Environmentally-friendly heavy oil additive and preparation method and use method thereof

A technology of additives and heavy oil, which is applied in the direction of fuel additives, petroleum industry, liquid carbon-containing fuels, etc. It can solve the problems of shortening the service life of the engine, adverse effects of heat transfer, and unstable combustion, so as to reduce corrosion and mechanical damage, and reduce product accumulation. Carbon and black smoke, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

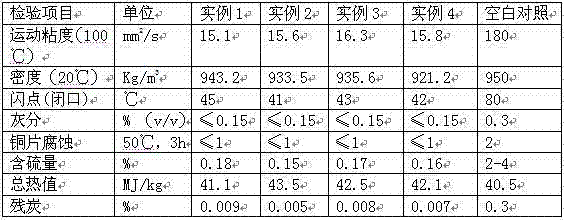

Embodiment 1

[0042] An environment-friendly heavy oil additive, consisting of the following components by weight:

[0043] 5 parts of polyethylene glycol fatty acid ester, 5 parts of alkylphenol polyoxyethylene ether, 10 parts of polyisobutylene, 5 parts of polyenol, 10 parts of isobutanol, 5 parts of polyamine ether, alkenyl butadiol imine 5 parts, 1 part sulfonated lignin, 25 parts water.

[0044] The preparation method of above-mentioned environment-friendly heavy oil additive comprises the following steps:

[0045] (1) Weigh each component according to the above ratio;

[0046] (2) At 20-25°C, add water into the reaction tank, then add isobutanol, polyisobutylene, and polyenol into the water, stir for 0.5, and mix well;

[0047] (3) Then add polyethylene glycol fatty acid ester and alkylphenol polyoxyethylene ether to the mixture in step (2), stir for 1 hour, and mix well;

[0048] (4) Add polyaminoether and alkenylbutanediolimine to the mixture in the above step (3), stir for 0.5h,...

Embodiment 2

[0052] An environment-friendly heavy oil additive, consisting of the following components by weight:

[0053] 8 parts of polyethylene glycol fatty acid ester, 8 parts of alkylphenol polyoxyethylene ether, 15 parts of polyisobutylene, 15 parts of polyenol, 20 parts of isobutanol, 8 parts of polyamine ether, alkenyl butanediol imine 10 parts, 3 parts of sulfonated lignin, 30 parts of water.

[0054] The preparation method of above-mentioned environment-friendly heavy oil additive comprises the following steps:

[0055] (1) Weigh each component according to the above ratio;

[0056] (2) Add water into the reaction tank at 20-25°C, then add isobutanol, polyisobutylene, and polyenol into the water, stir for 1 hour, and mix well;

[0057] (3) Then add polyethylene glycol fatty acid ester and alkylphenol polyoxyethylene ether to the mixture in step (2), stir for 2 hours, and mix well;

[0058] (4) Add polyaminoether and alkenyl butanediol imine to the mixture in the above step (3)...

Embodiment 3

[0062] An environment-friendly heavy oil additive, consisting of the following components by weight:

[0063] 15 parts of polyethylene glycol fatty acid ester, 13 parts of alkylphenol polyoxyethylene ether, 20 parts of polyisobutylene, 25 parts of polyenol, 20 parts of isobutanol, 20 parts of polyamine ether, alkenyl butanediol imine 20 parts, sulfonated lignin 5 parts, water 30 parts.

[0064] The preparation method of above-mentioned environment-friendly heavy oil additive comprises the following steps:

[0065] (1) Weigh each component according to the above ratio;

[0066] (2) Add water into the reaction tank at 20-25°C, then add isobutanol, polyisobutylene, and polyenol into the water, stir for 1 hour, and mix well;

[0067] (3) Then add polyethylene glycol fatty acid ester and alkylphenol polyoxyethylene ether to the mixture in step (2), stir for 2 hours, and mix well;

[0068] (4) Add polyaminoether and alkenyl butanediol imine to the mixture in the above step (3), s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com