Two-component polyurethane coating and preparation method thereof

A two-component polyurethane and polyurethane prepolymer technology, applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of non-planar roofs, anti-arc coatings flowing, and electrical insulation performance decline And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

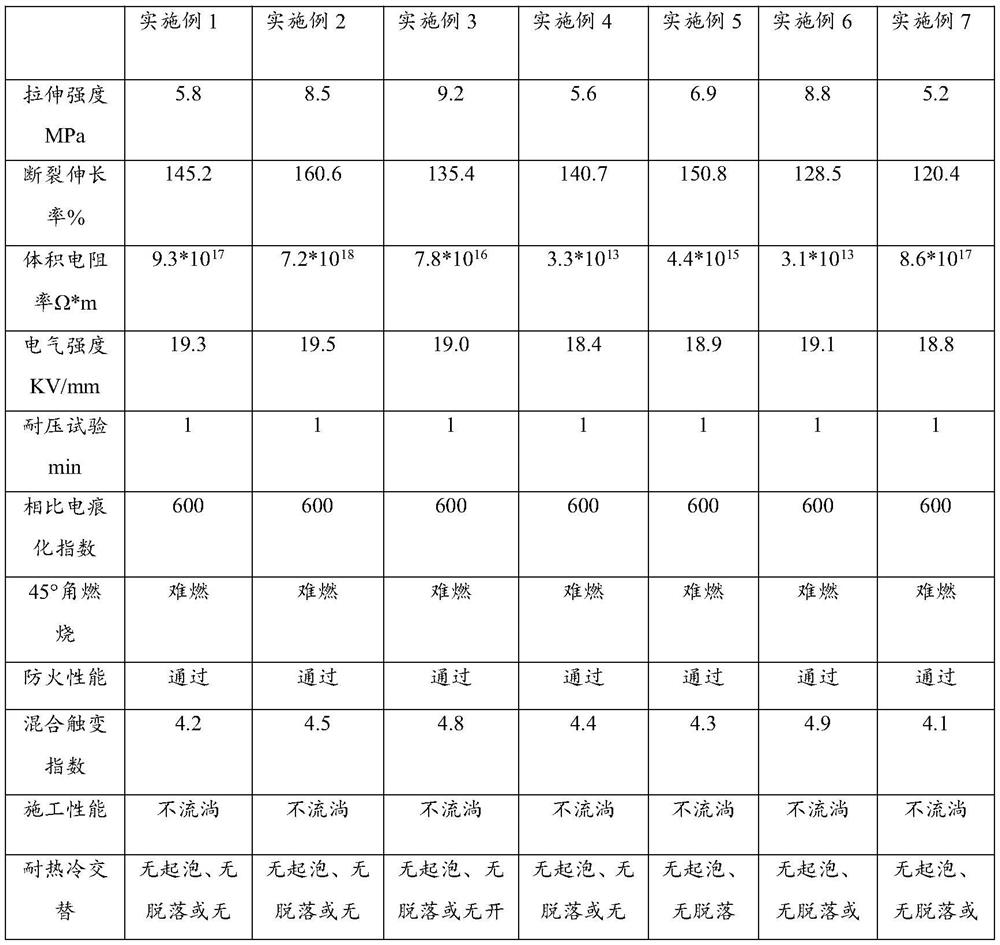

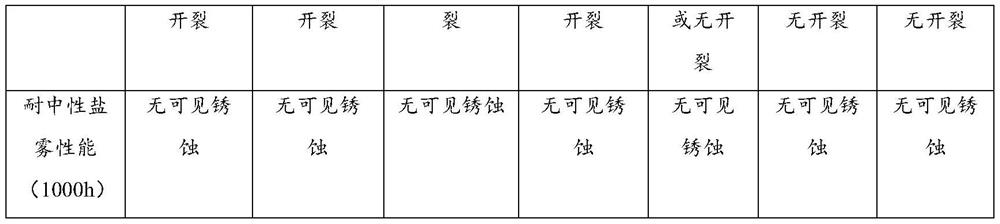

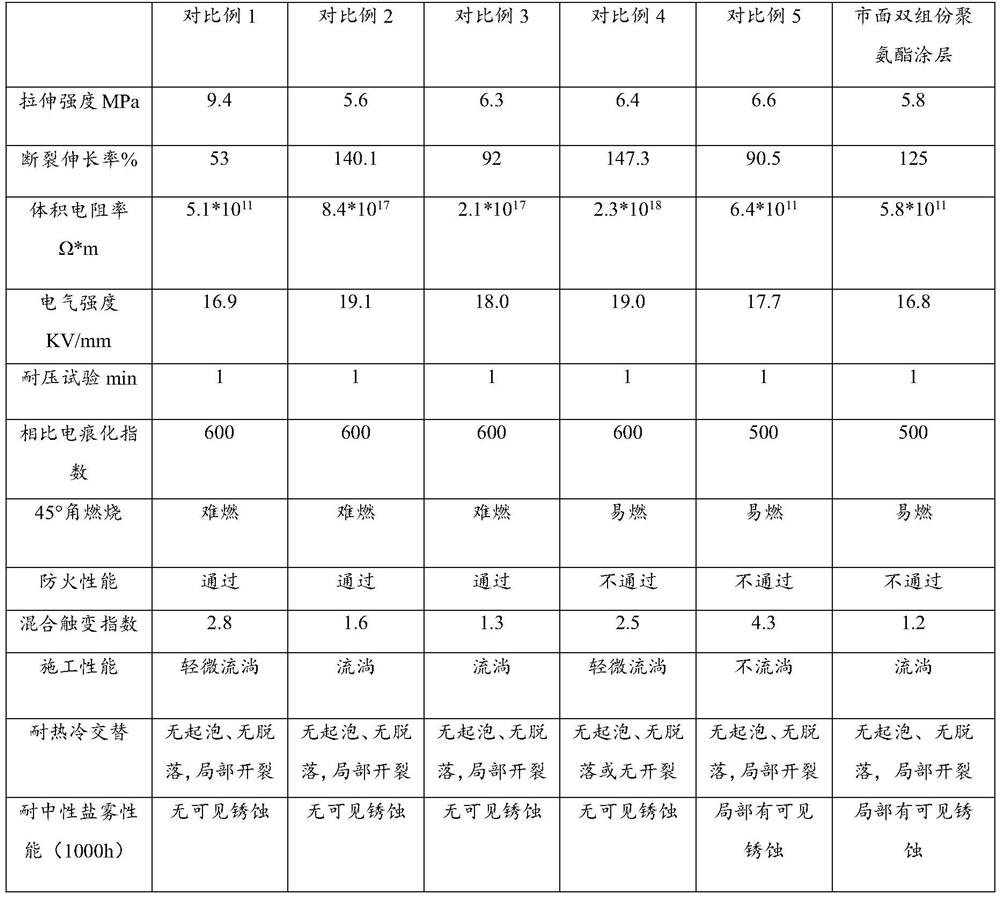

Examples

Embodiment 1

[0032] The present embodiment provides a kind of preparation method of two-component polyurethane coating, comprises the steps:

[0033] Preparation of component A: by weight, add 20 parts of primary refined castor oil (hydroxyl value 164mgKOH / g), 10 parts (hydroxyl value 450mgKOH / g) and 15 parts of flame-retardant plasticizer Fyrol TEP, heated to 120°C, stirred and dehydrated under vacuum for 2 hours, then cooled to 60°C, and then respectively added 0.1 part of DabcoT-12A, 0.2 part of adhesive 0.5 parts of defoamer BYK6880, 0.5 parts of leveling agent BYK3700, 0.3 parts of dispersant Efka4300, 0.5 parts of fumed silica AEROSIL R202, 0.5 parts of polyamide wax Add Optima into the planetary stirring mixer, then add 40 parts of magnesium hydroxide and 10 parts of 4A molecular sieve respectively, stir for 2 hours in a vacuum state and discharge to obtain component A.

[0034]Preparation of component B: respectively add 32 parts of isocyanate CDMDI100L and 8 parts of polymeth...

Embodiment 2

[0037] The present embodiment provides a kind of preparation method of two-component polyurethane coating, comprises the steps:

