Patents

Literature

219 results about "Dispersit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dispersit SPC 1000 or Dispersit is a dispersant used for oil spills, produced by U.S. Polychemical Corporation.

Extinguish material, preparation method and application thereof

ActiveCN101543672AGuaranteed efficiencyImprove permeabilityFire rescueBoring toolsSpecific gravityCompound (substance)

The invention provides a high-efficiency extinguish material for a major fire source, which comprises the following components by weight portion: 1 to 50 portions of component A, 1 to 2 portions of component B, 2 to 1,000 portions of component C, and 0 to 200 portions of component D. The component A is an inorganic silicate material; the component B comprises a foaming agent, a surfactant and a dispersing agent; the component C is water; and the component D comprises a defoamer, a fireproof material, a material generating flame-retardant gas through pyrolysis, a water absorber, a colloidal material and a filling material. The high-efficiency extinguish material overcomes the defects that the prior art has high production and using cost, fast running-off, low service efficiency, severer pollution and high residual quantity, has the advantages of low cost, controllable specific gravity, higher viscosity, difficult seepage, loose storage conditions, fast production, convenient use, safe performance and the like, and can achieve large batches of long-distance transportation. The high-efficiency extinguish material is applicable for large-scale fire extinguishing of oil products, flammable chemicals, large buildings, coal mines, forests and the like, other fire source control and the like.

Owner:徐志毅

Method for displacing oil base drilling muds and/or residues from oil base drilling mud using water-in-oil emulsion

ActiveUS7188676B2Improve breathabilityEfficacious in displacingCleaning apparatusFluid removalParticulatesParaffin wax

Fluid producing wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted solid particulates, including pipe dope, asphaltenes and paraffins. Such emulsions are of particular applicability in the displacement of oil base drilling muds and / or residues from such muds from producing wells. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

Preparation method of while-drilling plugging fluid for oil-based drilling fluid

ActiveCN104448136AGood compatibilityNo change in rheological propertiesDrilling compositionSludgeWell drilling

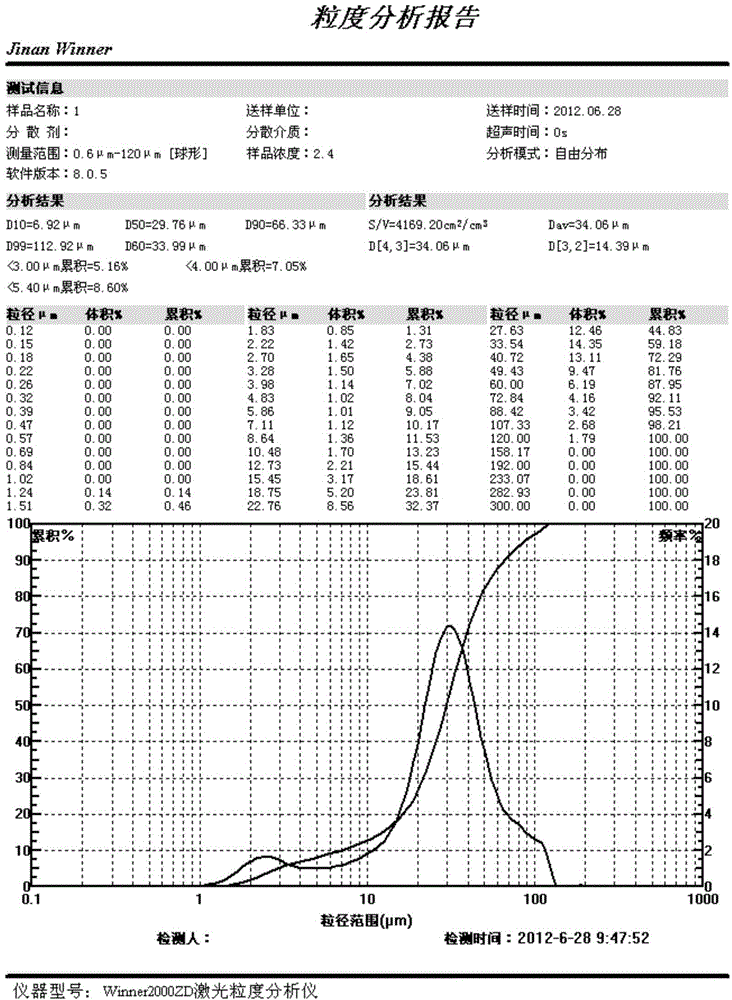

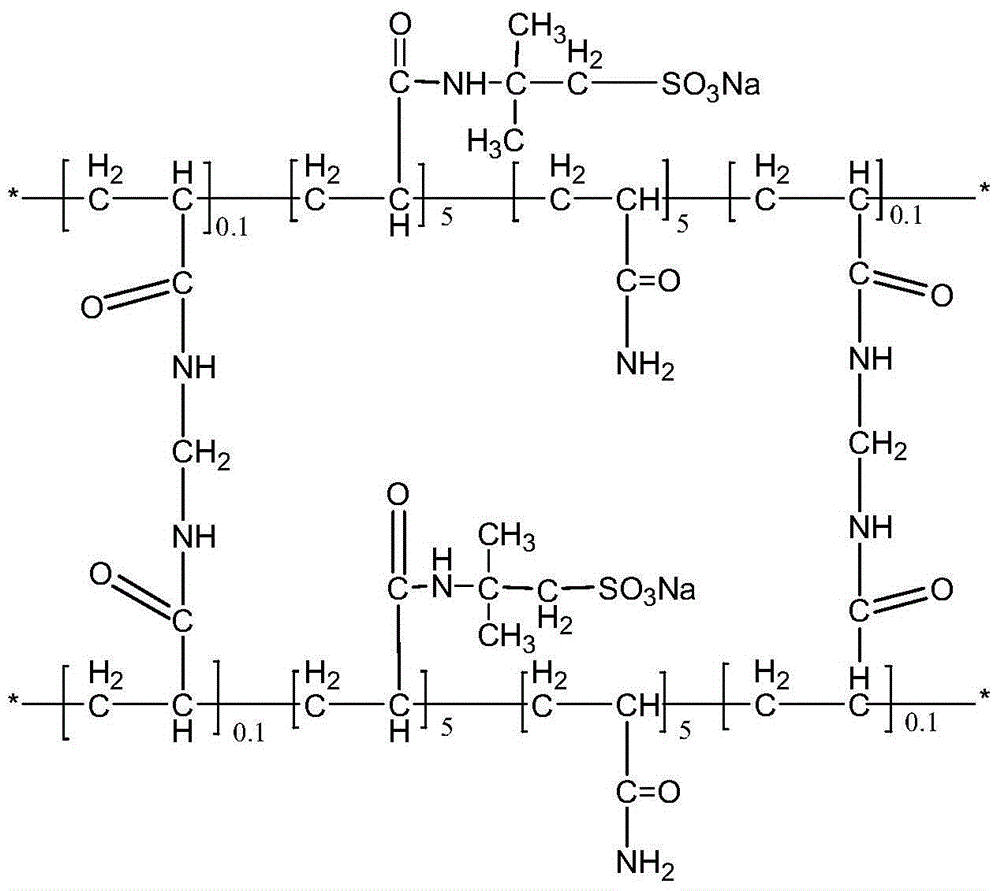

The invention relates to a preparation method of a while-drilling plugging fluid for oil-based drilling fluid, belonging to the technical field of drilling fluid treatment in petroleum drilling projects. The preparation method of the while-drilling plugging fluid for oil-based drilling fluid comprises the following steps: dropwise adding an aqueous phase which contains a propylene water-soluble organic monomer A, a water-soluble crosslinking agent B and a powder-like organic material C into oil D which contains a dispersing agent E; and after emulsification, initiating by using an oxidation-reduction initiating system to obtain a stable suspension plugging agent. According to the while-drilling plugging fluid, a deformation function is realized, the fluid has good compatibility with the oil-based drilling fluid, and can resist the temperature which reaches 150 DEG C, the particle size is 1 micron-100 microns, and the permeable loss of the nano-micron-grade cracks and pores in oil-based sludge drilling can be rapidly and effectively blocked, so that the drilling operation cost is reduced; and according to the oil-based while-drilling plugging agent prepared through the method, drying and granulation are not needed, and the agent can be directly used for while-drilling plugging in the oil-based drilling fluid, and is convenient to use and easy to popularize.

Owner:CHINA PETROCHEMICAL CORP +1

Fuel oil composition

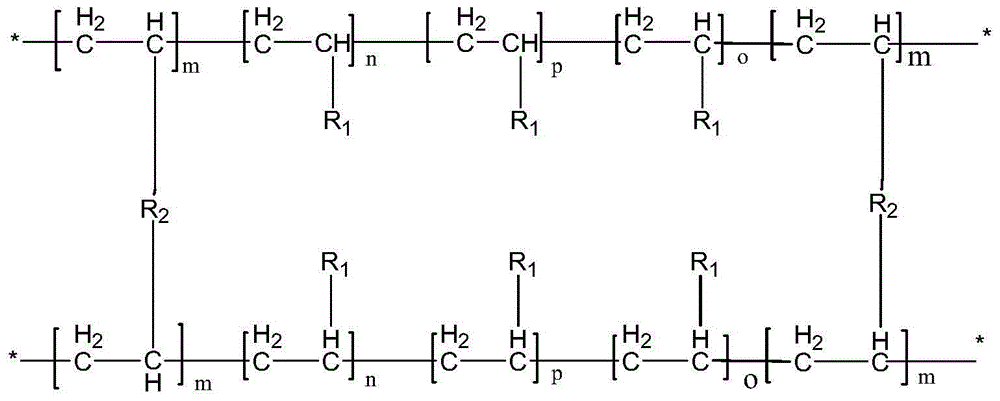

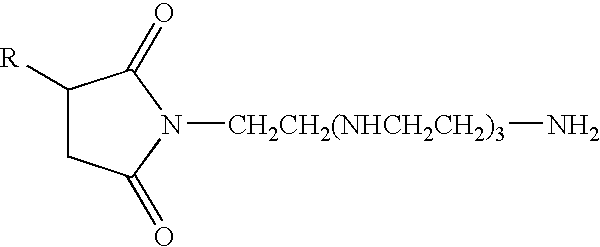

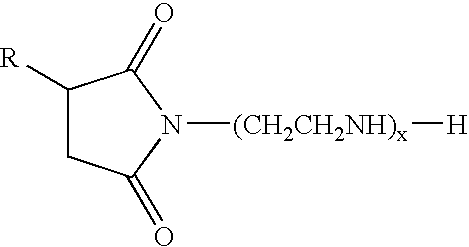

The invention provides a fuel oil composition comprising a major proportion of liquid hydrocarbon middle distillate fuel oil having a sulphur concentration of at most 0.05% by weight, and a minor proportion of a dispersant additive obtained by reacting, in a molar ratio A:B in the range 4:3 to 1:10, (A) a polyalkenyl derivative of monoethylenically unsaturated C4-C10 dicarboxylic acid material in which the number average molecular weight (Mn) of the polyalkenyl chain is in the range from 850 to 1150 with (B) a polyamine of general formulawhere m is in the range from 2 to 4 and n is in the range from 1 to 6; a process for the preparation of such a fuel composition, and a method of operation a compression-ignition engine with enhance injector cleanliness using such a fuel oil composition.

