Patents

Literature

55results about How to "Increase friction factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

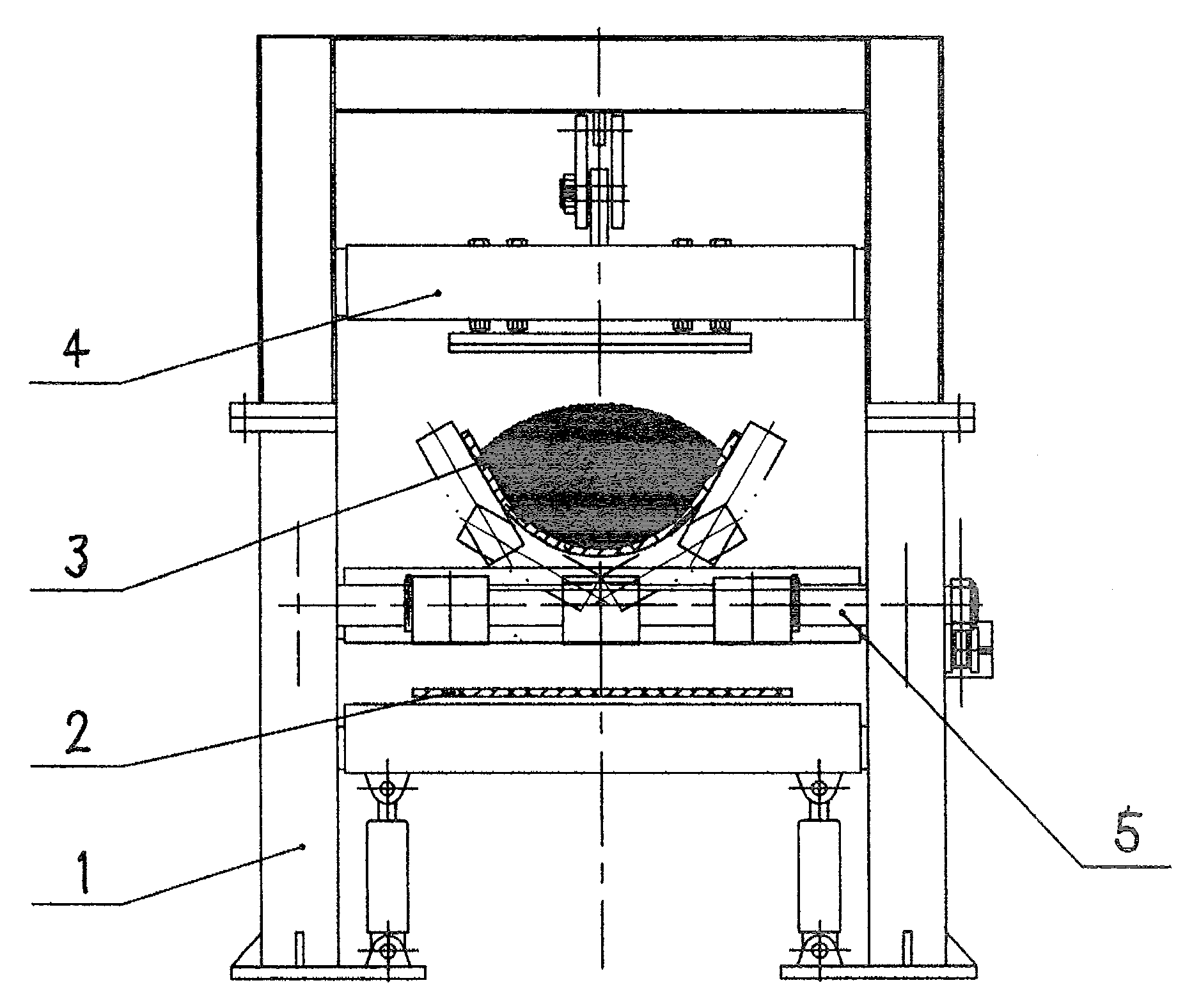

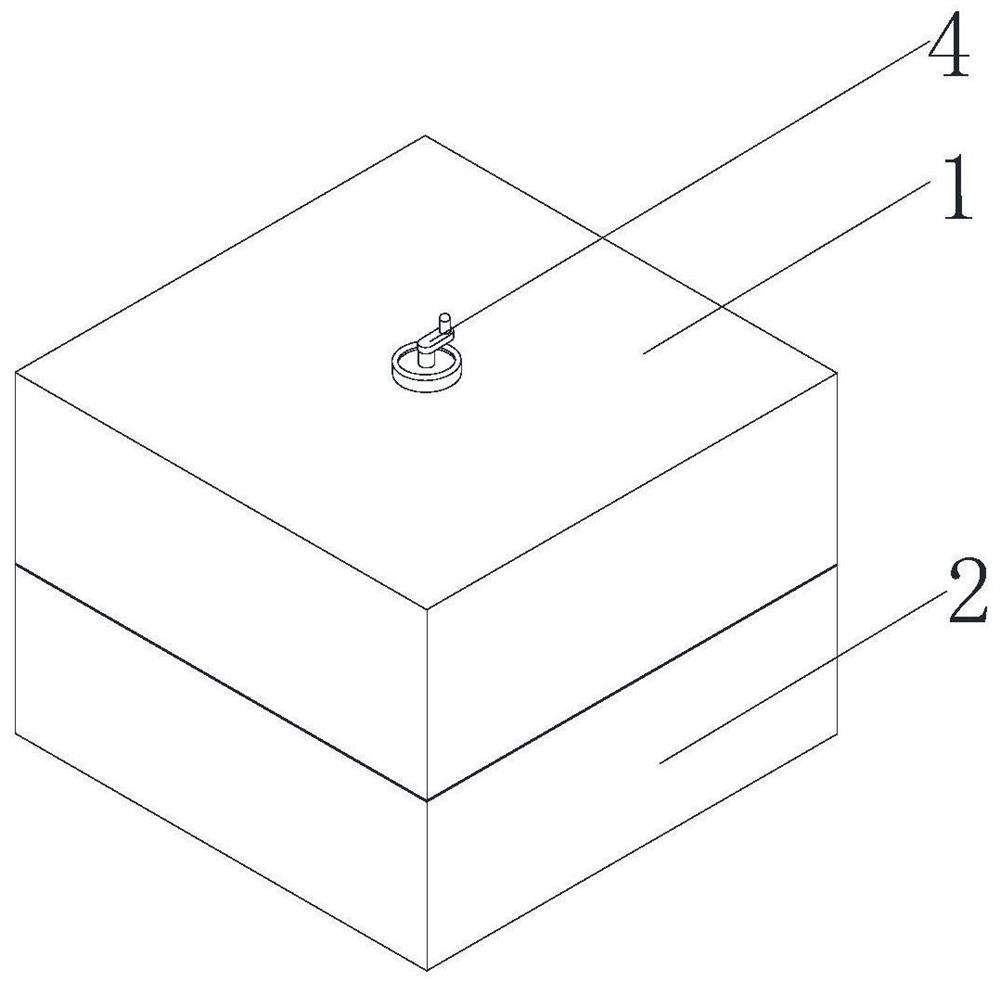

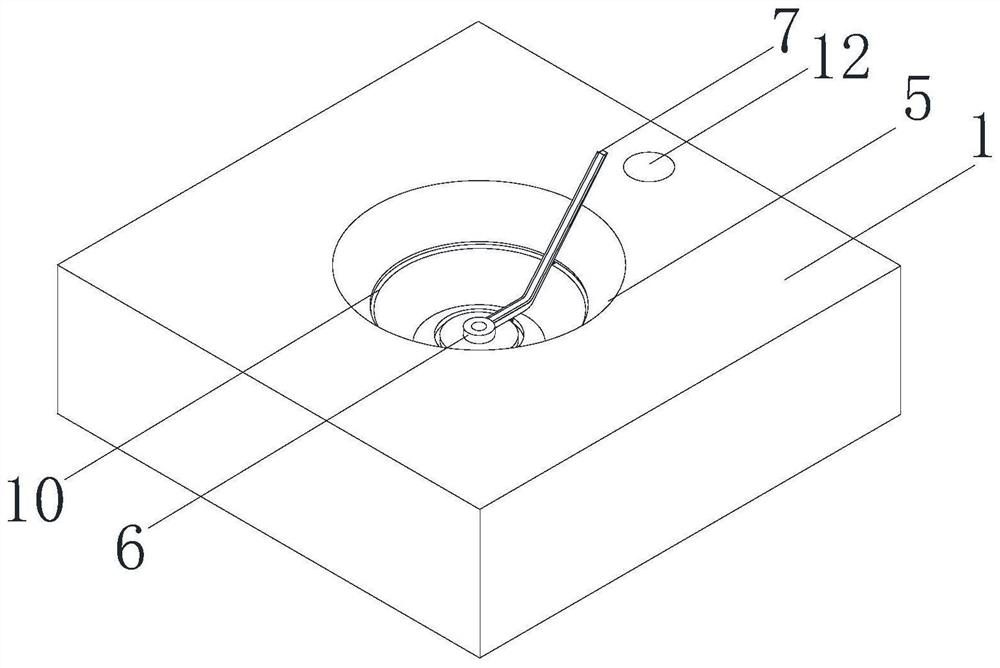

Slip vibration isolation support

ActiveCN105804263AHigh sensitivityGood filtering performanceBridge structural detailsShock proofingMagnetStructural engineering

