Preparation method of while-drilling plugging fluid for oil-based drilling fluid

An oil-based drilling fluid and plugging agent technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor compatibility and failure to meet the deformation and plugging of micron-scale pores and fractures, and achieve easy promotion and reduction The effect of drilling operation cost and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

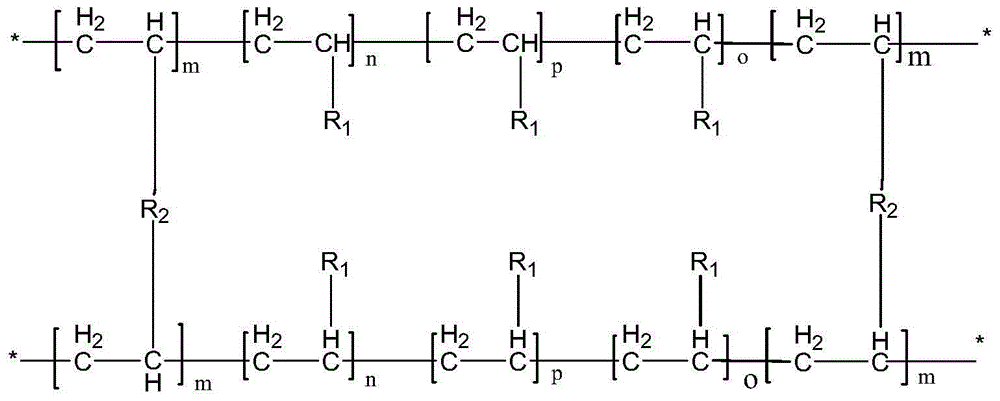

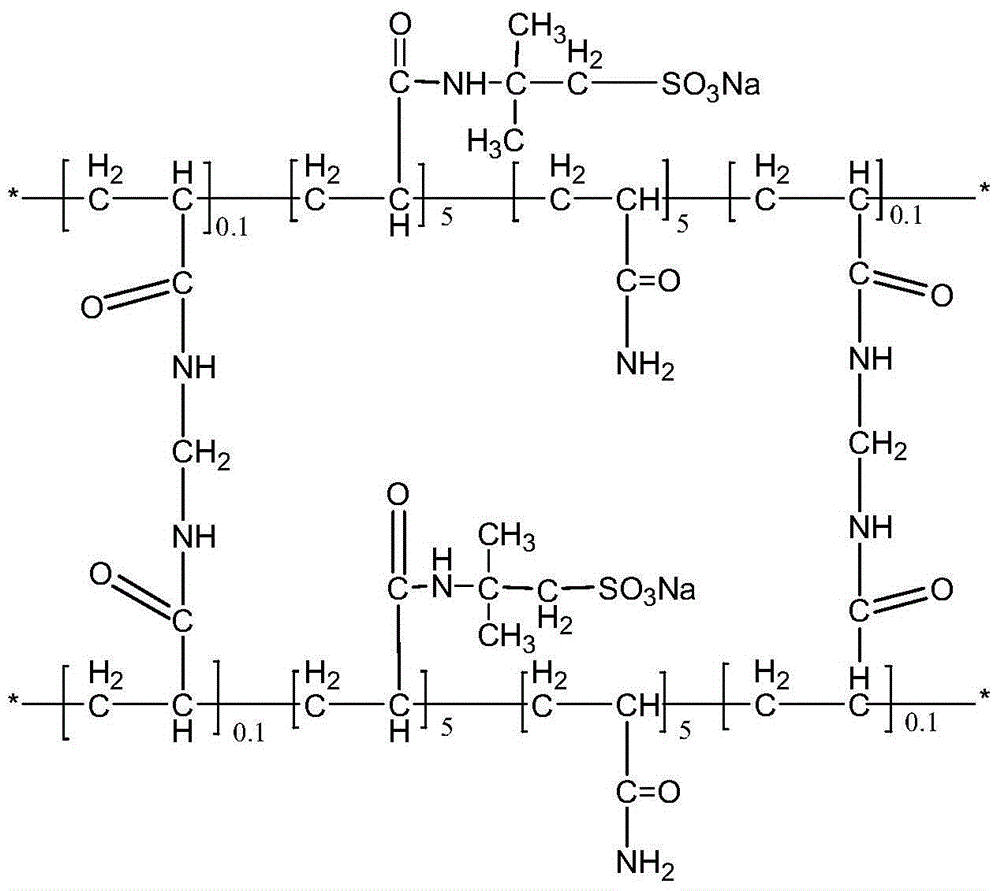

[0018] Example 1: Add 10.4g of AMPS to 80g of water, adjust the pH value to 9-11 with sodium hydroxide, then add 3.55g of AM, 0.15g of N,N-methylenebisacrylamide, and add 16.8g of bentonite, 8.4 1 g of silicon powder forms a uniformly dispersed aqueous solution; 8.4 g of sorbitol fatty acid ester and 3.6 g of alkylphenol polyoxyethylene ether are added in 160 g of white oil. Form a uniformly dispersed suspension system; heat the above system in a water bath at 40°C, add 10 mL of an aqueous solution of 0.17 g of ammonium persulfate and 10 mL of an aqueous solution of 0.17 g of sodium bisulfite under stirring, and the reaction is completed within 3 minutes to obtain the oil Lost circulation agent while drilling for base drilling fluid, its structural formula is:

