Aluminum oxide-containing polyaniline zinc powder flake epoxy heavy anti-corrosion coating and preparation method thereof

A polyaniline zinc-containing aluminum oxide technology, applied in the field of coatings, can solve the problems of poor anti-corrosion performance and environmental protection of pigments, and achieve the effects of improving aging resistance, aging resistance and penetration resistance, and improving coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

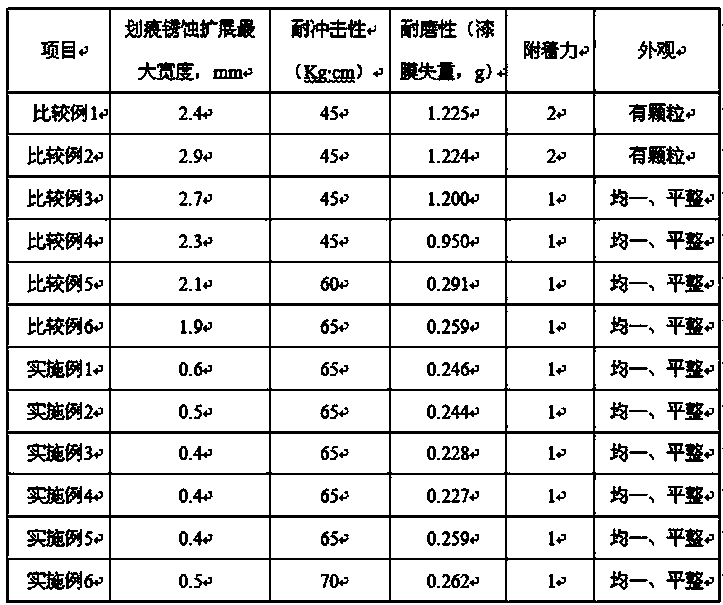

Examples

Embodiment 1

[0062] A preparation method of aluminum oxide-containing polyaniline zinc powder flake epoxy heavy-duty anticorrosion coating, comprising the steps of:

[0063] (1) Preparation of polyaniline zinc powder flakes: Mix 0.5 mole of aniline with 1 mole of perchloric acid and mix evenly, then set the volume to 2 liters; add 0.5 mole of ammonium persulfate into the aniline-doped acid solution evenly within 20 minutes, Stir at 10° C. for 0.5 hour to obtain the product polyaniline. In terms of parts by mass, mix 1 part of the obtained polyaniline with 5 parts of zinc powder flakes with a thickness of 0.01 μm and a diameter of 5 μm, continue stirring for 2 hours, centrifuge to collect the precipitate, wash with distilled water, and dry at 100 ° C for 1 hour. Grind with a mortar and sieve to obtain dark green polyaniline zinc powder scales.

[0064] (2) Preparation of coating component A:

[0065] (a) Component A mixed solvent: 1 part of xylene is mixed with 1 part of n-butanol to ...

Embodiment 2

[0074] A preparation method of aluminum oxide-containing polyaniline zinc powder flake epoxy heavy-duty anticorrosion coating, comprising the steps of:

[0075] (1) Preparation of polyaniline zinc powder flakes: Mix 0.1 mole of aniline and 0.2 mole of phosphoric acid and stir evenly, then set the volume to 1 liter; add 0.1 mole of benzoyl peroxide evenly into the aniline-doped acid solution within 10 minutes, Stir at -5°C for 0.5 hour to obtain the product polyaniline. In parts by mass, mix 1 part of the obtained polyaniline with 0.5 parts of zinc powder flakes with a thickness of 0.01 μm and a diameter of 5 μm, continue to stir for 1 hour, centrifuge to collect the precipitate, wash with distilled water, and dry at 80°C for 5 hours. Grind with a mortar and sieve to obtain dark green polyaniline zinc powder scales.

[0076] (2) Preparation of coating component A:

[0077](a) Component A mixed solvent: 1 part of styrene is mixed with 3 parts of tert-butanol to obtain a mi...

Embodiment 3

[0086] A preparation method of aluminum oxide-containing polyaniline zinc powder flake epoxy heavy-duty anticorrosion coating, comprising the steps of:

[0087] (1) Preparation of polyaniline zinc powder flakes: Mix 0.6 mol of aniline, 0.5 mol of phosphoric acid, and 0.6 mol of phytic acid and stir evenly, then set the volume to 1 liter; then add 0.6 mol of ammonium persulfate into aniline within 20 minutes The heteroacid solution was stirred at 5°C for 1 hour to obtain the product polyaniline. In terms of parts by mass, mix 1 part of the obtained polyaniline with 2 parts of zinc powder flakes with a thickness of 0.02 μm and a diameter of 9 μm, continue stirring for 2 hours, centrifuge to collect the precipitate, wash with distilled water, and dry at 80°C for 4 hours , ground with a mortar and sieved to obtain dark green polyaniline zinc powder scales;

[0088] (2) Preparation of coating component A:

[0089] (a) Mixed solvent of component A: Mix 2 parts of toluene with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com