Plate deburring equipment

A deburring and equipment technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve inconvenience, complexity and other problems, achieve the effect of increasing friction, increasing friction factor, and improving deburring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

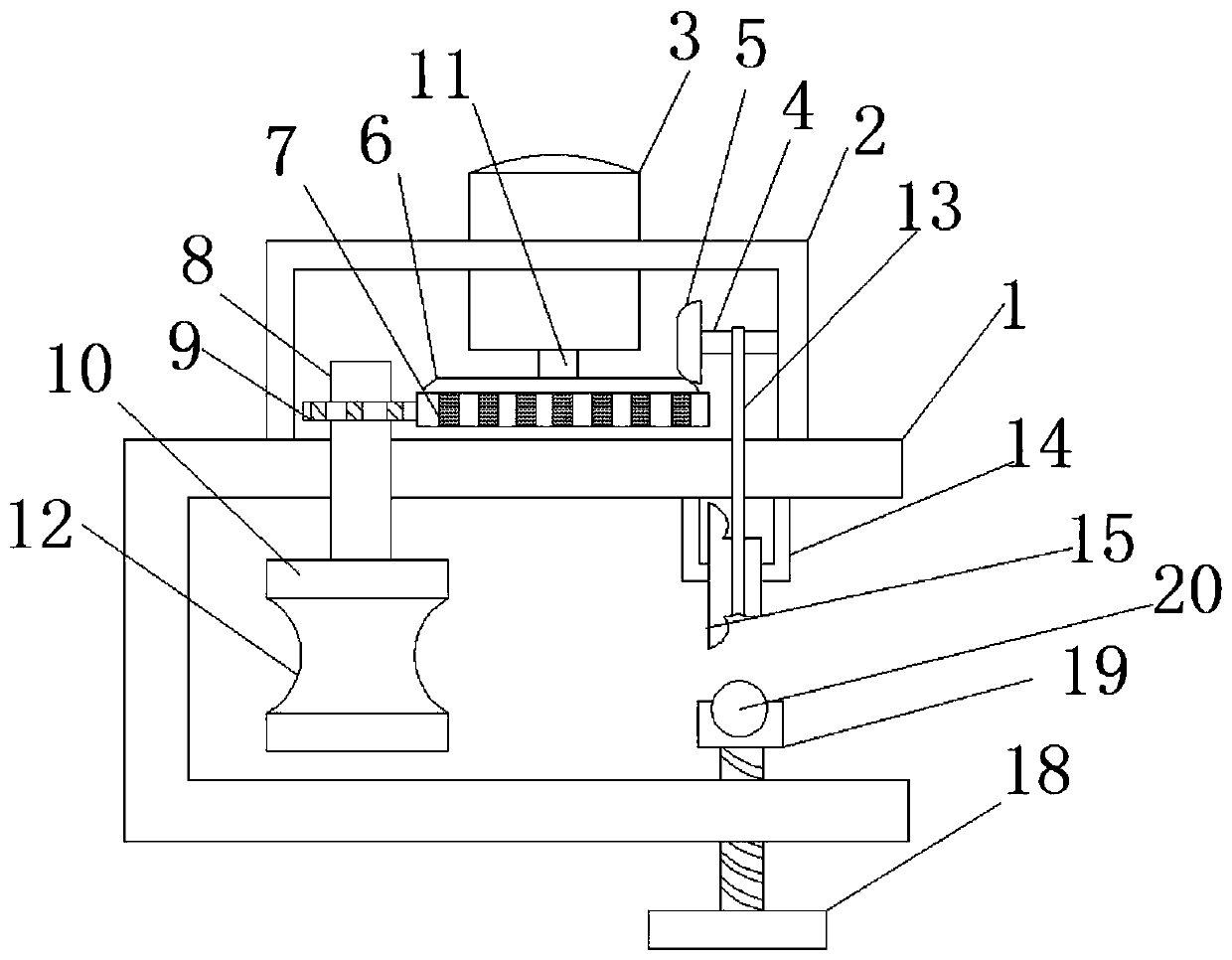

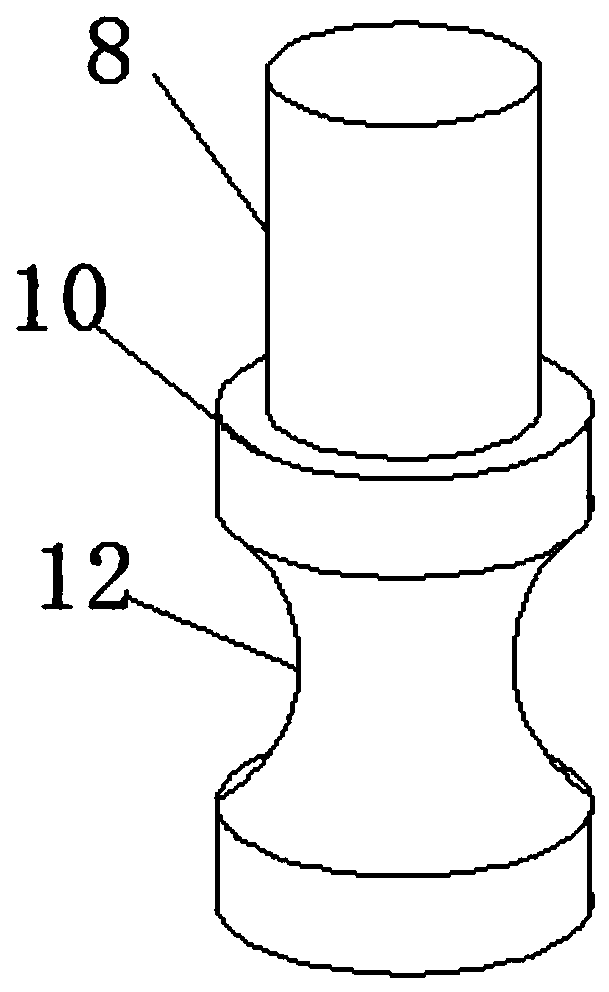

[0027] refer to Figure 1-3 , a plate deburring equipment, including a U-shaped groove 1, a power chamber 2 is welded to the top of the U-shaped groove 1, an air motor 3 is welded to the top of the power chamber 2, and a rotary column 11 is welded to the output end of the air motor 3 The bottom end of the rotating column 11 is welded with the first bevel gear 6, the bottom end of the first bevel gear 6 is welded with the first gear 7, one side of the power chamber 2 is connected with the rotating rod 4 through the rotation of the rotating shaft, and the top end of the rotating rod 4 is welded There is a second bevel gear 5, the first bevel gear 6 meshes with the second bevel gear 5, the top of the U-shaped groove 1 is connected to the rotating rod 8 through the rotating shaft at the inside of the power chamber 2, and the top of the rotating rod 8 is welded with the second bevel gear. Two gears 9, and the first gear 7 and the second gear 9 are meshed, the bottom end of the rota...