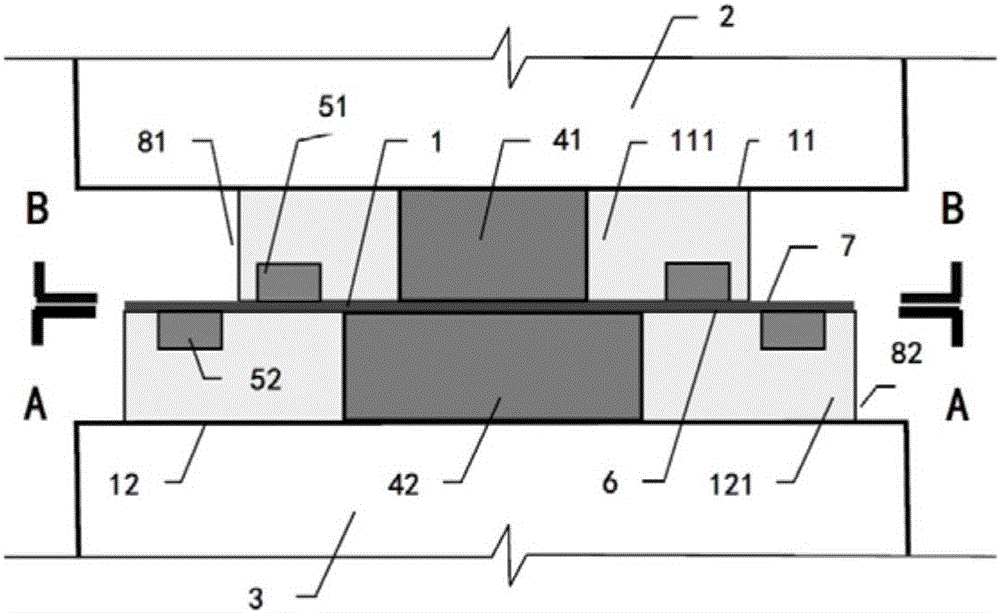

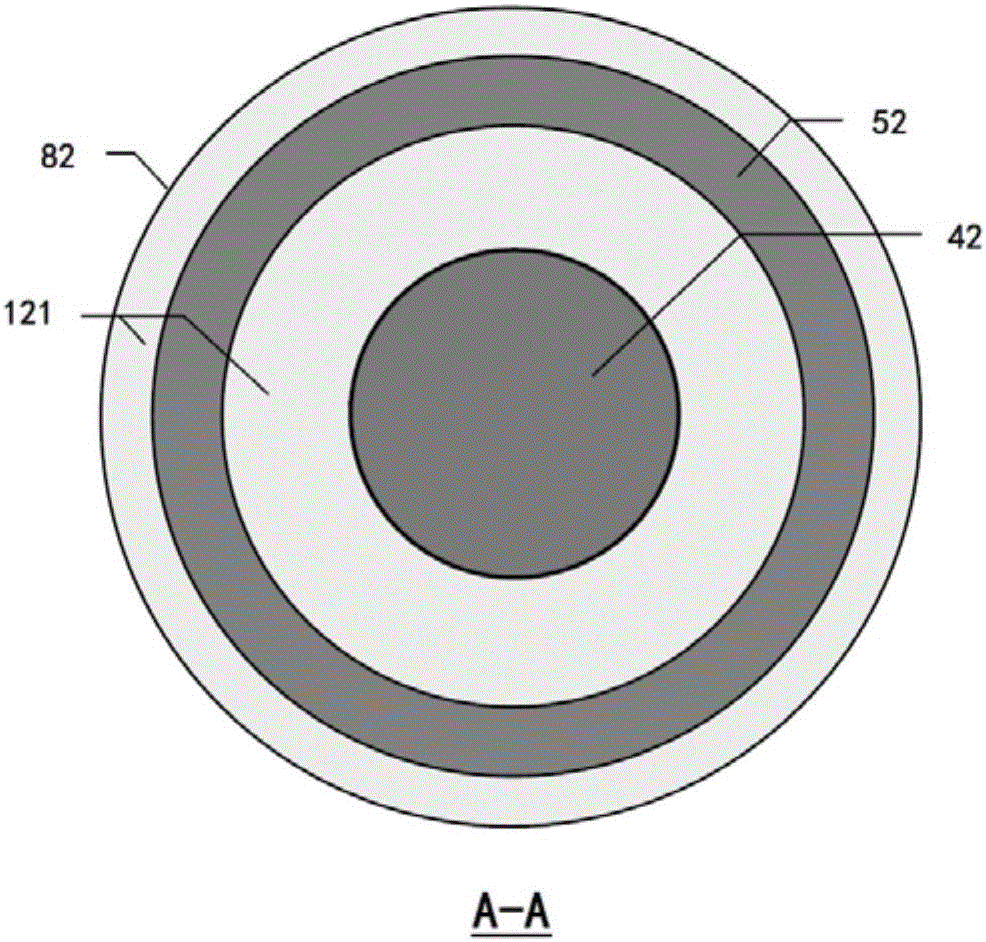

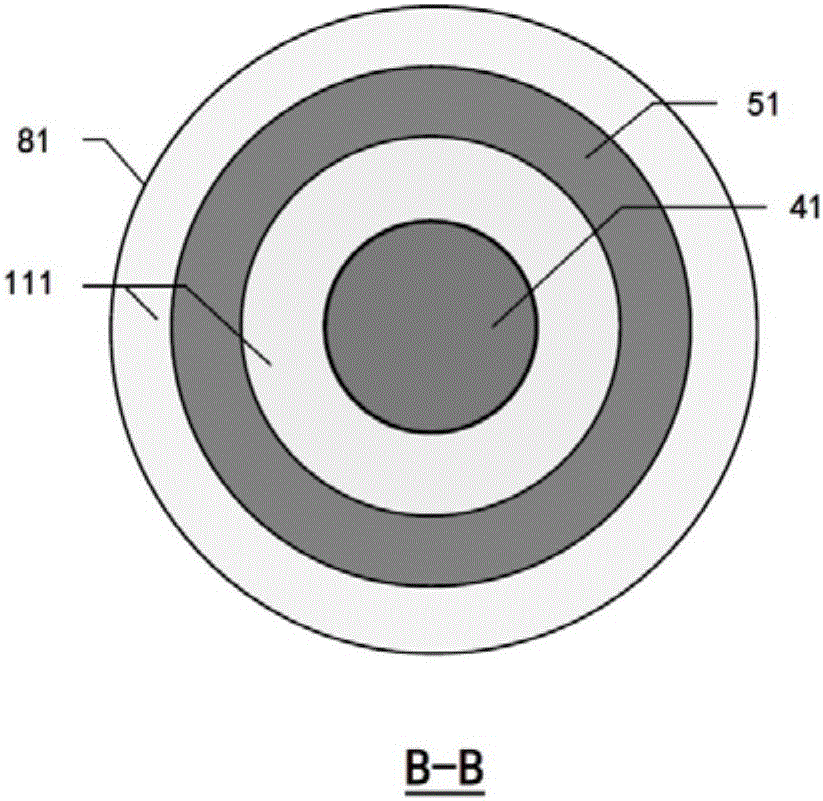

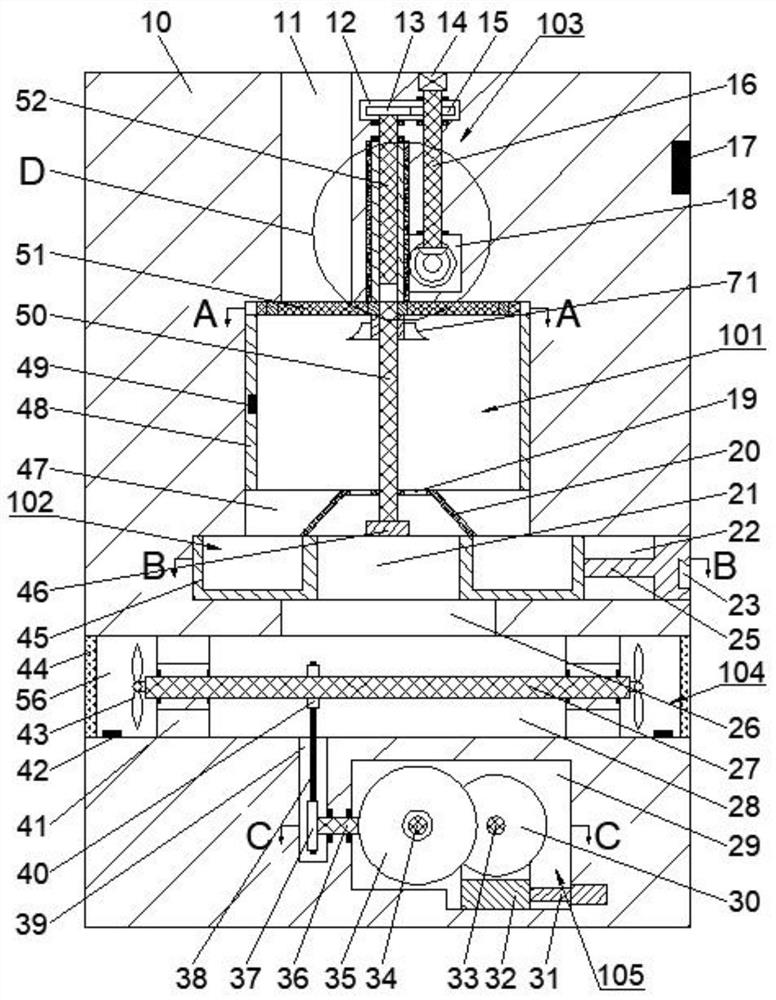

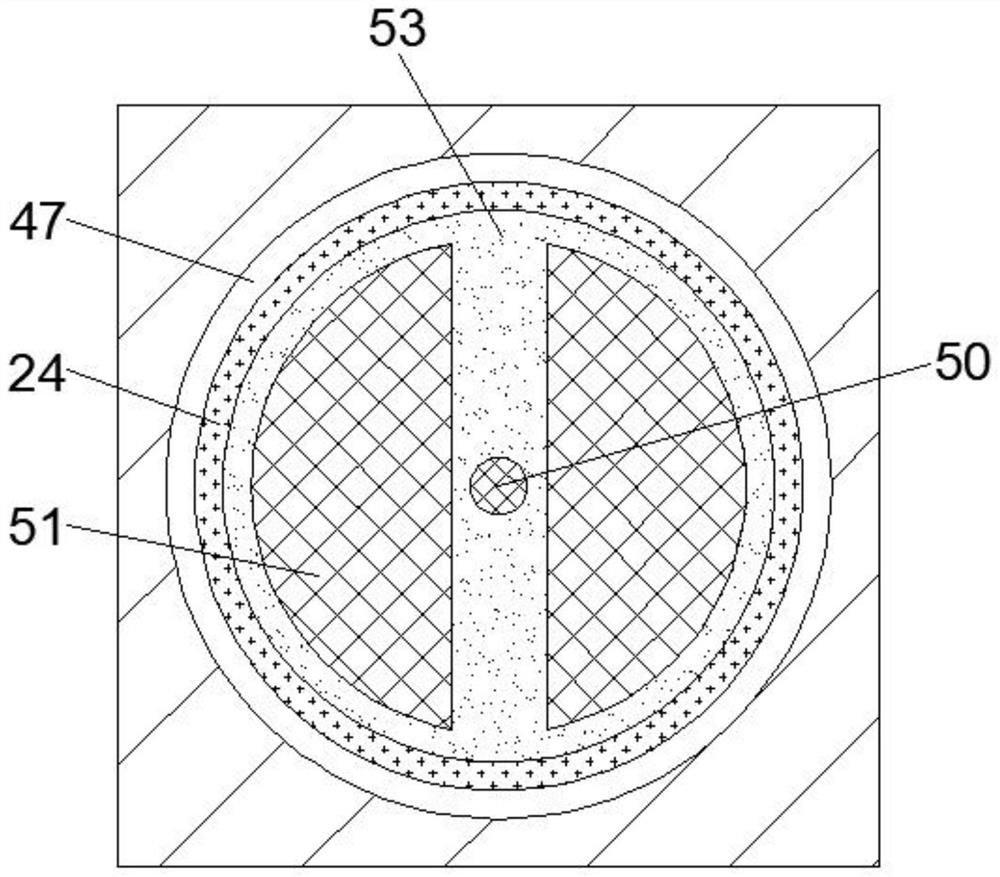

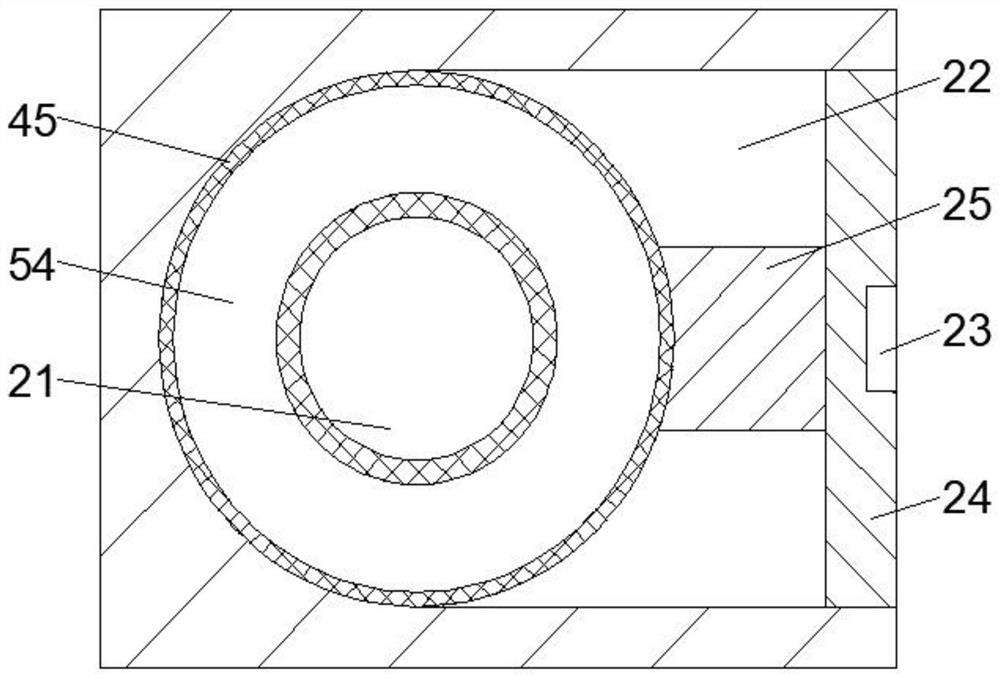

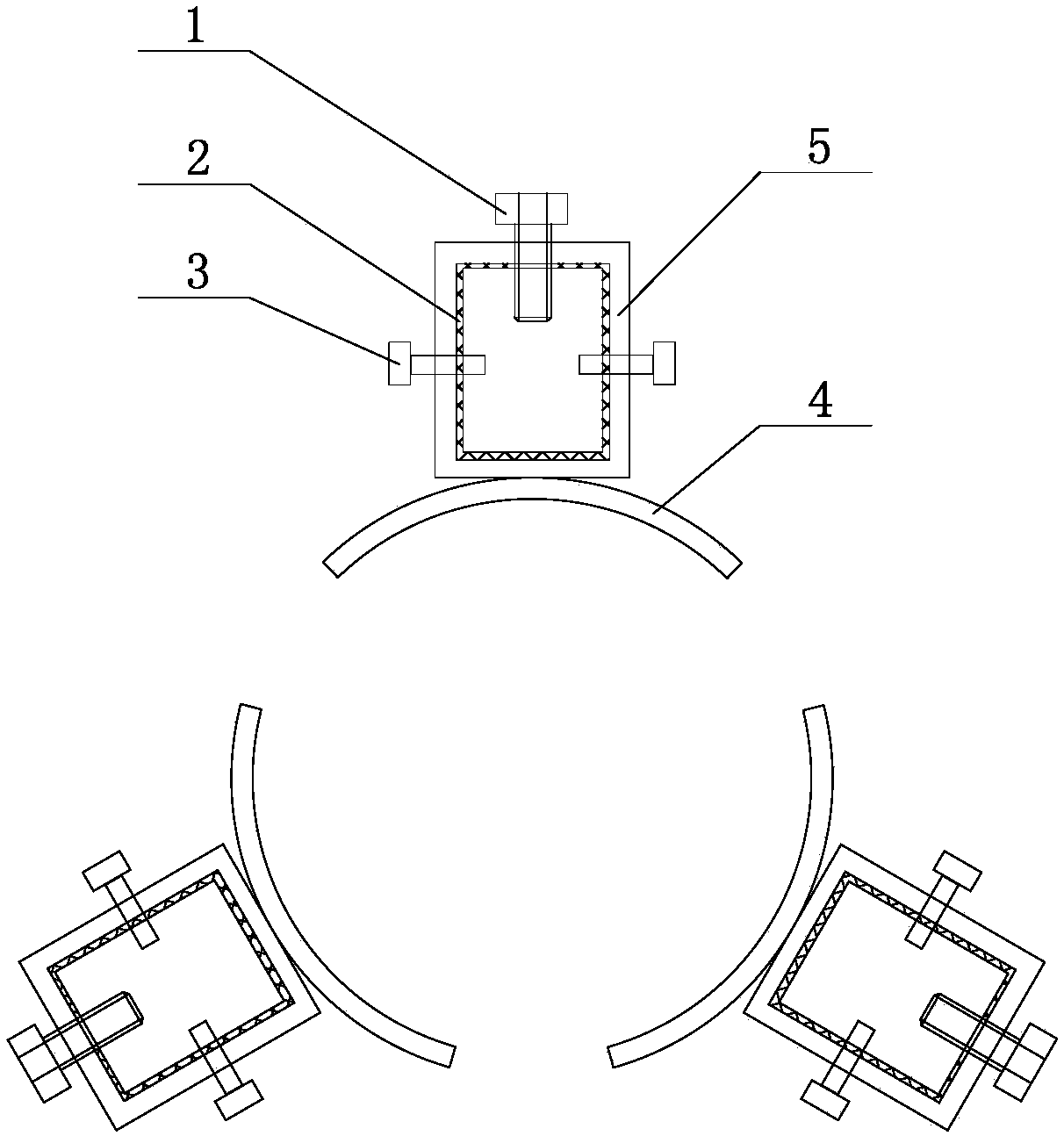

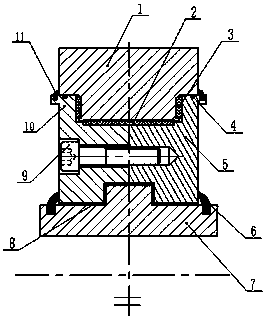

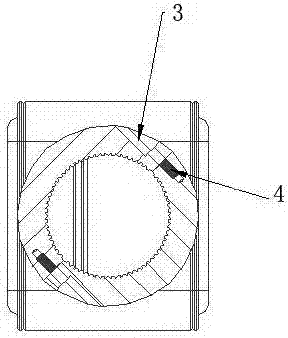

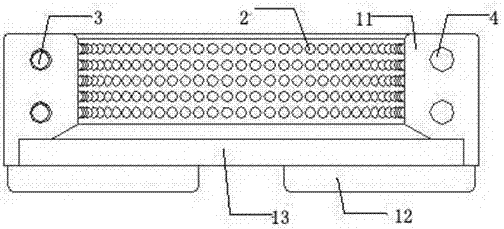

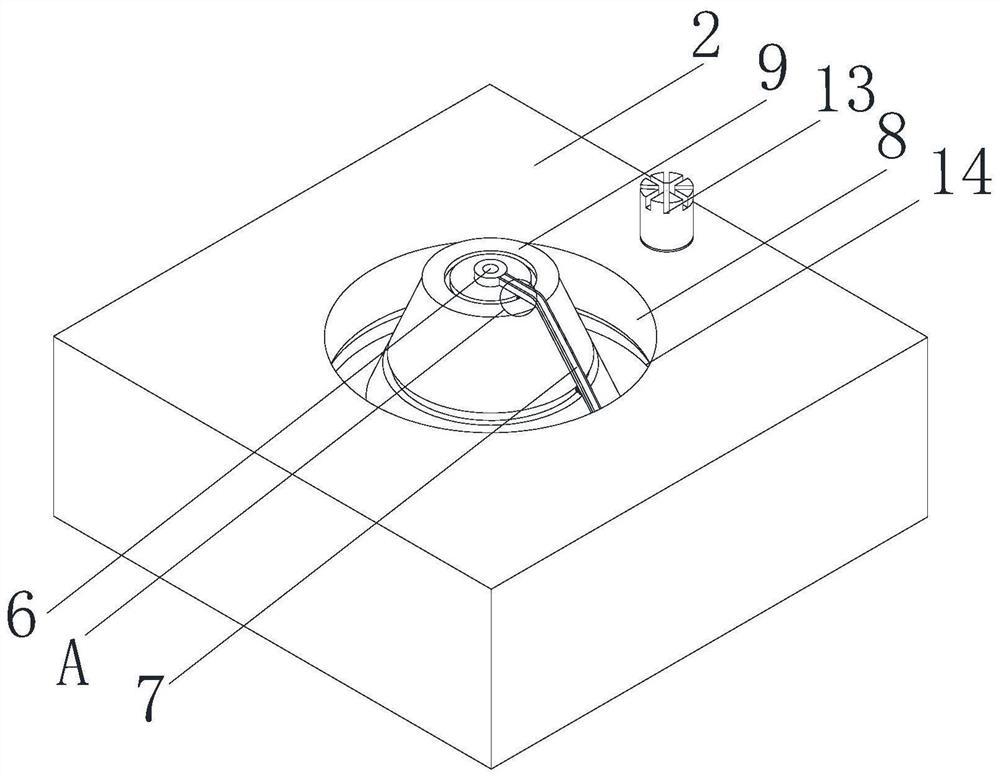

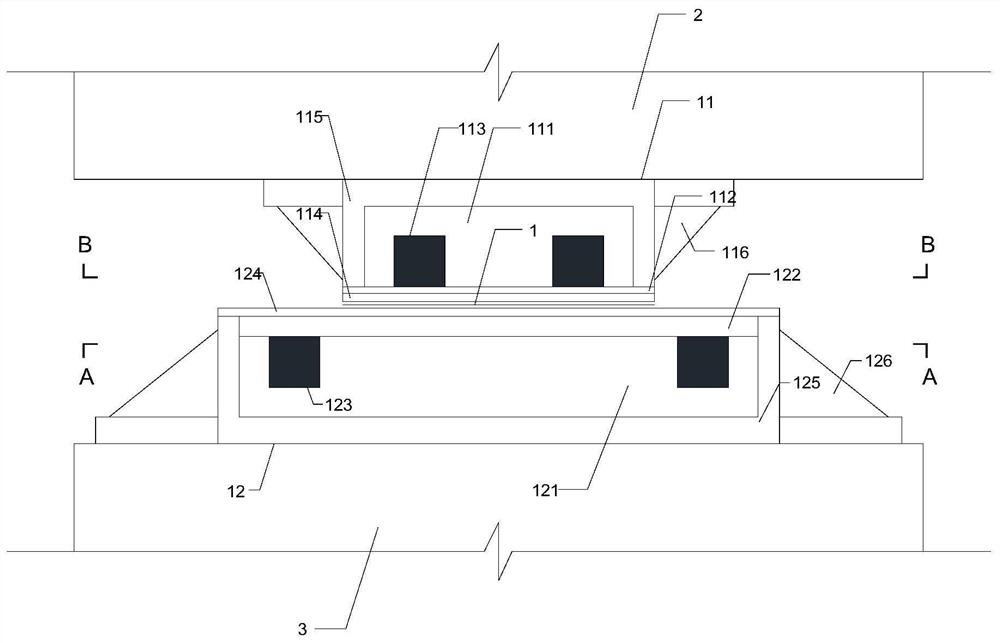

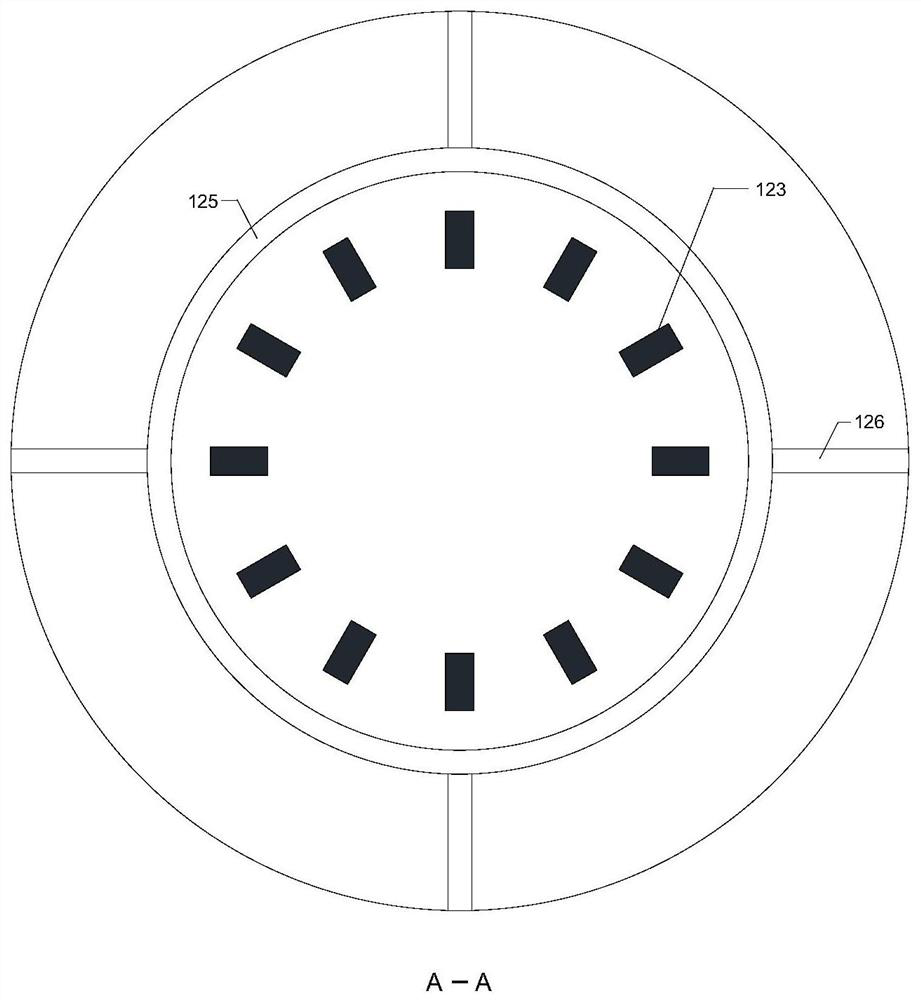

The invention discloses a slip vibration isolation support which comprises an upper support and a lower support. The upper support is supported by the lower support, and interlayer surfaces are arranged between the upper support and the lower support; the upper support and the lower support are both filled with lead core rubber and internally provided with annular permanent magnets in a staggered mode, and the upper permanent magnet and the lower permanent magnet are both arranged to be close to the interlayer surfaces so as to provide sufficient magnetic induction intensity; the vibration support adopts aluminum plates as the interlyaer surfaces, outer sealing is conducted through annular steel tanks, and the interlayer surfaces are covered with polytetrafluoroethylene plates. Compared with a traditional vibration isolation support, the internally arranged magnet type vibration isolation support has the advantages of being small in abrasion, high in sensitivity, good in filtering property, high in energy consumption, small in impact effect, high in self reset capacity, capable of saving space, good in tensile property and the like, and important significance in solving the technical problems that deformation of the vibration isolation support of the area with high seismic intensity is too large, the impact effect is significant, and the tensile property is weak is achieved.