Owner:SHELL OIL CO

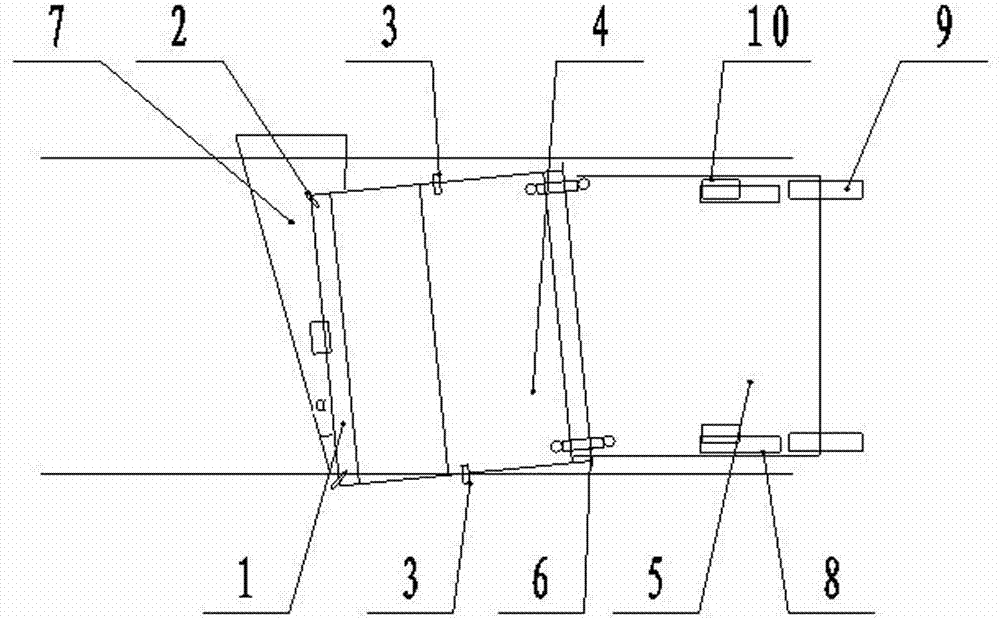

Method for correcting unconformable surface stratum shield tunneling construction

ActiveCN103032076AIncrease the excavation diameterIncrease flexibilityTunnelsSocial benefitsClassical mechanics

The invention relates to the technical field of tunnel shield construction, in particular to a method for correcting the unconformable surface stratum shield tunneling construction, and solves the difficult problems of difficulty in correction, long construction period, influence on normal traffic and the like of an existing method. The method comprises the following steps of: enlarging a shield excavation diameter; when shield posture deviation exceeds 5cm, injecting high pressure water with a dispersing agent from a radial grouting hole of a middle shield at the deviated side of a shield body; and when the shield body is deviated by 10cm, constructing a grotto in the deviation reverse direction of a cutter head on an excavation face, adding an auxiliary oil cylinder behind a shield tail at the deviated side of the shield, starting a driving oil cylinder to recover tunneling, and when the driving oil cylinder drives for 30cm every time, pouring polyurethane by the radial grouting hole of the middle shield at the deviated side of the shield. Flexibility of shield posture correction is improved; the rate of shield posture deviation is reduced; the grotto is constructed in the reverse direction of the shield deviation; a correction space is provided; the polyurethane is poured by the radial grouting hole of the middle shield so as to implement forced correction; the method has the advantages of simple process, flexibility for controlling the construction process, advanced technology and the like and excellent economic benefits and social benefits can be obtained.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

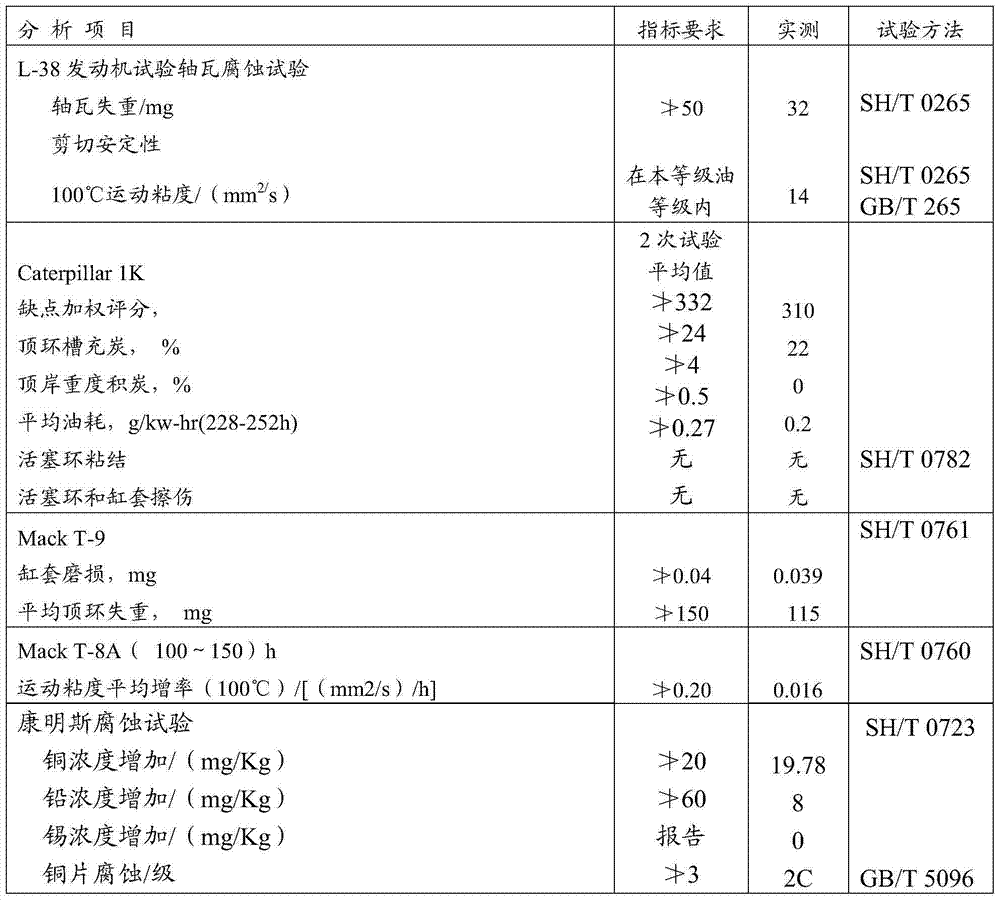

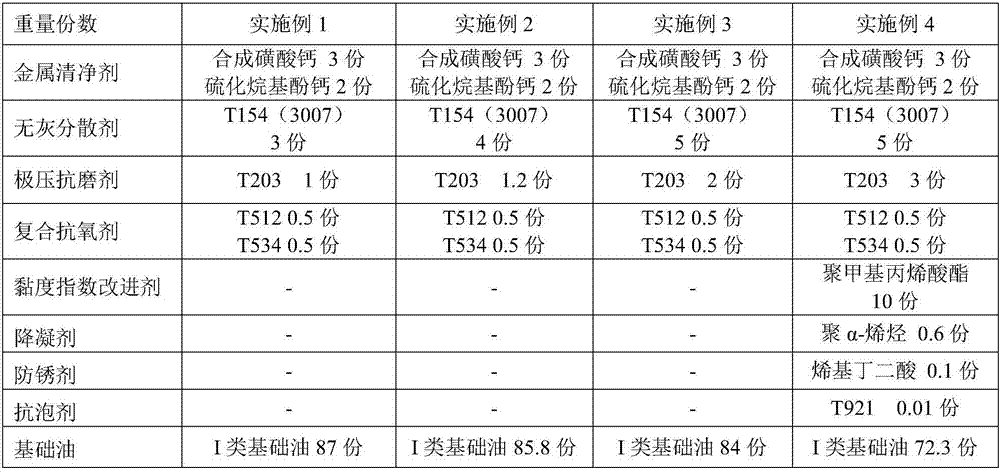

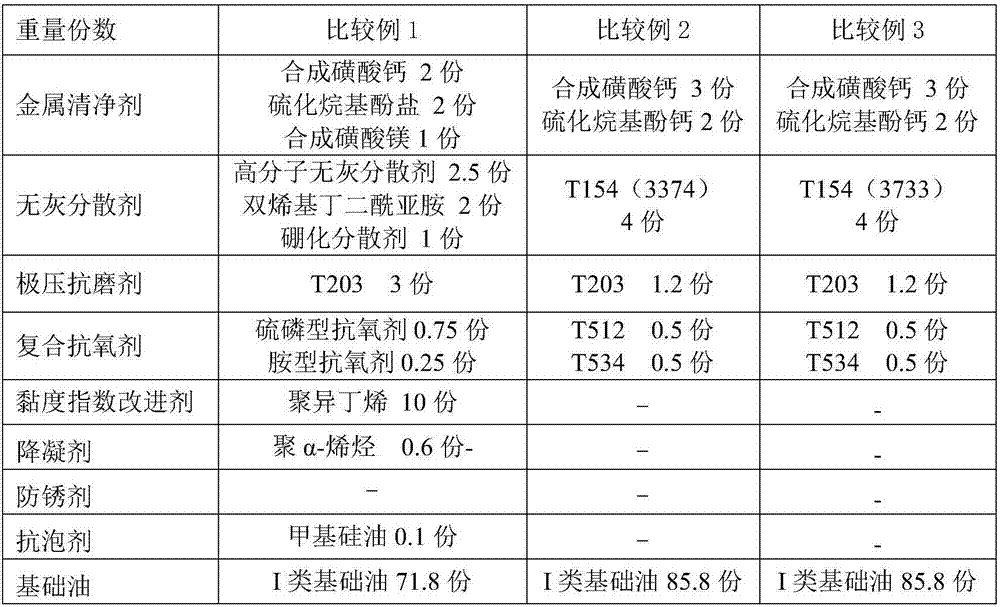

CF-4 grade diesel engine oil composition and uses thereof

The invention relates to a CF-4 grade diesel engine oil composition and uses thereof The CF-4 grade diesel engine oil composition includes the following components: by weight, a) 1-10 parts of a detergent; b) 1-15 parts of a dispersant; c) 1-10 parts of an antioxidant; d) 0-20 parts of a thickener; e) 0.03-2 parts of a pour point depressant; f) 0.01-1 part of an antifoaming agent; and h) 50-88 parts of base oil; in the technical scheme, the calcium content in the CF-4 grade diesel engine oil composition is not less than 2000 ppm, and the total content of calcium and magnesium is not less than 2700 ppm, the nitrogen content is not less than 500 ppm, and the technical scheme can meet the GB11122-2006 CF -4 quality grade requirement, and can be used in industrial production of the CF-4 grade diesel engine oil composition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Safety efficient cleaning agent for engine lubrication system

