Patents

Literature

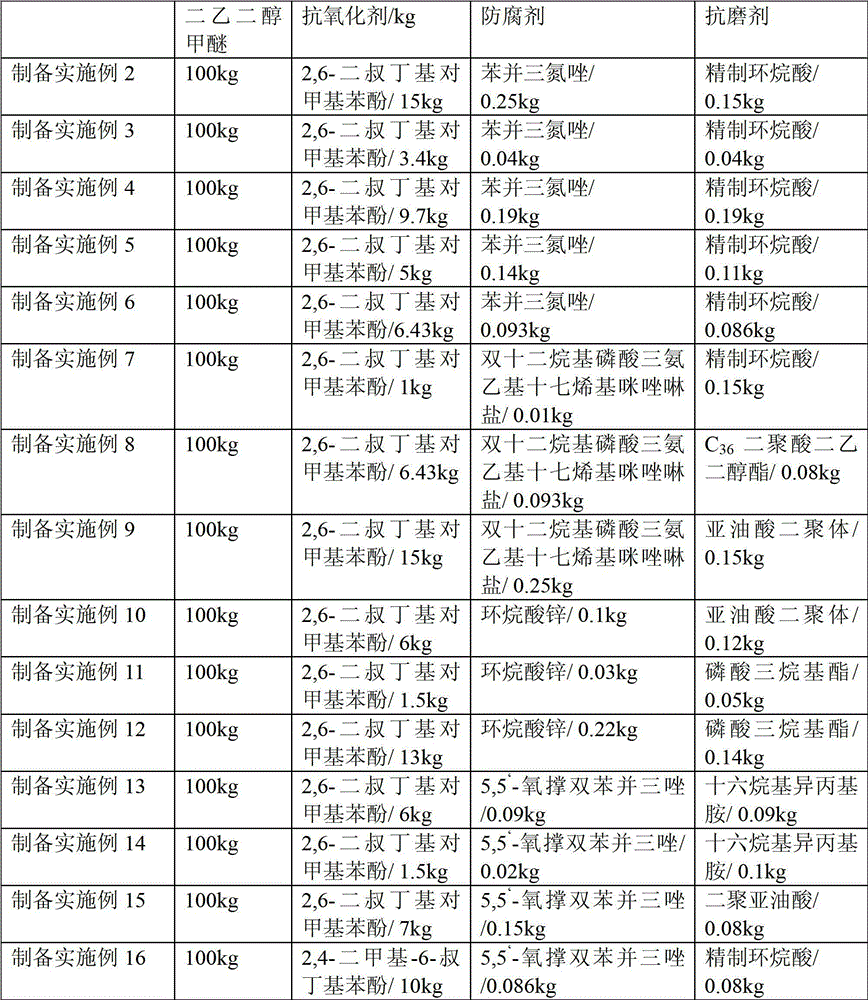

156 results about "Diethylene glycol monomethyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diethylene Glycol Monomethyl Ether is chemically known as a Methyl Diglycol, 2-hydroxy-2-methoxy-diethyl ether. Commercially it is known as a Methyl Carbitol, which is a trademark of Union Carbide. Diethylene Glycol Monomethyl Ether is an excellent solvent for the various resins & paste etc.

Method for purifying ethylenediamine

ActiveCN101723837AHigh purityAvoid corrosionAmino compound purification/separationEthylenediamineDiethylene glycol monobutyl ether

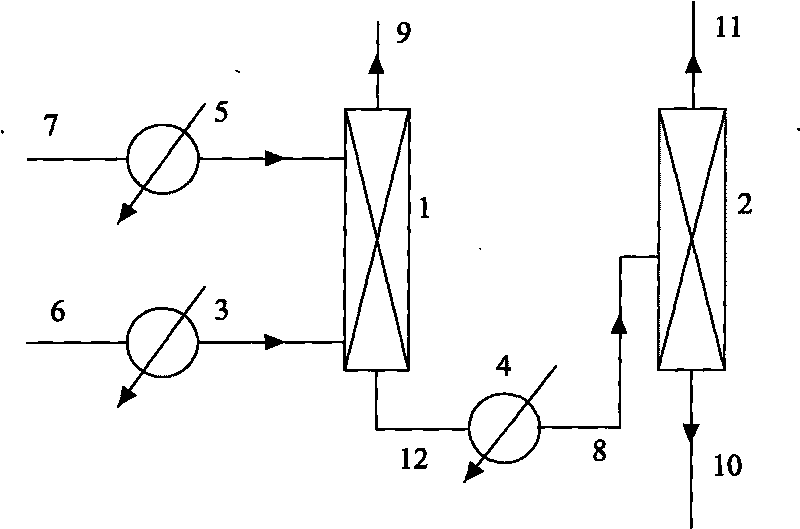

The invention discloses a method for purifying ethylenediamine, comprising the following steps: (1) heating extractant, feeding the extractant in to an extracting tower from the upper part of the extracting tower, gasifying 60.0-92.0% water-bearing ethylenediamine, feeding the ethylenediamine into the lower part of the extracting tower, making the ethylenediamine reversely contact the extractant on the upper part of the extracting tower in the extracting tower, discharging water from the top of the extracting tower and separating the mixture of the ethylenediamine and the extractant at the bottom of the extracting tower, wherein the extractant is diethylene glycol monomethyl ether, diethylene glycol dimethyl ether, triethylene glycol dimethyl ether or diethylene glycol monobutyl ether; and (2) heating the mixture of the ethylenediamine and the extractant, feeding the mixture of the ethylenediamine and the extractant to the middle part of the extracting tower, rectifying the mixture ofthe ethylenediamine and the extractant in a rectifying tower, separating the ethylenediamine on the top of the rectifying tower and discharging the extractant from the bottom of the rectifying tower.The method is mainly used for purifying the ethylenediamine.

Owner:山西玉龙化工有限公司

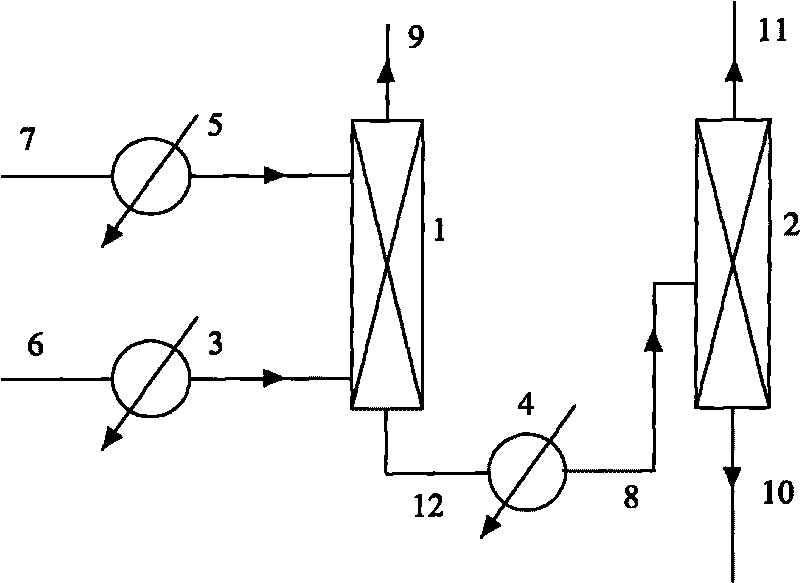

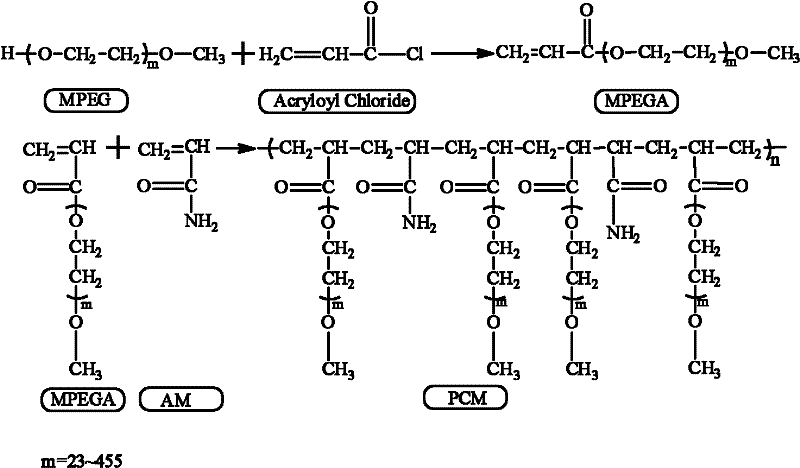

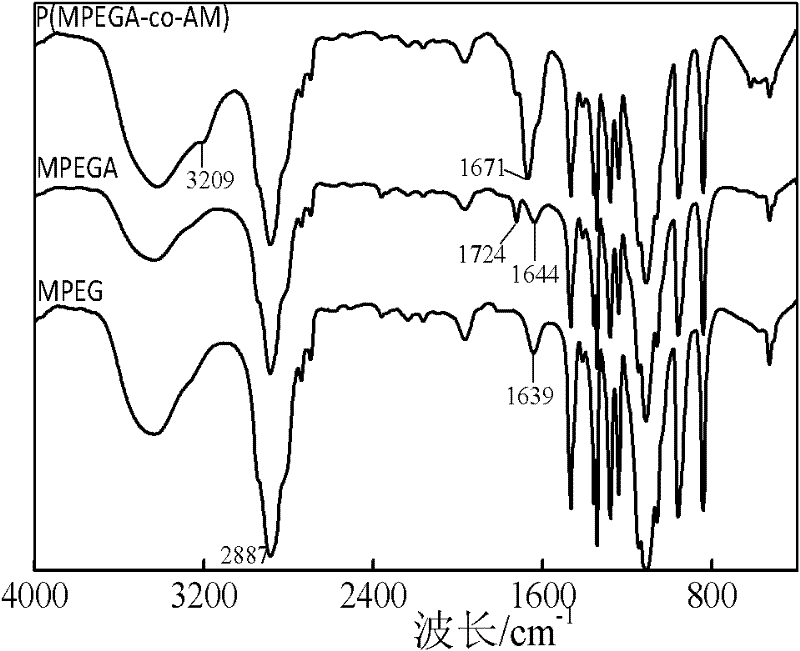

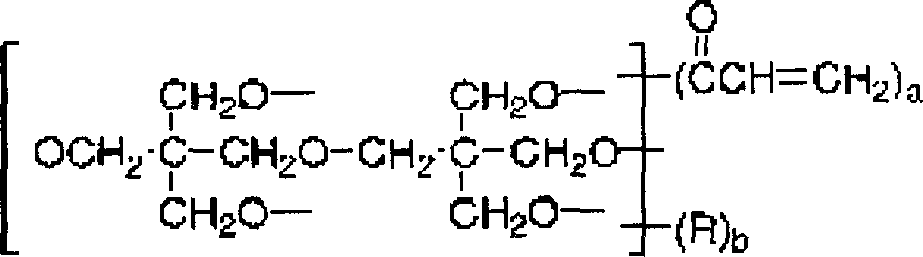

Preparation method of pectinate high-polymer phase-change energy storage material

The invention relates to a preparation method of a pectinate high-polymer phase-change energy storage material, which comprises the following steps: (1) in an ice water bath, after dissolving polyethylene glycol monomethyl ether in dichloromethane, adding an acid binding agent and acryloyl chloride, heating to 35-40 DEG C, and reacting in a nitrogen atmosphere for 6-8 hours; (2) in the ice water bath, adding a precipitant into the reaction solution, standing for 10-15 minutes, and carrying out vacuum filtration to obtain the acrylate polyethylene glycol monoester; and (3) dissolving the acrylate polyethylene glycol monoester and acrylamide monomers in a solvent, adding an initiator, heating to 70-85 DEG C, and reacting for 30-120 minutes to obtain the phase-change energy storage material with pectinate molecular chain shape. The phase-change material prepared by the method provided by the invention can flow in the form of a melt in the hot working process, and the pectinate molecular chain shape can reduce the plastification action on the base; and the invention has the advantages of simple preparation technique and low production cost.