Owner:TONGJI UNIV

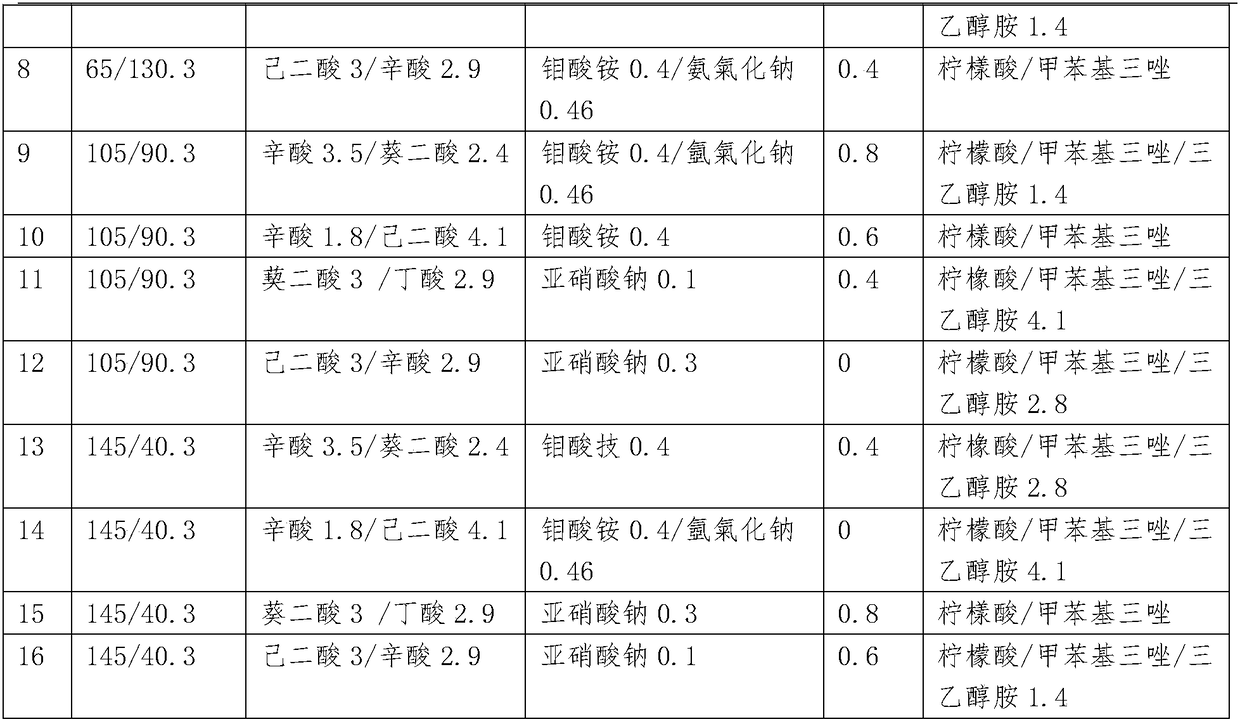

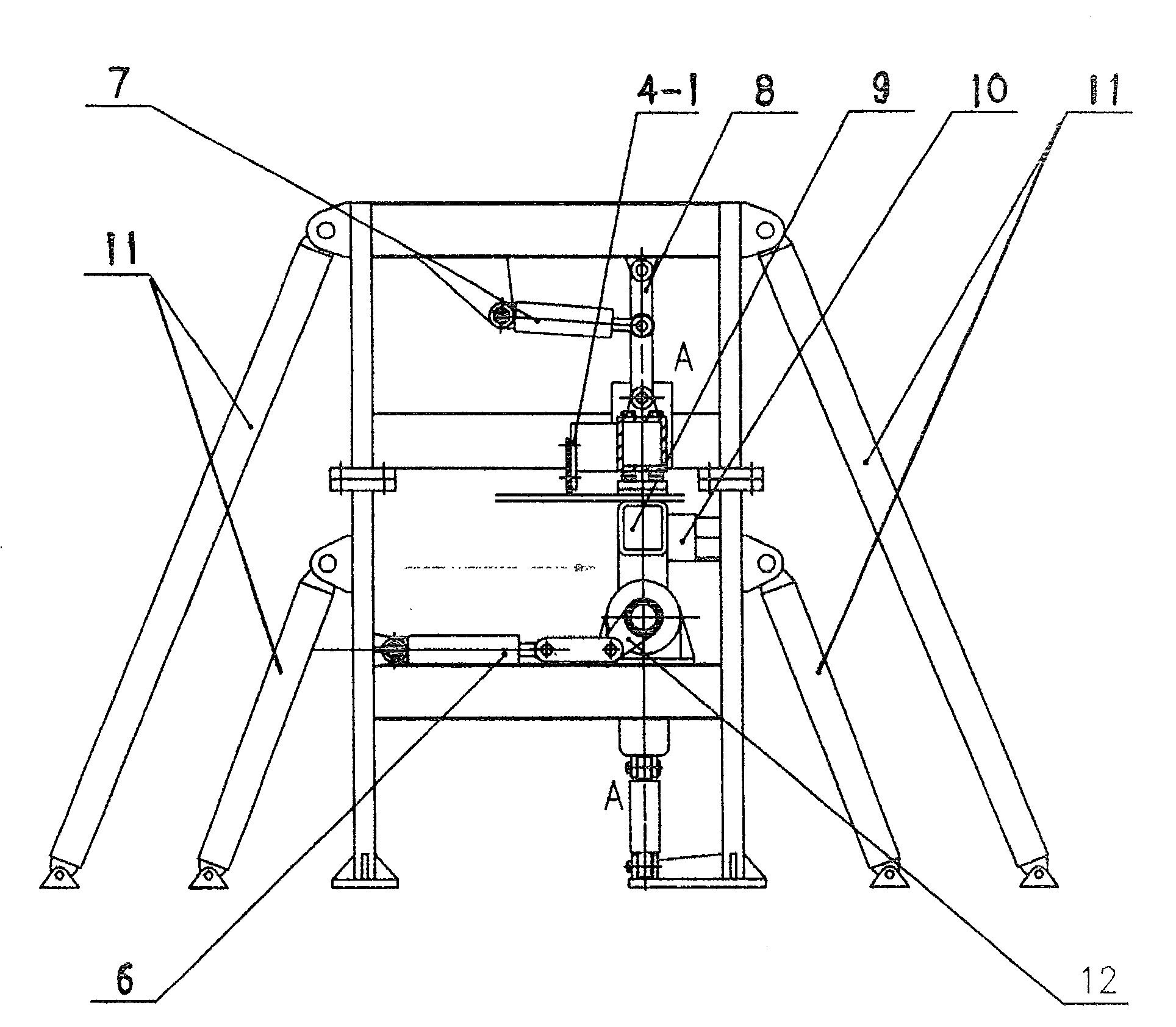

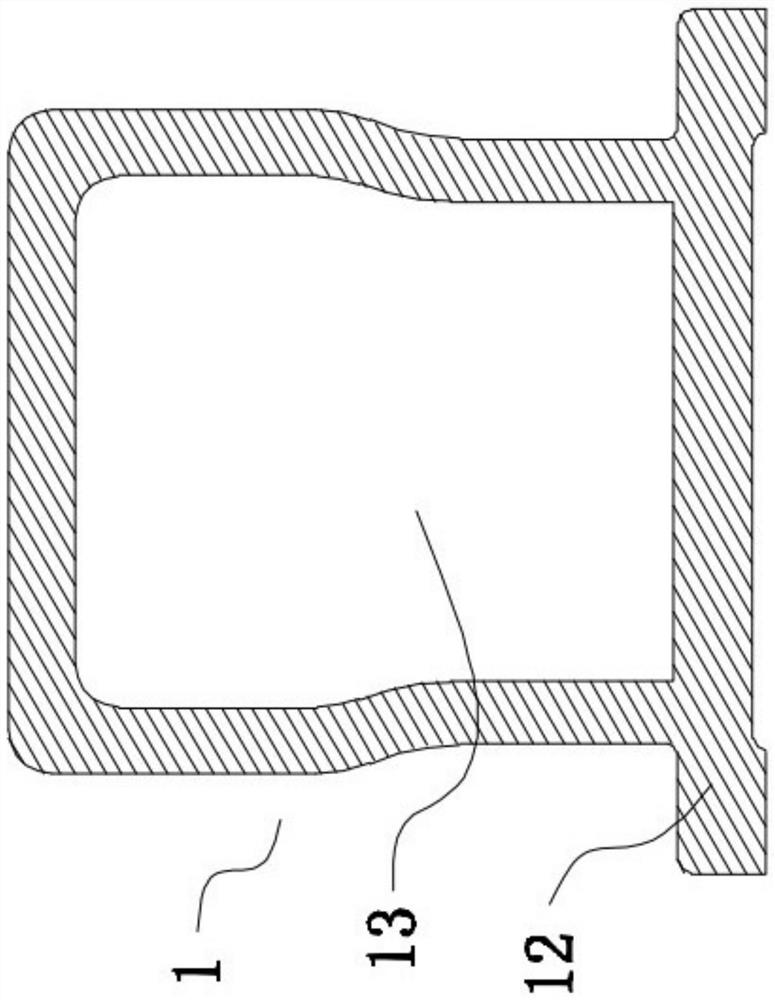

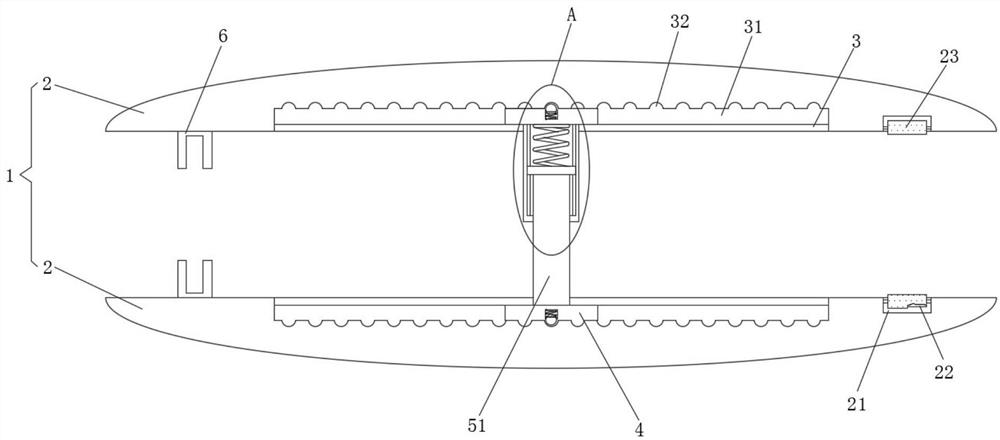

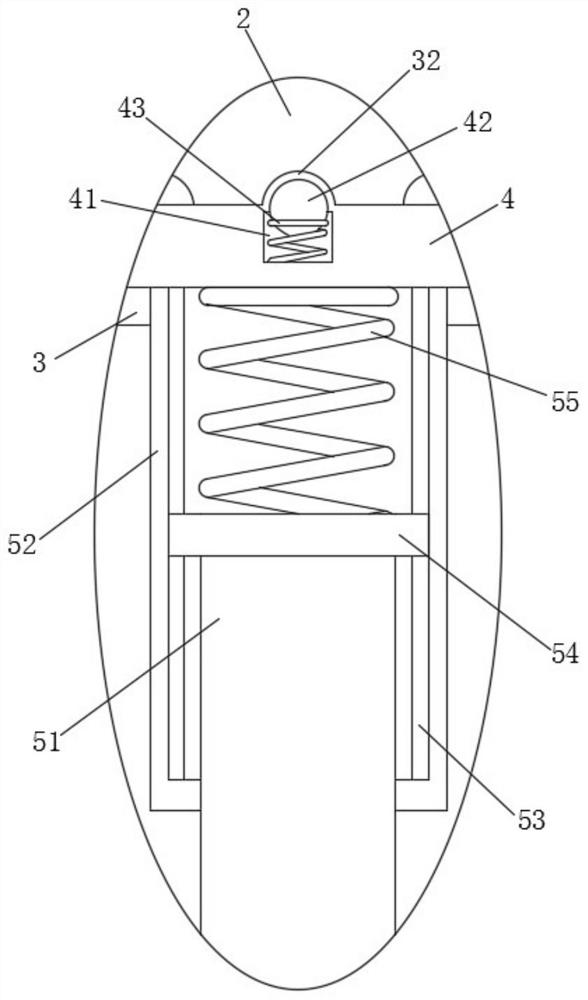

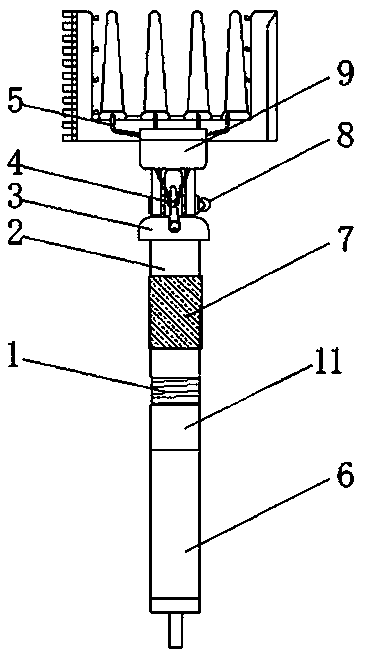

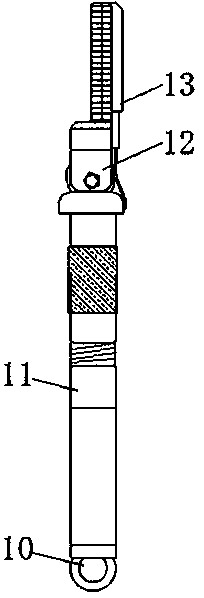

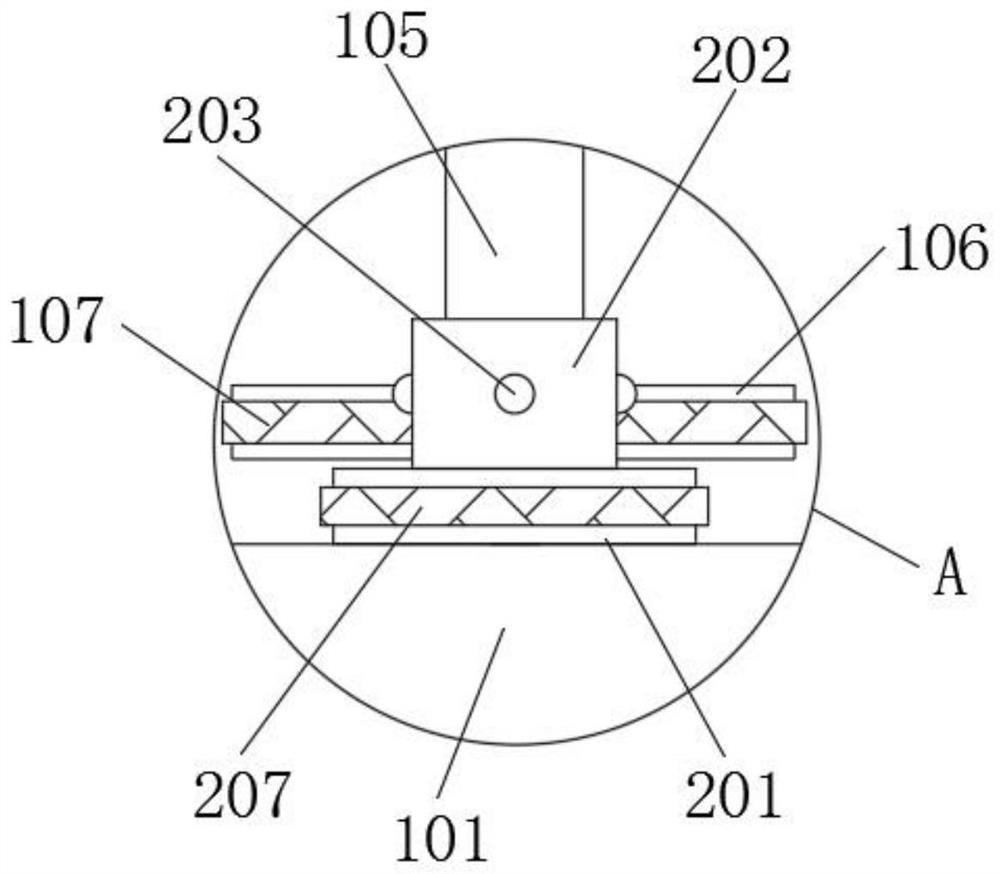

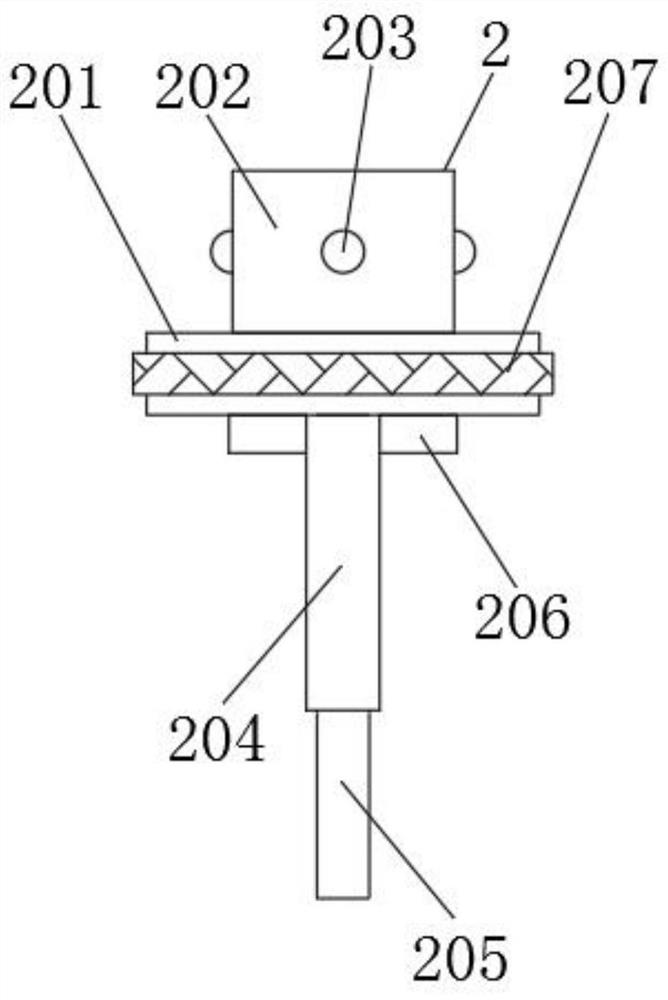

Surveying and mapping bracket device capable of being stably supported on flat road surface

InactiveCN112709913AIncrease contact areaIncrease friction factorStands/trestlesArchitectural engineeringStructural engineering

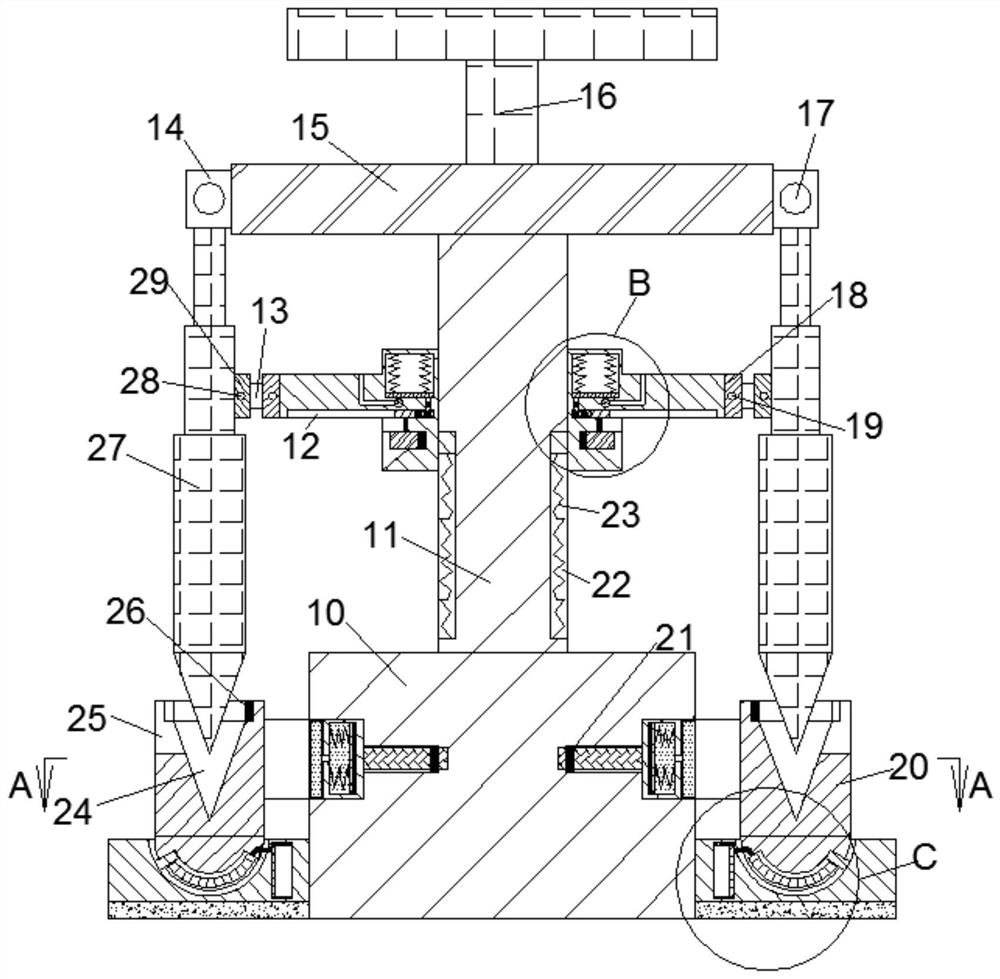

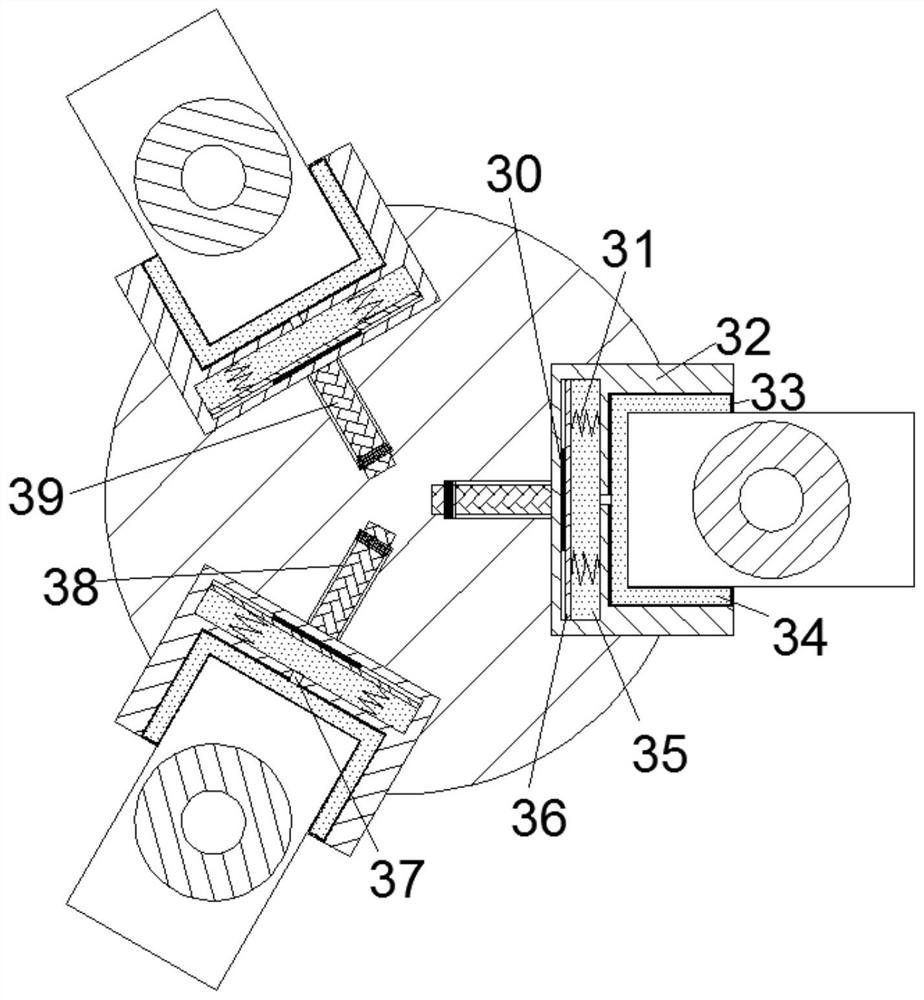

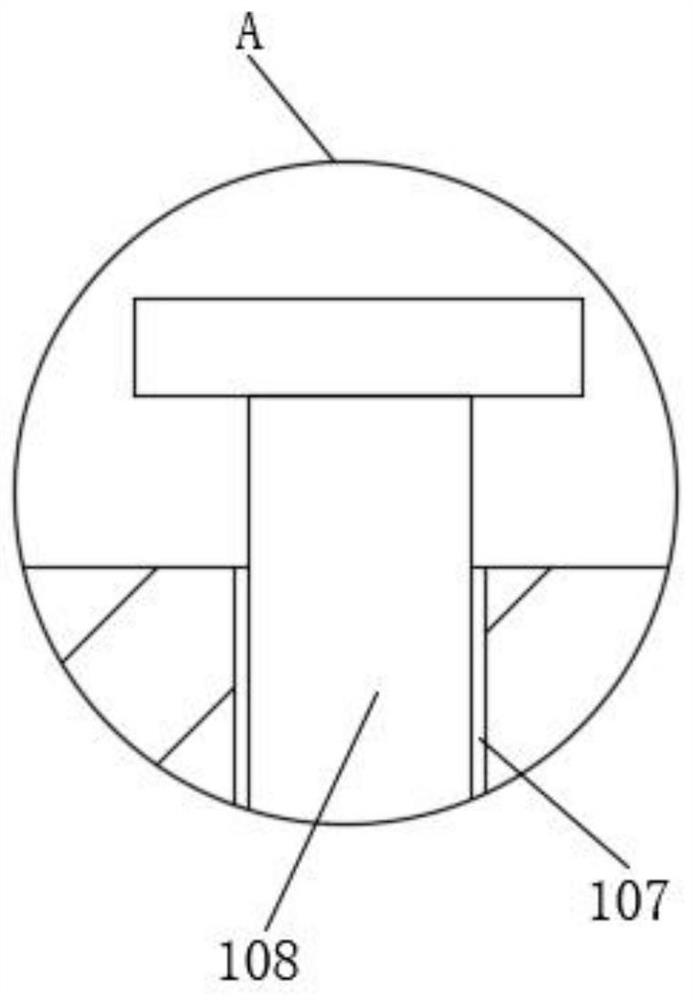

The invention discloses a surveying and mapping bracket device capable of being stably supported on a flat road surface. The surveying and mapping bracket device capable of being stably supported on the flat road surface comprises a base; a supporting rod is fixedly arranged at the top end of the base; three supporting sliding block sliding grooves with openings backing onto a center shaft of the supporting rod are evenly and fixedly formed in the supporting rod; a connecting balance weight mechanism is arranged at the position of each supporting sliding block sliding groove; three face expanding blocks are evenly and magnetically connected to the side wall of the base; anti-skid bottom plate blocks are fixedly arranged at the bottom ends of the face expanding blocks; hinge joint semispherical grooves with upward openings are fixedly formed in the top ends of the face expanding blocks; the hinge joint semispherical grooves are hinged to hinge joint semispheres; and hinge joint sliding rod sliding grooves with downward openings are fixedly formed in the bottom ends of the hinge joint semispheres. According to the surveying and mapping bracket device capable of being stably supported on the flat road surface, the contact area and the friction factor between the three sharp bottoms at the bottom end of the surveying and mapping bracket device and the ground can be automatically increased according to requirements, distance transportation of balancing weights can be automatically conducted according to the adjusted angle, and therefore supporting of a surveying and mapping bracket is further stabilized.

Owner:南京卓菲诗纸业有限公司

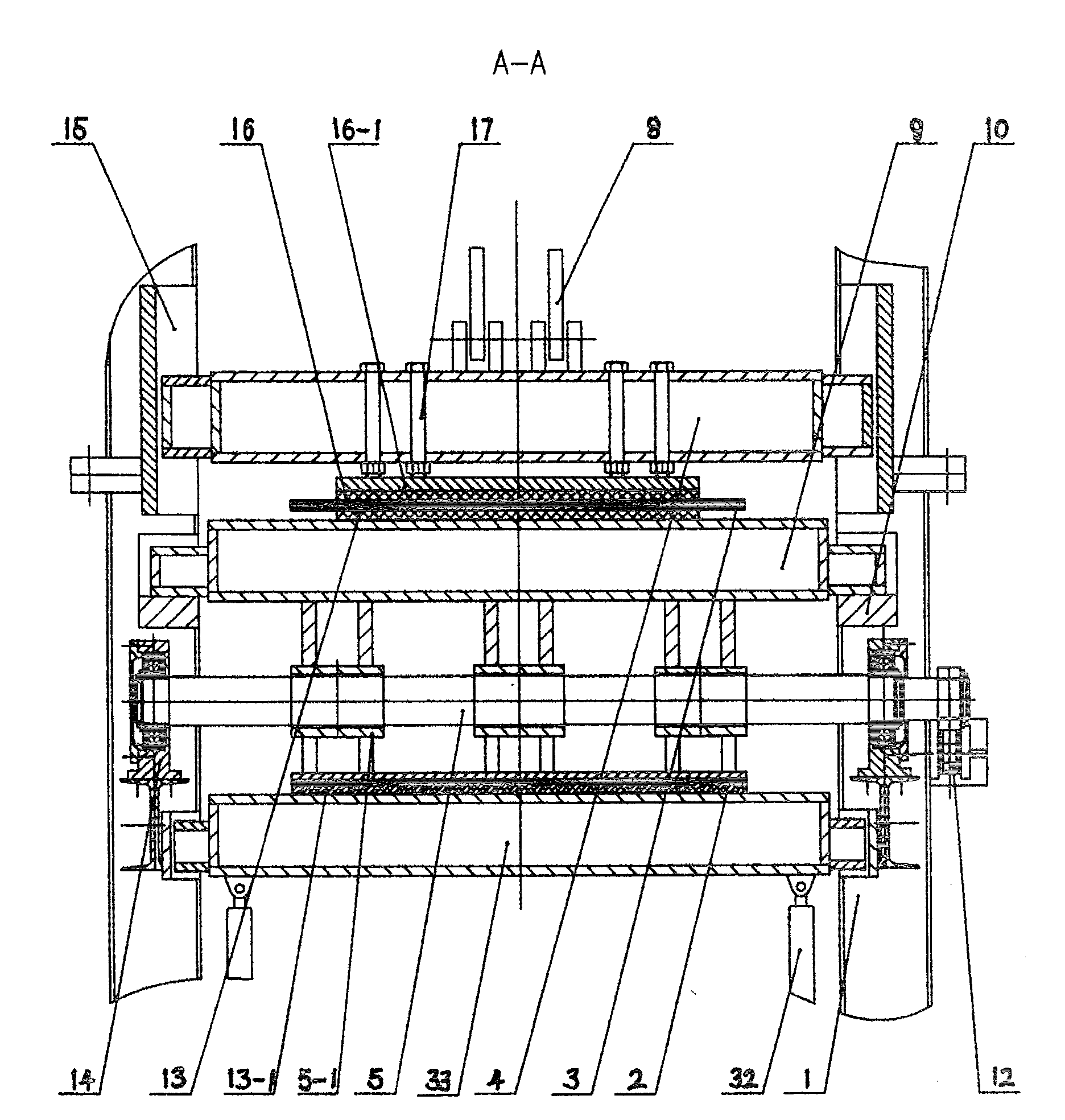

Plate deburring equipment

InactiveCN110883639AAvoid offsetIncrease frictionEdge grinding machinesGrinding drivesGear wheelPneumatic motor

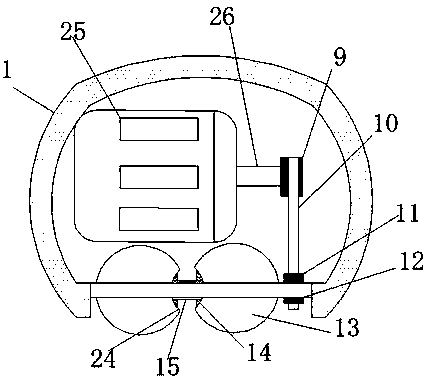

The invention discloses plate deburring equipment comprising a U-shaped groove. The top end of the U-shaped groove is fixedly connected with a power cabin with the top end fixedly connected with a pneumatic motor, and the output end of the pneumatic motor is fixedly connected with a rotating column; the bottom end of the rotating column is fixedly connected with a first bevel gear with the bottomend fixedly connected with first gears, and one side of the power cabin is rotatably connected with a rotating rod through a rotating shaft; the top end of the rotating rod is fixedly connected with asecond bevel gear, and the first bevel gear is engaged with the second bevel gear; the part, in the power cabin, of the top end of the U-shaped groove is rotatably connected with the rotating rod through the rotating shaft, and the top end of the rotating rod is fixedly connected with a second gear; and the first gears are engaged with the second gear, and the bottom end of the rotating rod is fixedly connected with a grinding column. Compared with an existing device, the plate deburring equipment has the advantages that the equipment is moved along the edge of a plate while the gears are driven by the pneumatic motor to engage mutually and the equipment is driven to grind the plate; and the deburring efficiency of the equipment is improved.