The invention discloses safety efficient cleaning agent for an engine lubrication system. The safety efficient cleaning agent for the engine lubrication system comprises, by weight percent, 55-98.7% of base oil, 1-15% of carbon deposit dissolving agent, 0.1-10% of detergent, 0.1-10% of dispersant, and 0.1-10% of nanometer antiwear agent. The safety efficient cleaning agent can be used to clean deposits such as carbon deposit, colloid and grease inside an automobile engine, so that operation of the engine lubrication system is smoother, the engine can be maintained effectively, and service life of the engine is prolonged effectively. The safety efficient cleaning agent has the advantages that fire in cleaning can be prevented by using the high-flash-point carbon deposit dissolving agent and the base oil, and use is safer; the efficient purification dispersant is high in cleaning power and has high dispersing action against particulate carbon deposit cleaned off, and accordingly blockage of oil circuits is avoided; and by the aid of the nanometer antiwear agent, wear resistance of the cleaning agent is improved, scuffing of a cylinder bore in cleaning due to thinning of engine oil can be prevented, and poisoning of a three-way catalyst caused by sulphuric antiwear agent can also be prevented.

Owner:SHENZHEN CHIEF CAR CARE PRODS DEV

Multifunctional on-line cleaning agent composition for heat conduction oil

InactiveCN101812380APrevent spoilageAvoid carbonizationOrganic detergent compounding agentsSurface-active detergent compositionsLiquid wasteAntioxidant

The invention discloses a multifunctional on-line cleaning agent composition for heat conduction oil, belonging to liquid heat transferring material processing aids with stable property. The composition is characterized by comprising the following components in percent by weight: 80.0-95.0 percent of kerosene, 2.0-18.0 percent of diesel oil, 0.5-5.0 percent of cleaning agent, 0-0.5 percent of corrosion inhibitor, 0-2.0 percent of dispersing agent, 0-3.0 percent of antioxidant, 0-2.0 percent of pour point depressant and 0.5-1.5 percent of flame retardant, and the consumption amount of the composition is 0.5-5.0 percent of the total operation amount of the heat conduction oil. The invention solves the problems of higher capital consumption, time waste, influence on production and environmental pollution caused by the stopping and cleaning of heat conduction oil heat transferring system equipment, provides the multifunctional on-line cleaning composition for the heat conduction oil, realizes the on-line regeneration of the heat conduction oil heat transferring system without stop production for cleaning and regeneration, prolongs the service life of equipment, improves the production capacity of the equipment, reduces the consumption of the heat conduction oil, the production cost and the emission of waste cleaning liquid and protects the environment.

Owner:SHANDONG XINGANG ENTERPRISE GRP CO LTD

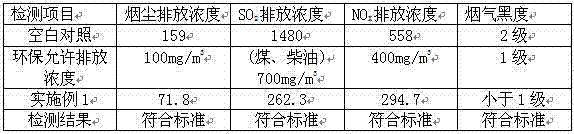

Environmentally-friendly heavy oil additive and preparation method and use method thereof

InactiveCN102559306ALong stable periodImprove performanceLiquid carbonaceous fuelsFuel additivesOil canActive agent

The invention discloses a new environmentally-friendly heavy oil additive and a preparation method and use method thereof. The additive comprises the following components in parts by weight: 10-30 parts of nonionic surfactant, 15-60 parts of combustion improver, 10-30 parts of quality stabilizer, 10-55 parts of purification dispersant, 1-8 parts of corrosion inhibitor and 20-50 parts of water. After the materials are combined according to percentages, the materials can be used with heavy oil mixed with water and the fuel properties of heavy oil are improved. The environmentally-friendly heavy oil additive has the following advantages: the combustion performance of heavy oil can be effectively improved, the liquidity of heavy oil can be increased, the heavy oil fuel oil with the additive has stable performance, long storage time, good atomizing effect, no pollution and high oil-saving efficiency, is easy in ignition and can not coke, the fuel oil does not corrode the equipment, has high combustion value and simple process, is difficult in black smoke generation, is convenient in use and can combust completely, and the equipment loss is reduced furthest.

Owner:山东国弘能源科技有限公司

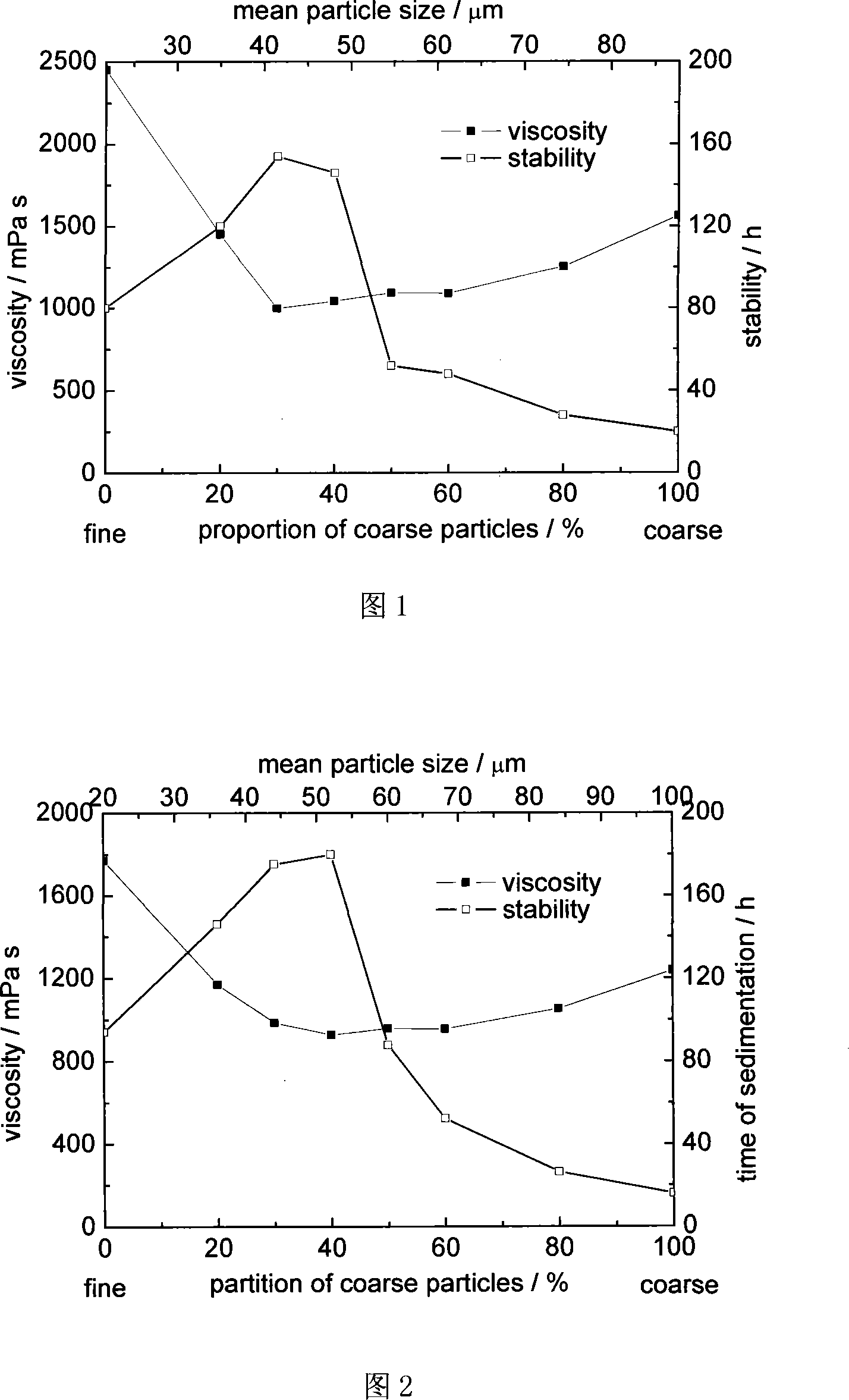

Water coke slurry for gasification and preparation method thereof

ActiveCN101225335AQuality improvementImprove particle size distributionLiquid carbonaceous fuelsGranularityLignosulfonates

The invention relates to water-coke slurry and the preparation method, in particular to a water-coke slurry for gasification with refinery coke as the material and the preparation method, which is characterized in that: the material compositions (mass percentages) are refinery coke of 60 to 80%, dispersing agent of 0.5 to 5% and water of 20 to 39.5%; the steps of the preparation method are as follows: the refinery coke is first broken up to less than 5mm, and then the broken refinery coke is divided into two parts, and the two parts are respectively grinded together with quantitative dispersing agent and water in two grinders; by adjusting the stick-coke ratio of two grinders, the water-coke slurries output from the two grinders have different granularity distributions, and the two water-coke slurries are mixed to obtain the water-coke slurry for gasification; when the viscosity is about 1000mPas, the concentration of the refinery coke in the water-coke slurry can be increased to 72%. The water-coke slurry has the advantages of legitimately utilizing the lignin-sulphonate industrial waste and changing waste into valuable, as well as preparing high-quality water-coke slurry for gasification, and having good fluidity and stability.

Owner:EAST CHINA UNIV OF SCI & TECH +2

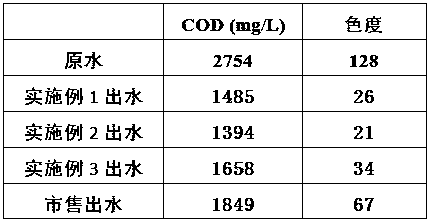

Environment-friendly micro-electrolysis ceramsite and preparation method thereof

InactiveCN108178246ALarge specific surface areaImprove adsorption capacityWater/sewage treatmentElectrolysisSludge

The invention provides an environment-friendly micro-electrolysis ceramsite and a preparation method thereof. The environment-friendly micro-electrolysis ceramsite is prepared from the following raw materials in percentage by mass: 30 to 40% of nanometer zero-valent iron, 20 to 30% of activated carbon, 20 to 30% of river and lake sludge, 5 to 10% of dispersant, 5 to 10% of adhesive, 5 to 10% of perforating agent, 5 to 10% of catalyst, and 0.1 to 0.5% of graphene. The environment-friendly micro-electrolysis ceramsite has the advantages that by utilizing the river and lake sludge to prepare theenvironment-friendly micro-electrolysis ceramsite, the resources of the river and lake sludge can be utilized; the specific surface area is large, the adsorption property is good, the mechanical strength is high, the service life is long, the physical and chemical properties are stable, the easiness in passivating and caking is avoided, the activating and reutilization effects are realized, and the like; the electrochemistry, oxidized reduction, physical adsorption and flocculent precipitation methods can be integrated, and the biodegradability of the wastewater is improved while the wastewater is treated.

