An anti-oxidation and anti-corrosion degreasing brightener for aluminum and magnesium alloys

A magnesium alloy and anti-oxidation technology, which is applied in the field of chemicals, can solve the problems of harsh pH control of cleaning agents, affecting sample cleaning efficiency, and blackening of material surfaces, achieving good polishing effects, enhanced cleaning effects, and improved corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

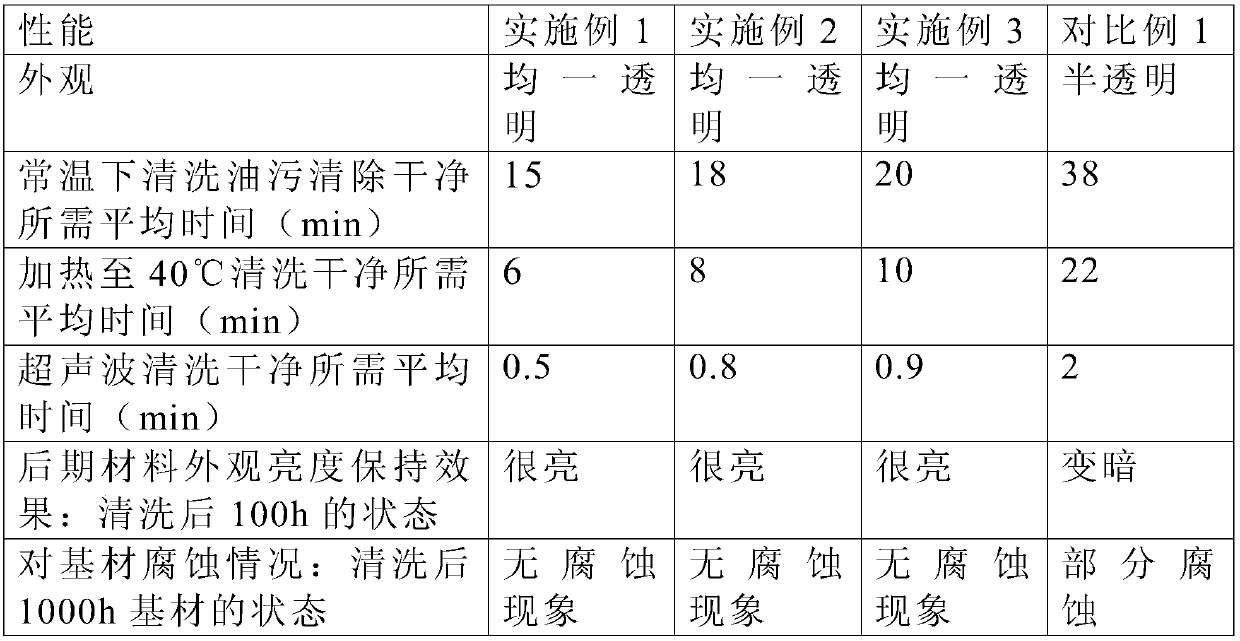

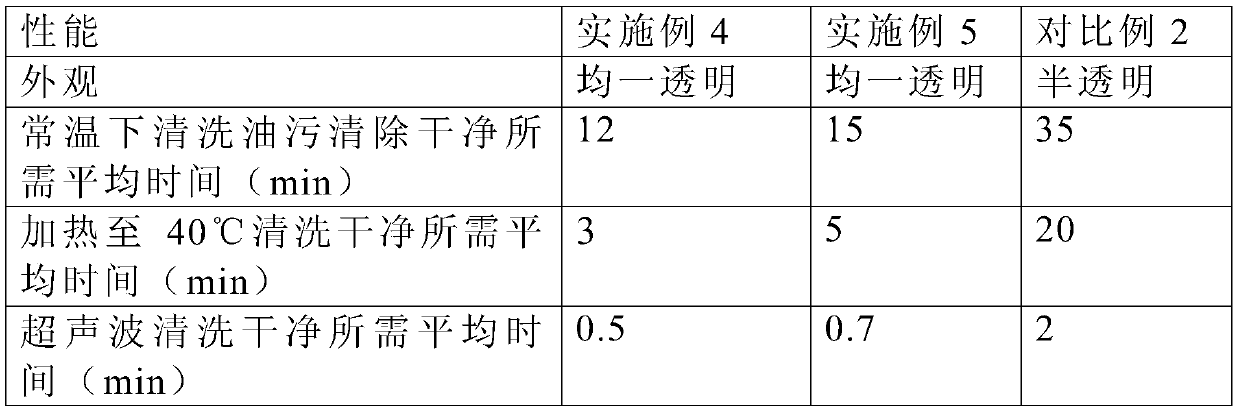

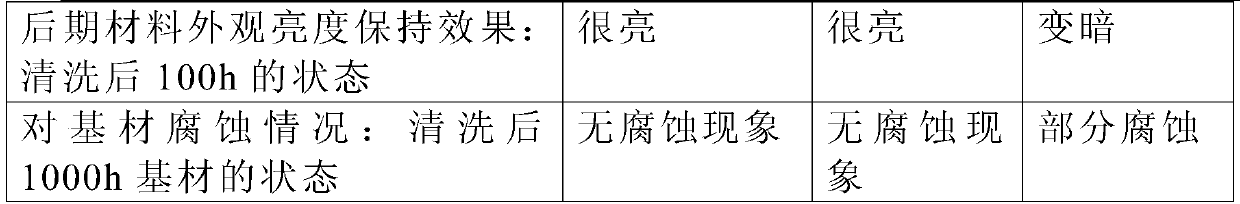

Examples

Embodiment 1

[0028] Preparation of fatty acid soap: Mix oleic acid and sodium hydroxide at a molar ratio of 1:1.2, add water at the same time, then stir and heat to 55°C, keep warm for 1.3h until the sample is uniform and transparent in appearance, and finally evaporate the water to dryness to obtain fatty acid soap.

[0029] Weigh the following components in parts by weight: 9 parts of monoethanolamine, 5 parts of diethylene glycol monobutyl ether, 4 parts of benzotriazole, 3 parts of 2-mercaptobenzothiazole, 3 parts of the above-mentioned fatty acid soap, lauryl 2 parts of alcohol polyoxyethylene ether, 2 parts of boric acid, 2 parts of tartaric acid, 0.8 part of Rhodafac ASI-80, 73.2 parts of water.

[0030] After uniformly mixing monoethanolamine, fatty acid soap, polyoxyethylene lauryl ether and water, turn on the electric stirring, and stir until it dissolves.

[0031] Add diethylene glycol monobutyl ether, benzotriazole, 2-mercaptobenzothiazole, and Rhodafac ASI-80 one by one, turn ...

Embodiment 2

[0034] Preparation of fatty acid soap: mix ricinoleic acid and potassium hydroxide at a molar ratio of 1:1.3, add water at the same time, then stir and heat to 52°C, keep warm for 1.4h until the sample is uniform and transparent in appearance, and finally evaporate the water to dryness to obtain fatty acid soap .