Owner:湖北乔木森家具有限公司

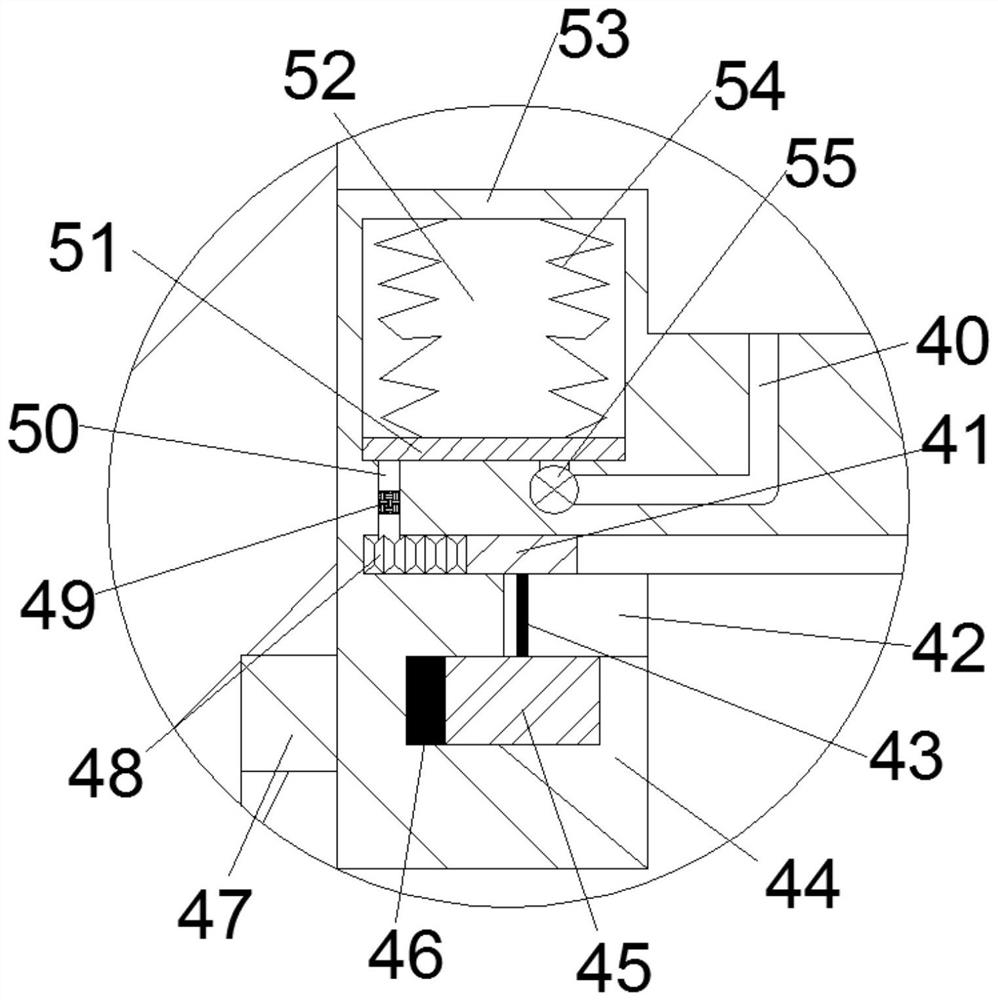

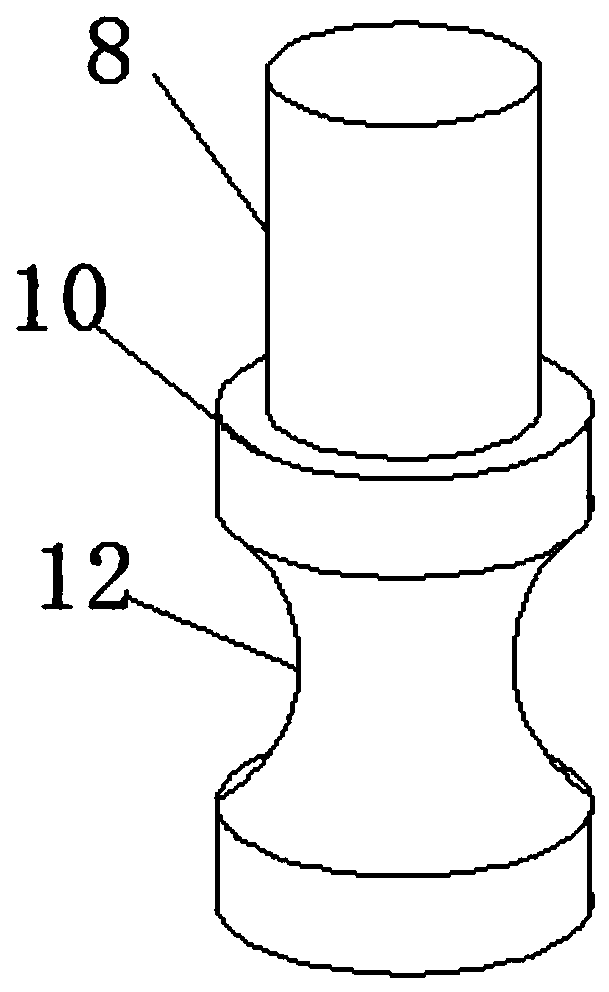

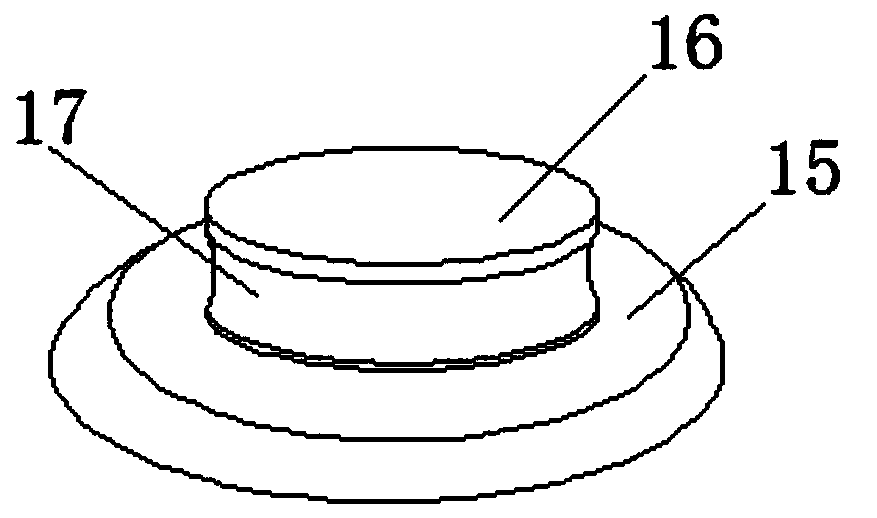

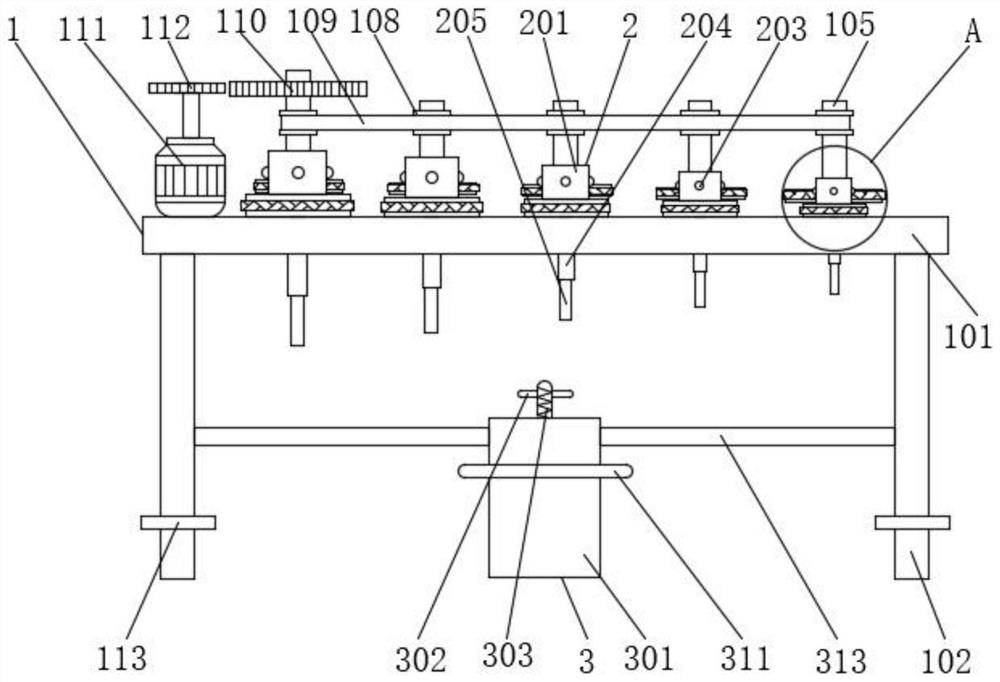

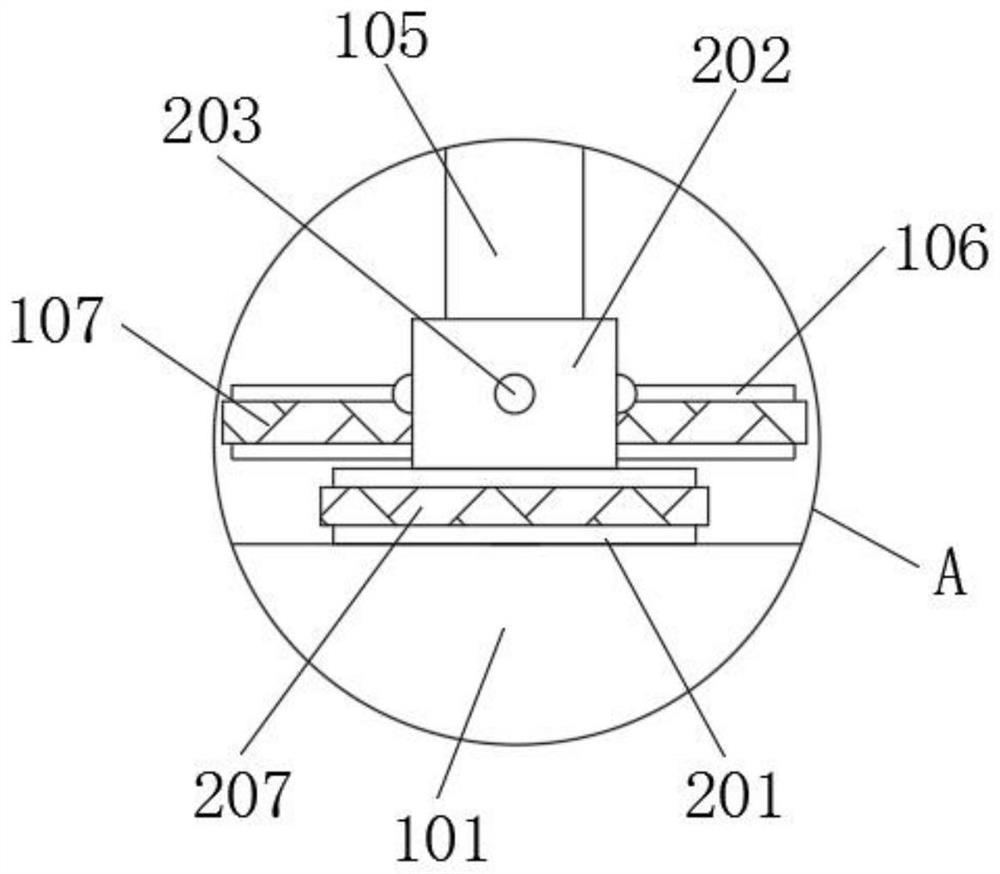

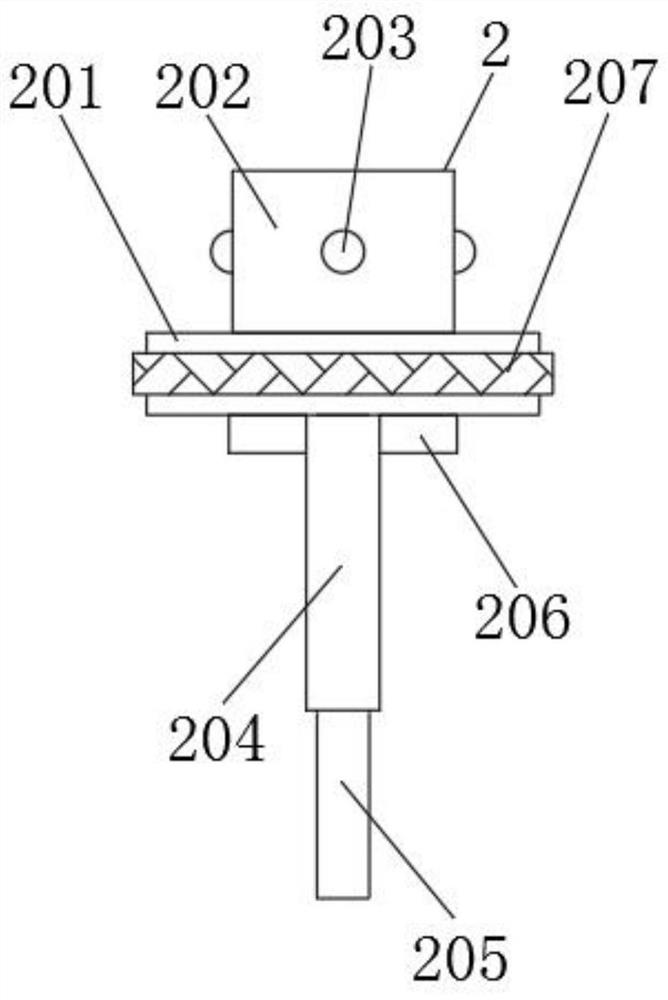

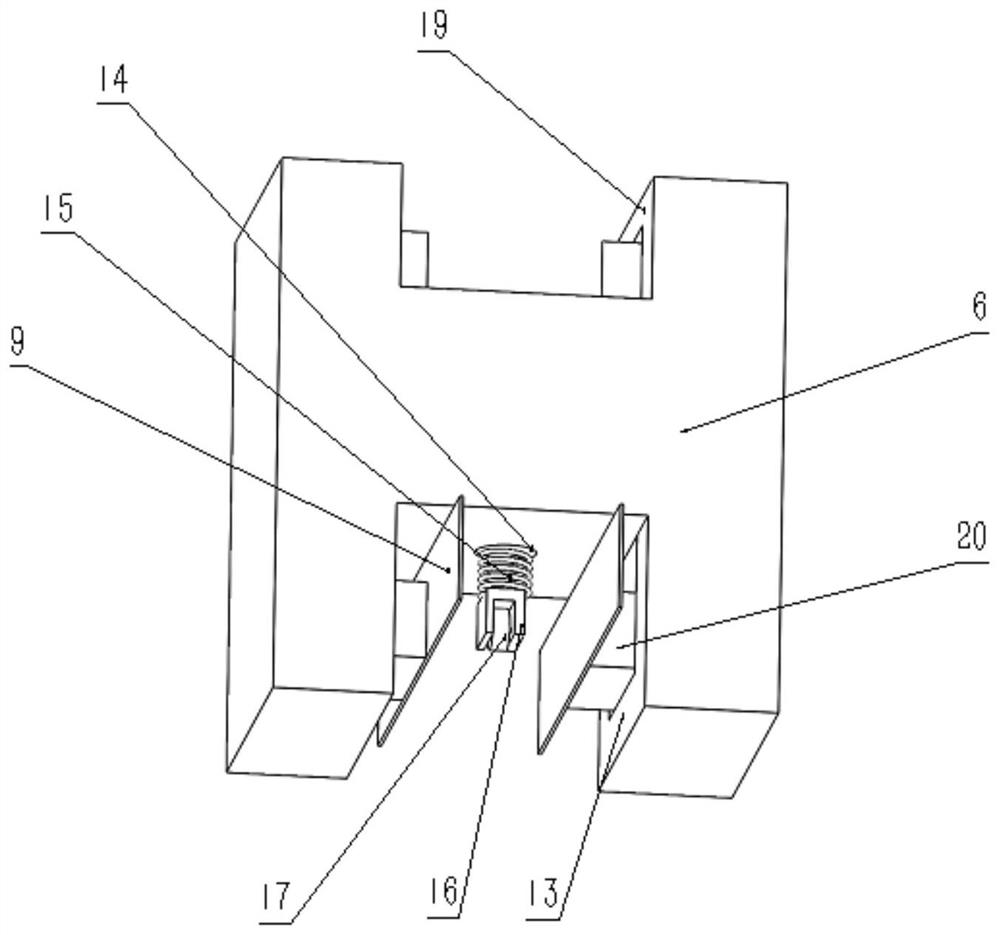

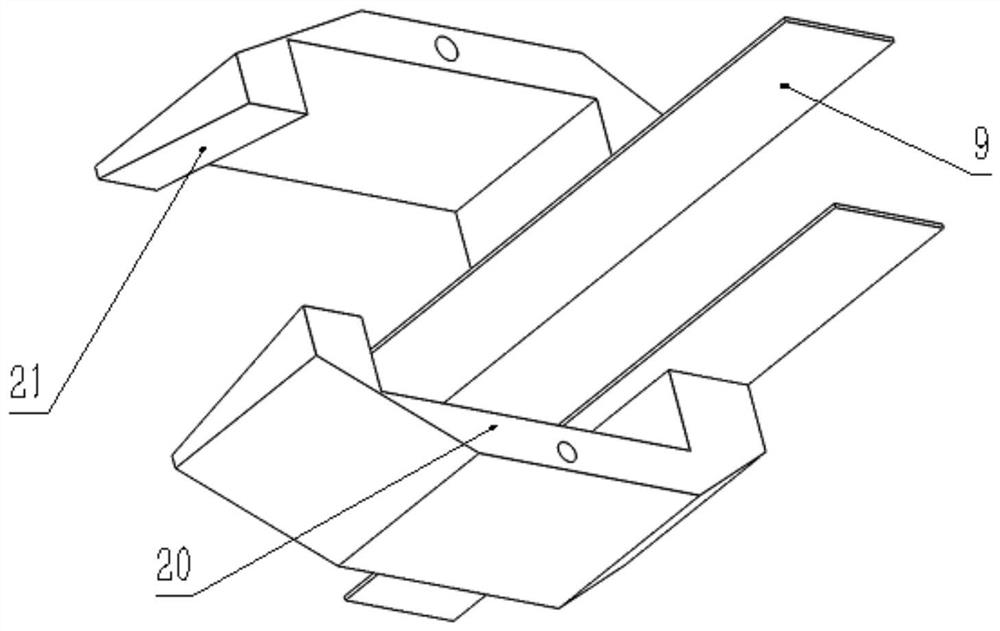

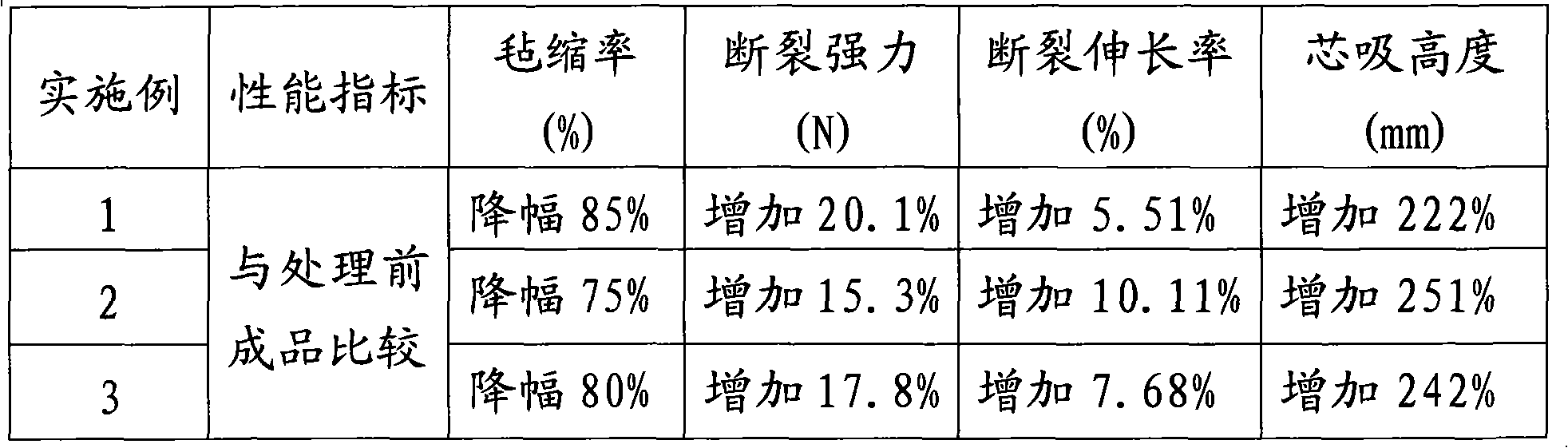

Multi-size screw fastening head placing platform for die assembling system

The invention discloses a multi-size screw fastening head placing platform for a die assembling system and belongs to the technical field of die assembling systems. The multi-size screw fastening headplacing platform comprises a placing mechanism, a plurality of screw fastening heads and a fixing mechanism; each of the screw fastening heads comprises a linkage wheel; a connector is fixedly connected with the top end of the linkage wheel; a hemispherical connecting fixture block is fixedly connected with the side face of the connector; a connecting rod is fixedly connected with the bottom endof the linkage wheel; a fastening rod for fastening a screw is fixedly connected with the bottom end of the connecting rod; the placing mechanism comprises a placing plate; four support frames distributed in a rectangular array are fixedly connected with the bottom of the placing plate; and two positioning blocks are fixedly connected with the bottom of the linkage wheel. The multi-size screw fastening head placing platform can automatically reset and calibrate the screw fastening heads on the platform to correctly reset the screw fastening heads and to prevent the situation that a screw locking robot cannot grab the screw fastening heads so as to further improve the production efficiency, and is convenient to fix and mount.

