Novel environmentally friendly high-fuel-value straw coal and preparation method thereof

A straw coal, environmental protection technology, applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of insufficient utilization, insufficient combustion of straw coal, difficult molding, storage, etc., to optimize fuel preparation, calorific value and flash The effect of high point and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

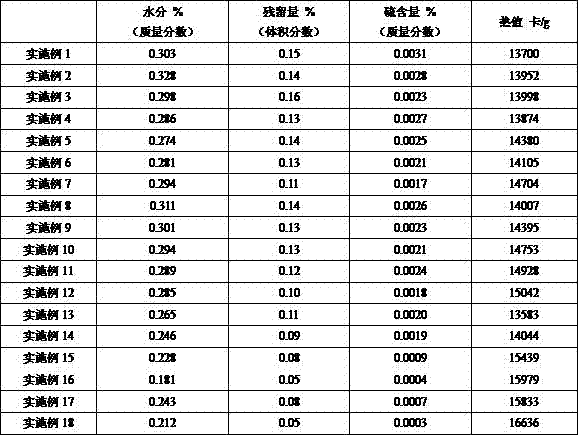

Examples

Embodiment 1

[0032] A method for preparing a novel environment-friendly high-combustion value straw coal, which comprises the following steps:

[0033] 1) 22 parts of corn stalks are pulverized in a pulverizer to reach 60 mesh;

[0034] 2) put the stalk powder that pulverizes into drying machine and dry, ensure that the stalk moisture content is at 6%;

[0035] 3) Take out the dried straw, first add 10 parts of slag, 2 parts of magnesium hydroxide, 5 parts of silicon dioxide, 2.5 parts of calcium carbonate, and 3 parts of ethyl acetate into a mixer at 40 °C, and mix evenly for 3 hours to obtain a mixed powder;

[0036] 4) Transfer the mixed powder obtained in 3) to a mixer, add 80 parts of absolute ethanol, and stir at 100 °C for 1 h to obtain a solidified powder;

[0037] 5) Put the above-mentioned mixed powder into a compression molding machine for compression molding to make granular fuel;

[0038] 6) Cooling, sieving and packaging the obtained granular fuel.

Embodiment 2

[0040] A method for preparing a novel environment-friendly high-combustion value straw coal, which comprises the following steps:

[0041] 1) 38 parts of corn stalks are pulverized in a pulverizer to reach 60 mesh;

[0042] 2) put the stalk powder that pulverizes into drying machine and dry, ensure that the stalk moisture content is at 6%;

[0043] 3) Take out the dried straw, first add 10 parts of slag, 2 parts of magnesium hydroxide, 5 parts of silicon dioxide, 2.5 parts of calcium carbonate, and 3 parts of ethyl acetate into a mixer at 40 °C, and mix evenly for 3 hours to obtain a mixed powder;

[0044] 4) Transfer the mixed powder obtained in 3) to a mixer, add 80 parts of absolute ethanol, and stir at 100 °C for 1 h to obtain a solidified powder;

[0045] 5) Put the above-mentioned mixed powder into a compression molding machine for compression molding to make granular fuel;

[0046] 6) Cooling, sieving and packaging the obtained granular fuel.

Embodiment 3

[0048] A method for preparing a novel environment-friendly high-combustion value straw coal, which comprises the following steps:

[0049] 1) 22 parts of corn stalks are pulverized in a pulverizer to reach 60 mesh;

[0050] 2) put the stalk powder that pulverizes into drying machine and dry, ensure that the stalk moisture content is at 6%;

[0051] 3) Take out the dried straw, add 25 parts of slag, 2 parts of magnesium hydroxide, 5 parts of silicon dioxide, 2.5 parts of calcium carbonate, and 3 parts of ethyl acetate into a mixer at 40 °C, and mix evenly for 3 hours to obtain a mixed powder;

[0052] 4) Transfer the mixed powder obtained in 3) to a mixer, add 80 parts of absolute ethanol, and stir at 100 °C for 1 h to obtain a solidified powder;

[0053] 5) Put the above-mentioned mixed powder into a compression molding machine for compression molding to make granular fuel;

[0054] 6) Cooling, sieving and packaging the obtained granular fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com