Owner:无锡市拜沃特环保科技有限公司 +1

Water blended synthetic diesel oil and its preparation method

InactiveCN1654605ASimple preparation processImprove performanceLiquid carbonaceous fuelsDiesel locomotiveKerosene

The water adding synthetic diesel oil contains composite fuel in 40-60 wt% except diesel oil; and the composite fuel consists of water 10-30 wt%, benzene 10-30 wt%, methanol 10-20 wt%, turpentine 20-45 wt%, isopropanol 5-10 wt%, fatty acid 5-10 wt%, dispersant 8-15 wt%, catalyst 5-10 wt% and assistant 2-5 wt%. The synthetic diesel oil has simple preparation process, stable performance and no delamination in long term storage, may be mixed in any ratio with diesel oil, kerosene, solvent oil, etc. before use. The product has less change in color and transparency, and may be used widely in diesel car, diesel locomotive, ship engine, diesel oil engine for air conditioner, boiler, etc.

Owner:谢仲达

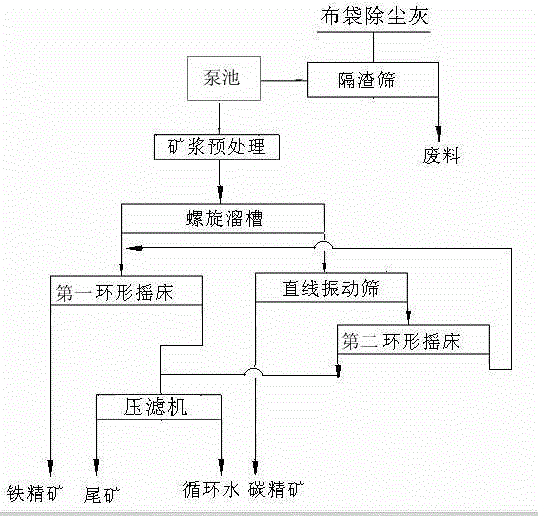

Beneficiation method for extracting iron and carbon from blast furnace bag dust

The invention relates to a beneficiation method for extracting iron and carbon from blast furnace bag dust, and belongs to the technical field of mineral processing. A slag separating screen for the blast furnace bag dust is used for removing a part of low-grade coarse fraction waste materials, and a fine fraction product flows automatically into a pump pool. After a dispersing agent is added into the fine fraction product, the fine fraction product is driven into a spiral chute through a pump for screening. A concentrate product in the spiral chute enters a first annular shaking table, and a qualified iron concentrate product can be obtained after screening of the concentrate product. First tailing on the first annular shaking table flow automatically into a tailing pressure filter directly. A tailing product in the spiral chute enters a linear vibrating screen. An oversize product is the qualified carbon concentrate, and an undersize product enters a second annular shaking table. A concentrate product on the second annular shaking table returns to the first annular shaking table for rescreening. A second tailing product enters the tailing pressure filter. Filter liquor of the pressure filter serves as circulating water for a beneficiation plant. According to the beneficiation method for extracting the iron and the carbon from the blast furnace bag dust, a valuable element containing the blast furnace bag dust is extracted, the additional value of the valuable element is increased, and the beneficiation method has important practical significance for cleaner production, energy conservation and emission reduction in the iron and steel industries.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

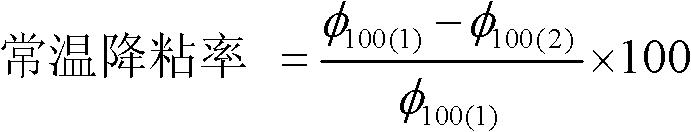

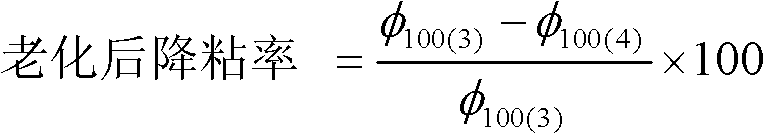

Dispersant for ultra-high density drilling fluid, preparation method and application

The invention discloses a dispersant for ultra-high-density drilling fluid, a preparation method and application thereof. The dispersant is prepared through the reaction of raw materials containing the following components in parts by weight: 10-40 parts of lignin, 1.5-20 parts of phenols, 2.5-15 parts of sulfonating agent, 0.5-5 parts of telomerization agent, 0.5-4 parts of catalyst and 100 parts of water. The method comprises the steps of mixing the components uniformly, carrying out reaction for 6-10 hours at the temperature of 160-180 DEG C, and then obtaining the dispersant for the ultra-high-density drilling fluid. The dispersant disclosed by the invention is applied to the ultra-high-density drilling fluid, and the surface properties of solid-phase weighting agents, such as barite and the like, can be remarkably improved; the hydration film formation for the surfaces of weighting agent particles is prompted, and the agglomeration role and frictional resistance among the weighting agent particles are reduced, so that the viscosity and shearing force of the prepared high-density drilling fluid are reduced, and the fluidity of the high-density drilling fluid is improved; and the dispersant is non-toxic and efficient, and the preparation method is simple and easy in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly fully-synthetic diesel engine oil and preparation method thereof

PendingCN111303970AImprove low temperature fluidityImprove liquidityLubricant compositionWaste oilDiesel engine

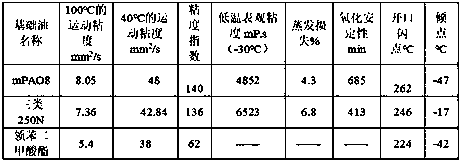

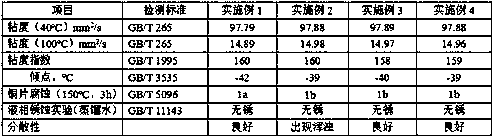

The invention relates to the technical field of lubricating oil, and particularly provides environment-friendly fully synthetic diesel engine oil which is composed of the following components in partsby weight: 77.2 parts of base oil, 5 parts of a detergent, 3 parts of an ashless dispersant, 1.2 parts of an antirust agent, 0.7 parts of an antioxidant, 4.4 parts of an extreme pressure agent, 0.5 parts of a friction modifier, 7.7 parts of a viscosity index improver, 0.3 parts of a pour point depressant, 0.3 parts of an anti-foaming agent, and 50 ppm of a demulsifying agent. The base oil is prepared by mixing mPAO8 which is catalytically synthesized by adopting metallocene, deeply hydrogenated and optimized straight-chain third-class mineral oil 250N and phthalate, and the mass ratio of mPAO8 to third-class mineral oil 250N to phthalate is 2: 2: 1. The low-viscosity diesel engine oil has the advantages that the base oil is blended according to a scientific proportion, the low-temperaturefluidity of the oil product is effectively improved, the oxidation resistance of the oil product is improved, the oil change period of the oil product is prolonged, the pollution degree of waste oilto the environment is reduced, the energy loss of the low-viscosity diesel engine oil is reduced, and the transmission efficiency of an engine is improved.

Owner:郑州市久润润滑油有限责任公司

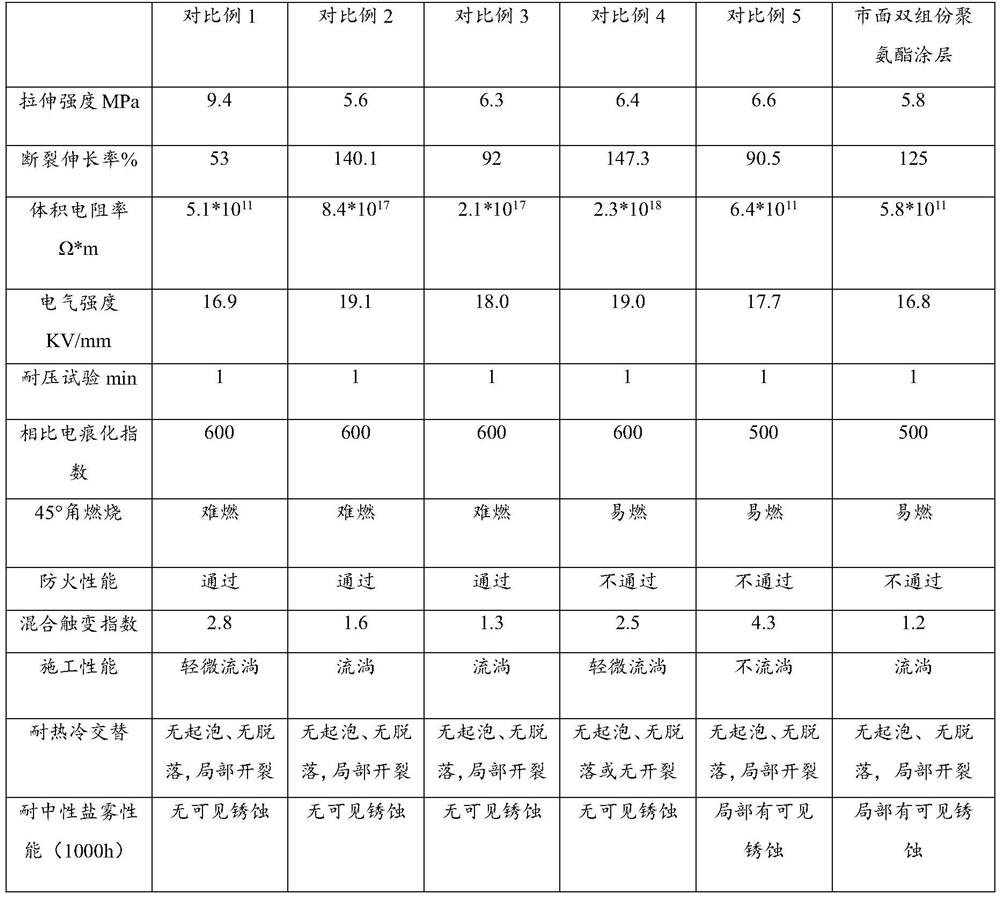

Two-component polyurethane coating and preparation method thereof

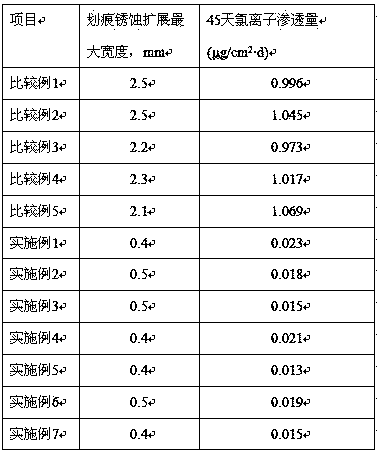

ActiveCN112029393AImprove insulation performanceImprove thixotropyFireproof paintsAnti-corrosive paintsPolymer sciencePtru catalyst