Owner:HAIAN DISCORY INSTR CO LTD

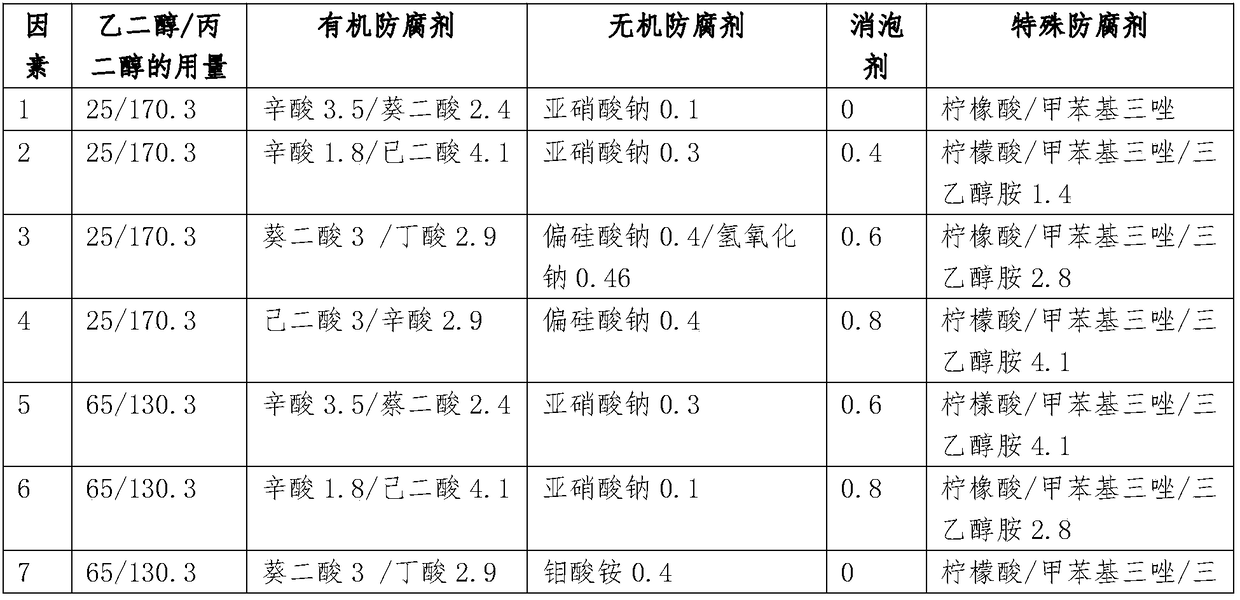

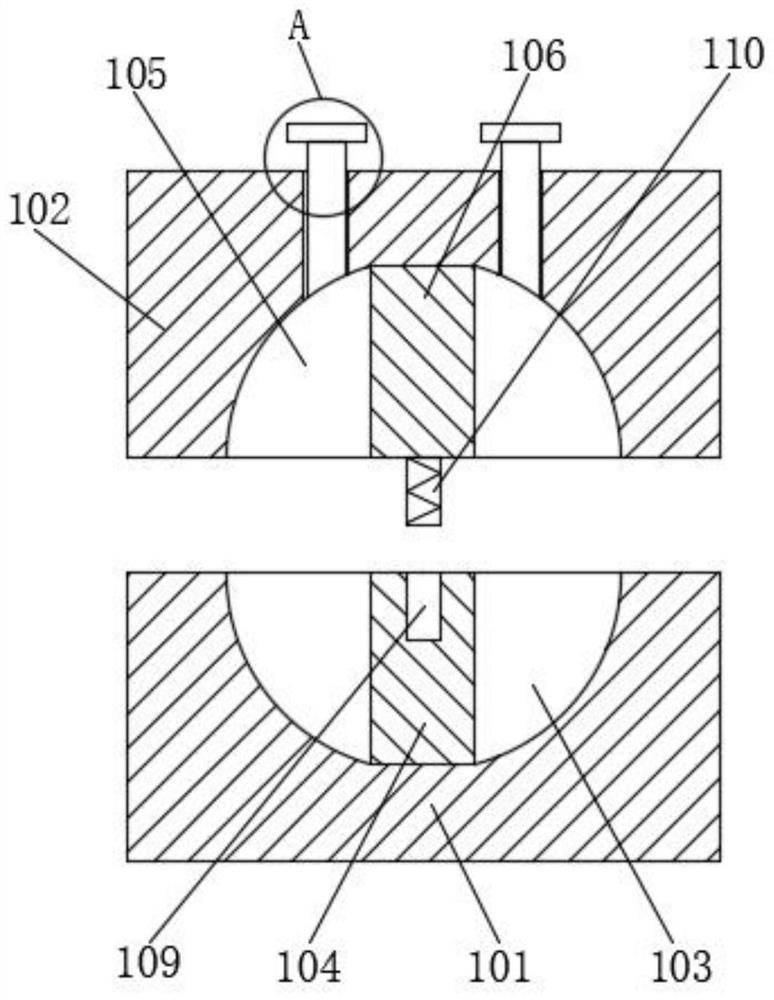

Anhydrous refrigerating fluid for internal combustion engine

InactiveCN108441176AIncrease heat transfer rateIncrease friction factorHeat-exchange elementsHigh resistanceCopper oxide

The invention discloses anhydrous refrigerating fluid for an internal combustion engine, and relates to the technical field of refrigerating fluid. The anhydrous refrigerating fluid is prepared from the following raw materials in percentage by mass: 85.53 to 95.0 percent of basic liquid, 1.2 to 3.0 percent of nano-particles, 1 to 3 percent of alkaline supplement agent, 0.75 to 1.47 percent of corrosion inhibitor, 0.5 to 2.0 percent of anti-foaming agent, and 2 to 5 percent of additive. A pH value is stabilized at 7.5 to 8.0; the basic liquid is prepared from mixed alcohol of ethylene glycol and propylene glycol; a nano-particle mixture is prepared from copper oxide nano-particles, silicon dioxide nano-particles and aluminum oxide nano-particles; the corrosion inhibitor is prepared from a mixture of sodium benzoate, heptanoic acid, toluene triazole, triazole, isooctanoic acid and diethylene glycol monomethyl ether. The anhydrous refrigerating fluid disclosed by the invention has high performance on comprehensive protection of multiple metals of an automobile cooling system; the complex type anhydrous refrigerating fluid has the advantages of good corrosion inhibitive ability, longlasting property, storage stability, high resistance to hard water, environmental friendliness and safety.

Owner:安徽职业技术学院

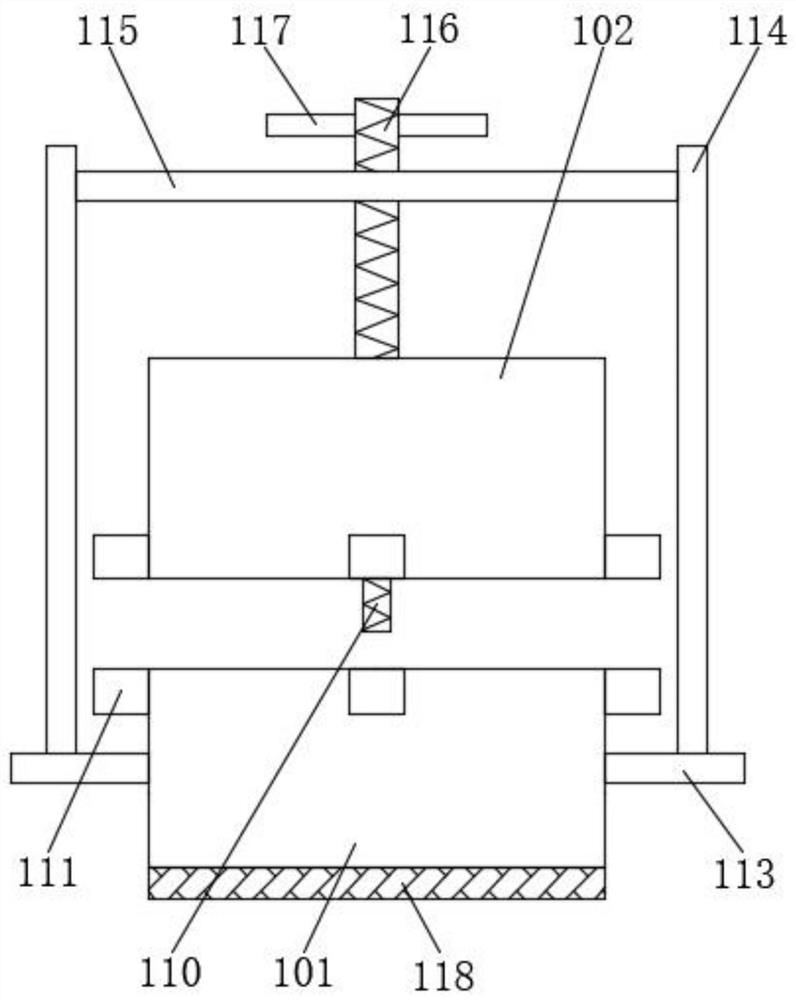

Manufacturing process of ball valve ball

ActiveCN111872329AImprove wear resistanceExtended service lifeFoundry mouldsFoundry coresPunchingManufacturing technology

The invention discloses a manufacturing process of a ball valve ball, and belongs to the technical field of ball valve ball manufacturing. The manufacturing process of the ball valve ball comprises the following steps of casting forming, mold opening for taking out, slotting, polishing, cleaning and surface spraying. A die mechanism comprises a lower die and an upper die, a hemispherical lower diecavity is formed in the outer wall of the top of the lower die, a cylindrical lower column core is fixedly connected to the middle of the lower die cavity, an upper die cavity matched with the lowerdie cavity is formed in the outer wall of the bottom of the upper die, and an upper column core matched with the lower column core is fixedly connected to the middle of the upper die cavity. Through the arrangement of the die mechanism special for casting forming of the ball valve ball and an extraction mechanism used in cooperation, after casting forming is carried out, a blank ball body is convenient to take out, production losses are reduced, and the production efficiency is improved; and in the casting forming process, a middle through hole is integrally formed, the subsequent punching procedure is reduced, and the working efficiency is further improved.

Owner:前程控股集团有限公司

Foreign body removal device for high voltage transmission line

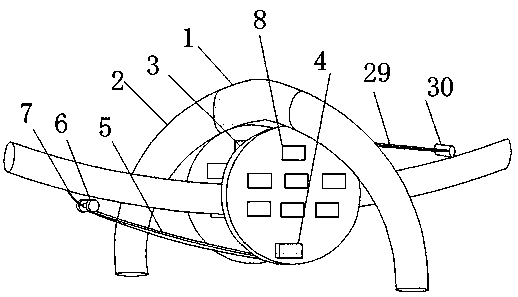

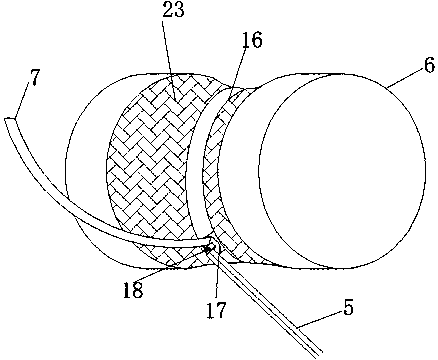

InactiveCN110504639ASolve processing problemsContact will notApparatus for overhead lines/cablesHigh pressureScrub brushes

The invention belongs to the technical field of electrical equipment and in particular relates to a foreign body removal device for a high voltage transmission line. Aiming at solving the technical problems that an existing electric transmission line cleaning device is difficult to clean foreign bodies on a transmission line and especially cleaning effect is poor for wound foreign bodies such as plastic bags, the following scheme is put forward, namely the foreign body removal device for the high voltage transmission line comprises a power box, the two sides of the power box are respectively rotatably connected with an arc-shaped balance bar by virtue of a spindle, the bottom of each arc-shaped balance bar is fixedly connected with a counterweight plate, a first rotary rod is rotatably connected between the bottoms of the two counterweight plates by virtue of a spindle, one side of the first rotary rod is fixedly connected with a first cleaning rod, one end of the first cleaning rod isrotatably connected with a rotary groove by virtue of a spindle, and one end of the rotary groove is fixedly connected with a sliding column. In the foreign body removal device provided by the invention, an arc-shaped triangular knife is arranged, the plastic bags on the transmission line are cut by virtue of the arc-shaped triangular knife, and tiny foreign bodies on the transmission line are seamlessly cleaned by virtue of coordination of a ring-shaped scrubbing brush and a brush substrate, so that the cleaning effect is improved.

Owner:HUBEI UNIV

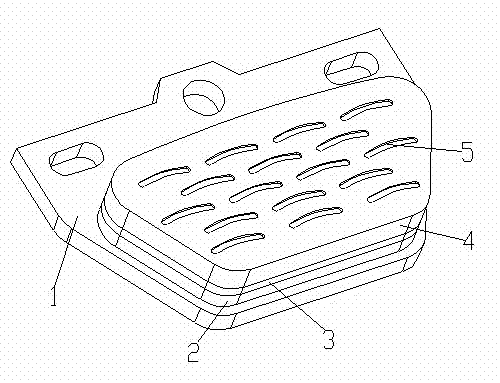

Brake pad

InactiveCN103089873AImprove cooling effectExtended service lifeFriction liningSlack adjustersInsulation layerMechanical engineering

The invention discloses a brake pad which comprises a steel plate, a friction block and a bonding heat insulation layer between the steel plate and the friction block. The brake pad is characterized in that a heat dissipation layer is arranged between the bonding heat insulation layer and a non-friction face of the friction block, an arc-shaped groove is arranged on a friction face of the friction block, the width of the arc-shaped groove is 1mm, the depth of the arc-shaped groove is 0.3mm, and the heat dissipation layer is composed of heat dissipation sheets. The design of the heat dissipation layer is favorable for rapid emission of heat produced on the friction block, service life of the friction block is prolonged, the design of the arc-shaped groove on the surface of the friction face quickens heat dissipation of the friction block, friction coefficients of the friction block are improved, and abrasion of the friction block is reduced.

Owner:盛土根

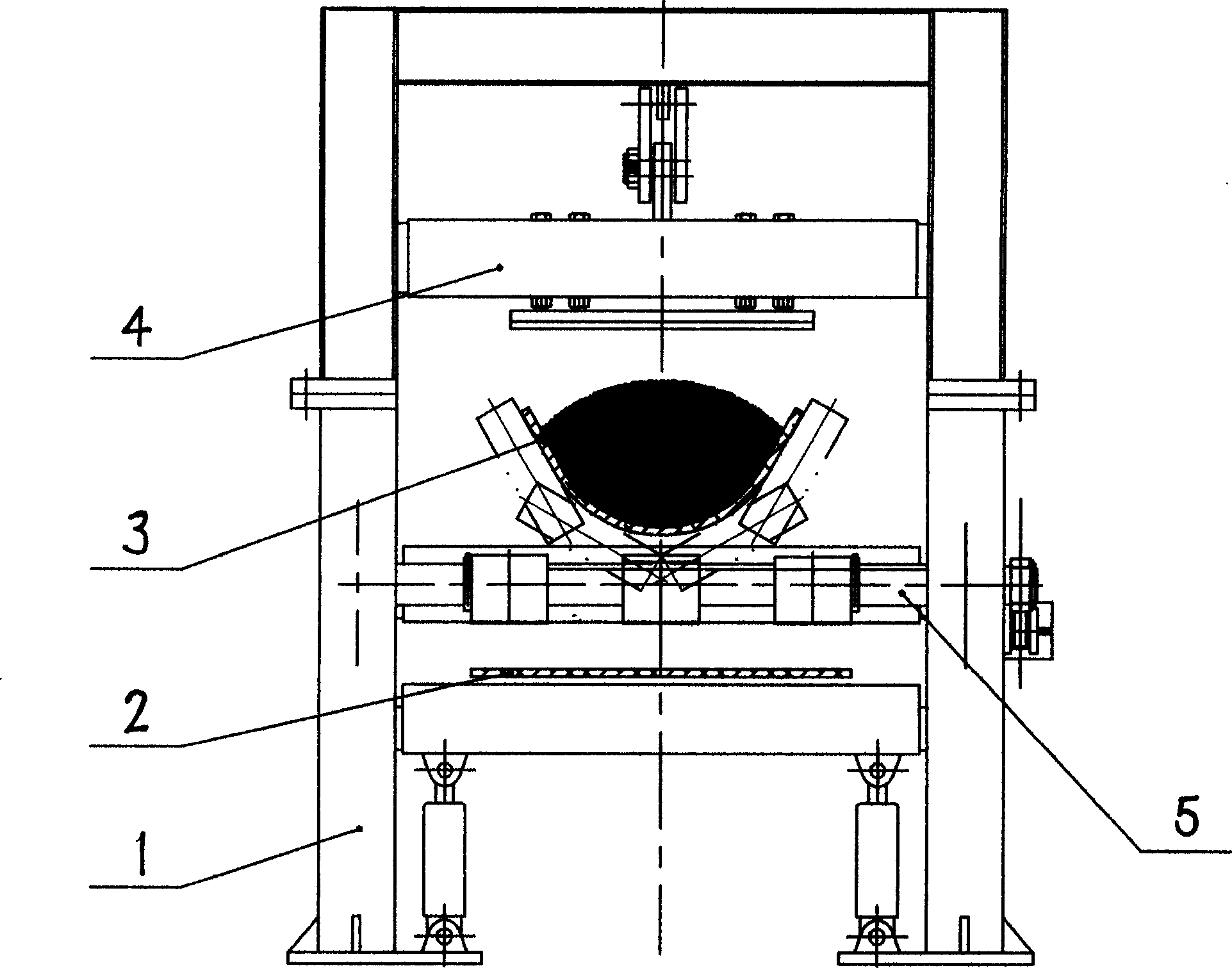

Belt-breaking hydraulic protection device for belt conveyor

InactiveCN1884018AIncrease friction factorStrong brakingControl devices for conveyorsEngineering safety devicesAirbag deploymentEngineering

A belt breakage hydraulic protection apparatus for a belt conveyor comprises multiple belt breakage hydraulic protection apparatuses equipped on the belt conveyor, corresponding multiple sensors, a control system composed of a terminal programmable controller and multiple sub-station PLC programmable controllers via advanced communication modules, and multiple hydraulic pump stations, wherein the electric control system can acquire and judge the belt breakage signals in time and send out instructions without resulting in mistaken braking actions, the actuating mechanism of the belt breakage hydraulic protection apparatus employs the oil pumps of hydraulic pump stations and multiple airbag type accumulators to transport high pressure oil to a pull-push oil cylinder, a rotary cylinder and a lifting cylinder, the cylinders drive a top-rising beam below the upper belt to rotate and an up-pressing beam above the upper belt to move up and down to press the broken upper belt; the lifting cylinder lift a lifting beam to move up and down to press the broken lower belt. The top-rising, up-pressing beam and lifting beam have a case type structure, and friction plates are disposed between the beams and the belt contact surface to get big brake force and obvious brake effect, so that the conveyor will not generate loading stop phenomenon and abrade the belt.

Owner:蔡瑜

Belt-breaking hydraulic protection device for belt conveyor

InactiveCN100581947CEasy to controlAvoid accidentsControl devices for conveyorsEngineering safety devicesAdhesive beltControl system

A belt breakage hydraulic protection apparatus for a belt conveyor comprises multiple belt breakage hydraulic protection apparatuses equipped on the belt conveyor, corresponding multiple sensors, a control system composed of a terminal programmable controller and multiple sub-station PLC programmable controllers via advanced communication modules, and multiple hydraulic pump stations, wherein the electric control system can acquire and judge the belt breakage signals in time and send out instructions without resulting in mistaken braking actions, the actuating mechanism of the belt breakage hydraulic protection apparatus employs the oil pumps of hydraulic pump stations and multiple airbag type accumulators to transport high pressure oil to a pull-push oil cylinder, a rotary cylinder and a lifting cylinder, the cylinders drive a top-rising beam below the upper belt to rotate and an up-pressing beam above the upper belt to move up and down to press the broken upper belt; the lifting cylinder lift a lifting beam to move up and down to press the broken lower belt. The top-rising, up-pressing beam and lifting beam have a case type structure, and friction plates are disposed between the beams and the belt contact surface to get big brake force and obvious brake effect, so that the conveyor will not generate loading stop phenomenon and abrade the belt.

Owner:蔡瑜

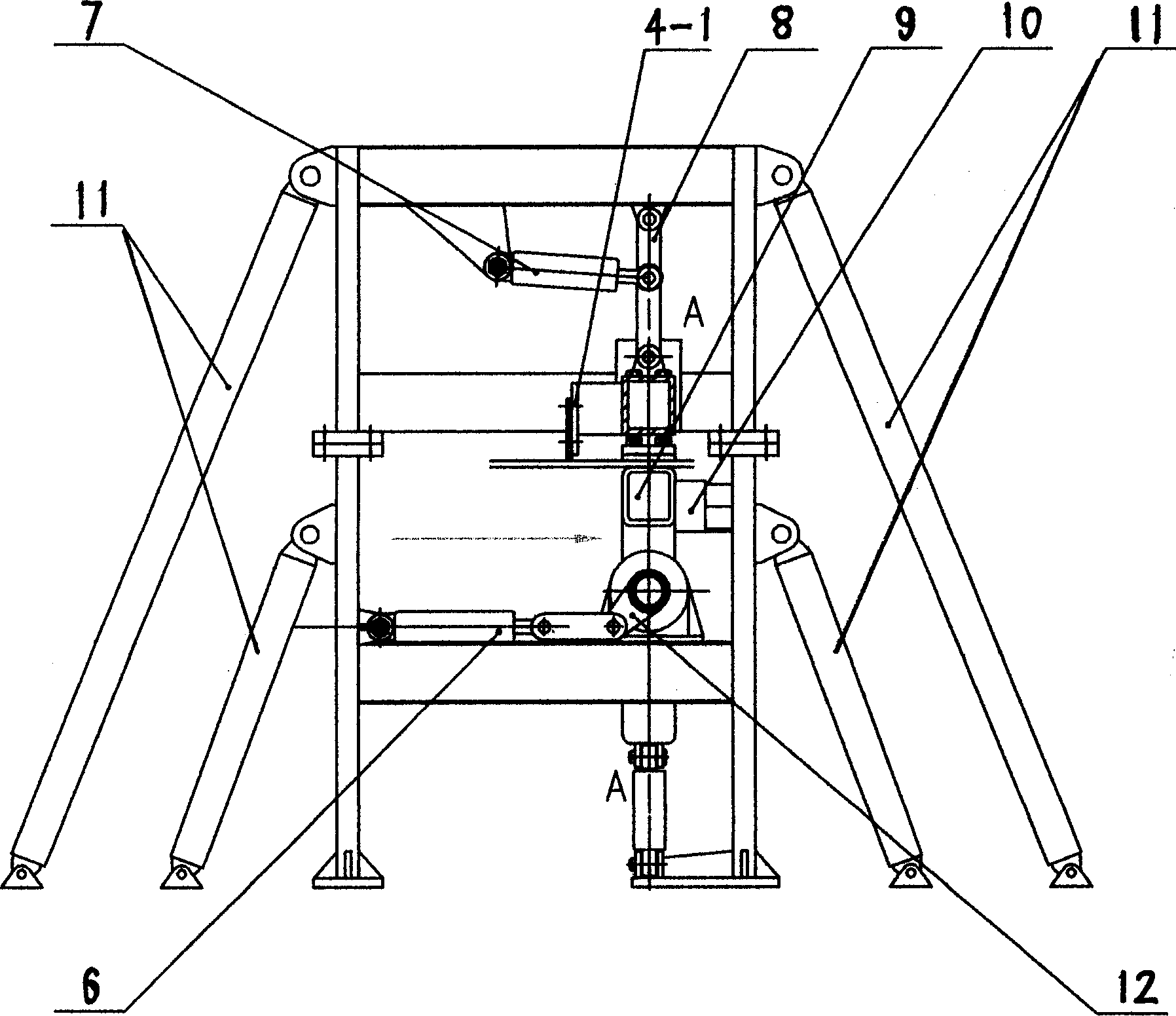

Locking device for preventing elevator from accidentally falling

A locking device for preventing an elevator from accidentally falling is used for safety protection for preventing the elevator from accidentally falling in the running process of the elevator and belongs to the technical field of manufacturing of auxiliary equipment for preventing the elevator from accidentally falling due to faults. The locking device comprises a gearbox and speed limiting mechanisms. Two gears which are engaged are rotationally arranged in the gearbox, and gear shafts of the gears are horizontal. Obliquely-downward connecting rods are fixedly connected to the positions, away from the engagement position, of the gears, the middle points between the two ends of the connecting rods are hinged to the tail ends of traction ropes of the speed limiting mechanisms, the ends, away from the gears, of the connecting rods are rotationally connected with sliding blocks, and the sliding blocks are connected with elevator guide rails in a sliding manner. By means of the locking device for preventing the elevator from accidentally falling, the manner that the gears are connected with the connecting rods is adopted, the elevator is prevented from falling accidentally in the manner of applying force through the connecting rods and increasing the friction force between the sliding blocks and the elevator guide rails, and the problem that an existing elevator safety anti-falling device is likely to be disturbed by external conditions due to the fact that electrical elements are adopted is solved.

