Environment-friendly fully-synthetic diesel engine oil and preparation method thereof

A fully synthetic, diesel engine technology, applied in the field of lubricating oil, can solve the problems of short oil change cycle and inability to meet, and achieve the effect of improving the oil change cycle, ensuring smooth startup, and excellent cleaning and dispersing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An environmentally friendly fully synthetic diesel engine oil consisting of the following parts by weight: base oil: 77.2 parts; detergent: 5 parts; ashless dispersant: 3 parts; rust inhibitor: 1.2 parts; antioxidant: 0.7 parts; Extreme pressure agent: 4.4 parts; Friction modifier: 0.5; Viscosity agent: 7.7; Pour point depressant: 0.3; Anti-foaming agent: 0.3; Anti-emulsifier: 50 ppm;

[0032] Among them, the base oil is a mixture of mPAO8 catalytically synthesized by metallocene, deep hydrogenation optimized linear three-chain mineral oil 250N, and phthalic acid ester. The mPAO8, three-class mineral oil 250N, and phthalate The mass ratio of acid ester is 2:2:1;

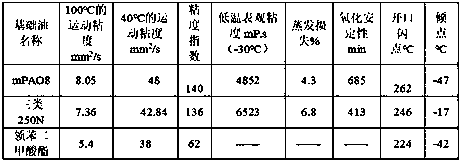

[0033] The specific physical and chemical indicators of base oil are as follows:

[0034]

[0035] Among them, the detergent is super-high alkali value sulfurized calcium alkylphenate;

[0036] Among them, the ashless dispersant is monoalkenyl succinimide, and monoalkenyl succinimide is prepared from highly active po...

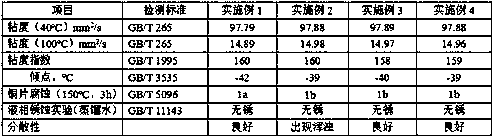

Embodiment 2

[0047] It is basically the same as Example 1, except that the base oil is obtained by mixing and mixing mPAO8 and Class III mineral oil 250N at a mass ratio of 1:1. The environment-friendly fully synthetic diesel engine oil of Example 2 is obtained.

Embodiment 3

[0049] It is basically the same as Example 1, except that the base oil is obtained by mixing and mixing terylene phthalate and Class III mineral oil 250N at a mass ratio of 1:1. The environment-friendly fully synthetic diesel engine oil of Example 3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com