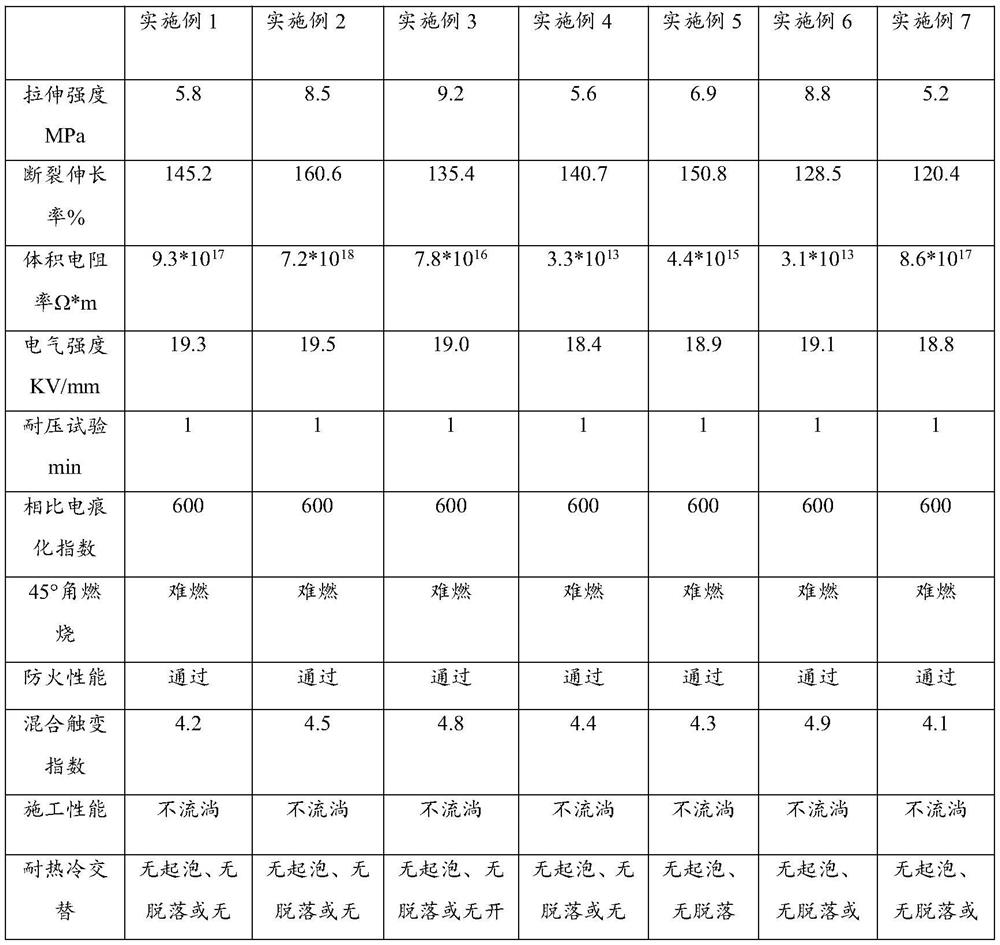

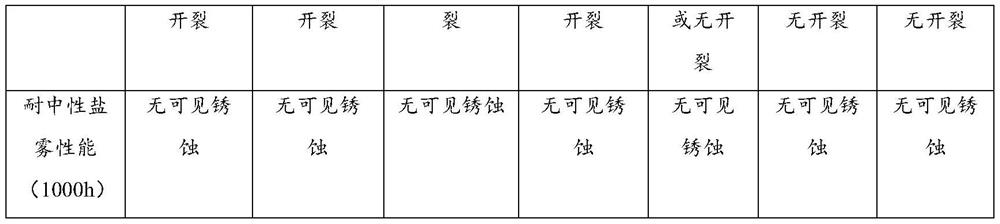

The invention provides a two-component polyurethane coating and a preparation method, and the two-component polyurethane coating comprises a component A and a component B. The component A comprises the following raw materials by weight: 30-60 parts of polymer polyol, 0.5-15 parts of a plasticizer, 0-0.6 part of a catalyst, 0.2-1 part of a tackifier, 0.3-1.3 parts of an antifoaming agent, 0.6-10 parts of a thixotropic agent, 0.5-1.5 parts of a leveling agent, 0-1.5 parts of a dispersant, 20- 60 parts of a filler and 4-10 parts of a desiccant; and the component B comprises a polyurethane prepolymer. The coating has the beneficial effects that the 45-degree-angle flame retardant property of the arc-proof coating for the roof of the rail transit vehicle meets the flame retardant grade of technical conditions of flame retardant materials of railway industry standard TB / T 3138 locomotives and vehicles, and the fireproof property meets the fireproof property requirements of materials and components of European Union EN 45545-2 rail vehicles. Under the requirements of GB / T 1771-2007 salt spray test standards, the coating is exposed in neutral salt spray for 1000 hours and has no visible corrosion.

Owner:湖北南北车新材料有限公司 +1

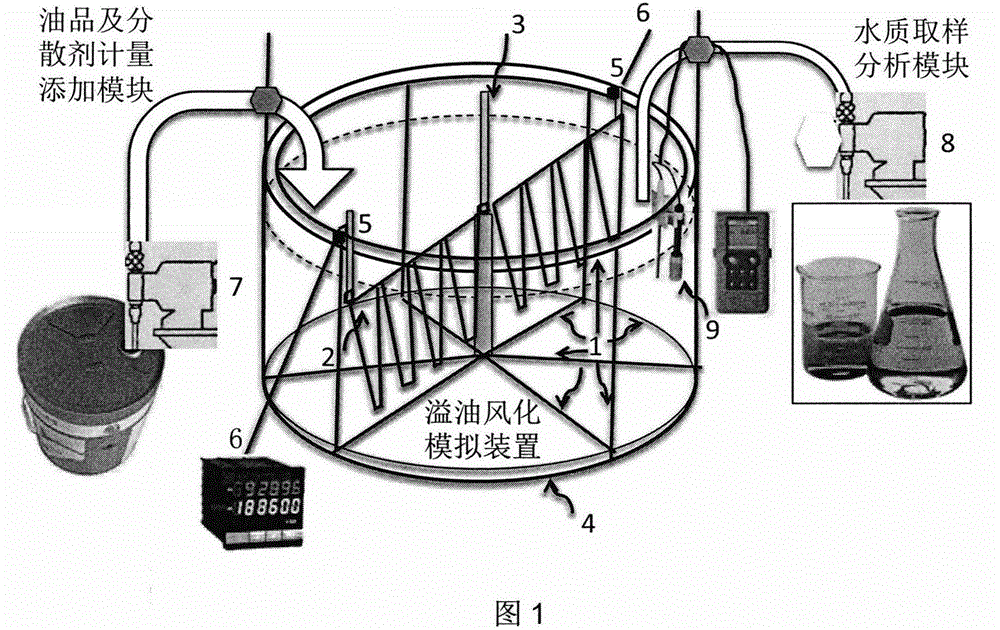

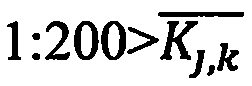

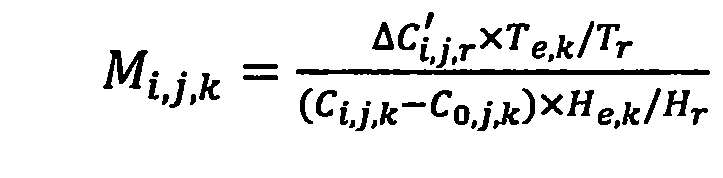

Scaling and simulating experiment device for influences of spilled oil weathering on water quality

InactiveCN105116125AMake up for the lack of water quality impactTesting waterWater depthWater quality

The invention discloses a scaling and simulating experiment device for influences of spilled oil weathering on water quality. The experiment device comprises a spilled oil weathering simulating device, an oil product and dispersing agent metering and adding module and a water quality sampling and analyzing module; for the influence factors such as weathering conditions such as spilled oil quantity, water surface oil films, water depth, waterflow, waves and natural lighting, spilled oil weathering and dispersed water quality concentration changes, the influences of spilled oil weathering (including spilled oil dispersion) on the water quality reappear in a scaling and simulating environment, and specific oil products and an experiment result under the condition of the scaling and simulating environment are reduced and converted into staged water quality index concentration variation amplitudes, caused by weathering in a real environment, of similar spilled oil. According to the experiment device, experimental technique support is supplied for scientifically understanding spilled oil and environmental fate and harm after the spilled oil is dispersed, performing spilled oil environment impact assessment and environment risk assessment, actively and effectively taking counter measures of pollution prevention, emergency disposal and environment modification.

Owner:CHINA WATERBORNE TRANSPORT RES INST

Low-sulfur diesel oil additive composition, and preparation method and application of same

InactiveCN103450955AImprove the lubrication effectAvoid harmLiquid carbonaceous fuelsFuel additivesOil additiveProcess engineering

The invention provides a low-sulfur diesel oil additive composition. The low-sulfur diesel oil additive composition is composed of a dispersing agent, a diesel oil lubrication improver, a pour point reducer, a cetane number improver and a low-sulfur solvent according to the proportion of parts by weight of 1:0.5-10:0.5-50:0.5-100:0.5-200. The low-sulfur diesel oil additive composition provided by the invention is used as an additive for the low-sulfur diesel oil, introduces no new sulfur element, can meet the environment protection rules, not only can avoid harm to vehicles caused by the new sulfur element introduced in the normal low-sulfur diesel oil additive, but also can obviously improve the lubricating property of the diesel oil, reduce attrition of a fuel injection system and prolong the service life of an engine, can improve the cetane number of the diesel oil, can enhance the combustion performance of the diesel oil, can reduce discharge of the pollutants, such as coking materials, particles, incomplete combustion discharge and CO, reduce carbon deposition of the engine, prolong the service life of the engine and improve the thermal efficiency of the engine, and also can lower the oil consumption.

