Primary oil aid, and primary oil and preparation method thereof

An oil additive and initial oil filling technology, which is applied in the fields of initial oil filling, initial oil filling and its preparation, can solve the problems of huge temperature difference, long storage time, and reduced efficiency of automobile engine, and achieves extended storage time, Good oxidation resistance, the effect of improving engine life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

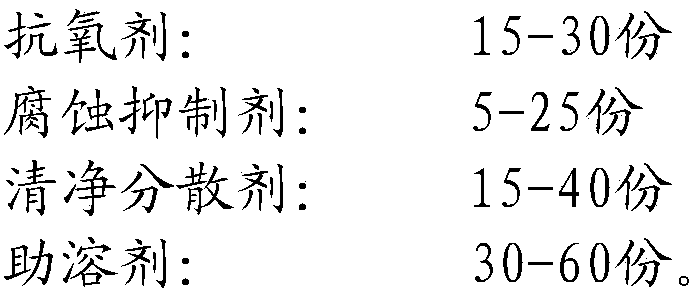

[0032] A kind of initial loading oil auxiliary agent, the composition of this auxiliary agent is calculated by weight percentage as:

[0033]

[0034] Preferably, the antioxidant is selected from 2,6-di-tert-butylphenol.

[0035] Preferably, the corrosion inhibitor is selected from the compound product of tetradecenylsuccinic acid and oleyl hydroxyethyl imidazoline according to the mass ratio of 1:5.

[0036] Preferably, the detergent and dispersant is selected from compound products of polyetheramine and polyisobutyleneamine in a mass ratio of 1:1.

[0037] Preferably, the co-solvent is selected from 120# solvent naphtha.

[0038] On the basis of the above-mentioned initial oil additives, the inventor further provides a corresponding initial oil formula, and its specific composition is calculated by weight percentage:

[0039] Isopentane: 6%

[0040] Isohexane: 4%

[0041] Isooctane: 8%

[0042] Alkylated gasoline: 60%

[0043] MTBE: 10%

[0044] Raffinate: 8%

[0...

Embodiment 2

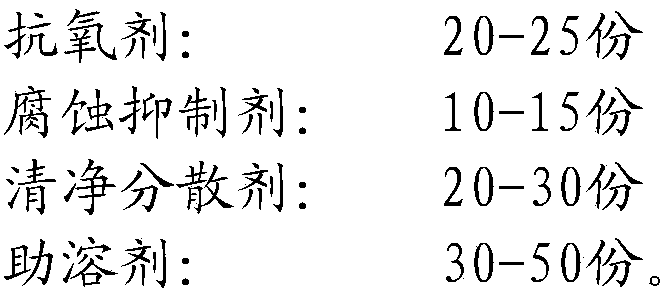

[0052] A kind of initial loading oil auxiliary agent, the composition of this auxiliary agent is calculated by weight percentage as:

[0053]

[0054]

[0055] Wherein preferably, the antioxidant is selected from 2,6-di-tert-butyl p-cresol;

[0056] Preferably, the corrosion inhibitor is selected from benzotriazole;

[0057] Preferably, the detergent and dispersant is selected from polyisobutene amine;

[0058] Preferably, the co-solvent is selected from dearomatized solvent naphtha D60;

[0059] On the basis of the above-mentioned initial oil additives, the inventor further provides a corresponding initial oil formula, and its specific composition is calculated by weight percentage:

[0060] Isopentane: 10%

[0061] Isohexane: 6%

[0062] Isooctane: 3%

[0063] Alkylated gasoline: 55%

[0064] MTBE: 12%

[0065] Raffinate: 10%

[0066] Toluene: 4%;

[0067] The dosage of the above initial oil additives is: 300mg / kg initial oil;

[0068] The preparation method ...

Embodiment 3

[0073] A kind of initial loading oil auxiliary agent, the composition of this auxiliary agent is calculated by weight percentage as:

[0074]

[0075] Wherein it is preferred that the antioxidant is selected from N,N-di-sec-butyl-p-phenylenediamine,

[0076] Preferably, the corrosion inhibitor is selected from dodecenylsuccinic acid,

[0077] Preferably, the detergent dispersant is selected from polyisobutylene succinimide,

[0078] Preferably, the cosolvent is selected from 200# solvent naphtha;

[0079] On the basis of the above-mentioned initial oil additives, the inventor further provides a corresponding initial oil formula, and its specific composition is calculated by weight percentage:

[0080] Isopentane: 8%

[0081] Isohexane: 5%

[0082] Isooctane: 5%

[0083] Alkylated gasoline: 58%

[0084] MTBE: 11%

[0085] Raffinate: 8.4%

[0086] Toluene: 4.6%;

[0087] The dosage of the above initial oil additives is: 600mg / kg initial oil;

[0088] The preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com