Owner:DONGHUA UNIV

Low-temperature and high-voltage resistant aluminum electrolytic capacitor work electrolyte and preparation method thereof

InactiveCN106783178AImprove solvating powerHigh degree of ionizationElectrolytic capacitorsDiethylene glycol monobutyl etherGlycerol

A low-temperature and high-voltage resistant aluminum electrolytic capacitor work electrolyte comprises by the mass percent: 45-75% of the main solvent, the 15-40% of the secondary solvent, 3-12% of the solute, 0.5-2% of the flash fire promotion additive, 0.2-1.5% of the gas absorption additive; the main solvent is one or more than one of the ethylene glycol, the propylene glycol, the glycerol, the polyethylene glycol 200 and the polyethylene glycol 400. The secondary solvent is one or more than one of the [Gamma]-butyrolactone, the dimethylformamide, the diglycolic simple methyl ether, the diethylene glycol monoethyl ether and the diethlyeneglycol monobutylether. The secondary solvent can be propylene carbonate and one or more than one of the [Gamma]-butyrolactone, the dimethylformamide, the diglycolic simple methyl ether, the diethylene glycol monoethyl ether and the diethlyeneglycol monobutylether. The low-temperature and high-voltage resistant aluminum electrolytic capacitor work electrolyte can resist the -55 DEG C and high voltage of 600V.

Owner:CENT SOUTH UNIV

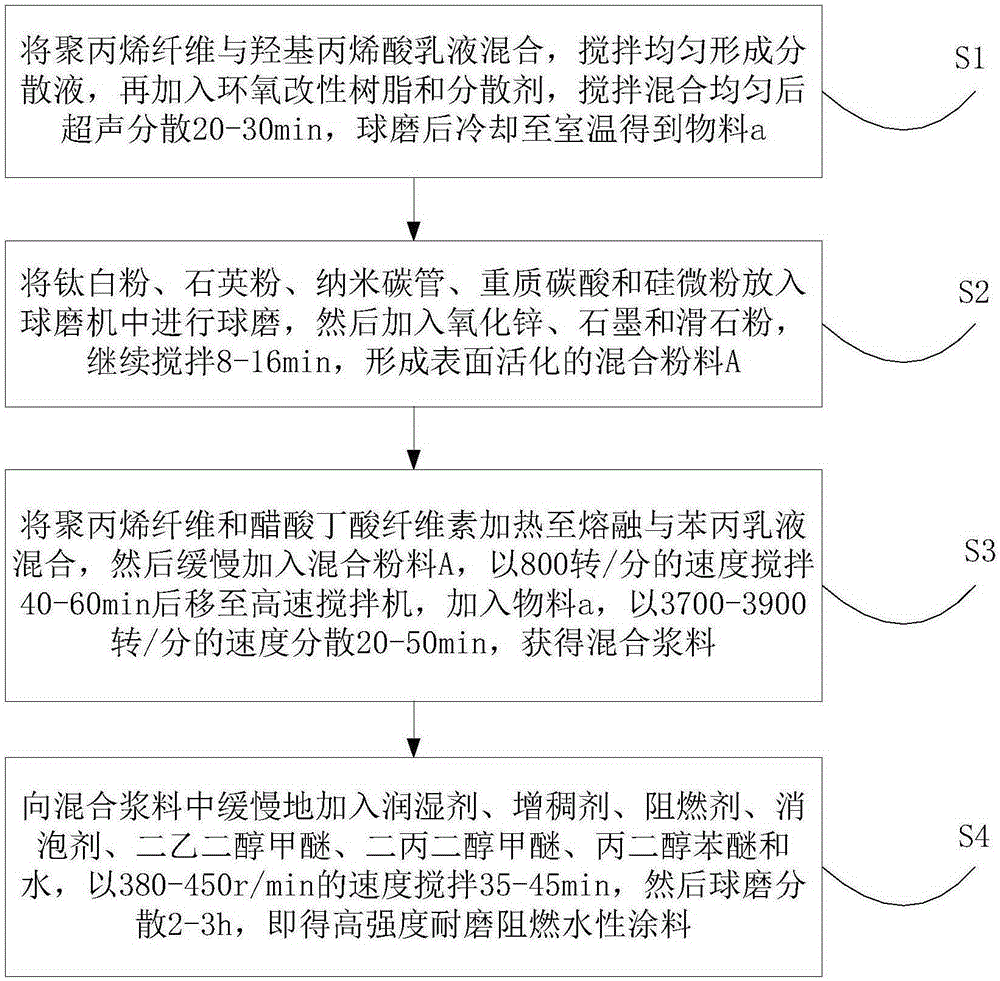

High-strength wear-resistant flame-retardant water-based paint and preparation method thereof

InactiveCN105199510AGood color retentionGood flexibilityFireproof paintsPolyurea/polyurethane coatingsWater basedWear resistant

The invention discloses high-strength wear-resistant flame-retardant water-based paint. The paint is prepared from, by weight, 100 parts of hydroxy acrylic acid emulsion, 75 parts of epoxy modified resin, 50 parts of water-based polyurethane emulsion, 40 parts of silicon-acrylic emulsion, 10 parts of styrene-acrylic emulsion, 5 parts of titanium dioxide, 3.5 parts of quartz powder, 3.5 parts of polypropylene fibers, 5.5 parts of cellulose acetate butyrate, 3 parts of silica powder, 4.5 parts of zinc oxide, 3.5 parts of carbon nano-tubes, 3.5 parts of graphite, 5 parts of coarse whiting, 5 parts of talcum powder, 3.5 parts of wetting agents, 6 parts of thickener, 2.5 parts of dispersant, 3.5 parts of flame retardant, 2 parts of antifoaming agents, 3 parts of diethylene glycol monomethyl ether, 4 parts of dipropylene glycol monomethyl ether, 5 parts of propylene glycol phenyl ether and 20 parts of water. The invention further provides a preparation method of the high-strength wear-resistant flame-retardant water-based paint. The water-based paint is high in strength, good in wear resistance and great in flame retardancy.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

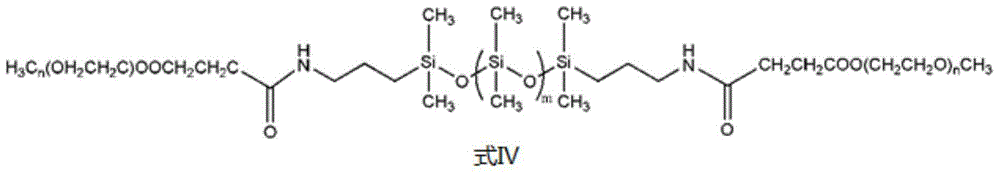

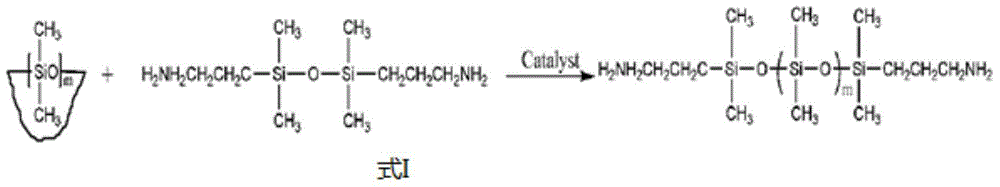

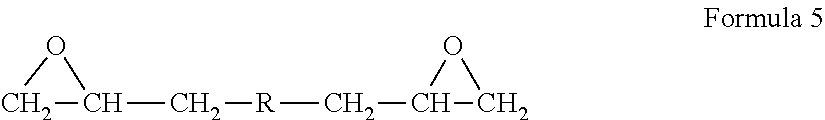

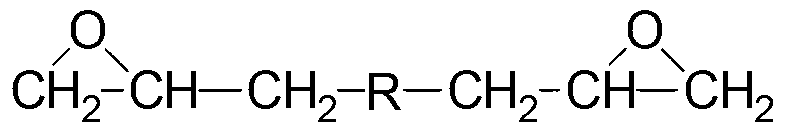

Bola type polyether-modified organosilicon surfactant and preparation method thereof

ActiveCN104645877AImprove surface activityGuarantee environmental safetyTransportation and packagingMixingAlcoholPolyethylene glycol

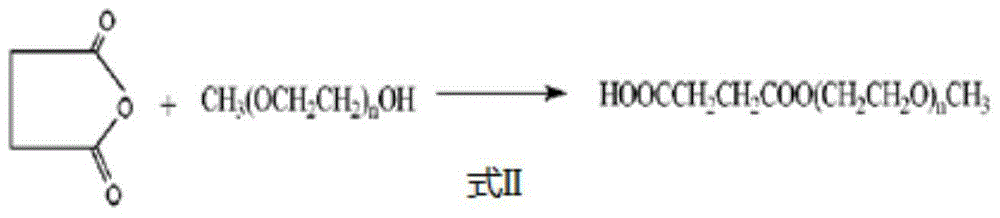

The invention discloses a Bola type polyether-modified organosilicon surfactant and a preparation method thereof. A general structural formula of the organosilicon surfactant is as shown in the specification, wherein m is an integer of 1-200; and n is an integer of 8-40. The preparation method comprises the following steps: (1) with cyclosiloxane and 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane as raw materials, preparing bis-aminopropyl-terminated modified polysiloxane in the presence of a catalyst; (2) enabling succinic anhydride to react with methoxy polyethylene glycol to obtain succinic acid mono polyethylene glycol monomethyl ether ester; and (3) enabling the bis-aminopropyl modified polysiloxane to react with the succinic acid mono polyethylene glycol monomethyl ether ester under the condition of lower alcohol as a solvent, so as to obtain the Bola type polyether-modified organosilicon surfactant. According to the preparation method disclosed by the invention, a catalyst, chloroplatinic acid, used by synthesis of an organosilicon surfactant in the prior art is abandoned to ensure environmental protection and safety; and in addition, the method disclosed by the invention is simple but not fussy in preparation technology and low in preparation cost, and can meet the requirements of industrialized enlarged production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

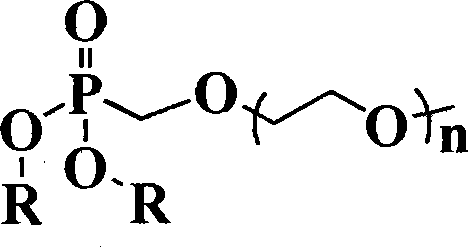

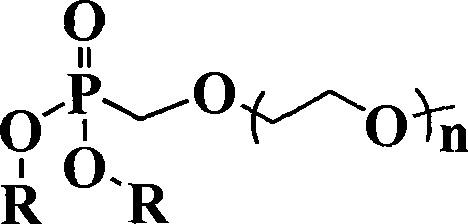

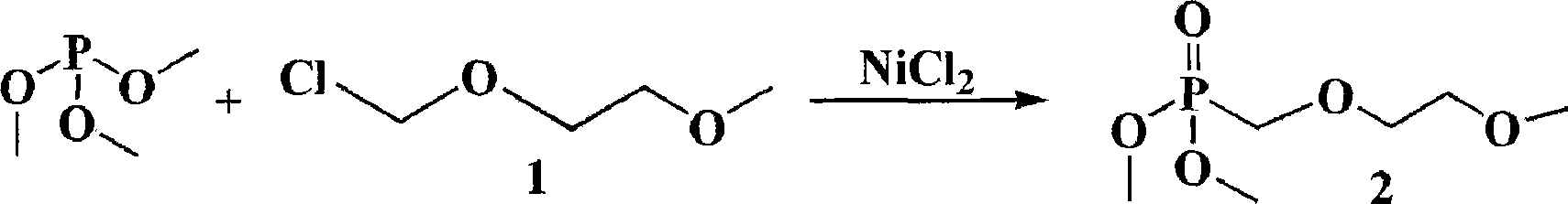

Phosphoester containing ethoxy unit, and preparation and use thereof

InactiveCN101440105AImprove securityImprove flame retardant performanceSecondary cellsPhosphorus organic compoundsOrganic phosphatesElectrochemistry

The invention discloses organic phosphates containing an ethyoxyl (CH2CH20) unit, a preparation method and application thereof. The organic phosphates have the following structural general formula: in the formula, n is 1 or 2; R can be CH3 or C2H5 or CF3CH2; and radicals of two R are the same. The preparation method is to heat ethylene glycol monomethyl ether containing chloromethyl or diethylene glycol monomethyl ether containing the chloromethyl and phosphite ester containing an R radical as raw materials by taking absolute nickelous chloride as a catalyst for a sufficient reaction, and distill at reduced pressure so as to obtain the organic phosphate. The organic phosphate prepared by the method has excellent flame retardance, thermal stability and excellent electrochemistry performance, can be used as secondary lithium ion battery high-safety electrolysing solution, and has wide industrial application prospect. The method has the advantages of simple steps, short time, completion in a common laboratory and easy popularization.