Owner:英杰惠能(北京)能源新技术有限公司

Blast furnace blowing semi-coke additive and preparation and use method thereof

The invention discloses a blast furnace injection semi-coke additive as well as a preparation method and a use method thereof, and belongs to the technical field of blast furnace coal injection. The additive comprises the following components in percentage by mass: 0.1-0.25% of a grinding aid, 58-80% of a composite waste residue type catalyst, 18-40% of a composite compound type catalyst and 1-4%of a dispersing agent. By adding the additive, the grindability and the ash melting point of semi-coke can be improved, the combustion effect is good, the injection amount of the semi-coke in a blastfurnace is greatly increased, the additive is suitable for large-scale popularization and application of blast furnace injection semi-coke, and a good foundation is laid for finally achieving completereplacement of coal with the semi-coke and achieving coal removal in a blast furnace injection system.

Owner:NANJING IRON & STEEL CO LTD

Method for preparing environment-friendly gasified oil and product

InactiveCN101962581AMeet the needs of lifeLife needs increaseLiquid carbonaceous fuelsPtru catalystLiquid fuel

The invention discloses a method for preparing environment-friendly gasified oil. The method comprises the following steps of: weighing each raw material component; placing a main material and a smell remover in additives into a reaction container for stirring; placing an auxiliary material, and a heating agent, a smoke suppressor and an emulsification cosolvent in the additives into the reaction container for stirring; placing an accelerant, a combustion improver, a dispersion agent and a catalyst in the additives into the reaction container for stirring; mixing and stirring the mixed solution prepared by the steps 1 and 2 and adding the mixture into the mixed solution prepared by the step 3 for stirring; testing the pH value of the mixed solution and adding a proper amount of acidity and alkalinity regulator; adding a proper amount of anti-freezing agent; and discharging to prepare the environment-friendly gasified oil. The invention also provides the environment-friendly gasified oil which comprises 65 to 85 percent of main material, 20 to 30 percent of auxiliary material and 1 to 3 percent of additives. The method has the advantages of simplicity, stable performance of a synthesized liquid fuel, combustion flame temperature of 1,100 DEG C, fuel heat value of 8,500KJ / kg, low fuel combustion lower limit value, complete combustion, convenient and safe use and broad application.

Owner:高英杰

Polyaniline coating capable of blocking and controlling chlorine ion penetration and preparation method thereof

ActiveCN103834209APrevent oxidationReduce spreadAnti-corrosive paintsPhysical chemistryPetrochemical

The invention discloses a polyaniline coating capable of blocking and controlling chlorine ion penetration and a preparation method thereof. The polyaniline coating capable of blocking and controlling the chlorine ion penetration comprises the following components in parts by weight: 35-85 parts of film forming substance, 1-25 parts of polyaniline, 0.01-10 parts of chlorine ion blocking and controlling agent, 0.1-5 parts of pigment, 1-15 parts of filler, 0.01-2 parts of anti-sag agent, 0.01-2 parts of dispersing agent, 0.01-2 parts of leveling agent, 0.01-0.5 part of defoaming agent and 5-65 parts of solvent. The preparation method comprises steps that components except polyaniline and chlorine ion blocking and controlling agent are uniformly stirred, then polyaniline and chlorine ion blocking and controlling agent are added, then grinding is carried out in a coating grinder and discharging is carried out after fineness is less than 60 microns. The polyaniline coating capable of blocking and controlling the chlorine ion penetration has the advantage that corrosion resistance and chlorine ion penetration resistance are obviously improved and can be applied to heavy corrosion protection projects such as petrochemical equipment, pipelines, oil platforms on the sea, wharf facilities and ships, especially applicable to heavy corrosion coating operation on the sea.

Owner:HOHAI UNIV

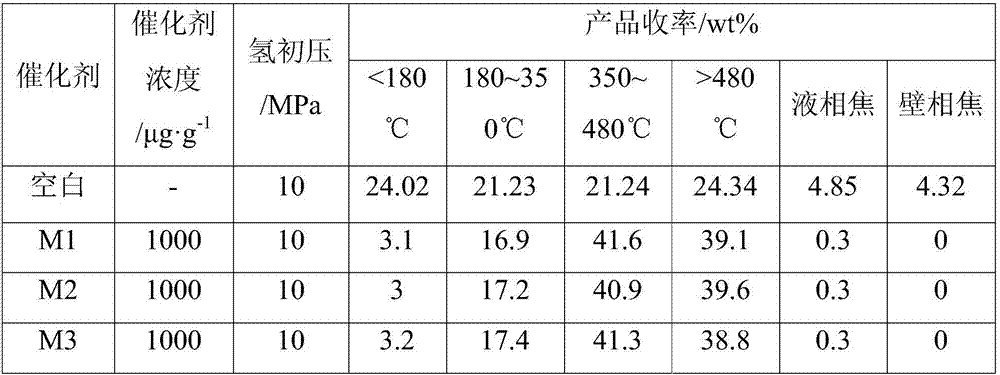

Recycling method of oil-soluble molybdenum-based slurry reactor hydrocracking catalyst

ActiveCN107486248AEfficient recyclingEfficient reuseOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils treatmentOrganic acidSlurry reactor

The invention relates to the technical field of petrochemical industry, in particular to a recycling method of an oil-soluble molybdenum-based slurry reactor hydrocracking catalyst. The method comprises the following steps of S101, performing oxidizing roasting on the abandoned molybdenum-based slurry reactor hydrocracking catalyst, dissolving a product after the oxidizing roasting with ammonia water, performing filtering, and collecting a first liquid phase, S102, adding a valcanizer to the first liquid phase obtained in S101, performing a reaction, and performing crystallization, filtering and water washing to obtain vulcanized metal salt, S103, reacting the vulcanized metal salt with organic acid, and S104, dissolving a product obtained in S103 in a dispersion aid, performing filtering, and collecting a second liquid phase to obtain an oil-soluble molybdenum-based catalyst precursor. The method can be used for high-efficiency recycling of metal molybdenum, and has the advantages of simple technology, mild condition, high metal molybdenum recovery rate, low-cost industrial application facilitation and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

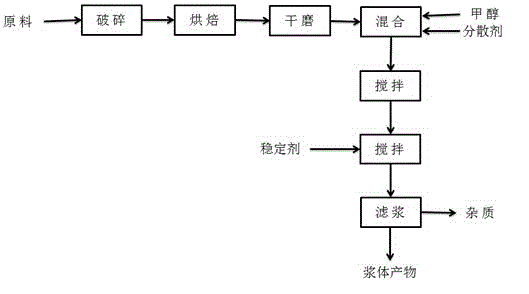

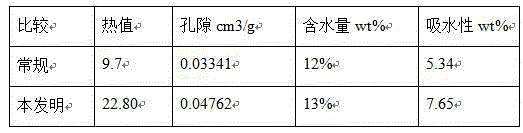

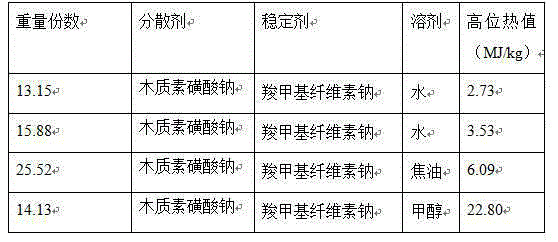

Slurry fuel prepared by baking biomass and application thereof

InactiveCN105018161AHigh calorific valueSave resourcesLiquid carbonaceous fuelsLiquid productSolvent

The invention discloses a slurry fuel prepared by baking biomass and an application thereof. The slurry fuel comprises solid and liquid products resulting from low-temperature baking of the biomass, methanol and additives, wherein the additives comprise a dispersant and a stabilizer. The dispersant is sodium lignosulfonate, and the amount of the dispersant is 2% of the weight of a dry basis. The stabilizer is sodium carboxymethyl cellulose, and the amount of the stabilizer is 0.1% of the weight of the dry basis. According to the invention, the solid and liquid products after the low-temperature baking of the biomass are used are mixed to make slurry; a defect of traditional biomass coal water slurry is overcome; and a heat value of the obtained slurry fuel is improved by using methanol to replace water as a solvent. The optimum higher heat value can reach 22.80 MJ / kg and provides a new idea for alleviating the energy security problem caused by oil shortages.

Owner:TIANJIN NORMAL UNIVERSITY

Aluminum oxide-containing polyaniline zinc powder flake epoxy heavy anti-corrosion coating and preparation method thereof

ActiveCN103834264AWith \"passivation\"Has a \"sustained release\" effectAnti-corrosive paintsEpoxy resin coatingsCoating systemFirming agent

The invention discloses aluminum oxide-containing polyaniline zinc powder flake epoxy heavy anti-corrosion coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises the following components in parts by mass: 35-85 parts of epoxy resin, 0.5-25 parts of polyaniline zinc powder flake, 0.1-10 parts of aluminum oxide, 0.1-5 parts of pigment, 1-15 parts of packing, 0.01-2 parts of anti-sag agent, 0.01-0.5 part of dispersant, 0.01-2 parts of flatting agent, 0.01-0.5 part of deforming agent and 5-40 parts of mixed solvent; and the component B comprises the following components in parts by mass: 40-90 parts of amine curing agent and 10-60 parts of solvent; and the coating is prepared by mixing and stirring the component A and the component B for 1-5 minutes according to a mass ratio being 1: (0.1-1):1. The corrosion resistance, seawater erosion and abrasion resistance, ageing resistance and anti-penetrating property of the coating system are obviously improved; and the coating can be applied to heavy anti-corrosion engineering in fields of petrochemical equipment, pipelines, offshore oil platforms, berthing facilities, ships and the like.

