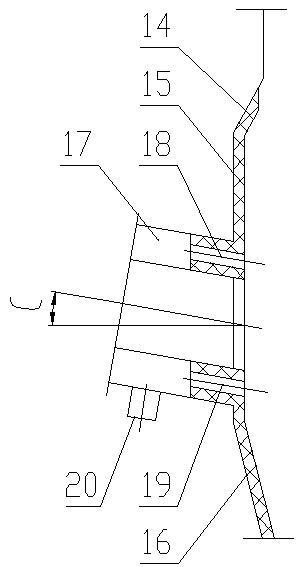

[0034] Such as Figure 1-Figure 5 As shown, the ultra-low emission energy-saving biomass circulating fluidized bed boiler of the present invention includes a drum 1, a full-membrane hearth 2, a fluidized bed combustion chamber 3, a separation and return system and a tail shaft flue 4. The upper part of the membrane hearth 2 is provided with a furnace water cooling screen 5 and a panel superheater 6, and the drum 1 is set above the full-membrane hearth 2 to separate the lower part of the feeding system from the rear side of the fluidized bed combustion chamber 3 Connection, the upper part of the separation and return system is connected to the upper part of the rear side of the full-membrane hearth 2 through the furnace flue gas outlet, and the top of the tail shaft flue 4 is connected to the top of the separation and return system through the offset central tube 8, and the flow The bottom of the fluidized bed combustion chamber 3 is provided with a primary air chamber 9, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com