[0019]

Embodiment 2

[0020] Example 2: Add 12.42g AMPS and 2.84g AA to 66g water, adjust the pH value to 7-11 with sodium hydroxide, then add 7.11g AM, 0.77g N, N-methylenebisacrylamide, fully dissolve and add 21.6 g of bentonite and 10.8g of silicon powder form a uniformly dispersed aqueous solution; add 8.4g of sorbitol fatty acid ester and 3.6g of alkylphenol polyoxyethylene ether into 80g of white oil; In the oil phase, a uniformly dispersed suspension system is formed; heat the above system in a water bath at 40°C, add 10mL aqueous solution of 0.4g ammonium persulfate and 10mL aqueous solution of 1.53g sodium bisulfite under stirring, and the reaction is completed within 3 minutes , to obtain the lost circulation agent while drilling for the oil-based drilling fluid, its structural formula is:

[0021]

Embodiment 3

[0022] Example 3: Add 7.2g of AA to 80g of water, adjust the pH value to 7-11 with sodium hydroxide, then add 7.2g of AM, 1.54g of N,N-methylenebisacrylamide, fully dissolve and add 20g of bluestone powder to form Uniformly dispersed aqueous solution; add 8.4g polyoxyethylene sorbitan monooleate and 4.5g sorbitan monooleate to 148g white oil, after completely dissolving, add the above aqueous solution to the oil phase, a uniformly dispersed suspension system is formed; the above system is heated in a water bath at 40°C, and a 10mL aqueous solution of 0.72g ammonium persulfate and a 10mL aqueous solution of 0.72g sodium bisulfite are added under stirring, and the reaction is completed within 3min to obtain The oil-based drilling fluid is used for plugging while drilling, and its structural formula is:

[0023]

[0024] Product of the present invention is evaluated, and result is as follows:

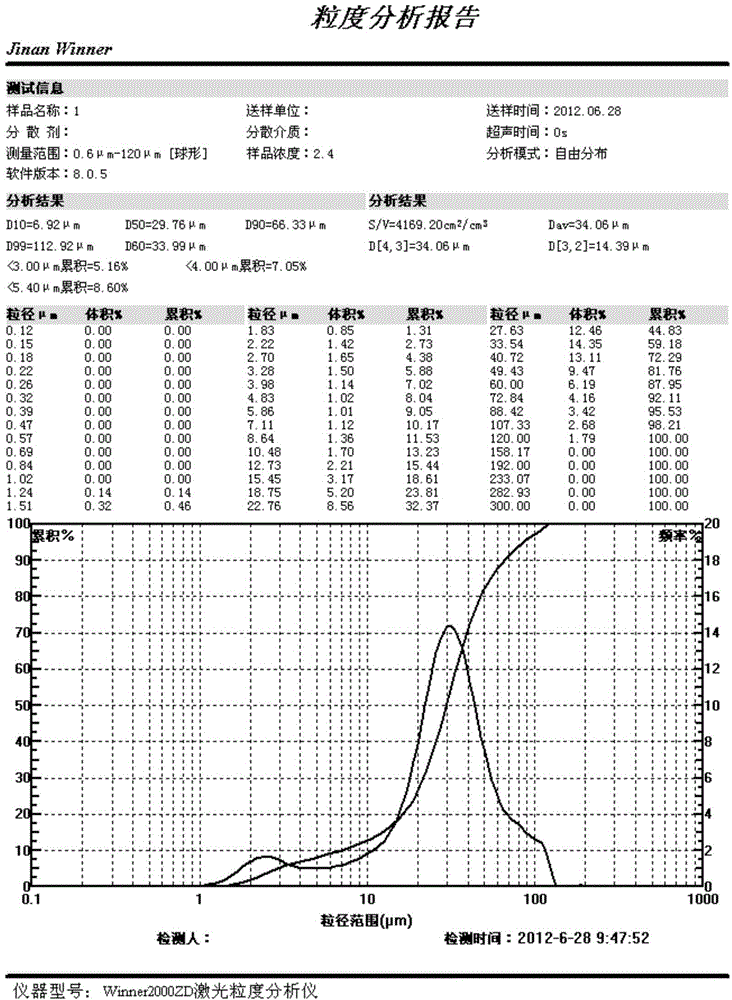

[0025] (1) Particle size analysis

[0026] The LWD plugging agent obtained in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com