Owner:HOHAI UNIV

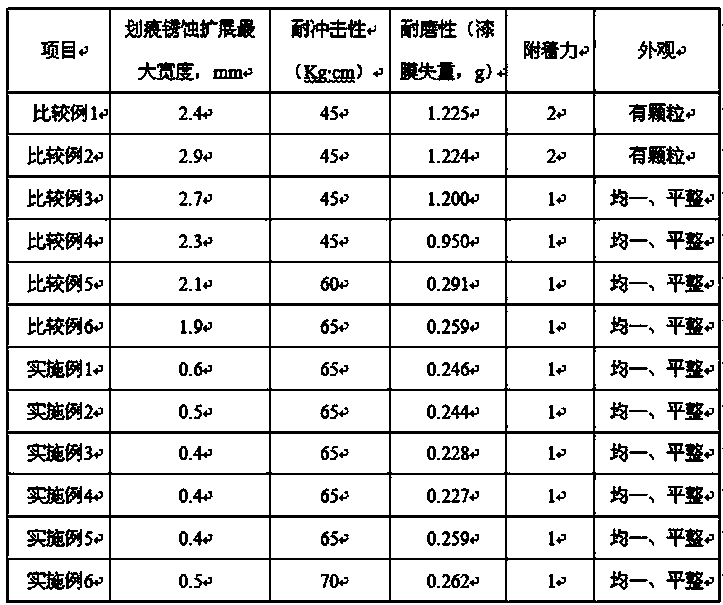

CF-4 diesel engine oil composition and its application

InactiveCN107312593AGuaranteed performanceGood dispersionLubricant compositionPreservativeClearing Agent

The invention relates to a CF-4 diesel engine oil composition and its application. The CF-4 diesel engine oil composition is mainly used for solving problems of high-temperature cleanliness and insufficient oil sludge dispersing property when the CF-4 diesel engine oil composition is applied to a vehicle diesel engine system in the prior art. The CF-4 diesel engine oil composition is prepared from, by weight, a), 2-5 parts of metal clearing agent; b), 2-5 parts of polyisobutylene-bis-succinimide ashless dispersing agent with low molecular weight, wherein the molecular weight scale is 3000-3200; c), 1-2 parts of phosphorus-containing wear resisting preservative; d), 0.1-1 part of composite antioxygen; e), 87-95 parts of basic oil. The technical scheme can well solve the problem, and can be applied to the industrial production of the CF-4 diesel engine oil composition.

Owner:CHINA PETROLEUM & CHEM CORP

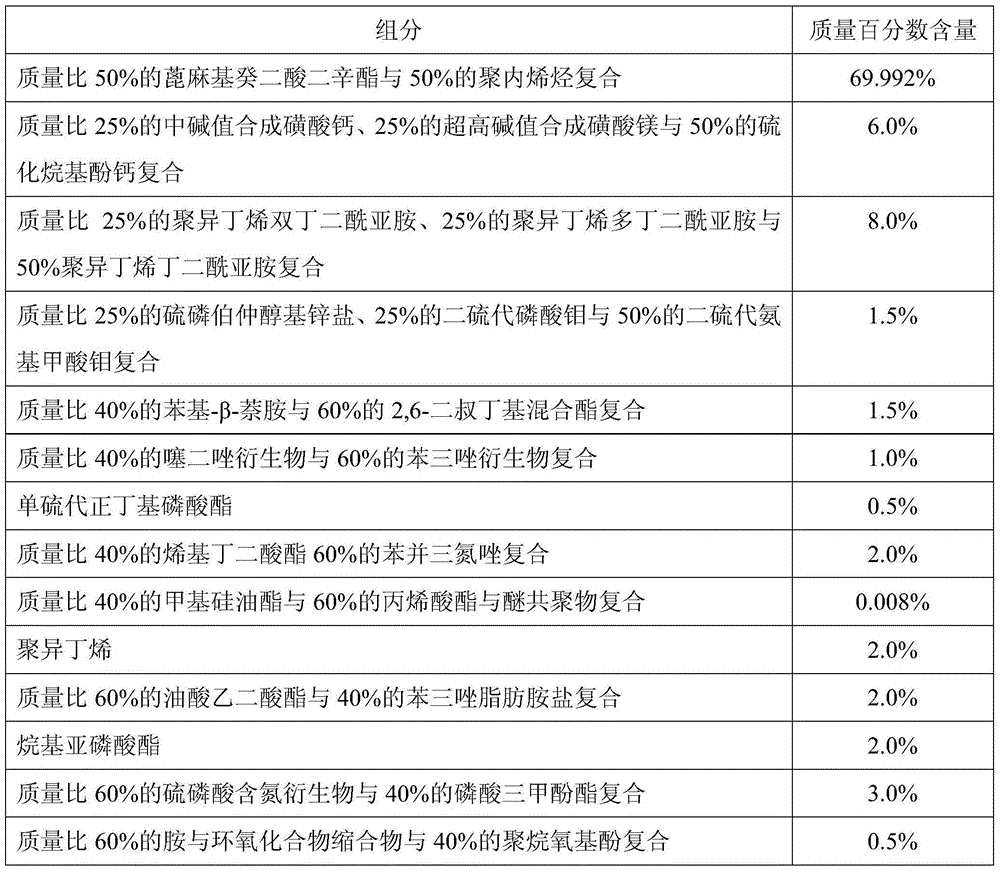

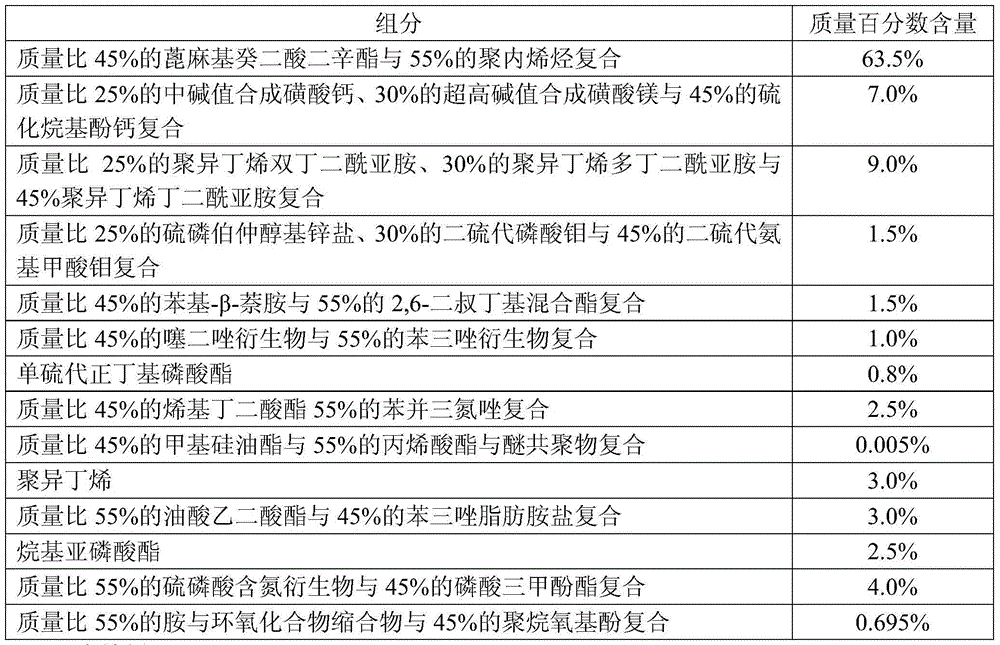

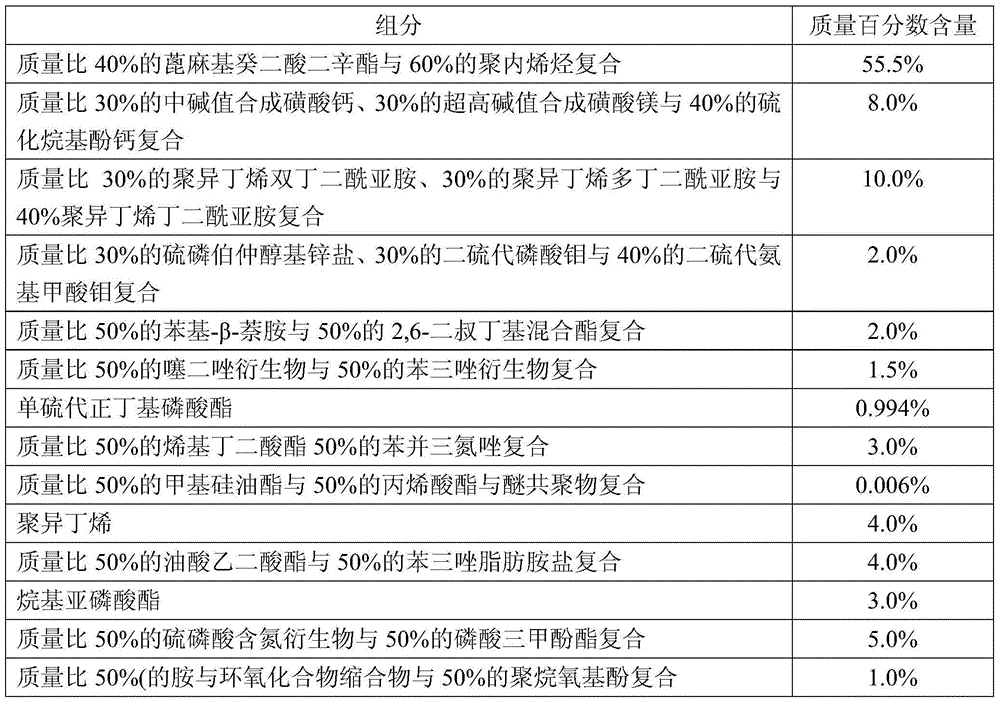

Coal water slurry blended fuel engine oil composition

ActiveCN104087375AExcellent viscosity-temperature propertiesAvoid stickingLubricant compositionOil sludgeBlack oil

The invention discloses a coal water slurry blended fuel engine oil composition. Polyinternalolefins and castor-bsae dioctyl sebacate used as base oil are matched with multiple composite additives to obtain the composition. The composite additives comprise an antiwear additive, an antioxidant preservative, an antifoam agent, a demulsifying compound, a viscosity index improver, a metal passivator, a detergent agent, a dispersing agent, an antioxidant, an oily agent, a friction improver, a reinforcing agent and a rust inhibitor. The engine oil composition has excellent cleaning and dispersion effects, prevents the piston ring from sticking, and keeps the engine clean. Due to excellent viscosity-temperature characteristic, excellent alkali number retentivity, acid neutralizing capacity and demulsifying capacity, the engine oil composition can inhibit the black oil sludge from generation, so that the engine is cleaner. Due to favorable high-temperature oxidation stability, high shear stability, favorable rubber compatibility, favorable cold-starting property and excellent fuel economical efficiency, the engine oil composition can not corrode or tarnish the moving parts, ensures the oil product to maintain sufficient oil film strength, has better extreme-pressure abrasion resistance, and lowers the abrasion and engine oil consumption.

Owner:GUANGXI UNIV

Non-foaming polyurethane water plugging and reinforcing material and preparation method thereof

InactiveCN111690358ALow viscosityImprove liquidityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPtru catalystPolyphenyl isocyanate

The invention discloses a non-foaming polyurethane water plugging and reinforcing material and a preparation method thereof. The material is composed of a component A and a component B. The componentA is prepared from 70-90 parts of water glass, 10-30 parts of a dispersing agent and 0.8-2 parts of a catalyst; and the component B comprises the following components in parts by weight: 70-90 parts of polymethylene polyphenyl isocyanate and 10-30 parts of a reinforcing agent. The preparation method comprises the following steps: adding the water glass into a stirring tank, adding the dispersing agent and the catalyst in the stirring process, and stirring for 30-40 minutes to obtain the component A; adding polymethylene polyphenyl isocyanate into the stirring tank, adding the reinforcing agentin the stirring process, and stirring for 20-30 minutes to obtain the component B; and mixing and grouting the component A and the component B according to the volume ratio of 1:1 by adopting a double-liquid grouting pump. The material is used for plugging and reinforcing gaps with small water flow in coal mines, underground engineering and subway tunnels. The material is simple, easy to obtain,low in viscosity, free of foaming, excellent in mechanical property and long in preservation time, and is particularly suitable for coal and rock mass gaps with small water flow.