Owner:WUHAN UNIV

Rapid low temperature extraction method for total astaxanthin from frozen Euphausia superba Dana

InactiveCN102334686AProspects for development are goodRich sourcesFood preparationAstaxanthinEthyl acetate

The invention relates to a rapid low temperature extraction method for total astaxanthin from frozen Euphausia superba Dana. The method comprises the following steps: (1) directly adding a frozen raw material of Euphausia superba Dana into a mixed solvent of ethyl acetate and ethylene glycol monomethyl ether, crushing the frozen raw material, homogenizing obtained mixture, and carrying out centrifugation, wherein, the upper layer of an obtained solution is clear liquid of a mixed solution of ester and ether, and the lower layer of the obtained solution is a mixture of water and minced shrimp;(2) taking the clear liquid of the mixed solution of ester and ether for pressure reduced recovery of the solvent, and carrying out drying so as to obtain crimson thick grease, that is, the extract of total astaxanthin of Euphausia superba Dana; (3) dissolving the extract of total astaxanthin of Euphausia superba Dana in anhydrous alcohol to produce a solution with a concentration of 300 to 500 mg / mL, and carrying out separation and collection. The method provided in the invention has the advantages of a simple process, low temperature and a short operation time, which enables the danger of oxidation deterioration in the process of extraction to be effectively reduced; the content of total astaxanthin in the obtained product is more than or equal to 0.5%.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Diethylene Glycol Monomethyl Ether Resistant Coating

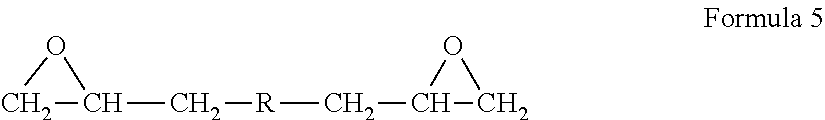

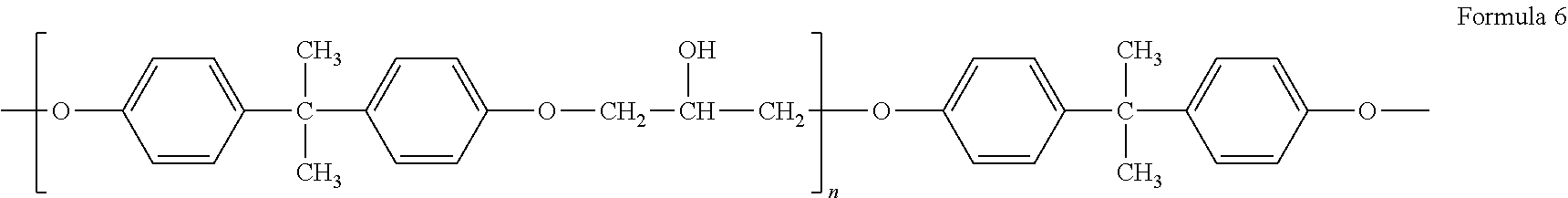

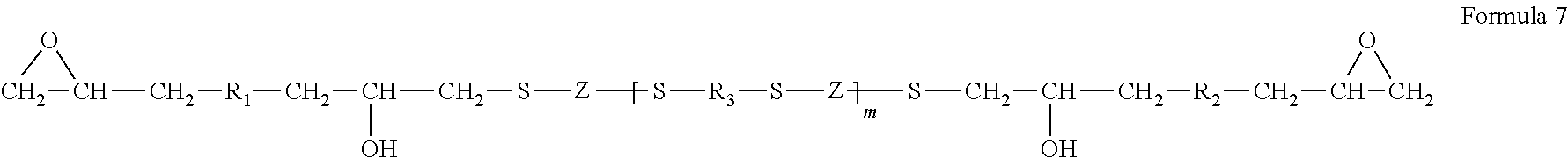

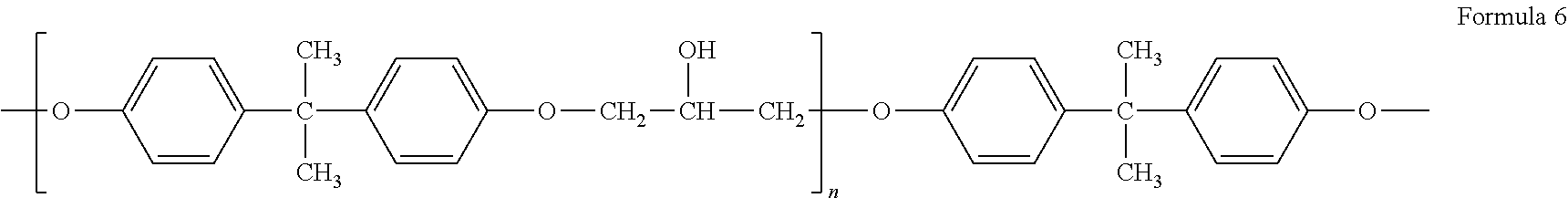

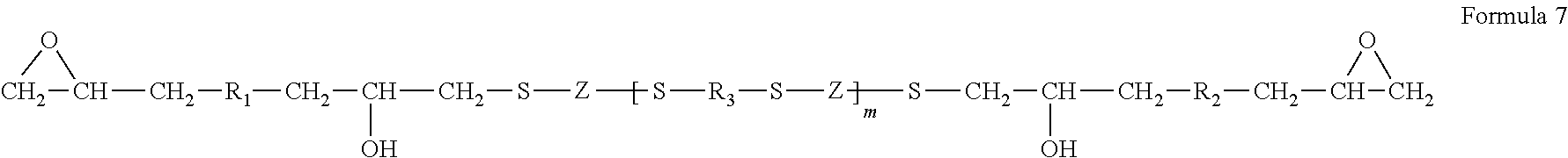

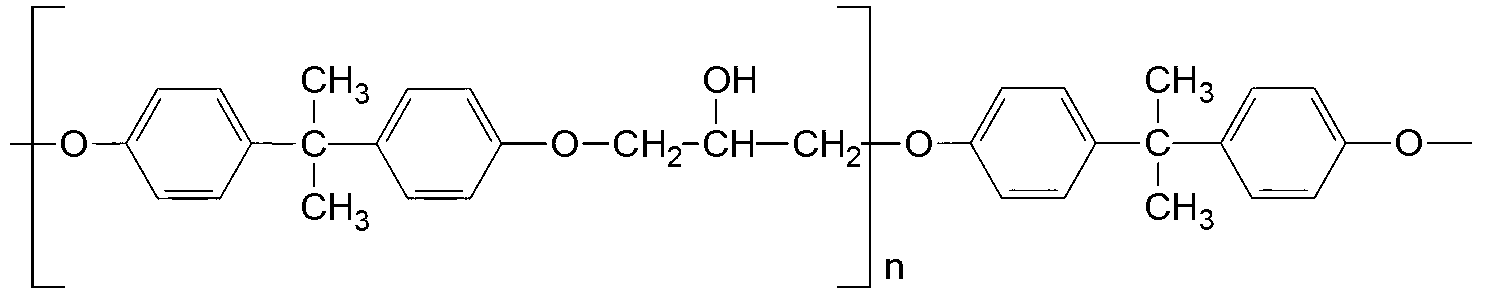

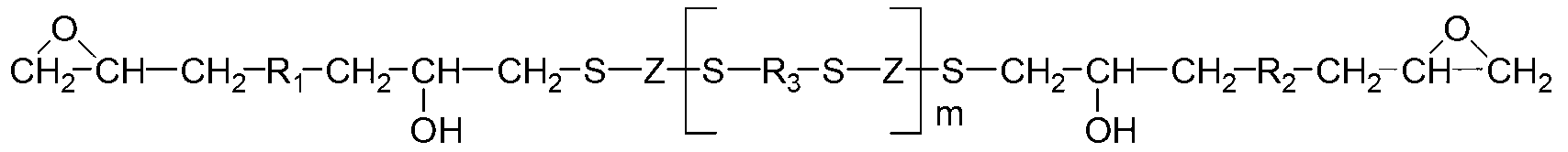

ActiveUS20120088862A1Semiconductor/solid-state device detailsSolid-state devicesPolyolSulfur containing

Diethylene glycol monomethyl ether resistant coatings include a base component including a sulfur-containing, epoxy functional polyol, and an activator component including an isocyanate curing agent.

Owner:PRC DE SOTO INT INC

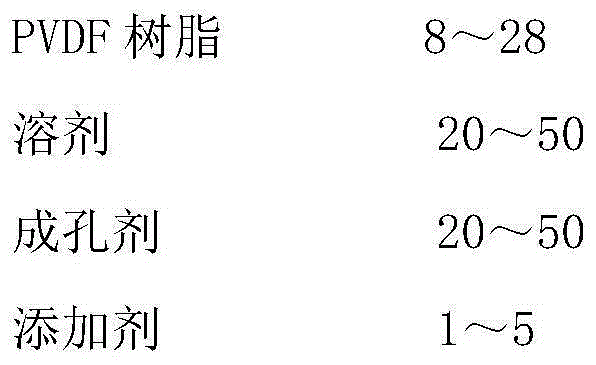

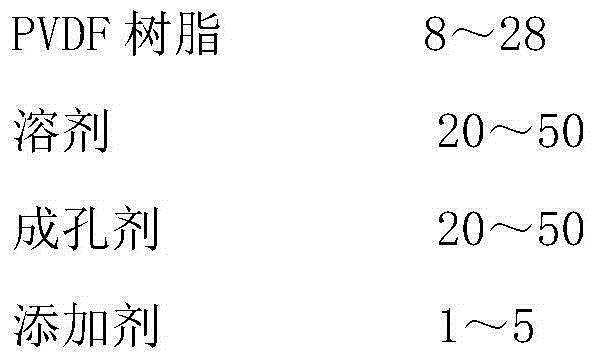

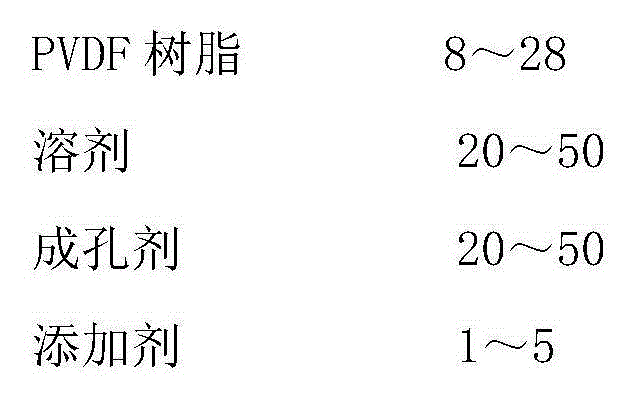

Film casting liquid for PVDF flat membrane and preparing method for PVDF flat membrane

InactiveCN104984663AObvious cortexImprove surface strengthSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer sciencePolyethylene glycol

The invention provides film casting liquid for a PVDF flat membrane and a preparing method for the PVDF flat membrane. The obtained PVDF flat membrane is high in surface strength and high in flux. The film casting liquid comprises, by weight, 8-28 parts of PVDF resin, 20-50 parts of solvent, 20-50 parts of pore-forming agent and 1-5 parts of additive. The solvent is dimethylformamide, dimethylacetamide and dimethyl sulfoxide. The pore-forming agent is ethylene glycol monomethyl ether and diethylene glycol monomethyl ether. The additive is polyvinylpyrrolidone and polyethylene glycol. The film casting liquid is cooled to 40-80 DEG C, the temperature is maintained for degassing for 4-6 hours, then the film casting liquid is evenly scraped on PET non-woven fabric through a film scraping machine and stayed in air for 1-2 minutes, the temperature of the surface of the film casting liquid is controlled to be lower than 40 DEG C, distilled water serves as gelling and cleaning liquid, after gelling and cleaning are conducted in the gelling and cleaning liquid for 5-10 minutes, the PET non-woven fabric is taken out, the PVDF flat membrane is obtained after the film is separated from the PET non-woven fabric, and the temperature of the distilled water is lower than the temperature of the surface of the film casting liquid by at least 10 DEG C.

Owner:黄义忠

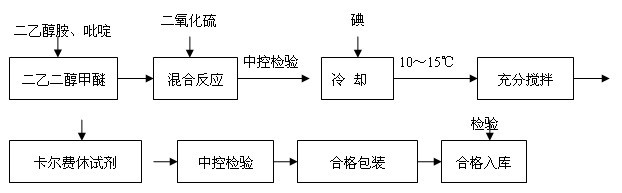

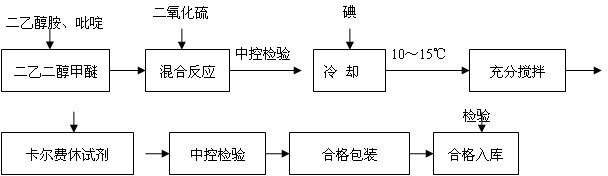

Safe stable type Karl Fischer reagent and preparation method thereof

The invention discloses a safe stable type Karl Fischer reagent which comprises the following components in percentage by mass: 60-64 percent of diethylene glycol monomethyl ether, 8-12 percent of diethanol amine, 3.5-5.5 percent of pyridine, 12-15 percent of sulfur dioxide and 8-12 percent of iodine. The preparation method of the safe stable type Karl Fischer reagent comprises the following steps of: adding the diethylene glycol monomethyl ether, the diethanol amine and the pyridine in a reaction kettle and mixing; introducing the sulfur dioxide; after the gas is introduced, cooling the mixed solution below 25DEG C; and adding the iodine and stirring the mixed solution until the iodine is completely dissolved and obtaining a target product. According to the safe stable type Karl Fischer reagent and the preparation method thereof disclosed by the invention, original poisonous dangerous solvent is replaced by a safety type solvent, so that the safe stable type Karl Fischer reagent is non-poisonous, safe, environment-friendly and stable in quality; and after the safe stable type Karl Fischer reagent is stored for a long time, the titer is still within a usable range.

