Dispersant for ultra-high density drilling fluid, preparation method and application

An ultra-high density and drilling fluid technology, applied in the field of oil drilling, can solve the problems of poor effect and ineffectiveness, and achieve strong salt pollution resistance and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

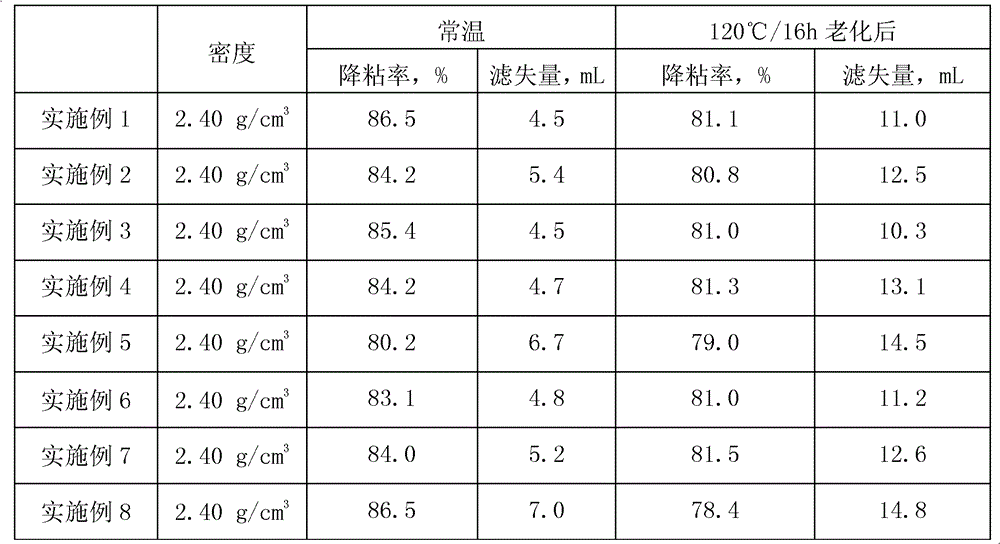

[0056] The dispersant for ultra-high-density drilling fluid is prepared from the following raw materials: 20 parts of herbal lignin, 10 parts of phenol, 8 parts of sodium sulfite, 2 parts of formaldehyde, 1.2 parts of p-toluenesulfonic acid, and 100 parts of water. React at 160-170°C for 8 hours, and dry to obtain dispersant SMS-19A.

[0057] Preparation of saline weighted base slurry: add 12g sodium chloride and 1.2g anhydrous sodium carbonate to 300mL distilled water, stir at high speed for 5 minutes, add 24g of experimental sodium bentonite, stir at high speed for 20 minutes, maintain in a grinding bottle for 24 hours, and stir at high speed Add 980g of barite, stir at high speed for 10 minutes, use it as a base slurry for adding salt water, and measure its Φ 1000 Readings, density and fluid loss, the density of the brine weighted slurry should be 2.40±0.05g / cm 3 within the range, Φ 100 The value should be within the range of 145±10, and the fluid loss at room temperature...

Embodiment 2

[0063] The dispersant for ultra-high density drilling fluid is prepared from the raw materials of the following components: 18 parts of woody lignin, 10 parts of p-cresol, 8 parts of sodium sulfite, 3 parts of formaldehyde, 1 part of p-toluenesulfonic acid, 100 parts of water, After mixing evenly, react at 160-170°C for 8 hours, and make dispersant SMS-19B after drying.

[0064] The results obtained by the test method in Example 1 are shown in Table 1.

Embodiment 3

[0066] The dispersant for ultra-high-density drilling fluid is prepared from the raw materials of the following components: 20 parts of woody lignin, 10 parts of phenol, 10 parts of sodium bisulfite, 4 parts of formaldehyde, 1.5 parts of p-toluenesulfonic acid, and 100 parts of water , After mixing evenly, react at 170-180°C for 6 hours, and dry to obtain dispersant SMS-19C.

[0067] The results obtained by the test method in Example 1 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com