[0038] Preparation of component A: by weight, add 30 parts in the reactor (hydroxyl value 56mgKOH / g), 9 parts (hydroxyl value 400mgKOH / g), 5 parts of flame retardant plasticizer DMMP, heated to 120 ° C, and stirred and dehydrated under vacuum for 2 hours, then cooled to 60 ° C, and then 0.3 parts of catalyst Dabco1028, 1 part of viscosity increase Agent ABITOL-E, 1 part of defoamer BYK-067A, 0.5 part of leveling agent BYK331, 0.6 part of dispersant Efka5244, 2.5 parts of polyamide wax Add Optima to the planetary stirring mixer, then add 28 parts of magnesium hydroxide, 22 parts of aluminum hydroxide, and 6 parts of desiccant 4A molecular sieve, stir for 2 hours in a vacuum state and discharge to obtain component A.

[0039] Prepare B component:

[0040] 25 parts of isocyanate MDI-50, 5 parts of polymethylene polyphenyl isocyanate Add in the ...

Embodiment 3

[0043] The present embodiment provides a kind of preparation method of two-component polyurethane coating, comprises the steps:

[0044] Prepare component A:

[0045] In parts by weight, add 40 parts in the reactor (hydroxyl value 140mgKOH / g), 12 parts (hydroxyl value 365mgKOH / g), 1 part flame retardant plasticizer Heat to 120°C, stir and dehydrate under vacuum for 2 hours, then cool down to 60°C, add 0.5 parts of catalyst Polycat@SA20, 0.2 parts of tackifier Add 0.8 parts of defoamer BYK085, 1.5 parts of leveling agent BYK306, 1.2 parts of dispersant BYK2155, 8 parts of fumed silica TS720, then add 25 parts of aluminum hydroxide, 10 parts of antimony trioxide, and 6 parts of 4A molecular sieve to the planet In a stirring mixer, stir under vacuum for 2 hours and discharge to obtain component A.

[0046] Prepare B component:

[0047] Add 44 parts of isocyanate MDI-100 and 2 parts of polymethylene polyphenyl isocyanate Cosmonate MX-200 into the reactor, continuously fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com