Owner:JIANGSU YONGHUA FINE CHEM

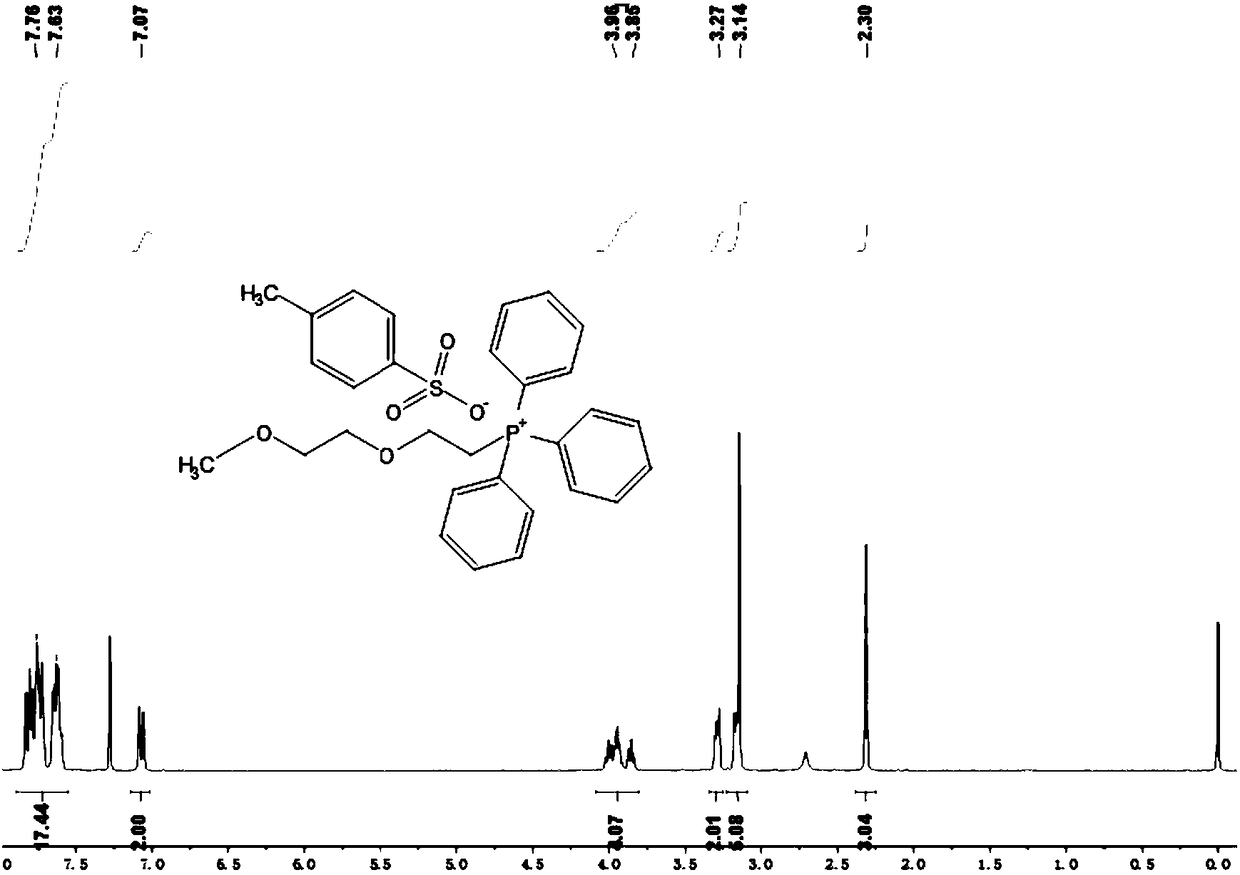

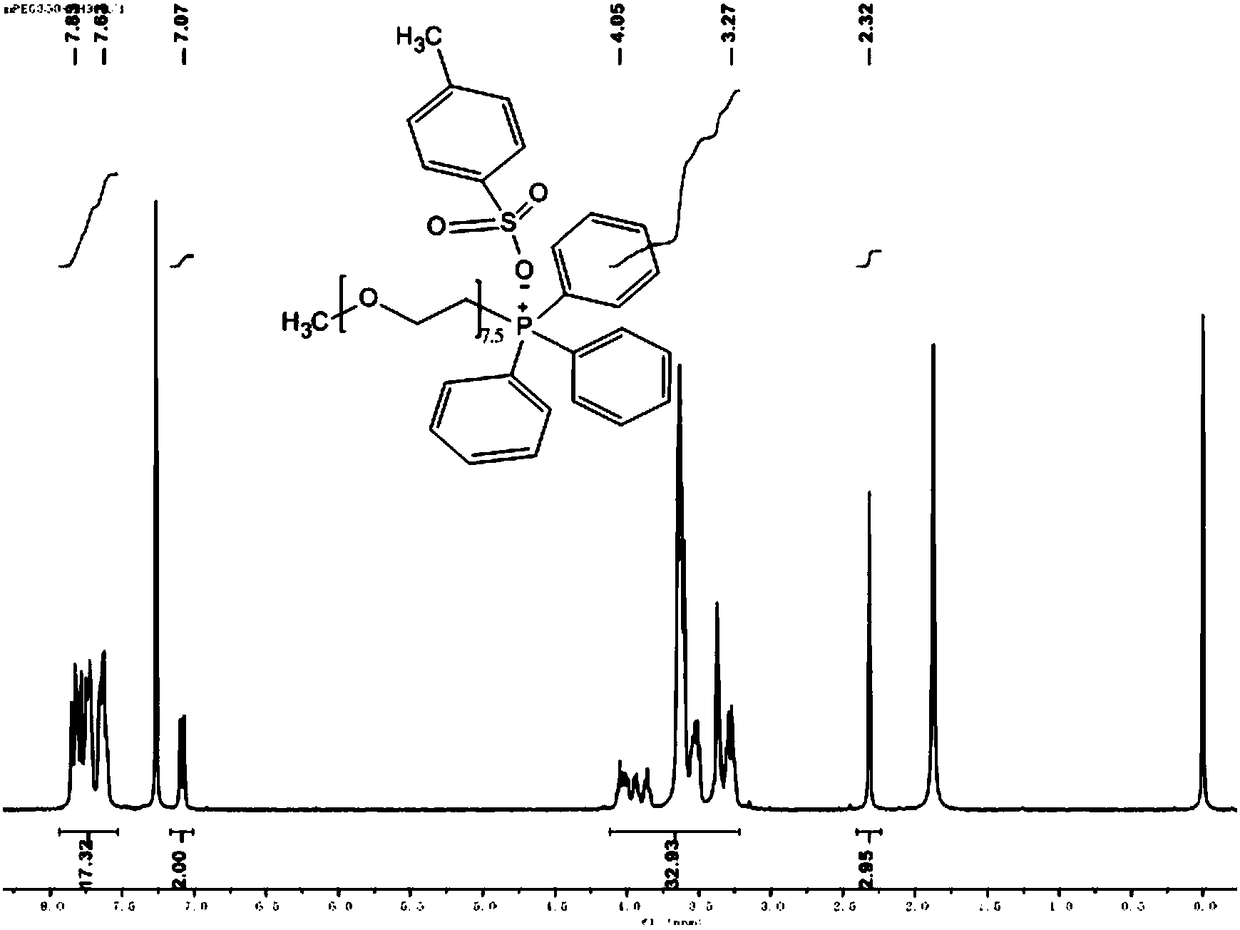

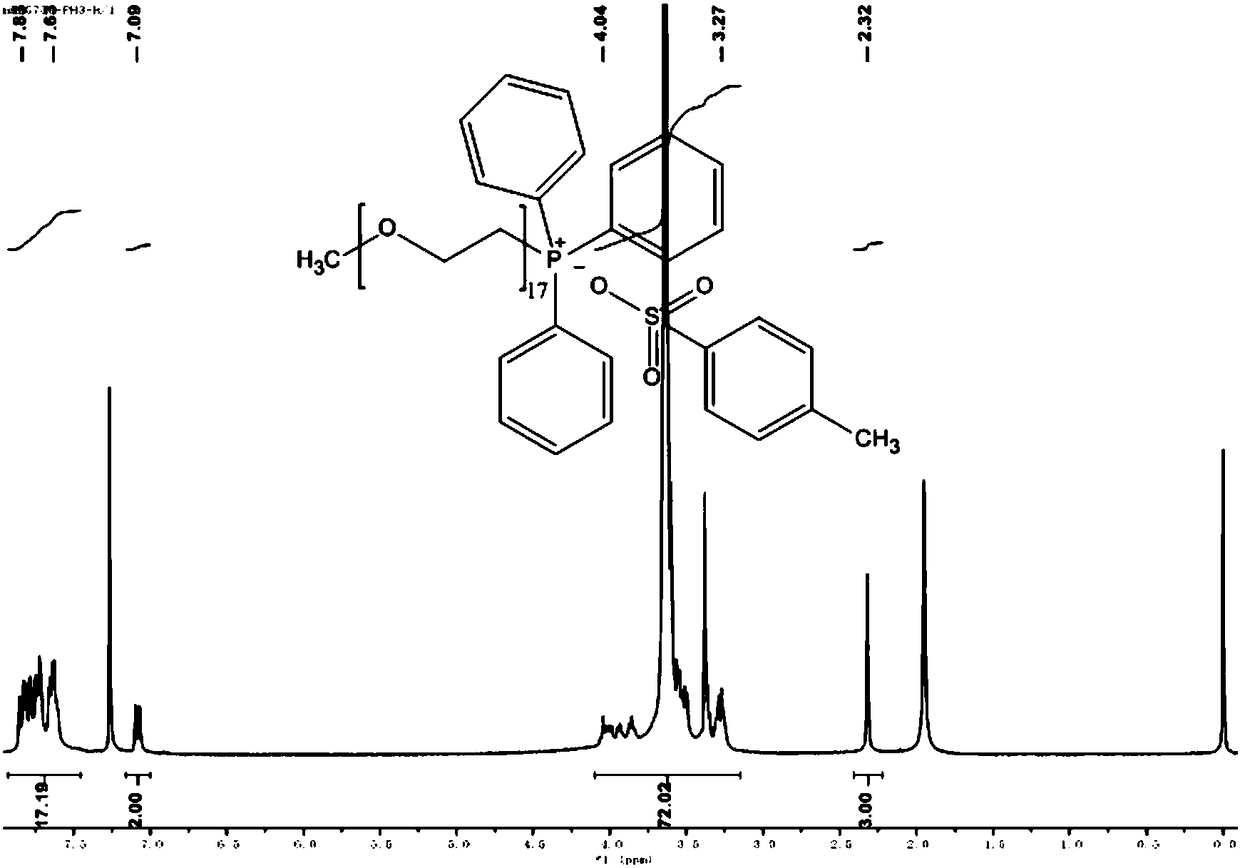

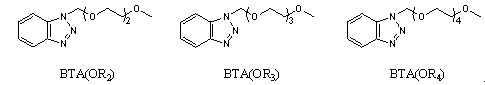

Quaternary phosphonium salts with p-toluenesulfonate as anions as well as synthesis method, preparation method and application of quaternary phosphonium salts

ActiveCN108299498AThe preparation method is simple and easyThe synthetic route is simpleAntibacterial agentsGroup 5/15 element organic compoundsPhosphoniumPhosphonium salt

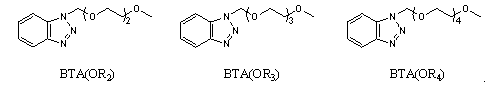

The invention discloses quaternary phosphonium salts with p-toluenesulfonate as anions as well as a synthesis method, a preparation method and an application of the quaternary phosphonium salts. The synthesis method adopts a simple two-step synthesis route, that is, diethylene glycol monomethyl ether / methoxypolyethylene glycols reacts with p-methyl benzene sulfonic chloride to prepare diethylene glycol monomethyl ether / methoxypolyethylene glycol p-toluenesulfonate, then, diethylene glycol monomethyl ether / methoxypolyethylene glycol p-toluenesulfonate further reacts with triphenylphosphonium toobtain diethylene glycol monomethyl ether / methoxypolyethylene glycol-triphenyl phosphine p-toluenesulfonate. Through the simple synthesis route, the product has good dissolution property and cell penetrability, better antibacterial and killing performance for microbes and an anti-tumor function.