Owner:贵州梯安客机电设备有限公司

Underground mining braking sparkless friction material and preparation method thereof

InactiveCN106085357AHigh compressive strengthIncrease friction factorOther chemical processesFriction liningFiberWollastonite

The invention provides an underground mining braking sparkless friction material. The underground mining braking sparkless friction material comprises the following components by mass: 1-9 parts of flame retardant fiber, 15-30 parts of reinforcing fiber, 1-8 parts of mixed powder of nano copper and electrolytic copper, 5-16 parts of g-C3N4, 1-6 parts of zirconia, 1-6 parts of silicon carbide, 8-12 parts of a modified resin mixture, 2-5 parts of magnesium hydroxide, 10-28 parts of barium sulfate, 1-3 parts of friction powder, and 8-12 parts of wollastonite. The flame retardant fiber and magnesium hydroxide, wollastonite involved in the friction material play a synergistic flame retardant role together and ensures sparkless braking of the friction material.

Owner:TRIUMPH HEAVY IND

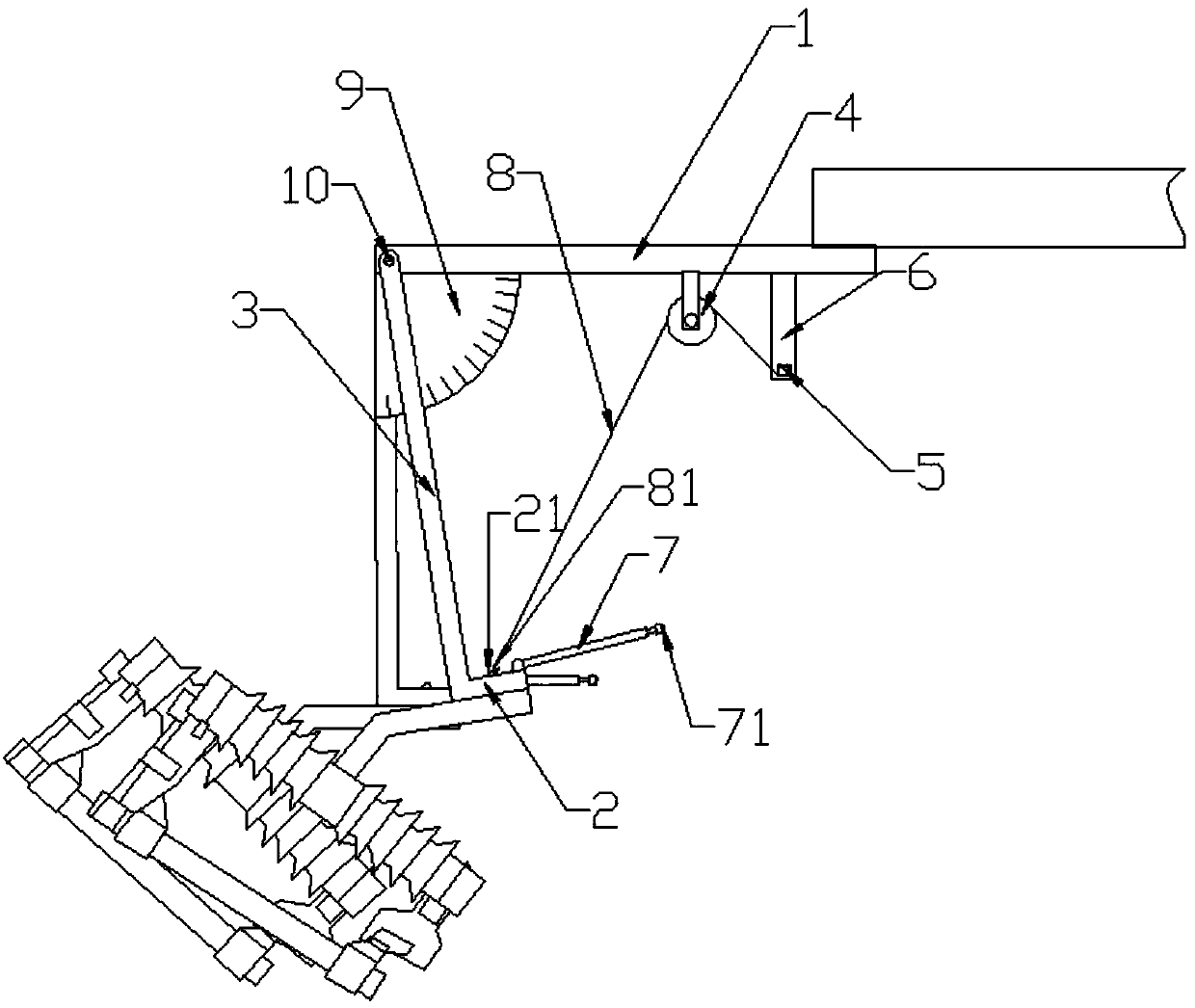

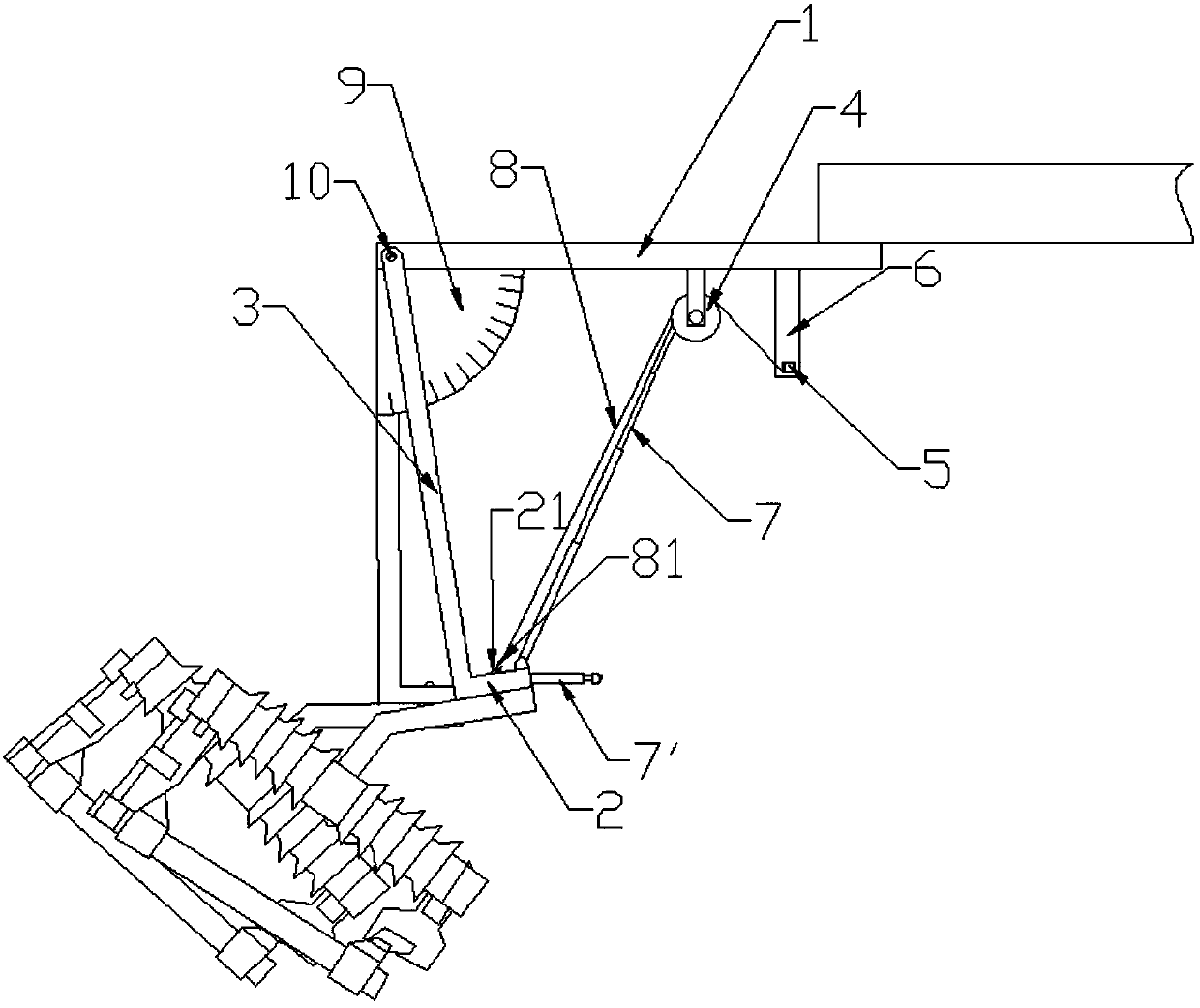

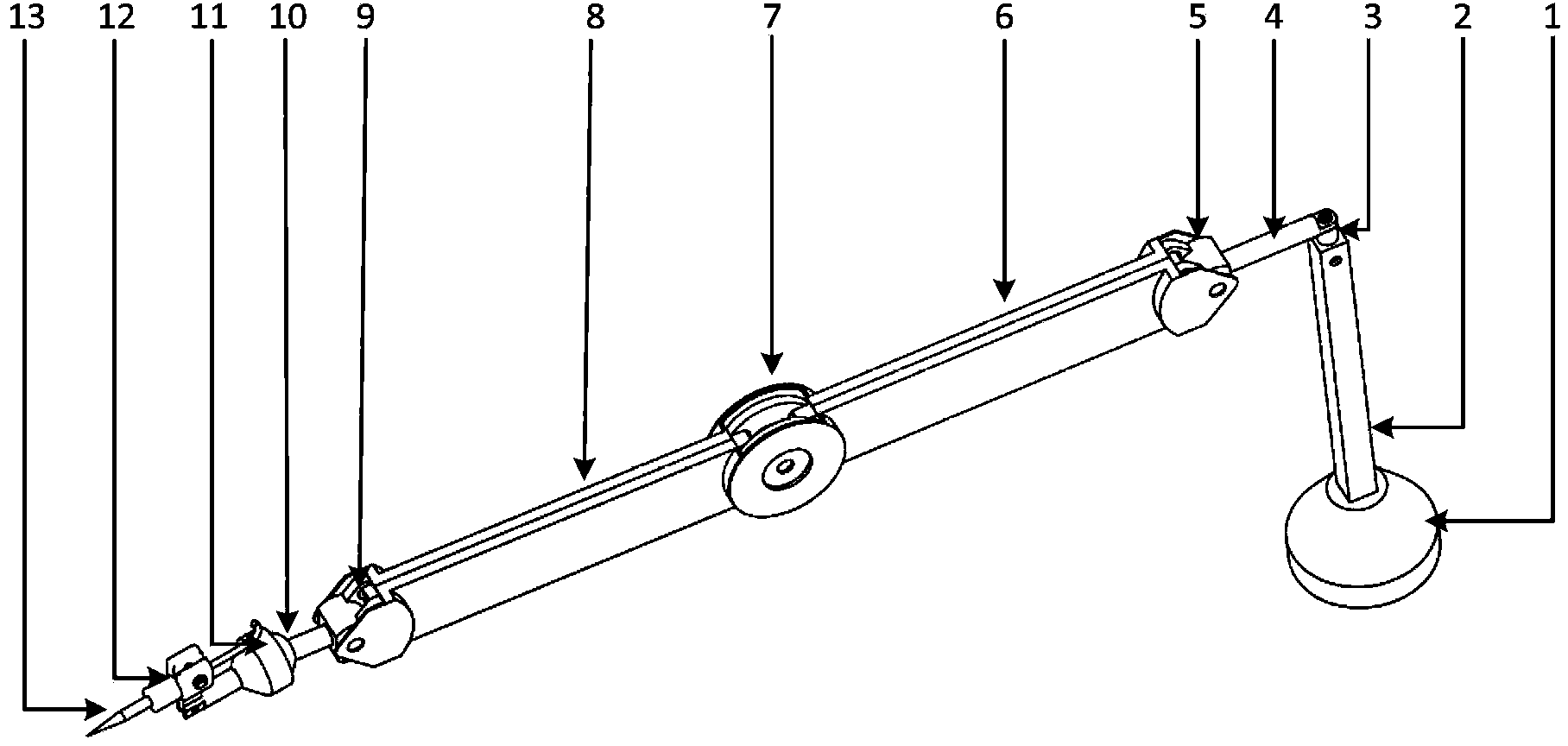

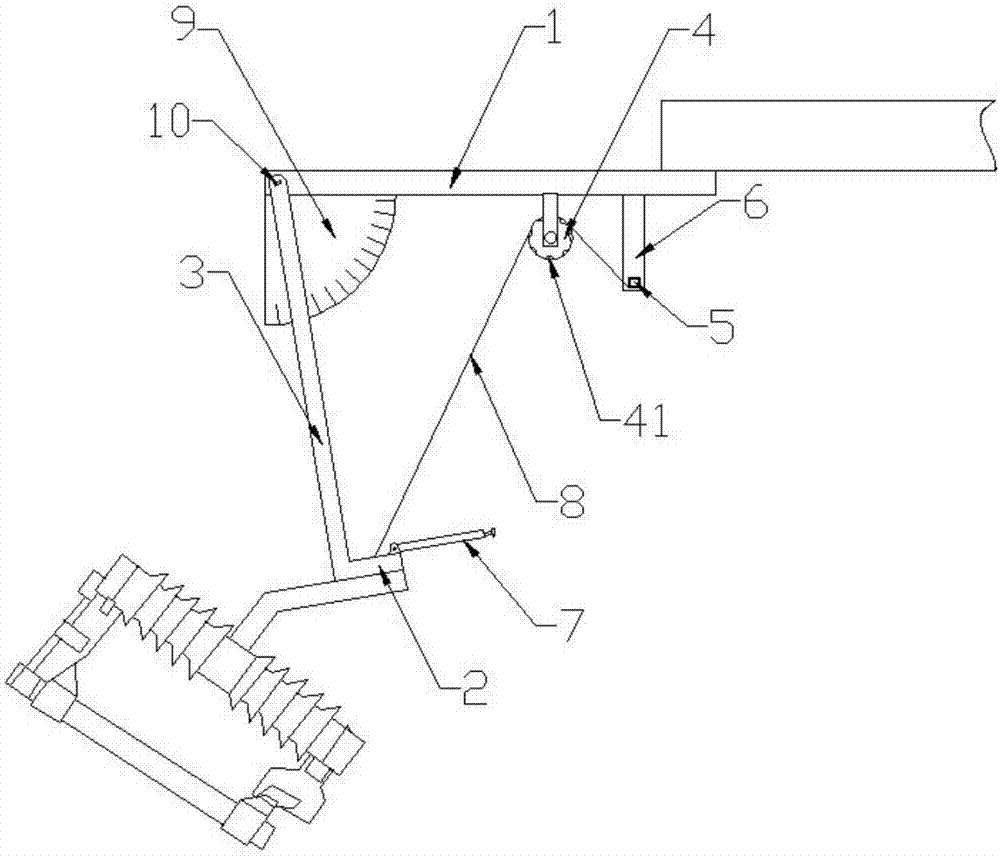

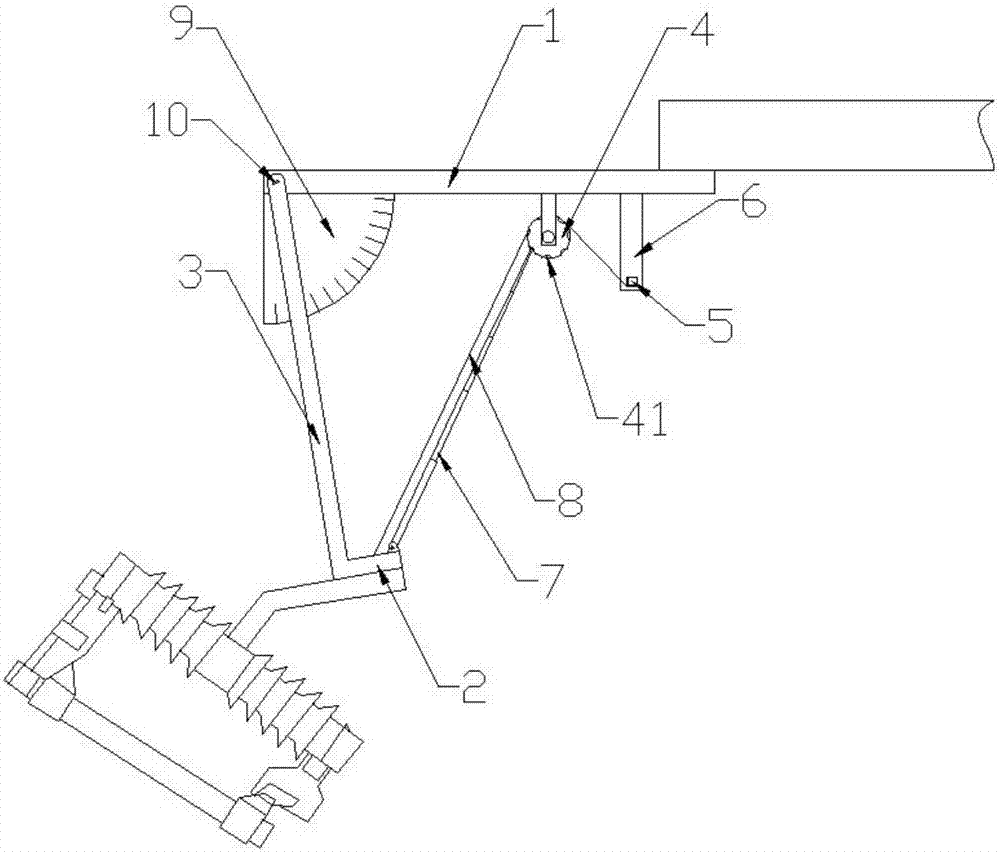

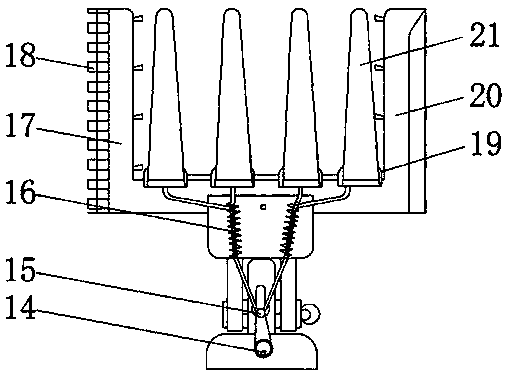

A drop-out fuse replacement device

InactiveCN105788989BFlexible adjustment of installation angleGuaranteed to workEmergency protective devicesEngineeringDrop out

The invention discloses a drop fuse replacement apparatus. The drop fuse replacement apparatus comprises a top plate, wherein a pair of linkage mechanisms are symmetrically connected to the front and back sides of the left end part of the top plate through a rotary shaft; each linkage mechanism comprises a rotary rod, a connecting plate, a hanging ring and a telescopic insertion rod; the connecting plate is provided with the hanging ring connected with a hook; each connecting plate is connected with a drop fuse; a fixed pulley and an insertion rod are arranged on the right side of the rotary shaft in sequence; the hook and the hanging ring connected with one connecting plate through the hook are arranged at one end of a cable rope penetrating through the fixed pulley; the other end of the cable rope is connected with a side wall of a winding column; a limiting insertion hole for the winding column to be inserted is formed in the insertion rod; a plurality of insertion holes are formed in the outer side wall of the rotary shaft of the fixed pulley; the telescopic insertion rod is arranged on the connecting plate; and a plug capable of being inserted and fixed in the insertion hole is arranged at the top of the telescopic insertion rod. According to the apparatus, a mounting angle of the drop fuse can be adjusted and the drop fuse can be firmly fixed and mounted; and a standby apparatus is provided, so that after a used device is damaged, the replacement and installation can be conveniently carried out and the repair efficiency can be improved.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

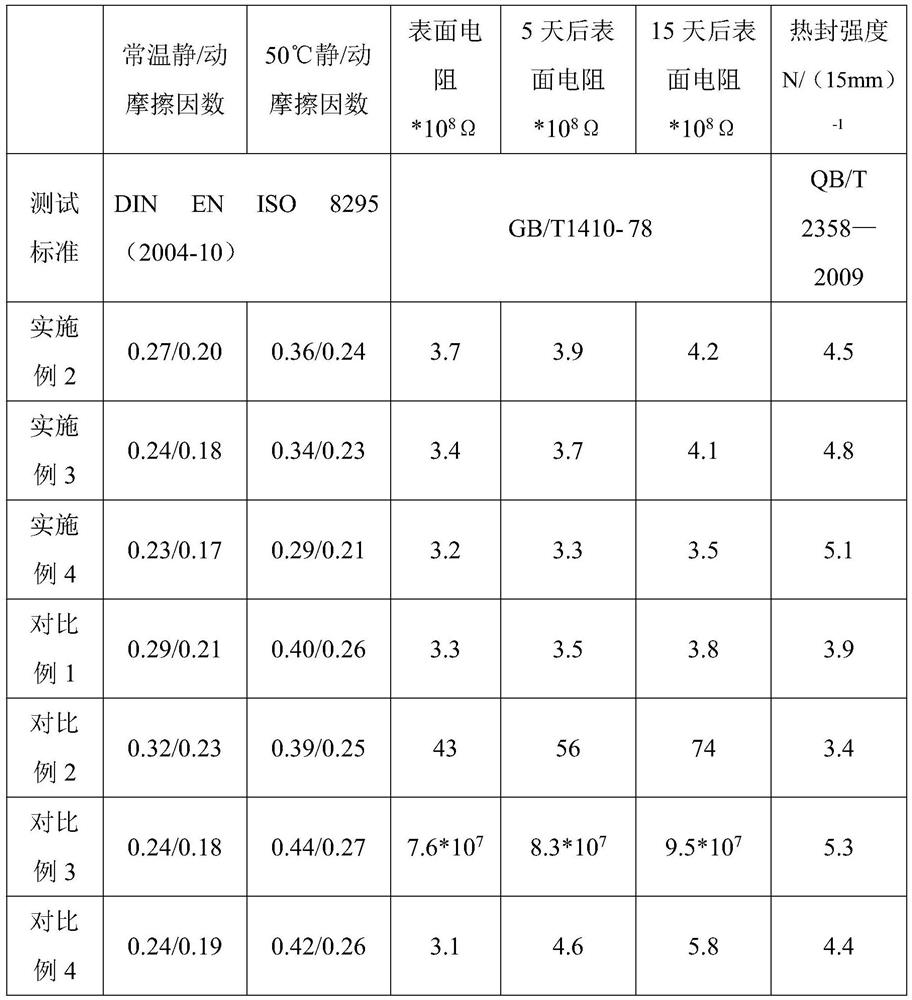

heat-sealing BOPP film for cigarettes and preparation method of BOPP film

ActiveCN113059880AImprove static/dynamic friction coefficient at room temperatureSmall static/dynamic friction coefficient at room temperatureFlexible coversWrappersPolymer scienceMeth-

