Preparation method of pectinate high-polymer phase-change energy storage material

A technology of phase-change energy storage materials and polymers, which is applied in the direction of heat exchange materials, chemical instruments and methods, and can solve the problems of reduced machinability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

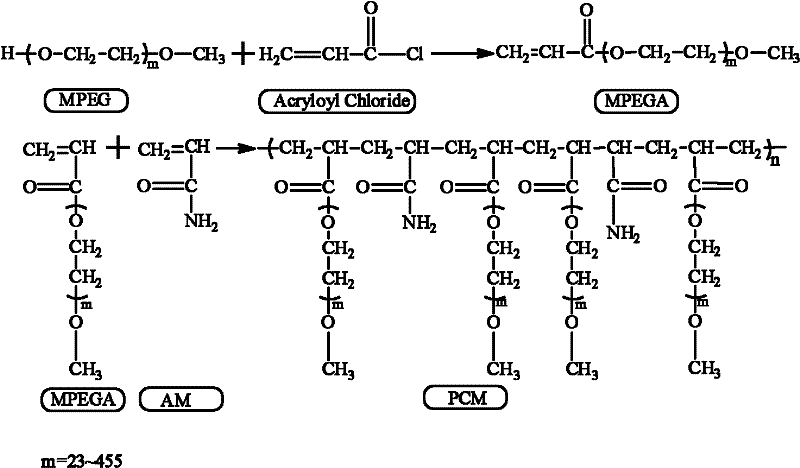

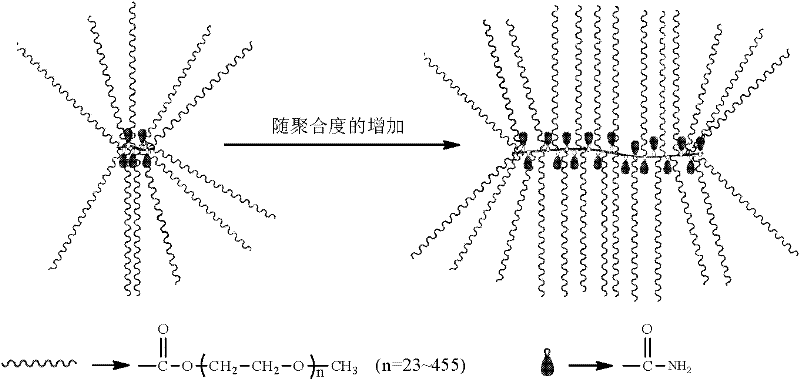

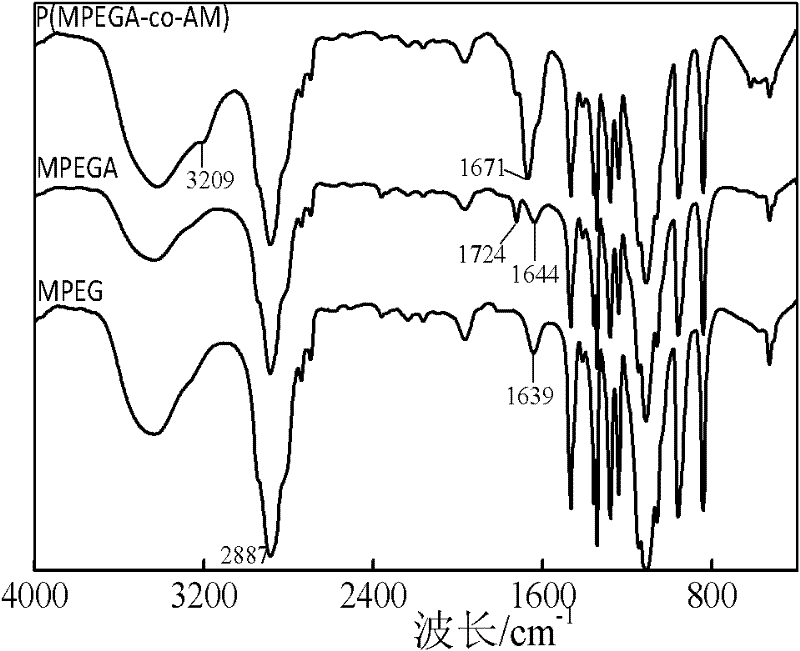

[0031] In an ice-water bath, dissolve 50 g of polyethylene glycol monomethyl ether (MPEG) with a molecular weight of 2000 in 100 ml of dichloromethane, add 0.663 g of acid-binding agent sodium carbonate, and add 2.03 ml of acryloyl chloride to the system after a period of nitrogen gas flow; The temperature of the system was raised to 35°C, and reacted for 8 hours under the protection of nitrogen; under an ice-water bath, anhydrous ether was added to the reaction solution, allowed to stand for 10 minutes, and filtered under reduced pressure to obtain polyethylene glycol monomethyl ether acrylate; Dissolve 2g of glycol monomethyl ether ester and 0.080g of acrylamide in 2ml of water, add 0.020g of ammonium persulfate, and react in water at 75°C for 40 minutes to obtain a phase-change energy storage material with a comb-like molecular chain shape. The preparation reaction formula is shown in figure 1 . From the structural diagram ( figure 2 ) It can be seen that when the degree...

Embodiment 2

[0037]In an ice-water bath, dissolve 50 g of polyethylene glycol monomethyl ether (MPEG) with a molecular weight of 1000 in 100 ml of dichloromethane, add 2.650 g of acid-binding agent sodium carbonate, and add 4.06 ml of acryloyl chloride to the system after passing nitrogen for a period of time; The temperature of the system was raised to 40°C, and reacted for 6 hours under the protection of nitrogen; under an ice-water bath, add n-hexane to the reaction solution, let it stand for 15 minutes, and filter under reduced pressure to obtain polyethylene glycol monomethyl ether acrylate; Dissolve 2g of alcohol monomethyl ether ester and 0.240g of N-isopropylacrylamide in a composite solvent of 1ml of water-ethanol (v / v=5 / 95), add 0.020g of azobisisobutyronitrile, and dissolve in 70°C water After reacting for 30 minutes, a phase-change energy storage material with comb-like molecular chain morphology was obtained.

Embodiment 3

[0039] In an ice-water bath, dissolve 50 g of polyethylene glycol monomethyl ether (MPEG) with a molecular weight of 1000 in 100 ml of dichloromethane, add 1.325 g of acid-binding agent sodium carbonate, and add 8.12 ml of acryloyl chloride to the system after passing nitrogen for a period of time; The temperature of the system was raised to 35°C, and reacted for 8 hours under the protection of nitrogen; under an ice-water bath, diethyl ether was added to the reaction solution, allowed to stand for 15 minutes, and filtered under reduced pressure to obtain polyethylene glycol monomethyl ether acrylate; polyethylene glycol acrylic acid Dissolve 2g of monomethyl ether ester and 0.080g of acrylamide in 1ml of water, add 0.020g of ammonium persulfate, and react in water at 85°C for 120min to obtain a phase-change energy storage material with a comb-like molecular chain shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com