Owner:JINAN UNIVERSITY

A method of inhibiting the polymerization of vinyl compounds

InactiveCN102295500AGood solubility and dispersibilityGood inhibition effectOrganic compounds purification/separation/stabilisationOrganic compound preparationDiethylene glycol monobutyl etherCompound a

A method for inhibiting the polymerization of vinyl compounds, comprising adding a polymerization inhibitor to a vinyl compound system, the components of which include component A and component B. Wherein A is one of piperidine oxygen free radicals, nitrophenol or benzoquinone, or a mixture of two or more; B is diethylene glycol monomethyl ether, diethylene glycol dimethyl ether or diethylene glycol monobutyl ether One, or a mixture of two or more; in parts by weight, A:B=1:(0.5~2.0). The polymerization inhibitor is first prepared into a solution with a solvent and then added to the vinyl compound system. The solvent is one of dimethylformamide, toluene or xylene, in parts by weight, (A+B): solvent=(2~ 8): 10. The addition amount of the polymerization inhibitor is 0.3-3.0wt.‰ based on the amount of component A based on the vinyl compound. The advantage of the invention is that it can reduce the consumption of solvent, and more importantly, it can obtain ideal polymerization inhibition effect by adding less polymerization inhibitor into the vinyl compound system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Diethylene glycol monomethyl ether resistant coating

Diethylene glycol monomethyl ether resistant coatings include a base component including a sulfur-containing, epoxy functional polyol, and an activator component including an isocyanate curing agent.

Owner:PRC DE SOTO INT INC

Photoresist developer compositions

ActiveCN1503064AGood compatibilitySemiconductor/solid-state device manufacturingPhotosensitive material processingDiacetone alcoholSodium bicarbonate

A photoresist developer composition is provided, to improve miscibility and to suppress or minimize the generation of residue after development, thereby enhancing the precision of photoresist pattern. The photoresist developer composition comprises 1-10 wt% of an inorganic alkali; 0.1-3.0 wt% of an organic solvent; 1.0-20.0 wt% of a surfactant; and 67-97.9 wt% of water. Preferably the inorganic alkali is selected from the group consisting of KOH, NaOH, sodium phosphate, sodium silicate, sodium carbonate, sodium bicarbonate and their mixtures; the organic solvent is selected from the group consisting of methanol, ethanol, 1-propanol, 2-propanol, butanol, diacetone alcohol, ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, ethylene glycol monobutyl ether, diethylene glycol monomethyl ether, diethylene glycol monoethyl ether, dipropyl glycol monomethyl ether, dipropyl glycol monoethyl ether and their mixtures; and the surfactant is a mixture of a nonionic surfactant and an anionic surfactant.

Owner:DONGJIN SEMICHEM CO LTD

Synthesizing process of polyethandiol mono methyl ether

ActiveCN100999572AReduce the amount of waterSolve the problem of high polyethylene glycol (PEG) contentSodium methoxidePropanol

The preparation process of polyethylene glycol monomethyl ether belongs to the field of ether compound synthesizing technology in organic chemistry. The preparation process includes the first washing reactor for 1-5 times with low boiling point solvent methanol, ethanol, propanol, etc; and the subsequent the reaction of ethylene oxide with one kind of initial material of methanol, polyethylene glycol monomethyl ether, diethylene glycol methyl ether, triethylene glycol methyl ether, etc in the presence of catalyst of solid sodium methoxide, methanol solution of sodium methoxide, KOH, NaOH, etc. The preparation process is reasonable and high in reaction activity, and the polyethylene glycol monomethyl ether has lowered polyethylene glycol content.

Owner:ZHEJIANG HUANGMA TECH

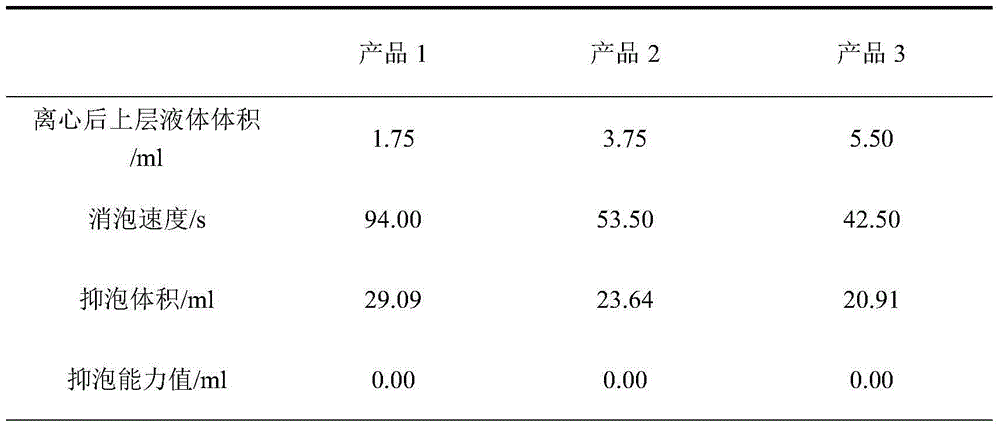

Novel organic silicon defoaming agent with excellent stability and defoaming ability

ActiveCN104645675AGood defoamingGood defoaming effectFoam dispersion/preventionEmulsionRoom temperature

The invention discloses a method for preparing a novel organic silicon defoaming agent with excellent stability and defoaming ability. The traditional emulsion type defoaming agent is good in defoaming performance and low in stability or is high in stability and poor in defoaming performance. The method disclosed by the invention is characterized in that a certain amount of diethylene glycol monomethyl ether is added during preparation, the defect that the stability and defoaming performance of the traditional emulsion type defoaming agent are difficultly considered simultaneously is overcome, and the stability of the emulsion is greatly improved under the condition that excellent defoaming performance of the defoaming agent is guaranteed. According to the technical scheme, the organic silicon defoaming agent comprises the following four substances in percentage by mass: 10-20 percent of silicone cream, 3-5 percent of a composite emulsifier, 0.6-1 percent of CMC-HV and 2-5 percent of diethylene glycol monomethyl ether, wherein the composite emulsifier comprises 57-72 percent of peregal and 28-43 percent of fatty alcohol, and the HLB value is 9-12. The preparation method comprises the following steps: adding the four substances into a reactor, heating, uniformly stirring, and cooling to room temperature; and finally, and emulsifying at a certain rotating speed for 5 minutes by virtue of a high-shear emulsifying machine while adding water, thereby obtaining the defoaming agent.

Owner:河北华茂环保科技有限公司

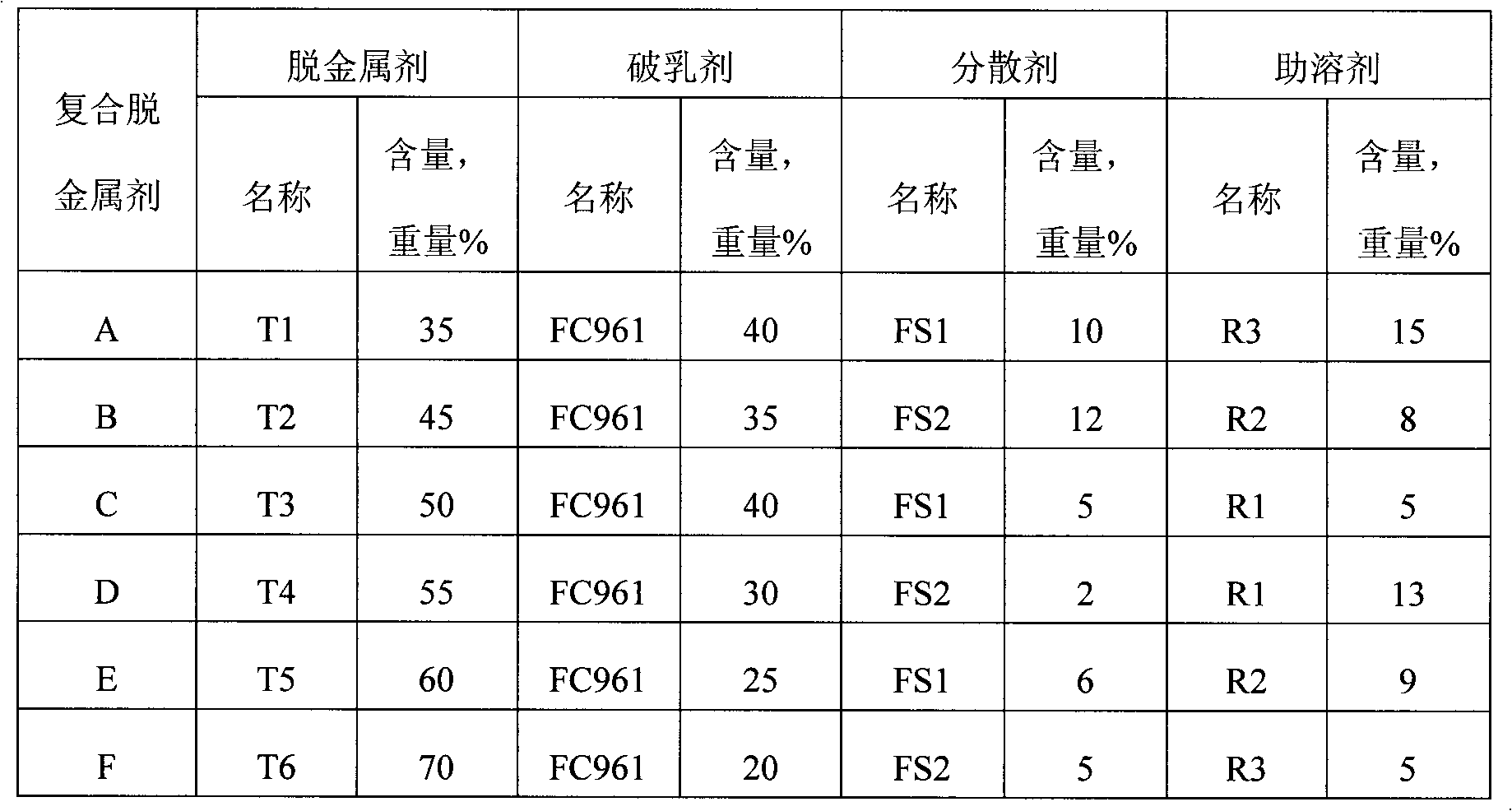

Composite demetalization agent and preparation method thereof

ActiveCN103146417AIncrease exposureHigh removal rateHydrocarbon oils refiningDiethylene glycol monobutyl etherPorphyrin

The invention discloses a composite demetalization agent and a preparation method thereof. The composite demetalization agent solves the problem that the existing composite demetalization agent cannot remove porphyrin compounds of metals such as nickel and vanadium and has a large use amount. The composite demetalization agent comprises 10 to 80wt% of a demetalization agent, 1 to 20wt% of a dispersing agent, 1 to 20wt% of a cosolvent and 10 to 50wt% of a demulsifier. The demetalization agent is a mixture of an organic acid and any one of precipitators and chelating agents. The dispersing agent is dodecyl trimethyl ammonium chloride or dodecyl trimethyl ammonium bromide. The cosolvent is selected from ethylene glycol butyl ether, diethylene glycol butyl ether and diethylene glycol monobutyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

