Polyaniline coating capable of blocking and controlling chlorine ion penetration and preparation method thereof

A technology of chloride ion penetration and polyaniline, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor anti-corrosion performance of pigments, environmental protection, limited improvement of comprehensive performance of coatings, and no consideration of the synergy of zinc powder, etc., to achieve excellent anti-corrosion performance and improve Chloride ion permeation resistance and effect of permeation resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

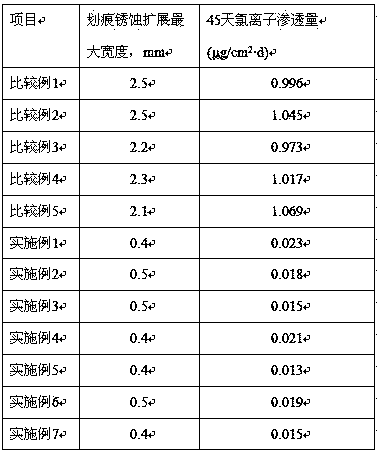

Examples

Embodiment 1

[0042] Put 0.5 part of dispersant (BYK-P104S), 1 part of leveling agent (BYK-VP-3609), 1 part of defoamer (BYK-065), 0.5 part of anti-sagging agent (fumed silica), 0.5 part of pigment ( Iron oxide red) 1 part, filler (talc powder) 2 parts, polyaniline 5 parts, chloride ion inhibitor (silver oxide, particle size 0.01-2 micron) 0.02 part, added to 50 parts of epoxy resin (bisphenol A-type epoxy resin (E-12) and 15 parts of solvent (toluene), stir evenly, then grind in a general-purpose paint grinder, and discharge after the fineness is less than 50 microns, to obtain polyaniline that resists and controls chloride ion penetration For component A of epoxy anti-corrosion coating, add 25 parts of amine curing agent (triethylenetetramine) to 75 parts of absolute ethanol, mix and stir until the curing agent is fully dissolved to obtain component B; combine component A and component B Mix and stir for 0.5h at a mass ratio of 1:0.3 to obtain a polyaniline epoxy anticorrosion coating tha...

Embodiment 2

[0045] Put 0.5 part of dispersant (Anti-Terra-P), 1 part of leveling agent (BYK-VP-354), 1 part of defoamer (Defom5400), 1 part of anti-sagging agent (kaolin), pigment (titanium dioxide) 1 part, 2 parts of filler (barite powder), 10 parts of polyaniline, 0.1 part of chloride ion inhibitor (silver oxide, particle size 0.01-2 microns), added to 80 parts of alkyd resin (60% oily coconut oil alkyd resin) and 25 parts of solvent (xylene), stir evenly, and then grind in general-purpose coating equipment, and discharge the material after the fineness is less than 60 microns, and obtain polyaniline alkyd resin anticorrosion that prevents and controls chloride ion penetration The paint is sprayed twice on the surface of four 150mm×100mm×1mm No. 45 steel plates that have been conventionally sandblasted to Sa2.5, dried at room temperature for 15 days, and then sprayed with a 60°C liquid with a weight ratio of rosin:paraffin=l:1 Carry out edge banding and conduct coating performance test....

Embodiment 3

[0047] Put 1.1 parts of dispersant (Disperbykl06), 0.8 parts of leveling agent (PerenolF40), 0.5 parts of defoamer (Defom5300), 1 part of anti-sagging agent (bentonite), 1 part of pigment (litonite), filler (heavy carbonic acid Calcium) 2 parts, polyaniline 10 parts, chloride ion inhibitor (silver oxide, particle size 0.01-2 microns) 0.3 parts, added to 60 parts of rosin-modified phenolic resin and 20 parts of solvent (xylene), Stir evenly, then grind in a general-purpose paint grinder, and discharge the material after the fineness is less than 60 microns, to obtain a polyaniline phenolic resin anticorrosive coating that prevents and controls chloride ion penetration, and four pieces of it are conventionally sandblasted to Sa2.5 The surface of 150mm×100mm×1mm No. 45 steel plate was sprayed with the paint twice, dried at room temperature for 15 days, and then edge-sealed with a 60°C liquid with a weight ratio of rosin:paraffin=l:1, and the coating performance test was carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com