Embodiment 2

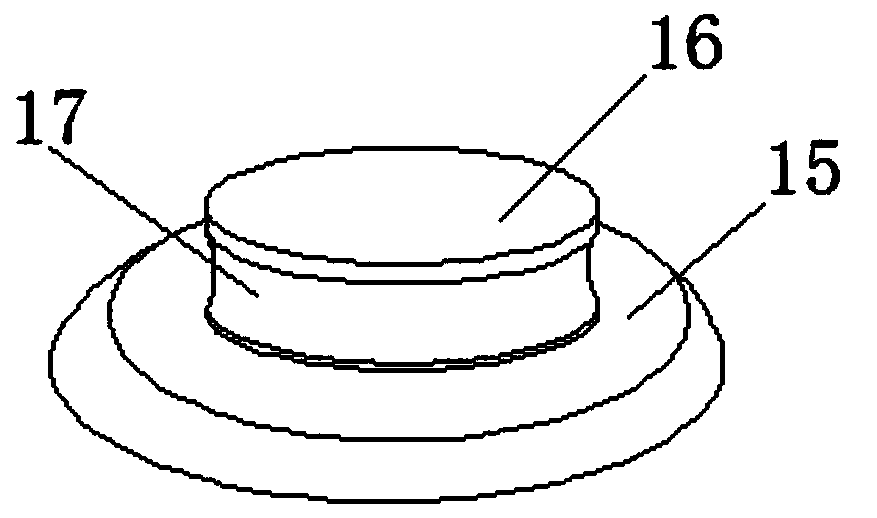

[0032] refer to Figure 4 , a plate deburring equipment. Compared with Example 1, in order to improve the friction between the arc-shaped rubber disc and the plate, the arc-shaped rubber disc 15 is provided with an anti-slip groove 21 outside. When the arc-shaped rubber disc 15 When the disc 15 is bent, the anti-slip groove 21 on the arc-shaped rubber disc 15 increases the friction factor on the surface of the plate, improves the friction force of the arc-shaped rubber disc 15 when bending, and makes the arc-shaped grinding groove 12 exert pressure on the plate at all times .

[0033] Working principle: Turn on the air motor 3, the air motor 3 drives the rotating column 11 to rotate, the rotating column 11 drives the first bevel gear 6, the second bevel gear 5, the first gear 7, and the second gear 9 mesh with each other to drive grinding When the column 10 grinds the edge of the plate, it drives the whole device to move under the rotation of the rotary block 16. At the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com