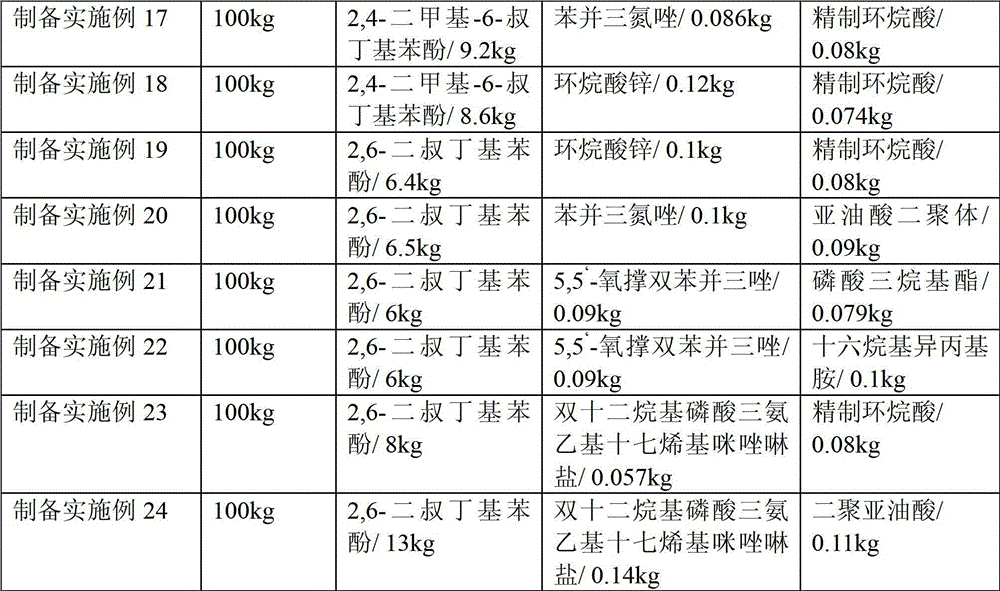

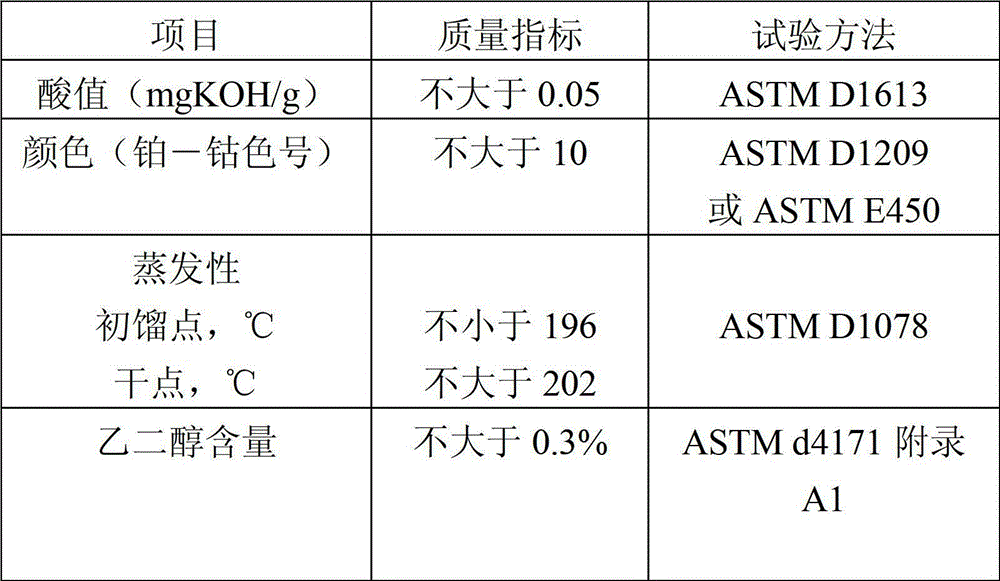

Deicing composition for military jet fuel

ActiveCN102977942AMaintain anti-icing performanceRaw materials are easy to getLiquid carbonaceous fuelsAntioxidantJet fuel

The invention relates to a deicing composition for military jet fuel. The deicing composition for military jet fuel comprises diethylene glycol monomethyl ether, an antioxidant, a corrosion remover and an antiwear agent. The deicing composition for military jet fuel has a high flash point and is particularly suitable for the military jet fuel.

Owner:PLA AIR FORCE OIL MATERIAL RES INST

Diethylene glycol monomethyl ether resistant coating

Owner:PRC DE SOTO INT INC

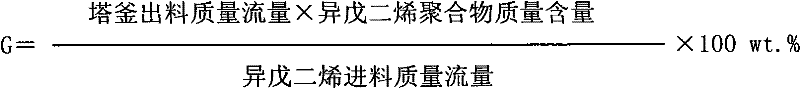

Method for refining isoprene by extractive distillation

InactiveCN102295513AGood solubility and dispersibilityGood inhibition effectDistillation purification/separationHydrocarbonsDiethylene glycol monobutyl etherExtractive distillation

A method for refining isoprene by extraction and rectification, in which isoprene is subjected to extraction and rectification in the presence of solvent dimethylformamide, and a polymerization inhibitor that inhibits the polymerization of isoprene is added to the system, and its components Contains Part A and Part B. Wherein component A is piperidine oxygen free radical and / or nitrophenol, and component B is diethylene glycol monomethyl ether and / or diethylene glycol monobutyl ether; In parts by weight, component A: component B= 1: (0.5-2.0). The polymerization inhibitor is first prepared into a solution with solvent dimethylformamide and then added to the extractive distillation system, in parts by weight, (component A+component B): dimethylformamide=(2~8): 10; The addition amount of the polymerization inhibitor is 0.3-3.0wt.‰ based on the amount of component A based on isoprene. The invention greatly improves the solubility and dispersibility of the polymerization inhibitor in the extraction and rectification system by adding an auxiliary component to the polymerization inhibitor, so that the polymerization inhibitor has better polymerization inhibition performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified metal polishing solution

InactiveCN105568289AImprove polishing effectImprove wear resistanceNano al2o3Diethylene glycol monomethyl ether

The invention discloses a modified metal polishing solution. The modified metal polishing solution is prepared from modified polyethylene wax, sodium oleate, citric acid, sodium tripolyphosphate, diethanol amine, ethanol amine, lauryl diethanolamine, hydroxy propyl cellulose, diethylene glycol monomethyl ether, polypropylene oxide polyoxyethylene propylene propylene glycol ether, quartz sand, nanometer aluminum oxide, gelatin, methionine, trialkylamine, sodium alkyl benzene sulfonate, glucose, sodium silicate, citrate and deionized water. The modified metal polishing solution is high in polishing efficiency, good in stability and good in corrosion resisting and wear resisting performance.

Owner:繁昌县陈氏金属制品有限公司

Preparation method of water-based biological magnetic fluid

InactiveCN101719407AHigh crystallinityImprove uniformityMixing methodsMagnetic liquidsWater basedCrystallinity

The invention relates to a preparation method of a water-based biological magnetic fluid, belonging to the technical field of biological materials. The preparation method comprises the following steps: dissolving ferric iron salt and water-soluble high polymers in diglycol, and heating and stirring the mixture for reaction in a nitrogen protection environment; then, rapidly injecting a diglycol monomethyl ether solution and continuously heating the mixture for reaction; and further adding acetone, adsorbing for separation by a magnet, and washing and dispersing the mixture in de-ionized water to obtain the water-based biological magnetic fluid. The water-soluble Fe3O4 magnetic nanometer particles prepared by the invention have good biological compatibility, narrow particle size distribution of the nanometer particles, good uniformity, high degree of crystallization and good controllability. The prepared water-based biological magnetic fluid has good stability and biological compatibility, and the magnetic response efficiency and the rheological characteristics of the biological magnetic fluid can be adjusted and controlled through the surface characteristics of the magnetic nanometer particles, which comprise the type, the structure and the coating rate of a coating material.

Owner:SHANGHAI JIAO TONG UNIV

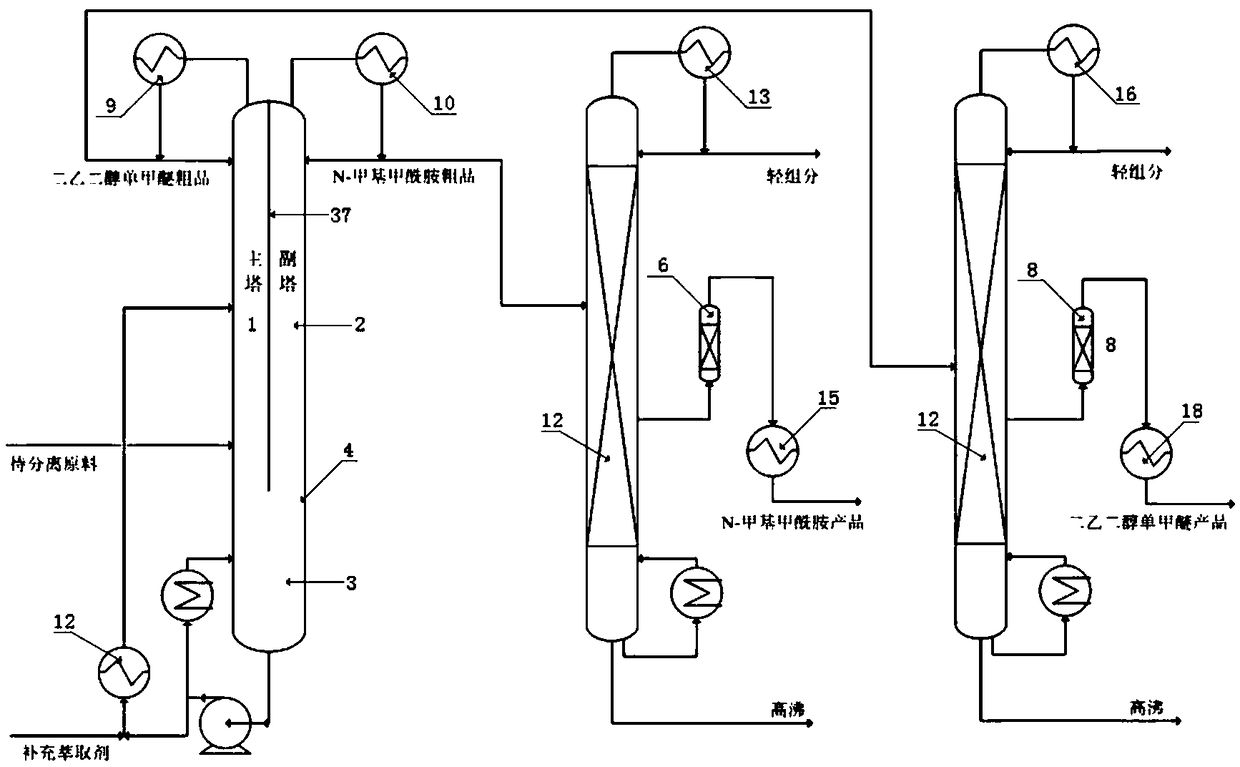

Method for recycling N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid

PendingCN109320431AAchieve separationReduce energy consumptionEther separation/purificationCarboxylic acid amide separation/purificationDiethylene glycolMetal

The invention relates to the field of solvent recycling, in particular to a method for recycling N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid. The method adopts an extraction dividing-wall rectifying method to recycle N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid; the paint remover waste liquid is rectified and separated through a main tower and an auxiliary tower of an extraction dividing-wall rectifying tower, and N-methylformamide crude product and diethylene glycol monomethyl ether crude product are obtainedrespectively; the N-methylformamide crude product passes through a N-methylformamide refining tower and a metal removing tower to obtain N-methylformamide, and the diethylene glycol monomethyl ethercrude product passes through a diethylene glycol monomethyl ether refining tower and the metal removing tower to obtain diethylene glycol monomethyl ether. The method can be adopted to conduct continuous production; the separation of the N-methylformamide and the diethylene glycol monomethyl ether is achieved; the method has the advantages that the purity of separated products is high; the technological procedure is simple; energy consumption and equipment investment in the separation process can be effectively lowered at the same time.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

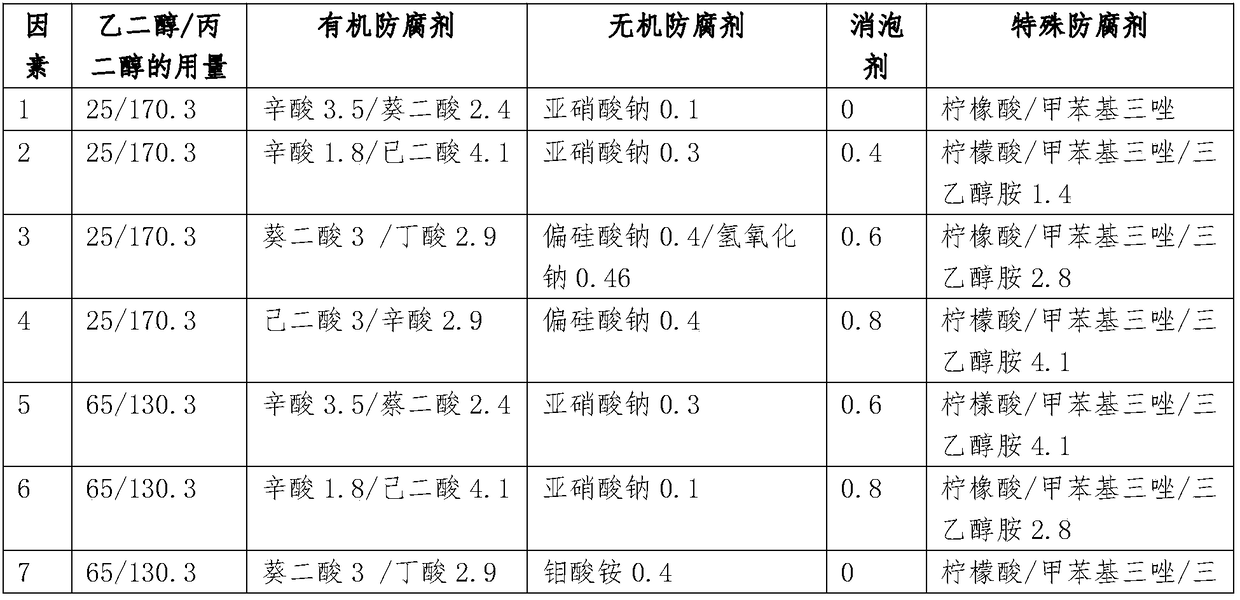

Anhydrous refrigerating fluid for internal combustion engine

InactiveCN108441176AIncrease heat transfer rateIncrease friction factorHeat-exchange elementsHigh resistanceCopper oxide

