Shell injection molding process for bluetooth sound equipment

A bluetooth audio and casing technology, applied in household components, applications, coatings, etc., can solve problems such as insufficient adhesion of surface spraying, and achieve the effects of improving interlayer adhesion, good mechanical properties, and good forming and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

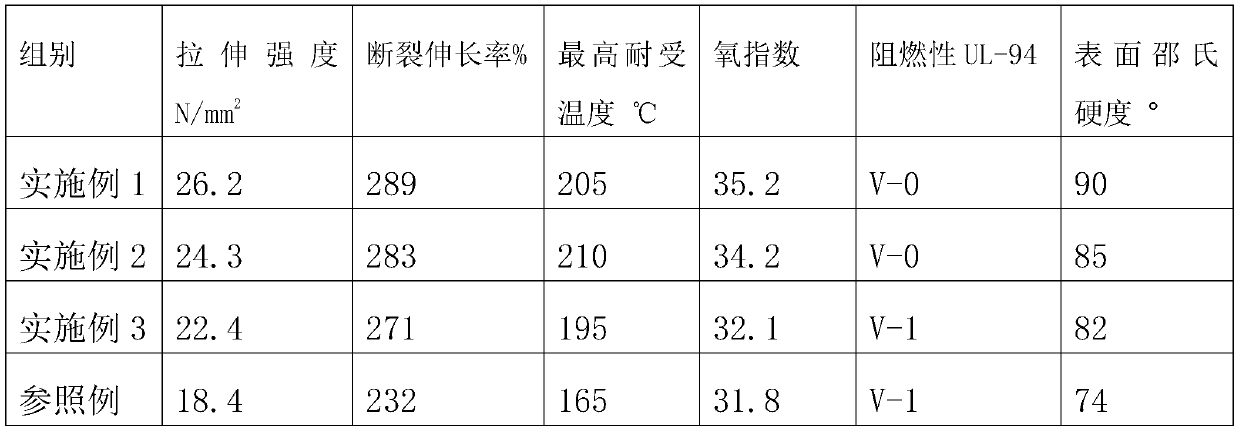

Examples

Embodiment 2

[0037] Prepared according to the following injection molding process:

[0038] S1), mold design: process the mold according to the shape, size and size of the Bluetooth audio shell, design the glue point and cooling flow channel, and polish the surface of the existing mold cavity. The surface roughness of the mold cavity is 0.1-0.2 Ra / um;

[0039] S2), modified plastic granulation: 90 parts of synthetic resin, 3 parts of dilauryl thiodipropionate anti-aging agent, 2 parts of hindered phenolic antioxidant, 4 parts of flame retardant, 3 parts of polymer Acrylate toughening agent and 1 part of phosphite triester stabilizer are mixed evenly, sent to a mixer at 200°C, mixed and stirred for 15 minutes, and then extruded through an extruder to granulate, and the desired modified product is obtained after cooling. Permanent plastic masterbatch; a mixture of polycarbonate and polybutylene terephthalate, the mass ratio of the two is 3:1.

[0040] S3), plastic masterbatch drying: use d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com