Owner:山东金鼎新能源材料有限公司

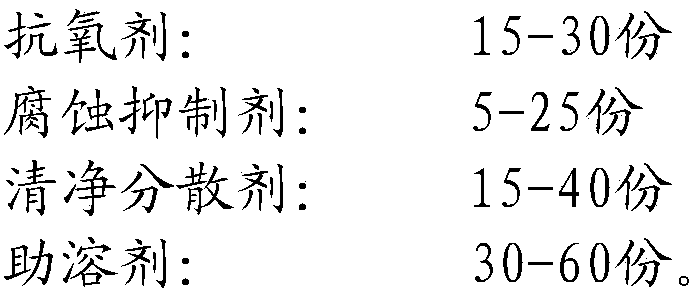

Primary oil aid, and primary oil and preparation method thereof

InactiveCN110684568AImprove antioxidant capacityExtended storage timeLiquid carbonaceous fuelsFuel additivesPetrochemicalTert butyl

The invention belongs to the field of petrochemical industry, and particularly relates to a primary oil aid, and primary oil and a preparation method thereof, wherein the primary oil aid comprises anantioxidant, a corrosion inhibitor, a detergent dispersant and a cosolvent, has good corrosion resistance, can be adsorbed on the inner surface of an engine so as to prevent the corrosive components in an oil product from corroding the engine, protect the engine and prolong the service life of the engine, and has good oxidation resistance. According to the invention, by combining the primary oil aid, isopentane, isohexane, isooctane, alkylated gasoline, methyl tert-butyl ether, raffinate oil and toluene to obtain primary oil, the primary oil aid can react with the unstable free radicals in theprimary oil to terminate the chain reaction in the fuel oxidation process and eliminate the free radicals, so that the primary oil is in a stable state, the storage time of the engine and the oil product is prolonged, and the good cold starting performance, the combustion performance and the power performance are achieved; and after the primary oil is combusted, the combustion efficiency of the engine is high, the oil consumption is low, and the tail gas emission is little.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Coking demulsifier and preparation method thereof

InactiveCN103951009AReduce oil contentPromote stratificationFatty/oily/floating substances removal devicesNon-miscible liquid separationDemulsifierInorganic ions

The present invention discloses a coking demulsifier, which comprises, by weight, 25-40% of a cationic surfactant, 5-10% of a dispersant, 5-10% of a wetting agent, 10-20% of a corrosion inhibitor, and the balance of water. The present invention further discloses a preparation method for the coking demulsifier. According to the present invention, rapid demulsification of the delayed coking apparatus oil-water separation tank can be achieved, and the oil content in the discharged water can be significantly reduced; the water is clear after demulsification; corrosion of the water body on equipment is reduced; and the coking demulsifier does not contain inorganic ions, and does not affect the existing water system.

Owner:宜兴汉光高新石化有限公司

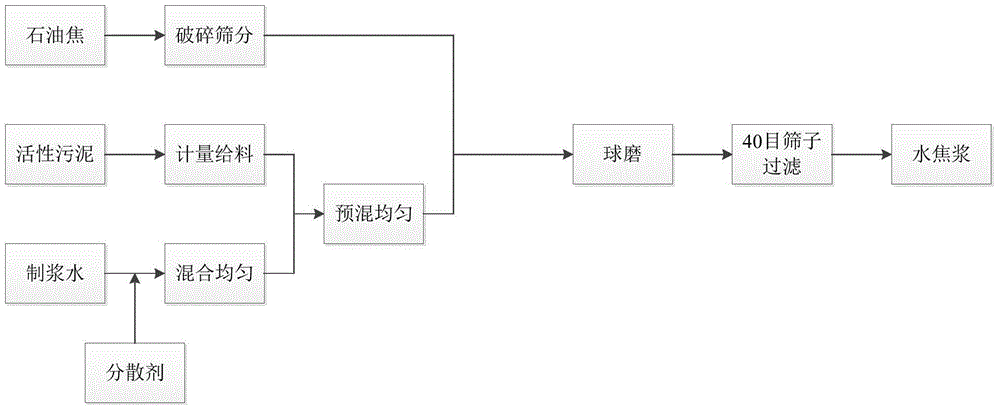

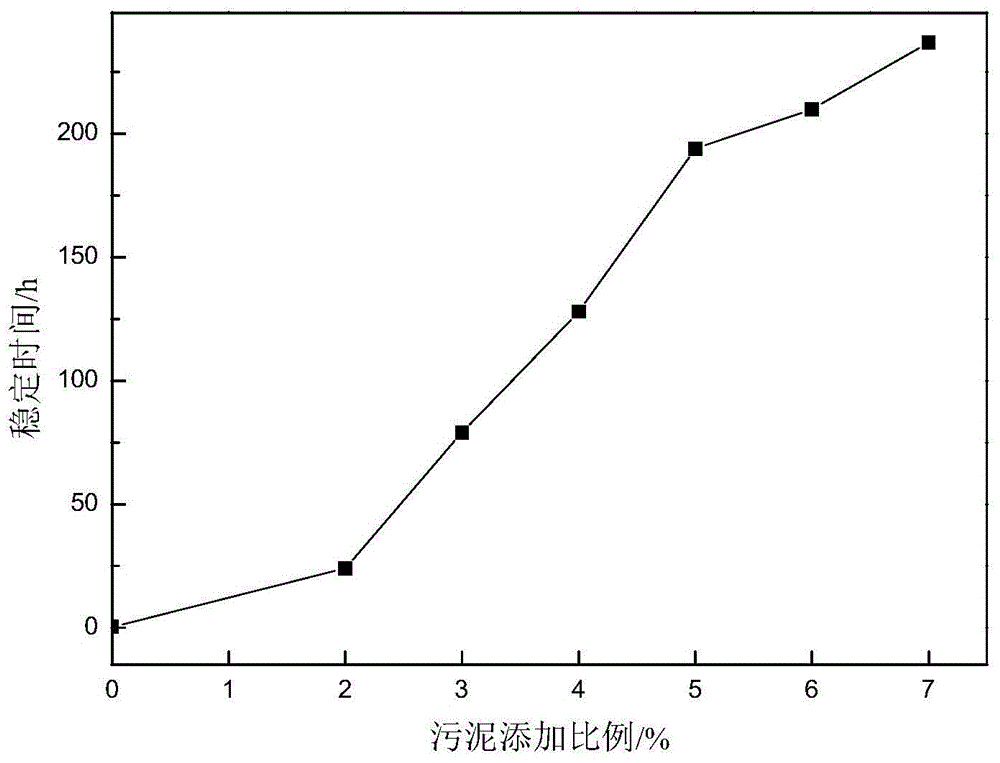

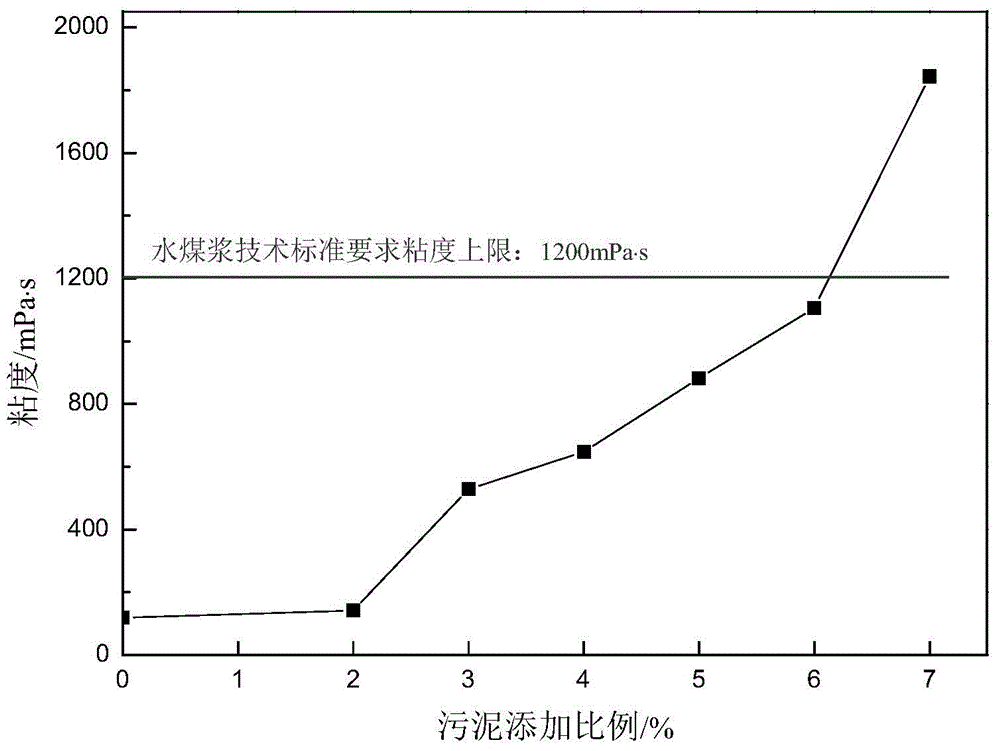

Method for improving stability of water-coke slurry

The invention relates to a method for improving stability of water-coke slurry. The water-coke slurry is prepared from the raw materials, including petroleum coke, activated sludge, water and a dispersing agent. The method comprises the steps of (1) sieving petroleum coke through a sieve, and remaining petroleum coke of which the particle size is less than 0.8mm; (2) dissolving the dispersing agent into water, and uniformly agitating for later use; (3) integrally uniformly mixing the dispersing agent solution obtained in step (2) and activated sludge, pouring into a ball mill tank together with the petroleum coke processed in step (1), wherein the quantity ratio of large balls to small balls in the ball mill tank is 30: 150; a ball mill rotates at the speed of 230 to 380r / min; the ball milling costs 30 to 50 minutes; (4) filtering the slurry obtained by ball milling through a sieve with 40 meshes so as to remove impurities and large particles and obtain water-coke slurry. According to the method, the activated sludge is doped into the water-coke slurry to greatly improve the stability of the water-coke slurry, so that the problem of poor stability of the water-coke slurry can be completely solved; meanwhile, a new treatment way is provided to the activated sludge of a melting plant, and the sludge treatment cost of the melting plant can be reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com