Slurry fuel prepared by baking biomass and application thereof

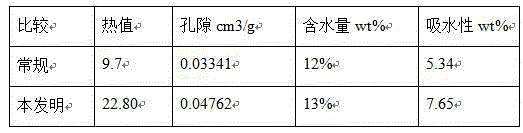

A biomass and fuel technology, applied in liquid carbon-containing fuels, fuels, petroleum industries, etc., can solve the problems of limited large-scale use, low slurry concentration, poor grindability, etc., to improve calorific value and save coal resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

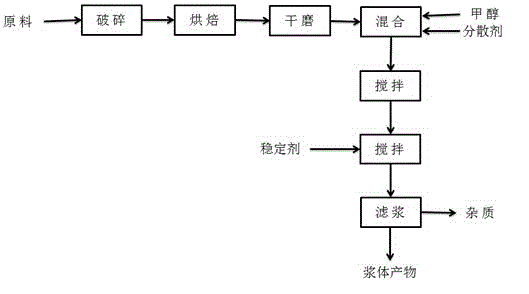

Method used

Image

Examples

Embodiment 1

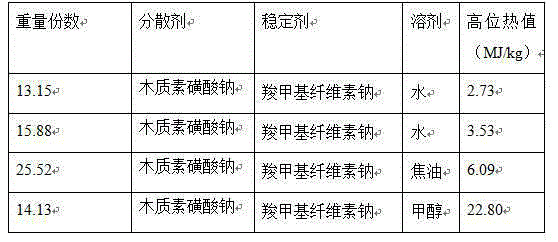

[0029] The biomass solid fuel particles were crushed, baked at 290°C for 1 hour under an inert atmosphere, and solid and liquid products were collected. The solid product was crushed to a particle size below 3mm, and dried in an oven at 105°C for 3h. The dried samples were divided into two parts, and placed in an ND7 planetary ball mill to grind for 15 min and 30 min, respectively, to obtain coarse powder and fine powder with different particle size distributions. Mix equal masses of coarse powder and fine powder to obtain a graded solid product powder. Take 45 parts by weight of the powder and 15 parts by weight of the liquid product after baking, and mix them to obtain a solid-liquid mixture. Add 0.9 parts by weight sodium lignosulfonate and 39.055 parts by weight methyl alcohol in the mixture, after stirring for 15min with the rotating speed of 1200r / min in electric stirrer, then add 0.045 parts by weight sodium carboxymethylcellulose therein, with the same Stir at high s...

Embodiment 2

[0031] The biomass solid fuel particles were crushed, baked at 290°C for 1 hour under an inert atmosphere, and solid and liquid products were collected. The solid product was crushed to a particle size below 3mm, and dried in an oven at 105°C for 3h. The dried samples were divided into two parts, and placed in an ND7 planetary ball mill to grind for 15 min and 30 min, respectively, to obtain coarse powder and fine powder with different particle size distributions. Mix equal masses of coarse powder and fine powder to obtain a graded solid product powder. Take 40 parts by weight of the powder and 13.33 parts by weight of the liquid product after baking, and mix them to obtain a solid-liquid mixture. Add 0.8 parts by weight sodium lignosulfonate and 45.83 parts by weight methyl alcohol in the mixture, after stirring for 15min with the rotating speed of 1200r / min in the electric mixer, add 0.04 parts by weight sodium carboxymethylcellulose to it again, with the same Stir at high...

Embodiment 3

[0033] The biomass solid fuel particles were crushed, baked at 290°C for 1 hour under an inert atmosphere, and solid and liquid products were collected. The solid product was crushed to a particle size below 3mm, and dried in an oven at 105°C for 3h. The dried samples were divided into two parts, and placed in an ND7 planetary ball mill to grind for 15 min and 30 min, respectively, to obtain coarse powder and fine powder with different particle size distributions. Mix equal masses of coarse powder and fine powder to obtain a graded solid product powder. Take 35 parts by weight of the powder and 11.667 parts by weight of the liquid product after baking, and mix them to obtain a solid-liquid mixture. Add 0.7 parts by weight of sodium lignosulfonate and 52.598 parts by weight of methyl alcohol into the mixture, after stirring for 15min at a speed of 1200r / min in an electric mixer, add 0.035 parts by weight of sodium carboxymethylcellulose therein, with the same Stir at high spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com