The invention discloses anhydrous refrigerating fluid for an internal combustion engine, and relates to the technical field of refrigerating fluid. The anhydrous refrigerating fluid is prepared from the following raw materials in percentage by mass: 85.53 to 95.0 percent of basic liquid, 1.2 to 3.0 percent of nano-particles, 1 to 3 percent of alkaline supplement agent, 0.75 to 1.47 percent of corrosion inhibitor, 0.5 to 2.0 percent of anti-foaming agent, and 2 to 5 percent of additive. A pH value is stabilized at 7.5 to 8.0; the basic liquid is prepared from mixed alcohol of ethylene glycol and propylene glycol; a nano-particle mixture is prepared from copper oxide nano-particles, silicon dioxide nano-particles and aluminum oxide nano-particles; the corrosion inhibitor is prepared from a mixture of sodium benzoate, heptanoic acid, toluene triazole, triazole, isooctanoic acid and diethylene glycol monomethyl ether. The anhydrous refrigerating fluid disclosed by the invention has high performance on comprehensive protection of multiple metals of an automobile cooling system; the complex type anhydrous refrigerating fluid has the advantages of good corrosion inhibitive ability, longlasting property, storage stability, high resistance to hard water, environmental friendliness and safety.

Owner:安徽职业技术学院

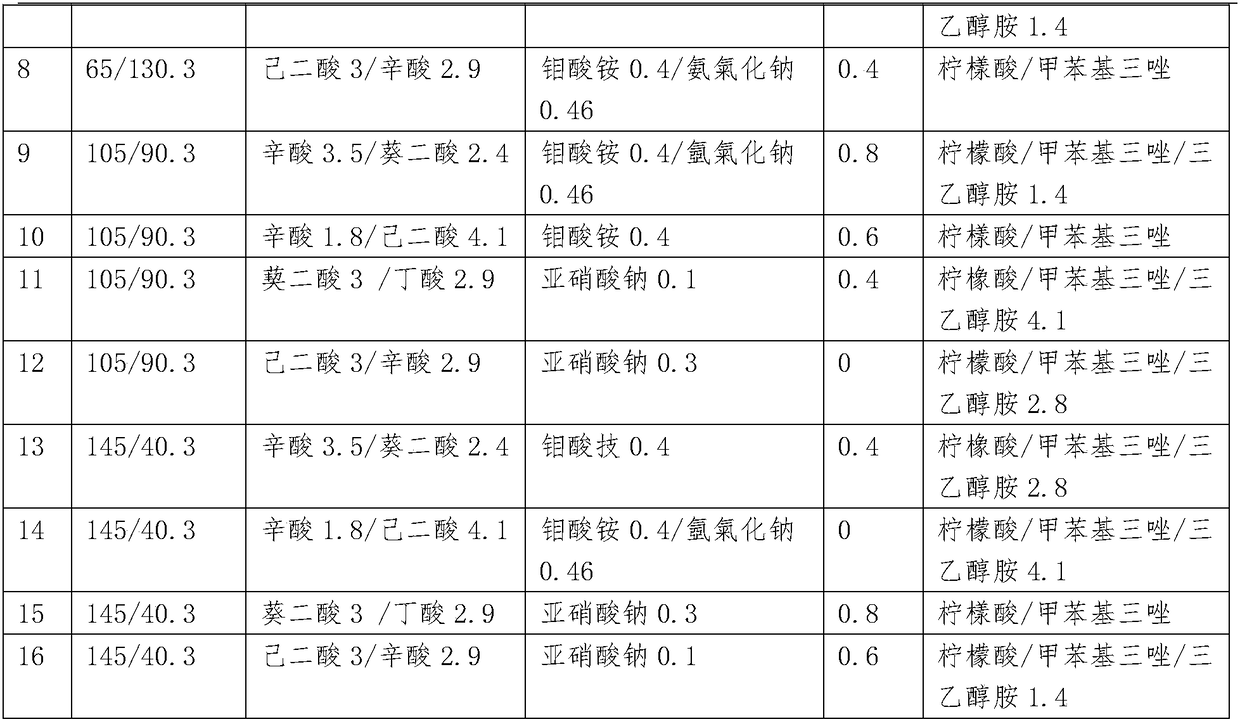

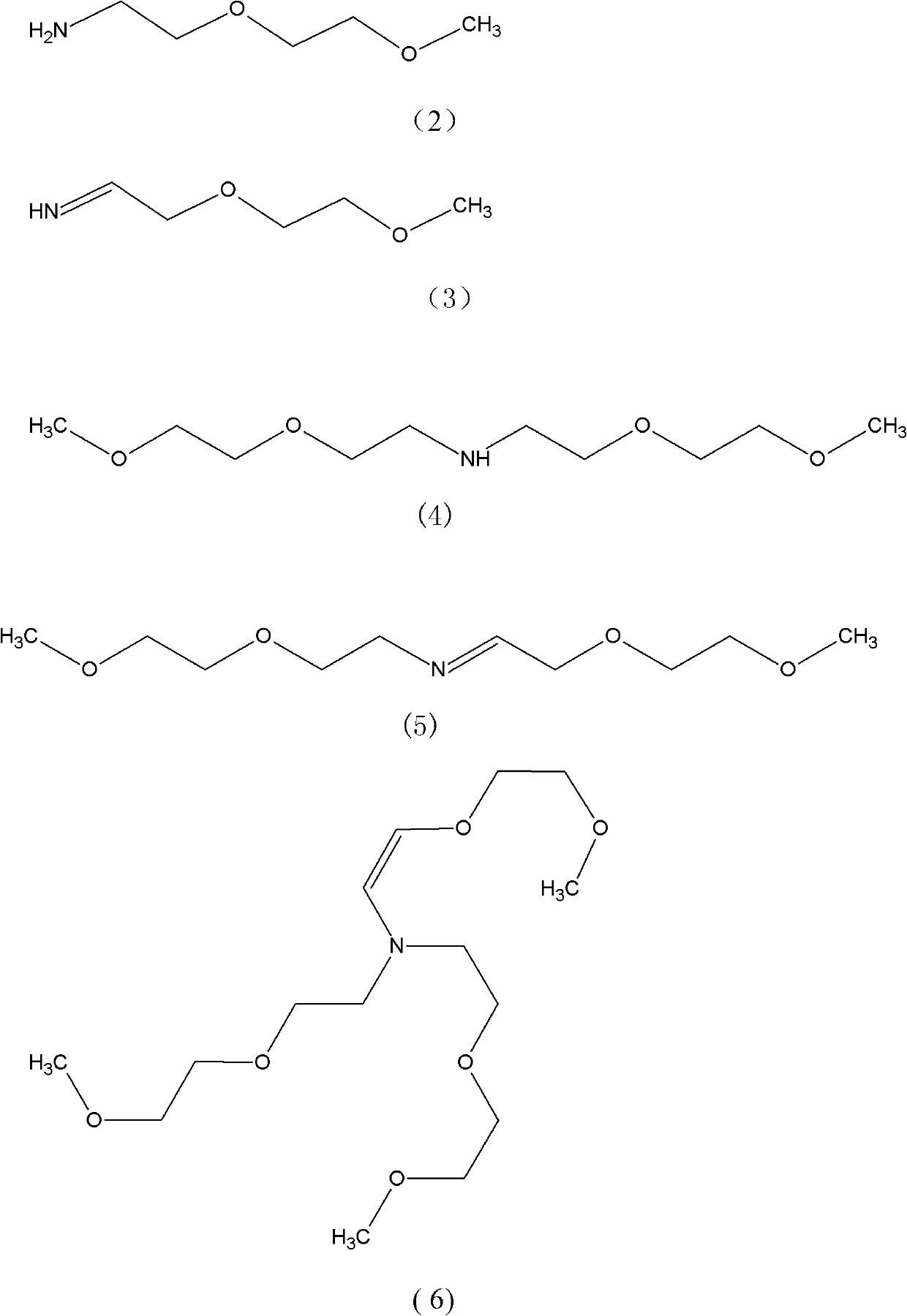

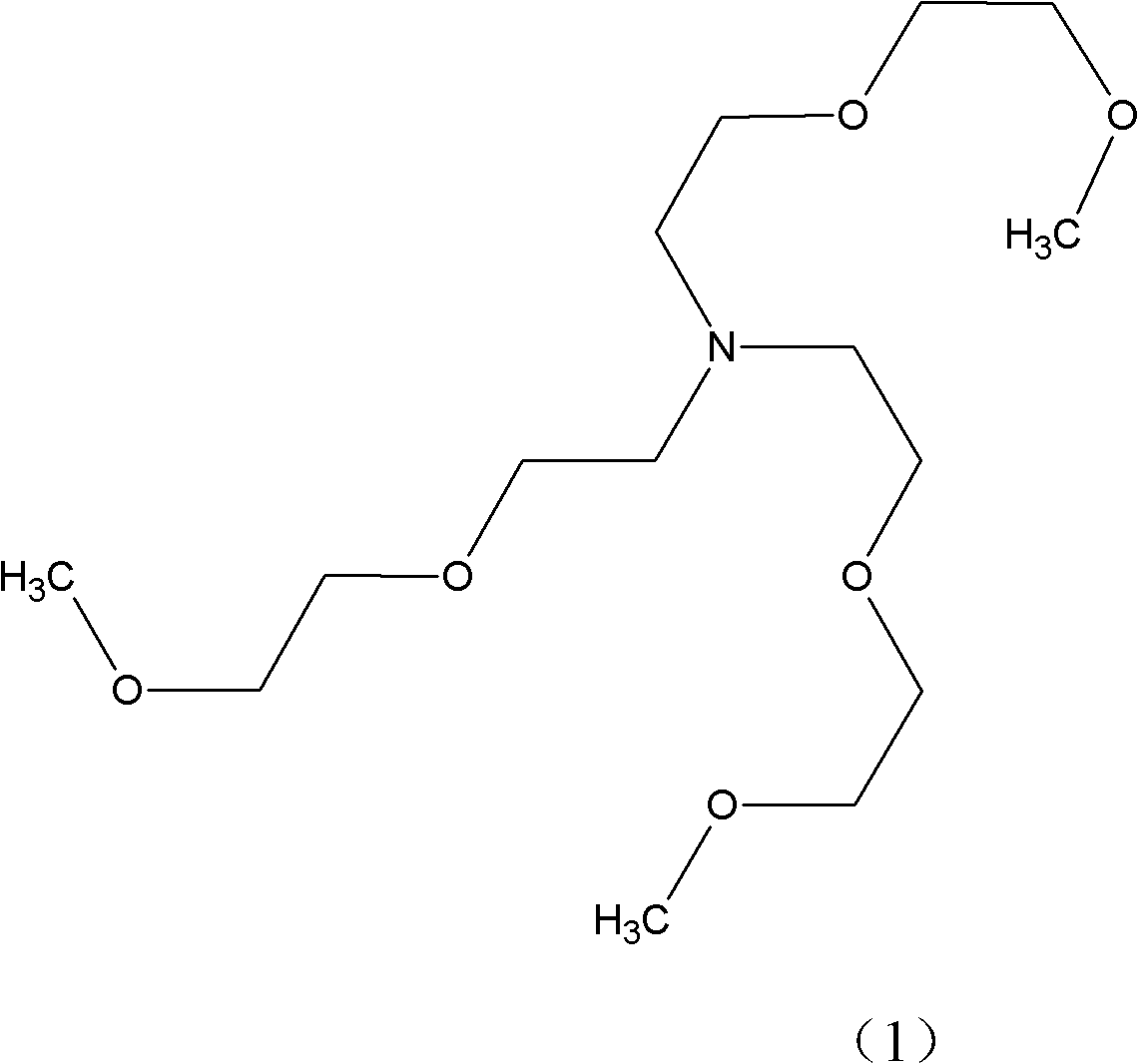

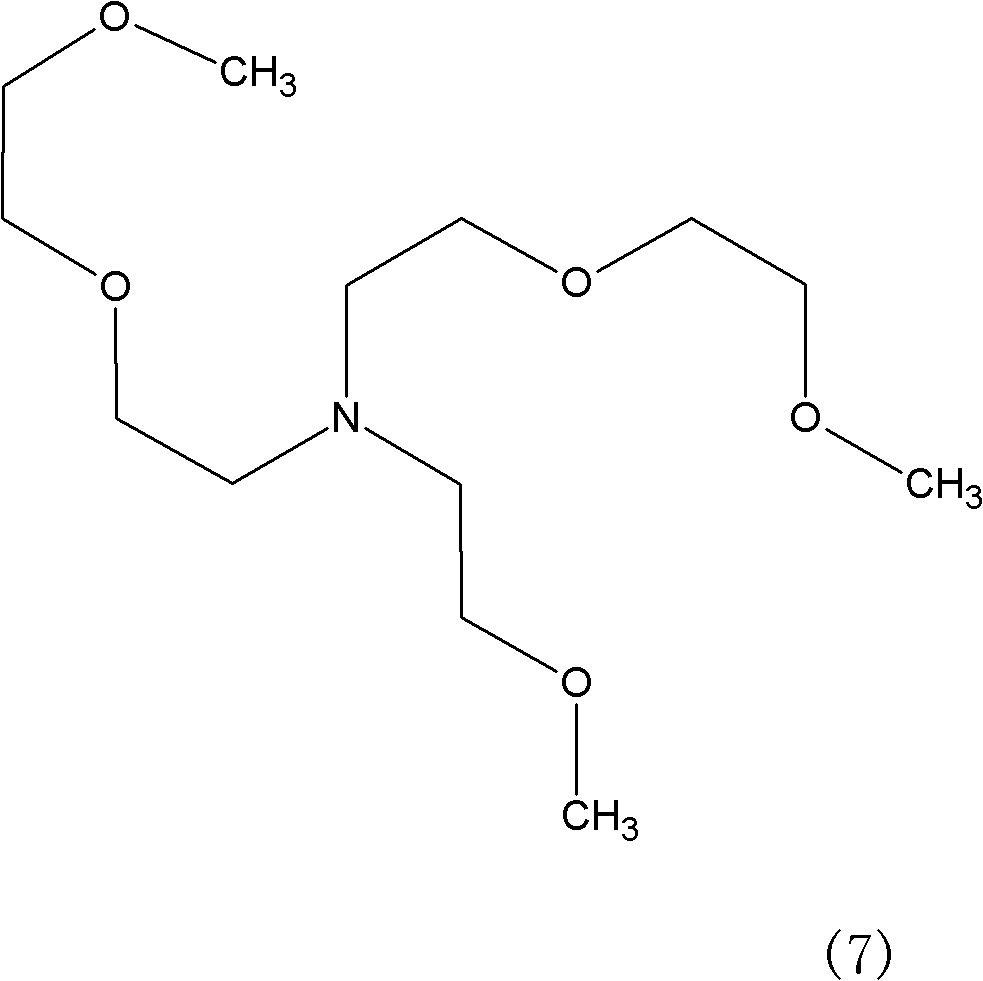

Method for synthesizing tris(dioxa-3,6-heptyl)amine

InactiveCN101948394AOvercome deaminationOvercoming the aminolysis reactionOrganic compound preparationAmino-hyroxy compound preparationHydrogenAmmonia

The invention relates to a method for synthesizing tris(dioxa-3,6-heptyl)amine. The conventional method for synthesizing the tris(dioxa-3,6-heptyl)amine has low selectivity, low yield and long production period. The method comprises the following steps of: catalyzing diglycol simple methyl ether serving as a raw material by a framework Cu-Ni bimetallic catalyst in the absence of solvent; and introducing hydrogen and ammonia under normal pressure and at the temperature of between 130 and 150 DEG C with stirring so as to synthesize the tris(dioxa-3,6-heptyl)amine, wherein the feeding volume ratio of the hydrogen to the ammonia is controlled to be 1:(5-10); and when the mass ratio of the diglycol simple methyl ether to 3,6-dioxa amine in reaction solution reaches (1.5-2):1, ammonia introducing is stopped and hydrogen introducing speed is not changed until the mass percentage of the diglycol simple methyl ether is less than or equal to 2 percent. The method has the advantages of high selectivity, high yield, convenient subsequent separation and suitability for industrialized production and the production and preparation of the tris(dioxa-3,6-heptyl)amine.

Owner:浙江皓华制药有限公司

Light sensitive resin composition

ActiveCN1702554AHigh light sensitivityImprove transmittanceStatic indicating devicesPhotosensitive materials for photomechanical apparatusDiethylene glycol diethyl etherCarboxylic acid

The photosensitive resin composition comprises (a) an acrylic copolymer obtained by copolymerizing (i) an unsaturated carboxylic acid, an unsaturated carboxylic acid anhydride or a mixture of them, (ii) an epoxy-containing unsaturated compound and (iii) an olefinically unsaturated compound, (b) a 1,2-quinonediazido compound and (c) one or more solvents selected from the group consisting of benzyl alcohol, hexyl alcohol, diethylene glycol dimethyl ether, diethylene glycol methylethyl ether, diethylene glycol diethyl ether, dipropylene glycol diethyl ether, dipropylene glycol dimethyl ether and dipropylene glycol methylethyl ether. So this invention provides a photosensitive resin composition which is excellent in performances such as sensitivity transmittance, insulation and chemical resistance, remarkably improves flatness and coating property in particular, and is suitable for forming an interlayer insulating film in a process for fabricating LCD, etc.

Owner:DONGJIN SEMICHEM CO LTD