[0035] Weigh the following components in parts by weight: 9 parts of triethanolamine, 2 parts of diethylene glycol monomethyl ether, 2 parts of dipropylene glycol monomethyl ether, 1 part of 3,5,5-trimethylhexanoic acid, benzotri 4 parts of azoles, 2 parts of the above-mentioned fatty acid soap, 2 parts of polyethylene glycol 600, 0.5 parts of Rhodafac ASI-800, 2 parts of citric acid, 4 parts of maleic acid, and 70.2 parts of water.

[0036] After uniformly mixing triethanolamine, fatty acid soap, polyethylene glycol 600 and water, turn on the electric agitator, and fully agitate until it dissolves.

[0037] Add diethylene glycol monomethyl ether, dipropylene glyco...

Embodiment 3

[0040] Preparation of fatty acid soap: Mix coconut oleic acid and ammonia water at a molar ratio of 1:1.4, add water at the same time, then stir and heat to 58°C, keep warm for 1.2h until the appearance of the sample is uniform and transparent, and finally evaporate the water to dryness to obtain fatty acid soap.

[0041]Weigh the following components in parts by weight: 2 parts of triethanolamine, 6 parts of monoethanolamine, 5 parts of tripropylene glycol monomethyl ether, 1 part of diethylene glycol monobutyl ether, 4 parts of 3,5,5-trimethylhexanoic acid 1 part of benzotriazole, 2 parts of triethanolamine borate, 3 parts of fatty acid soap mentioned above, 1 part of surfactant macrogol 600 monooleate, 0.5 part of Rhodafac ASI-80, 5 parts of boric acid , 69.5 parts of solvent.

[0042] After uniformly mixing triethanolamine, monoethanolamine, fatty acid soap, polyethylene glycol 600 monooleate and water, turn on the electric agitator, and fully agitate until it dissolves. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com