The invention discloses a heat-sealing BOPP film for cigarettes. The BOPP film is prepared by directly co-extruding three layers of structures, namely a surface layer, a core layer and an inner layer; the surface layer is prepared from the following raw materials in parts by weight: 38-45 parts of a polypropylene random copolymer, 20-26 parts of a propylene-ethylene copolymer, 25-32 parts of an ethylene-methyl acrylate copolymer, 7.5-9 parts of modified crystal tourmaline powder, 1.5-2 parts of 1,6-hexanediol diglycidyl ether, 4.6-5.2 parts of a mixture of trimethylmethiloxy ammo-terminated polydimethylsiloxane and hydroxyl-terminated methyl-3,3,3-trifluoropropyl polysiloxane and 3-4.5 parts of polytetrafluoroethylene modified polyethylene wax powder; and the core layer is prepared from the following raw materials in parts by weight: 80-90 parts of homo-polypropylene, 12-17 parts of a propylene-ethylene copolymer, 7-9 parts of an ethylene-methyl acrylate copolymer and 2-3 parts of nano silicon dioxide. The heat-sealing BOPP film for the cigarettes has the advantages that the static / dynamic friction factor is small; the antistatic effect is good and lasting; and the low-temperature heat sealing performance is good, and the comprehensive performance is excellent.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

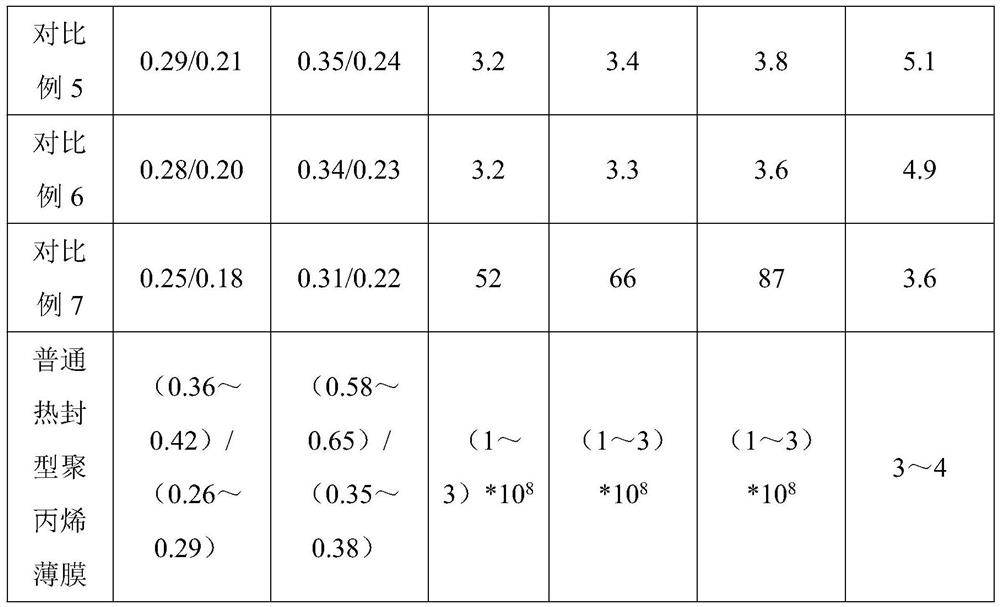

Swaddling clothes facing anti-crease shrink-proof finishing process

InactiveCN101349005AAvoid damageImprove the surface friction factorPhysical treatmentBiochemical fibre treatmentEngineeringPre treatment

The invention discloses a crease resisting anti-shrinkage finishing technique for a sweater fabric. The technique comprises the follow steps that: the sweater plug material is subjected to plasma pretreating, glutamine transaminase is adopted to process the sweater plug material pretreated by plasma, and finally, the sweater plug material is washed by water and dried naturally. The technique realizes the crease resisting anti-shrinkage finishing on the sweater plug material by the plasma together with the glutamine transaminase, remarkably improves the crease resisting anti-shrinkage property of the sweater plug material, has the advantage of health and environment protection, and improves the performances of the sweater plug material of rupture intensity, rupture extending rate and core absorbing height and the like.

Owner:JIANGNAN UNIV +1

Full-automatic efficient electrostatic dust collection device convenient to adjust

InactiveCN111729759AClean up in timeImprove the efficiency of cleaning dustVapor flow controlElectrodes cleaningDust controlEngineering

The invention discloses a full-automatic efficient electrostatic dust collection device convenient to adjust. The device comprises a machine body; an exhaust cavity with an upward opening is formed inthe machine body; a dust collection cavity communicated with the exhaust cavity is formed below the exhaust cavity; a dust collection mechanism is arranged in the dust collection cavity; the dust collection mechanism comprises an anode dust collection barrel fixedly arranged in the dust collection cavity; a pressure sensor is fixedly arranged in the left end wall body of the anode dust collectionbarrel; and a mounting plate is fixedly arranged between the front end wall and the rear end wall of the dust collection cavity. The invention discloses a full-automatic efficient electrostatic dustcollection device convenient to adjust. A rotating plate and a cleaning block are arranged; the driving mechanism can drive the cleaning block to rotate and move downwards at the same time, so that the cleaning block can scrape off dust adsorbed on the inner wall of the anode dust collection cylinder, the dust adsorbed on the inner wall of the anode dust collection cylinder can be cleaned up automatically in time, the dust cleaning efficiency is improved, and the dust collection effect and efficiency are guaranteed.

Owner:HANGZHOU JINZHUAN NEW ENERGY EQUIP CO LTD

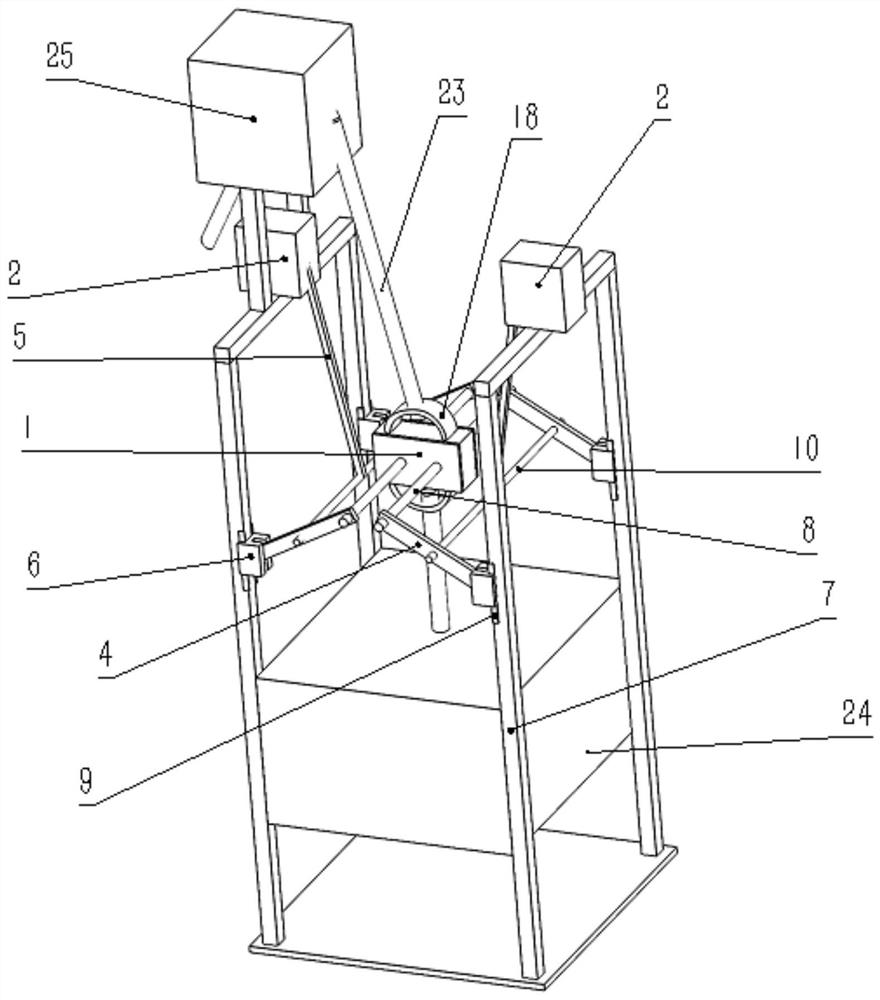

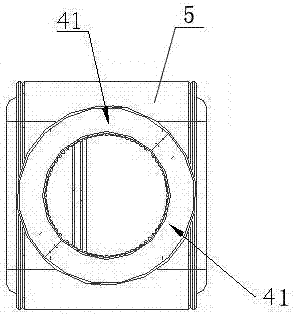

Rack used for pain therapeutic apparatus

The invention relates to a rack used for a pain therapeutic apparatus comprising a therapeutic probe. The rack is characterized by comprising a slider crank mechanism, a hinge connecting rod mechanism and a magnetic spherical hinge mechanism which are sequentially connected, and the therapeutic probe which is mounted on the magnetic spherical hinge mechanism is moved or positioned along with movement of the rack. Compared with the prior art, the rack has the advantages such that free movement is realized, self-locking of the optional position is achieved, and operation is convenient.

Owner:SHANGHAI UNIV OF ENG SCI

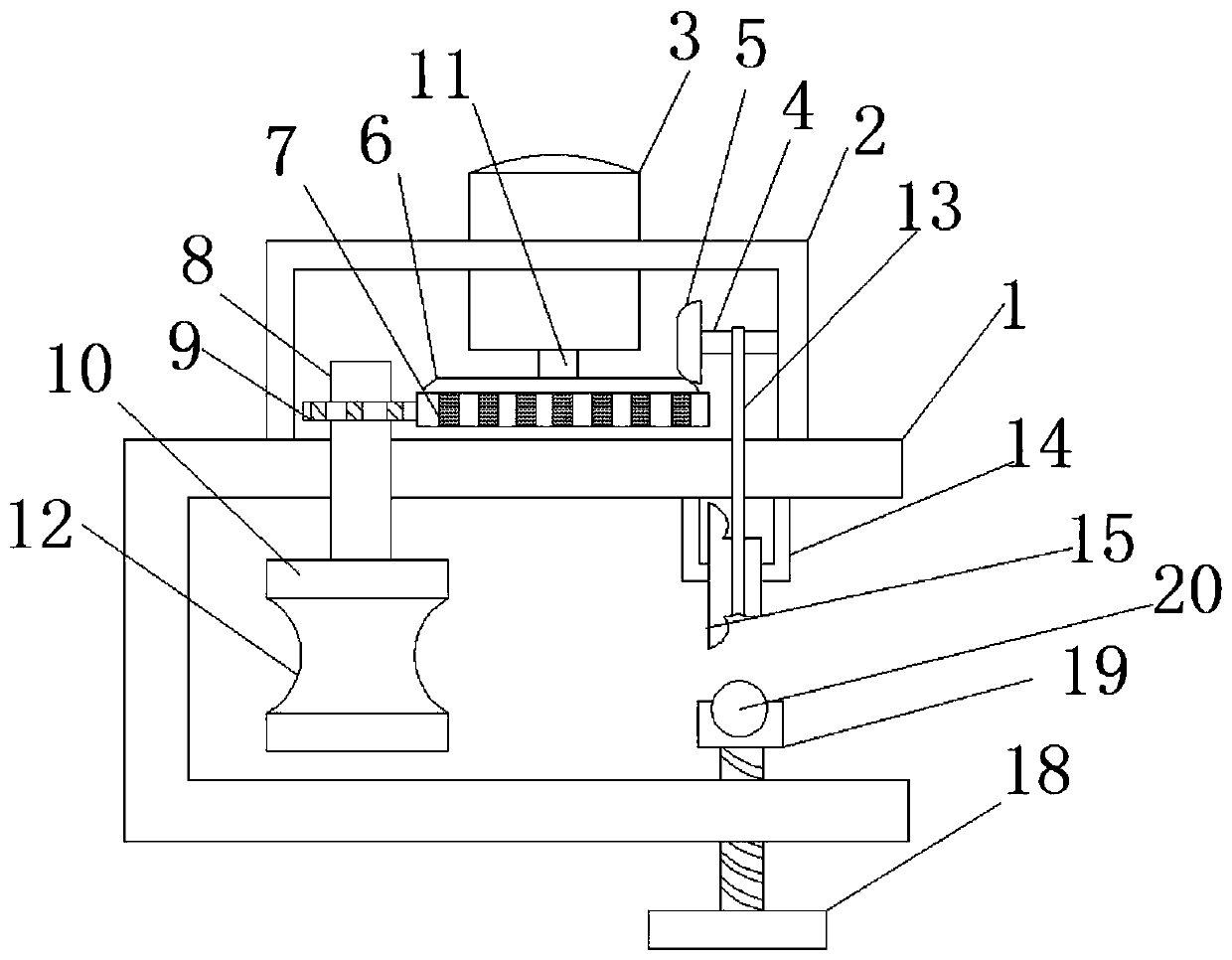

Damage-proof clamp for lathe chuck

InactiveCN108655436AAvoid damageIncrease friction factorChucksPositioning apparatusWear resistantEngineering

The invention is mainly applied to clamping of precise workpieces of lathes in mechanical machining, and particularly relates to a damage-proof clamp for a lathe chuck. The damage-proof clamp comprises clamping jaw assemblies, wherein each clamping jaw assembly comprises a fixing sleeve, the fixing sleeve is a rectangular hollow clamping sleeve, the inner end of the fixing sleeve is fixedly connected with an arc-shaped adjusting spring piece, the outer end of the fixing sleeve is provided with a pressing bolt, and the inner side face of the fixing sleeve is provided with a rubber wear-resistant layer. According to the design of the damage-proof clamp, the contact area is increased, so that the friction factor is increased, the clamping force is properly reduced, the clamping requirement ismet, and the damage to the workpiece is avoided.

Owner:ZIBO HUAYUAN MINING CO LTD

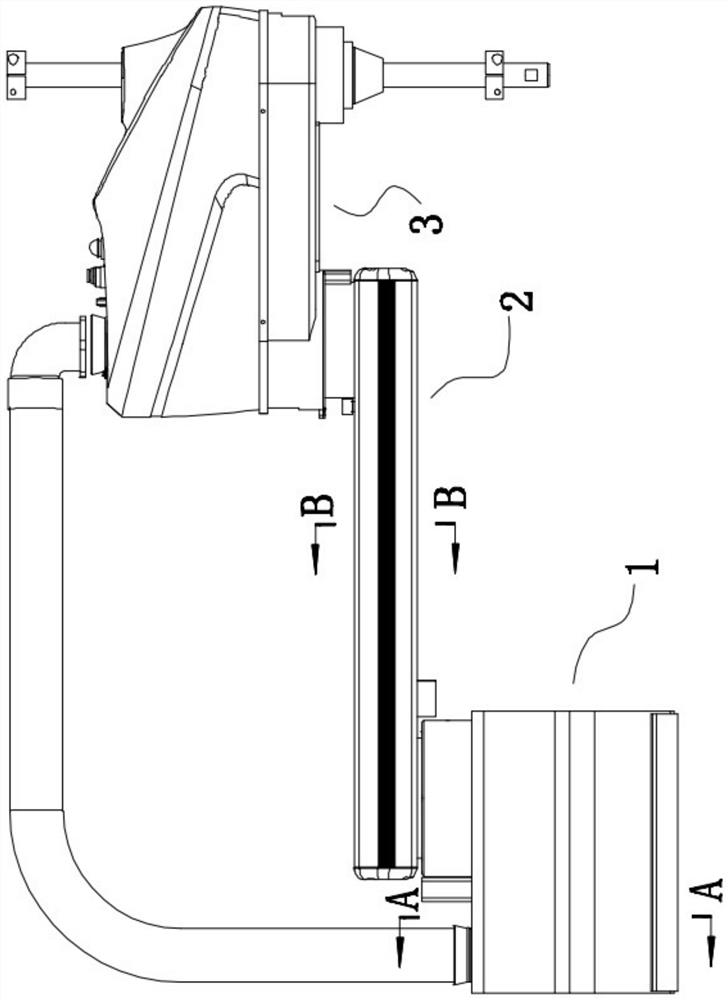

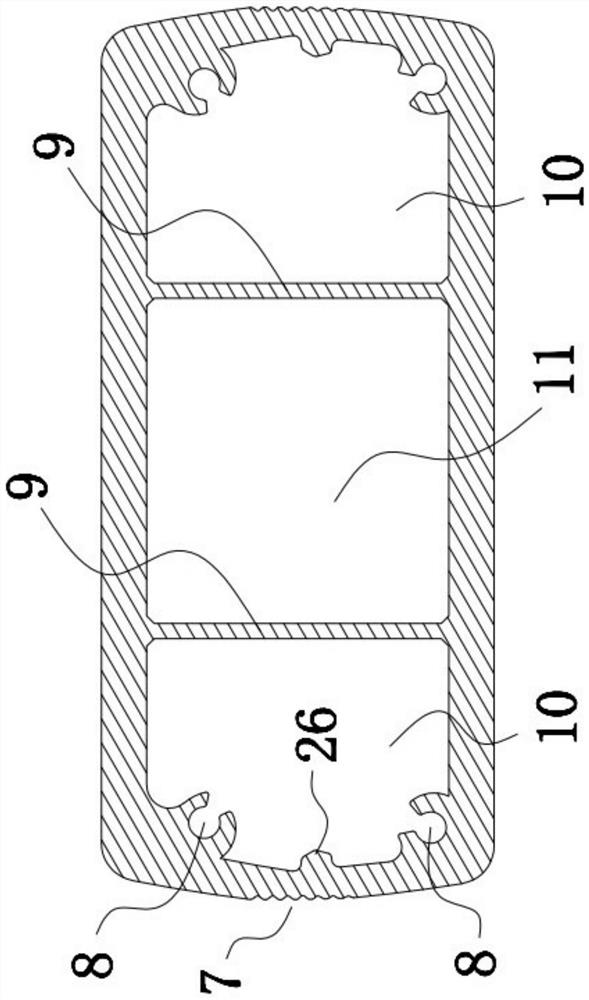

Four-axis manipulator with extruded profile

PendingCN113500588AReduce dosageHigh protection levelProgramme-controlled manipulatorWhole bodyClassical mechanics

The invention discloses a four-axis manipulator with an extruded profile. The four-axis manipulator comprises a machine base is an extruded profile with the same cross section profile, an arm part and a wrist part; one end of the arm part is in shaft connection with the machine base, and the arm part is an extruded profile with the same cross section profile; the end, far away from the machine base, of the arm part is in shaft connection with the wrist part, the wrist part is a casting, arc plates are arranged at the two ends of the wrist part in the length direction of the wrist part, the wrist part is provided with an upward opening, the edge contour of the opening is in a kidney-shaped hole shape, a housing is buckled on the opening, and an inner convex part for increasing the thickness of the wrist part is arranged on the inner wall of the wrist part. A blind hole is formed in the inner convex part; and the arm part is longer than the wrist part and the machine base, and the wall thickness of the machine base is larger than that of the arm part. Extruded profiles or castings are selected according to the characteristics of different parts of machinery, so that the cost is reduced while the performance of the parts is ensured, and the whole body is lighter.

Owner:苏州玖钧智能装备有限公司

Self-lubricating bearing

InactiveCN107781292AAvoid corrosionAvoid wear and tearSliding contact bearingsBearing unit rigid supportSurface mountingEngineering

The invention discloses a self-lubricating bearing. The main content is: the left inner ring is fixedly installed together with the right inner ring through bolts, and the outer ring is installed horizontally in the groove between the right inner ring and the left inner ring. Radial filler, axial filler is installed between the right end surface of the boss of the left inner ring and the bottom surface of the groove at the left end of the outer ring, and axial filler is installed between the left end surface of the boss of the right inner ring and the bottom surface of the groove at the right end of the outer ring. The filler, the right inner ring and the left inner ring are fixedly installed on the support through the dust-proof ring, and the dust-proof ring is stuck in the groove on the support, and the joint surface between the right inner ring and the left inner ring and the support A rubber gasket is installed, and the outer ring is fixedly installed on the right inner ring and the left inner ring through the end face collar, and an "O" type sealing ring is installed at the horizontal contact between the outer ring and the left inner ring, and the outer ring and the right inner ring An "O" type seal ring is installed at the contact point in the horizontal direction, the left end face clamp ring is stuck in the groove of the left inner ring, and the right end face clamp ring is stuck in the groove of the right inner ring.