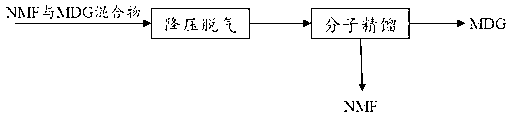

Industrial separation method of N-methylformamide and diethylene glycol monomethyl ether

InactiveCN109096142AEfficient purificationHigh purityEther separation/purificationCarboxylic acid amide separation/purificationMean free pathTower

The invention relates to an industrial separation method of main components N-methylformamide (NMF) and diethylene glycol monomethyl ether (MDG) in an electronic chemical stripper. A low-pressure molecular distillation method is adopted to efficiently recover the NMF and the MDG in the waste electronic chemical stripper, and has the advantages of energy saving and safety and environmental protection. A high-purity NMF and MDG separation refining process mainly comprises the following steps of 1) depressurization and degassing: decompressing and degassing the mixture of the NMF and the MDG to prevent entrainment splashing caused by sudden pressure drop after materials enter a molecular rectification tower; 2) molecular rectification of enabling the degassed materials to enter the molecularrectification tower achieve separation by utilizing the feature that molecular mean free paths of the two components are different. Compared with the conventional process, the method achieves the effect that the the purity of the finished NMF and the finished MDG is over 99%, and the rectified NMF and the rectified MDG reach the purity requirement of the electronic chemical stripper and achieve the separation and the purification of the NMF and the MDG.

Owner:福建钰融科技有限公司 +2

Lubricant composition containing corrosion resistant ionic liquid

Owner:YANTAI ZHONGKE RES INST OF ADVANCED MATERIALS & GREEN CHEM ENG

Method for preparing 4-trifluoromethylphenyl piperazine

InactiveCN102060712AHigh reaction yieldIncrease contentOrganic compound preparationAmino compound preparationTrifluoromethylphenylpiperazineN-Butyl Alcohol

The invention relates to a method for preparing 4-trifluoromethylphenyl piperazine, which comprises the following steps of: firstly, reacting diethanol amine with thionyl chloride to obtain bis(2-chloroethyl)amine, reacting 4-trifluoromethylaniline with bis(2-chloroethyl)amine in normal butanol or diethylene glycol monomethyl ether under the heating condition to obtain 4-trifluoromethylphenyl piperazine hydrochloride, and neutralizing with an alkaline to obtain the 4-trifluoromethylphenyl piperazine. The method for preparing the 4-trifluoromethylphenyl piperazine has the advantages of high reaction yield, less production of three wastes, easy reaction control, small production danger, simple product purification, high content and the like.

Owner:天津均凯农业科技有限公司

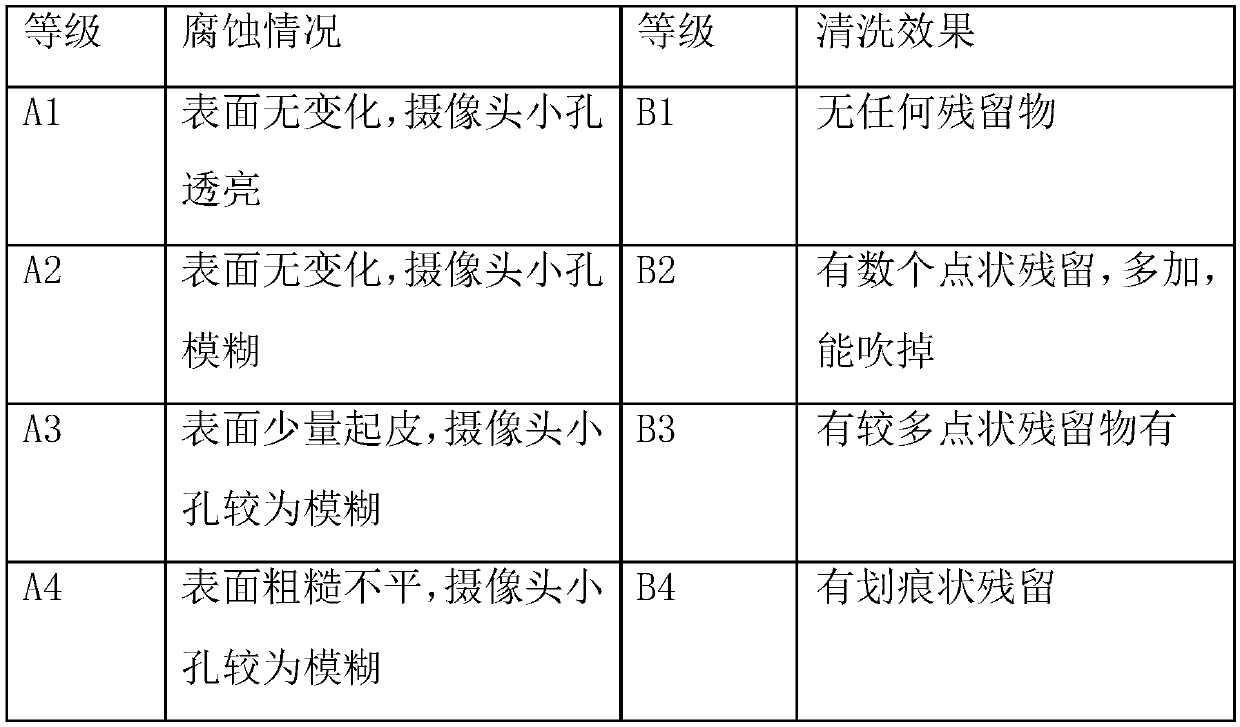

Neutral cleaning agent for coated optical glass

InactiveCN109536295AInhibitionAvoid residualOrganic detergent compounding agentsPolymeric surface-active compoundsDiethylene glycol monobutyl etherCleansing Agents

The invention discloses a neutral cleaning agent for coated optical glass. The neutral cleaning agent is prepared from the following raw materials in parts by weight: 2-5 parts of a complexing agent,10-15 parts of a dispersing agent, 2-8 parts of a surfactant, 0.05-1 part of a foam inhibitor, 0.01-0.05 part of essence, 0.02-0.1 part of a preservative and the balance of water, wherein the sum of the parts of the raw materials is 100 parts. According to the invention, the foam inhibitor is prepared by selecting one or two of ethylene glycol monobutyl ether, ethylene glycol monomethyl ether, diethylene glycol monomethyl ether, diethylene glycol monobutyl ether and tributyl phosphate as defoaming component(s), thus not only avoiding the corrosion of an anti-fingerprint film layer on the surface of the glass, but also inhibiting the generation of foams; therefore, the phenomenon of residual silicon-containing defoaming agents is effectively avoided; the effects of no residue, low foam andeasy rinsing are achieved; and the technical problem that in the prior art, the cleaning agent is poor in defoaming effect is solved.

Owner:合肥普庆新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com