Ageing-resistant power cable

A power cable and anti-aging technology, which is applied in the field of power cables, can solve problems such as power outages and short-circuit accidents that are difficult to find, and achieve the effects of good filling and reinforcing effects, good bonding force, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

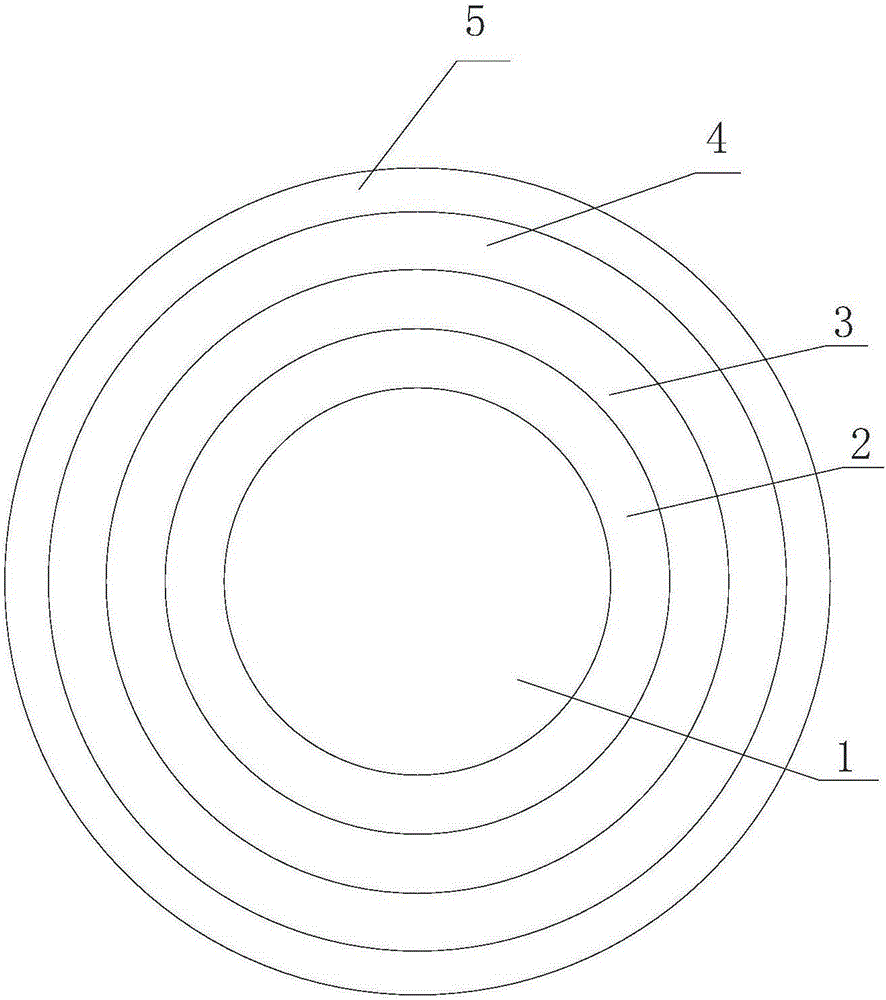

[0017] refer to figure 1 , an aging-resistant power cable, comprising a conductor 1, the conductor 1 is covered with an insulating layer 2, the insulating layer 2 is covered with an inner sheath layer 3, the inner sheath layer 3 is covered with an armor layer 4, and finally The outer layer is a protective layer 5; the insulating layer 3 is made of metallocene polyethylene plastic.

[0018] The raw materials of metallocene polyethylene plastics include by weight: 30 parts of metallocene polyethylene, 40 parts of methyl vinyl silicone rubber, 1,1,3,3-tetramethylperoxy-2-ethylhexanoic acid butyl 1 part, 1.5 parts of potassium ammonium dichromate, 15 parts of modified silkworm chrysalis protein fiber, 60 parts of nano-silica, 15 parts of glass microspheres, 16 parts of diatomaceous earth, 10 parts of calcium carbonate, 4 parts of calcium-zinc composite stabilizer , 0.5 parts of isopropyl tris (n-ethylamino-ethylamino) titanate, 3 parts of naphthenic oil, 0.5 parts of chlorinated ...

Embodiment 2

[0020] refer to figure 1 , an aging-resistant power cable, comprising a conductor 1, the conductor 1 is covered with an insulating layer 2, the insulating layer 2 is covered with an inner sheath layer 3, the inner sheath layer 3 is covered with an armor layer 4, and finally The outer layer is a protective layer 5; the insulating layer 3 is made of metallocene polyethylene plastic.

[0021] The raw materials of metallocene polyethylene plastics include by weight: 50 parts of metallocene polyethylene, 20 parts of methyl vinyl silicone rubber, 1,1,3,3-tetramethylperoxy-2-ethylhexanoic acid butyl 3 parts, 0.5 parts of potassium ammonium dichromate, 30 parts of modified silkworm chrysalis protein fiber, 40 parts of nano-silica, 25 parts of glass microspheres, 7 parts of diatomaceous earth, 18 parts of calcium carbonate, 1 part of calcium-zinc composite stabilizer , 2.5 parts of isopropyl tris (n-ethylamino-ethylamino) titanate, 1 part of naphthenic oil, 1.8 parts of chlorinated pa...

Embodiment 3

[0023] refer to figure 1 , an aging-resistant power cable, comprising a conductor 1, the conductor 1 is covered with an insulating layer 2, the insulating layer 2 is covered with an inner sheath layer 3, the inner sheath layer 3 is covered with an armor layer 4, and finally The outer layer is a protective layer 5; the insulating layer 3 is made of metallocene polyethylene plastic.

[0024] The raw materials of metallocene polyethylene plastics include by weight: 38 parts of metallocene polyethylene, 36 parts of methyl vinyl silicone rubber, 1,1,3,3-tetramethylperoxy-2-ethylhexanoic acid butyl 1.5 parts, 1.2 parts of potassium ammonium dichromate, 18 parts of modified silkworm chrysalis protein fiber, 50 parts of nano-silica, 18 parts of glass microspheres, 10 parts of diatomaceous earth, 12 parts of calcium carbonate, 2.5 parts of calcium-zinc composite stabilizer , 1 part of isopropyl tris (n-ethylamino-ethylamino) titanate, 1.9 parts of naphthenic oil, 1 part of chlorinated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com