Owner:CHANGZHOU FEISHENG PLASTIC MACHINERY

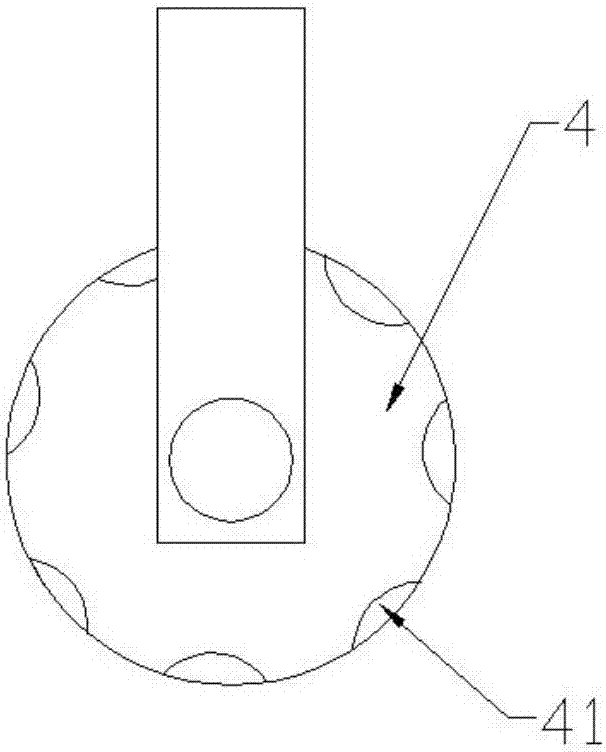

A drop-out fuse auxiliary installation device

InactiveCN105790141BGuaranteed to workFlexible adjustment of installation angleSwitchgearEngineeringRadial surface

The invention discloses an auxiliary mounting apparatus for a drop fuse. The auxiliary mounting apparatus comprises a top plate, wherein the right end part of the top plate is fixedly connected with a cross arm; the left end of the top plate is connected with a rotary rod through a rotary shaft; the rotary rod, a fixed pulley and an insertion rod are arranged at the lower part of the top plate in sequence from left to right; the lower end of the rotary rod is connected with a connecting plate; the connecting plate is connected with the drop fuse; one end of a cable rope penetrating through the fixed pulley is connected with the connecting plate while the other end of the cable rope is connected with a side wall of a winding column; a limiting insertion hole for limiting rotation of the winding column is formed in the insertion rod; a plurality of insertion holes are uniformly formed in the periphery of each of two radial surfaces of the fixed pulley; and a telescopic insertion rod is mounted on the upper surface of the connecting plate in a manner of corresponding to the insertion holes in the periphery of each of the two radial surfaces of the fixed pulley. The apparatus is mounted between the drop fuse and the cross arm, the drop fuse can be firmly mounted on the cross arm, and a mounting angle of the drop fuse can be conveniently and flexibly adjusted according to actual needs of an operation site to ensure the drop fuse to normally work.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

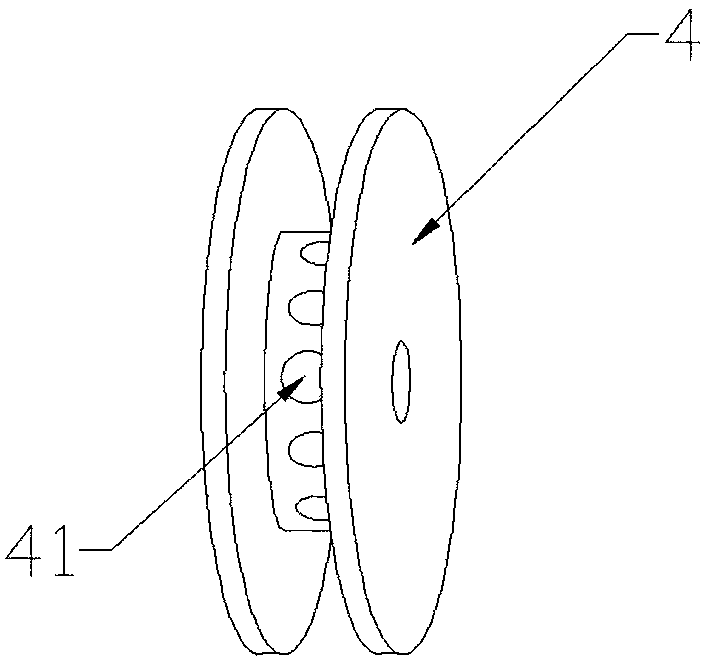

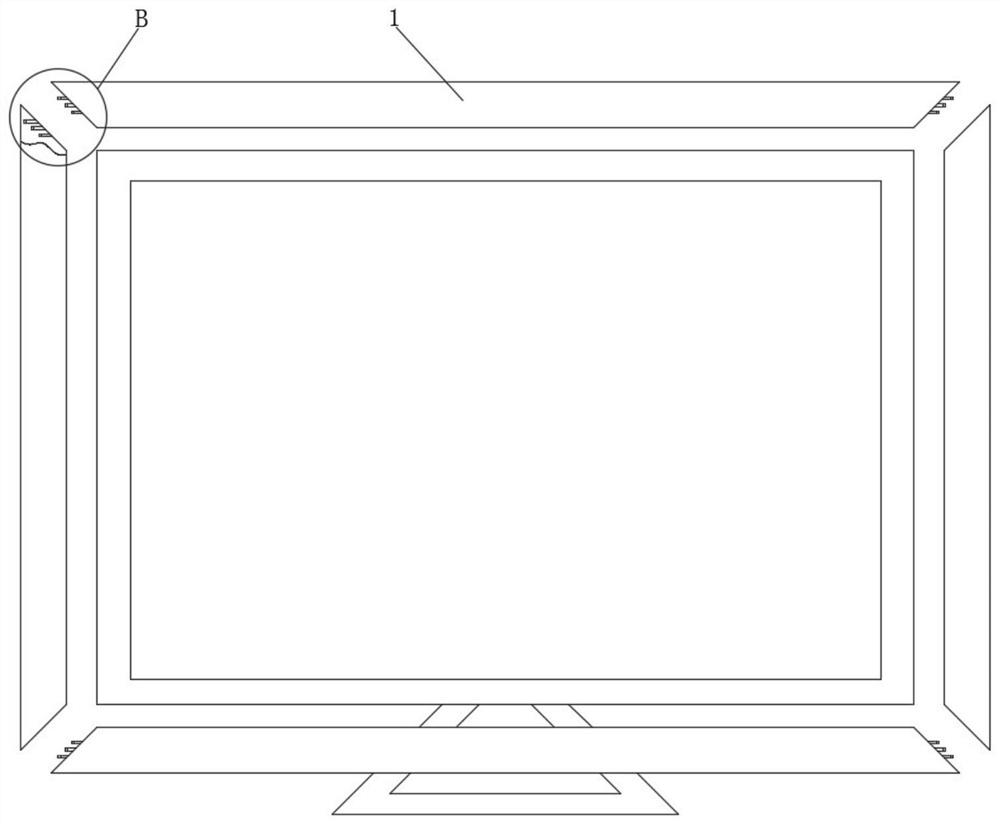

Atmosphere lamp for intelligent household appliance and using method

InactiveCN111911838AGood effectImprove viewing experienceLighting support devicesLighting elementsDisplay deviceEngineering

The invention discloses an atmosphere lamp for an intelligent household appliance and a using method. The atmosphere lamp comprises four sets of mounting plates, each set of mounting plates comprisestwo clamping plates, the top view of each clamping plate is of an oval half-shaped structure, the two ends of each clamping plate are of triangular structures, and parallel sliding ways are formed inthe upper portions and the bottom sides of the opposite sides of the two clamping plates; limiting discs are installed in the sliding ways, the limiting discs between the two clamping plates are connected through telescopic rods, limiting grooves are formed in the top sides and the bottom sides of the sliding ways, limiting holes are formed in the inner walls, away from the open ends, of the sliding ways, movable holes are formed in the sides, close to the limiting holes, of the limiting discs, and balls are installed in the movable holes; rotating holes are formed in the sides, opposite to each other, of the two clamping plates in the direction where the clamping plates are located, rollers are installed in the rotating holes, inserting holes are formed in one ends of the clamping plates,and inserting strips are fixed to the ends, away from the inserting holes, of the clamping plates. Through the cooperative use of the devices, the frame of a display can be eliminated, and the influence of a black frame on the viewing experience when the atmosphere lamp is turned on is avoided.

Owner:NANJING BAIYA INTELLIGENT TECH CO LTD

OPLC joint closure end protection device

PendingCN107179589AImprove fastening forceIncrease friction factorFibre mechanical structuresProtection KITElectric cables

Owner:ZHONGTIAN TECH MARINE SYST CO LTD

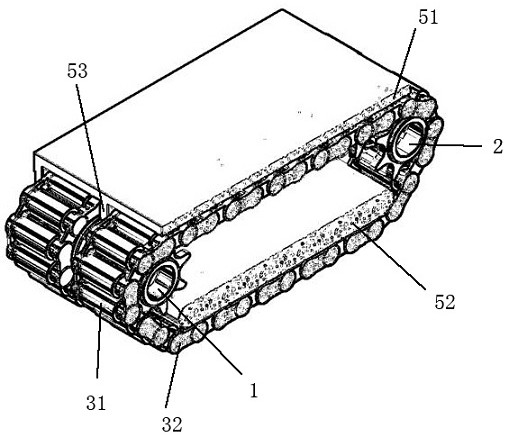

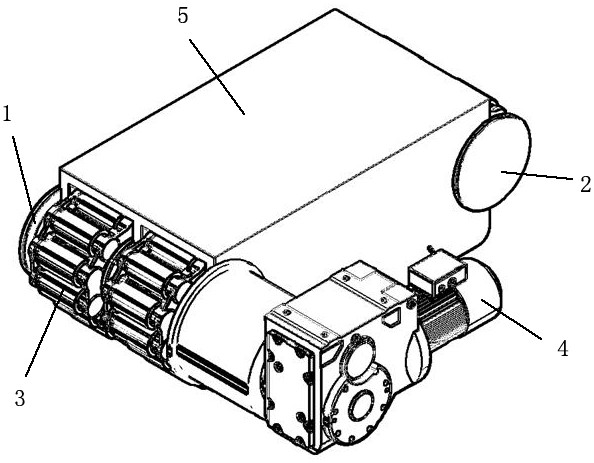

A kind of active roller car

An active-type roller vehicle comprises an active chain wheel and a guiding wheel which are connected through a roller chain. The active chain wheel is connected with a gear motor through a transmission shaft, the roller chain comprises rollers and roller pins, the roller pins are connected with the rollers through holes formed in the two ends of the roller pins, and the rollers are connected intothe annular roller chain in series through the roller pins. According to the active-type roller wheel, the gear motor drives the active chain wheel to drive the roller chain to move along a fixed path, so that a large heavy load component is driven. The roller vehicle chain wheel adopts the upper-arranged mode, only bears torque and does not bear a radial load, the life of a driving device is effectively prolonged, and thus the roller vehicle chain wheel is specially suitable for the occasion that a cart operation mechanism needs to bear an over-weight load, but the structural arrangement space is small, and the size is limited; and the gear motor driving device is applied to a roller vehicle bearing structure to enable the roller vehicle bearing structure to become the active-type rollervehicle, and a driving mechanism special for driving a crane cart to operate does not need to be arranged any longer.

Owner:HENAN WEIHUA HEAVY MACHINE

Spinning type soil loosening device for cultivation of sugarcane

The invention discloses a spinning type soil loosening device for cultivation of sugarcane. The device comprises a rack, a solid rod, a fixing block and a curved surface support frame, wherein an extending thread section is arranged at the bottom of the solid rod and sleeved with a lock sleeve and a lengthened casing pipe, the lengthened casing pipe is matched with the extending thread section foruse, lengthening of the device can be realized, the use comfort is improved, the lengthened casing pipe is longer than the extending thread section, a fixing ring is mounted at the bottom of the lengthened casing pipe, a fixing block is mounted at the top of the solid rod, the surface of the fixing block is connected with the curved surface support frame through a bolt, a pull ring is mounted atone end of the bolt, a protective casing is mounted on the surface of the curved surface support frame, a tightener is mounted at the bottom of the protective casing, limiting springs are mounted in the protective casing, and rake teeth are mounted at the top of the curved surface support frame.

Owner:陈西

Preparation method of high-strength paper-based friction composite material

InactiveCN111057307APrevent flocculation and agglomerationGood compatibilityCellulosePolyvinyl alcohol

The invention relates to a preparation method of a high-strength paper-based friction composite material, which belongs to the technical field of friction materials. According to the invention, polypropylene fiber, bamboo fiber and aramid fiber are used as raw materials; carboxymethyl cellulose, polyvinyl alcohol and methyl triethyl silane are added; the high-strength paper-based friction composite material is prepared; the nano aluminum oxide, the silicon carbide microspheres and the talcum powder are added; the added nano aluminum oxide can be used as a hard point grinding material of the paper-based friction material; the friction factor and the wear resistance of the friction material can be effectively improved; the silicon carbide microspheres are added, the holes can enable the adhesive to be better bonded with the resin; the bonding strength of the paper-based friction material is improved, oil flowing can be promoted due to the holes, the friction material is more heat-resistant, the friction factor and the energy absorption rate of the friction material can be improved, the friction performance of the material can be adjusted by adding talcum powder, and the friction material has better comprehensive performance.

Owner:李可禛

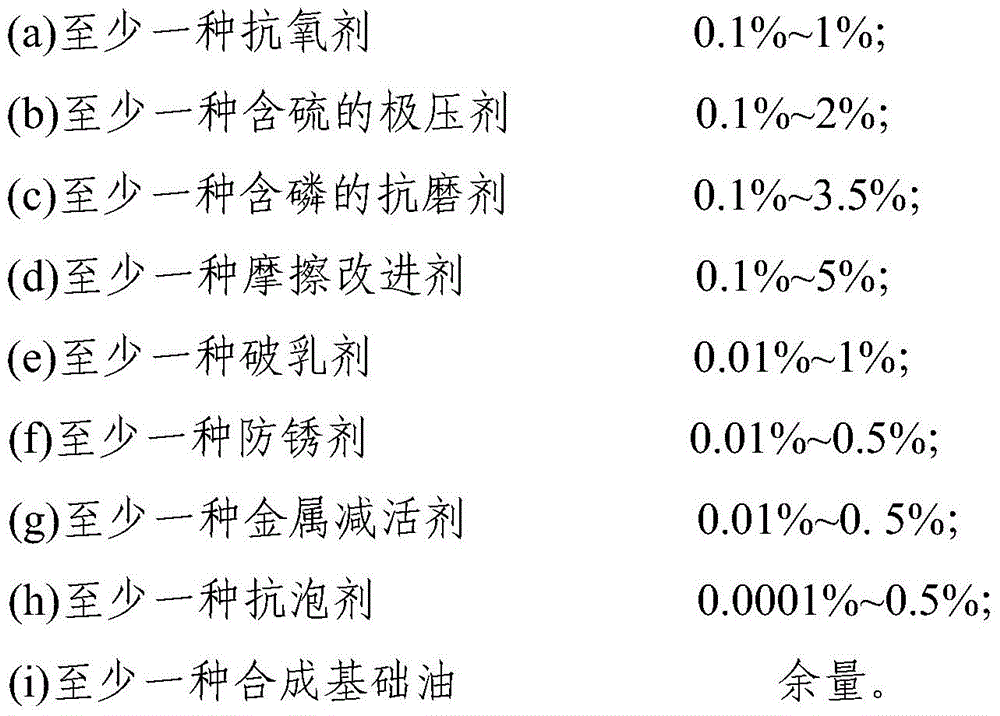

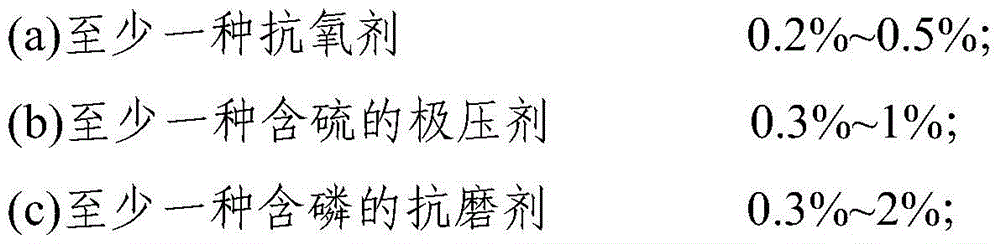

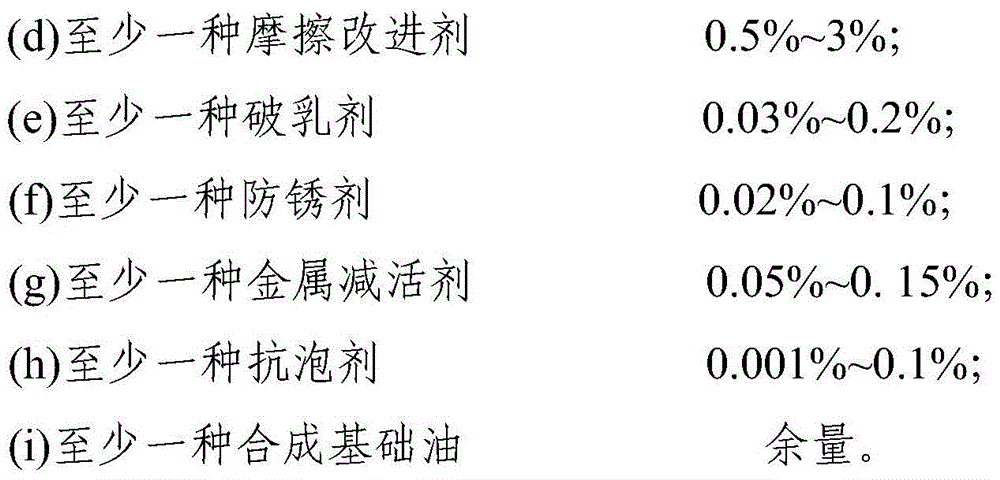

A kind of marine gearbox oil composition

Owner:CHINA PETROLEUM & CHEM CORP

Flash treatment equipment for plastic parts

ActiveCN112192805AGood removal effectGuaranteed resection effectPlastic recyclingStructural engineeringMechanical engineering

Owner:浙江海邦机械科技有限公司

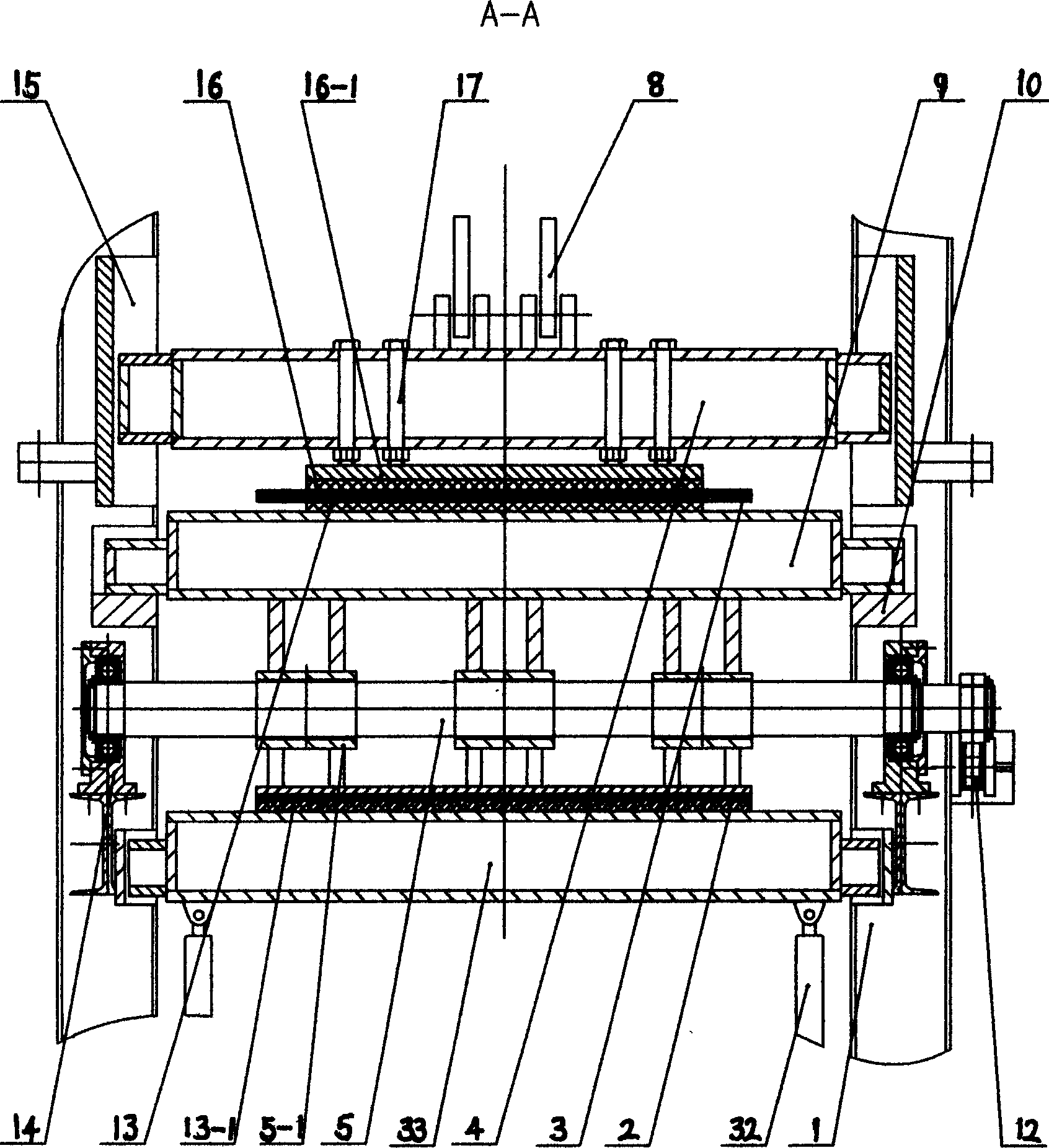

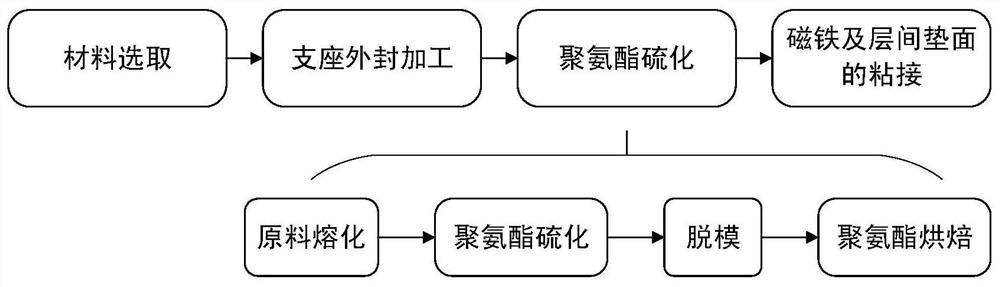

A method of manufacturing a sliding shock-isolation bearing

ActiveCN108643378BReduce wearReduce coefficient of frictionProtective buildings/sheltersShock proofingFilling materialsEngineering

A manufacturing method of a sliding shock insulation support comprises the following steps that a material of the support is selected; the shape of the support is designed; the support is machined; material selecting of the support comprises material selecting of support outer seals, inner fillers, magnets and interlayer underlying surfaces; the support shape design comprises the steps that annular steel channels serve as the outer seals of an upper-layer support body and a lower-layer support body correspondingly, the outer seals are filled with materials with the shore hardness being 80 or above, the permanent magnets are evenly arranged in the centers of the filled materials in a surrounding mode, and the two layers of interlayer underlying surfaces are arranged on the filled materials;and support machining comprises the technologies of filled material machining and magnetic and interlayer underlying surface bonding. A formed device has the technical advantages of being small in abrasion, high in sensitivity, good in filter performance, low in energy consumption, small in impact effect, high in self-resetting capacity, capable of saving spaces, good in tensile property and thelike, and the manufacturing method has important significance in solving the technical problems that a shock insulation support in an area with high seismic intensity is large in deformation, remarkable in impact effect, poor in tensile capacity and the like.

Owner:TONGJI UNIV

A multi-size screw fastening head placement platform for mold clamping system

The invention discloses a multi-size screw fastening head placement platform for a mold clamping system, which belongs to the technical field of mold clamping systems. A multi-size screw fastening head placement platform for a mold clamping system includes a placement mechanism, multiple A screw fastening head and a fixing mechanism, the screw fastening head includes a linkage wheel, the top of the linkage wheel is fixedly connected with a connector, the side of the connector is fixedly connected with a hemispherical connection block, and the bottom end of the linkage wheel is fixedly connected with a joint. The connecting rod is fixedly connected with a fastening rod for fastening the screws at the bottom end of the connecting rod. The placing mechanism includes a placing plate, and the bottom of the placing plate is fixedly connected with four support frames distributed in a rectangular array. Two positioning blocks. It can automatically reset and calibrate the screw fastening head on the platform, so that the screw fastening head can be reset accurately, preventing the screw locking robot from being unable to grasp the screw locking robot, thereby improving production efficiency, and is easy to fix and install.

Owner:HAIAN DISCORY INSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com