Patents

Literature

134results about How to "Strong braking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

All-electric vehicle recycled energy management method and system

ActiveCN108215895AStrong brakingIncrease profitElectrodynamic brake systemsElectric powerElectrical batterySteep slope

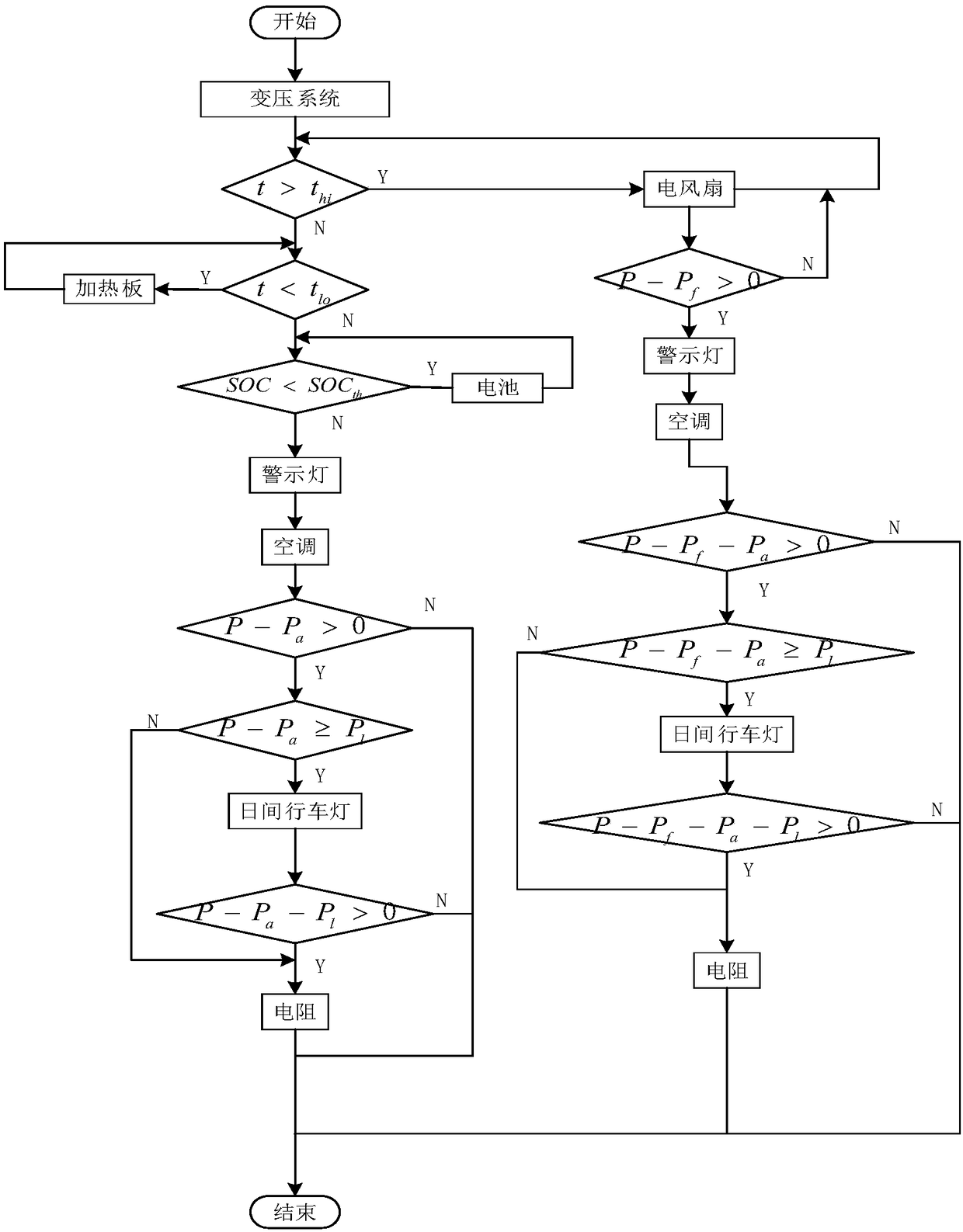

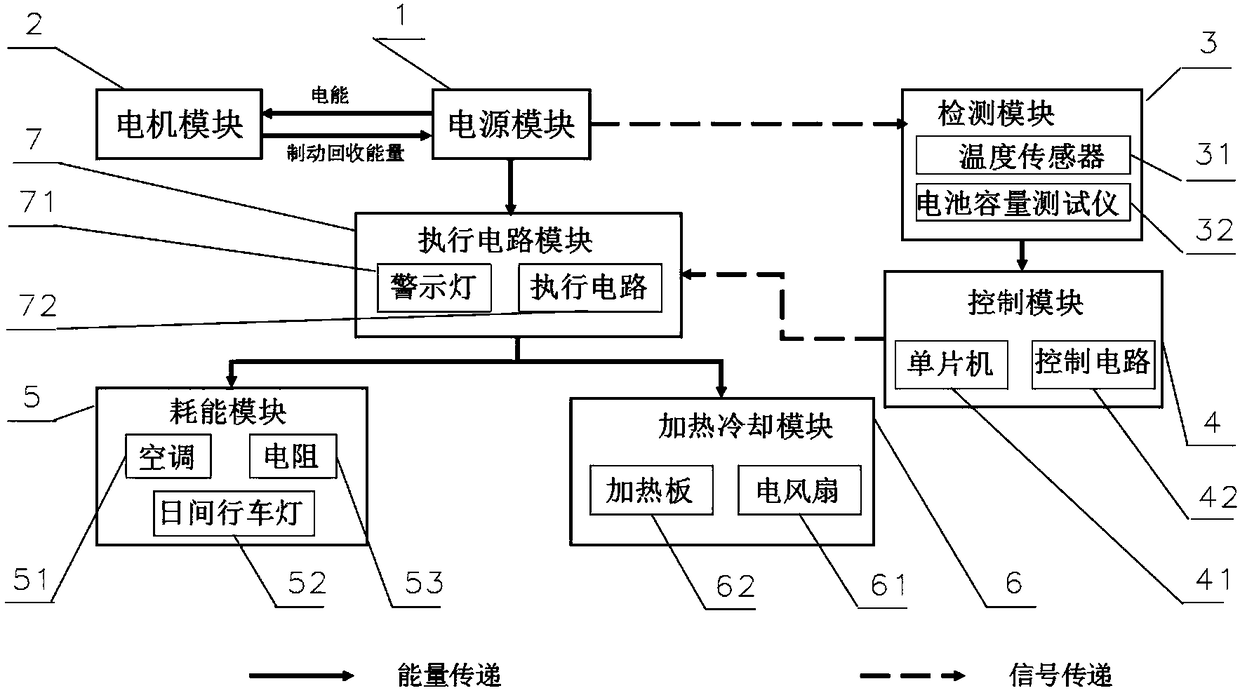

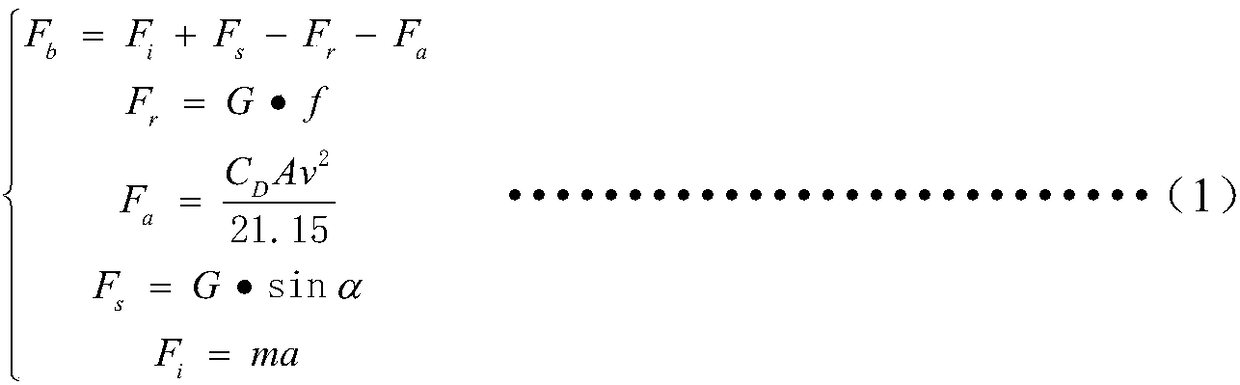

The invention discloses an all-electric vehicle recycled energy management method and system; the method comprises detecting temperature of a battery, using the battery temperature, power level of thebattery and a residual electricity conversion power value as input signals, comparatively judging the input signals, preset battery temperature upper limit and lower limit and a preset battery powerlevel threshold, and controlling a flow direction of electricity converted from recycled braking energy. The system comprises a motor module, a power module, a detection module, a control module, an executive circuit module, a power consumption module and a heating-cooling module. The all-electric vehicle recycled energy management method and system are specific to recycled energy management for an all-electric vehicle during adaptive sliding on a long and steep slope, it is ensured that the power level of a battery is maintained in a suitable range, and the all-electric vehicle can apply theresidual recycled braking energy to vehicular power-consuming devices at the premise of having good braking performance.

Owner:JILIN UNIV

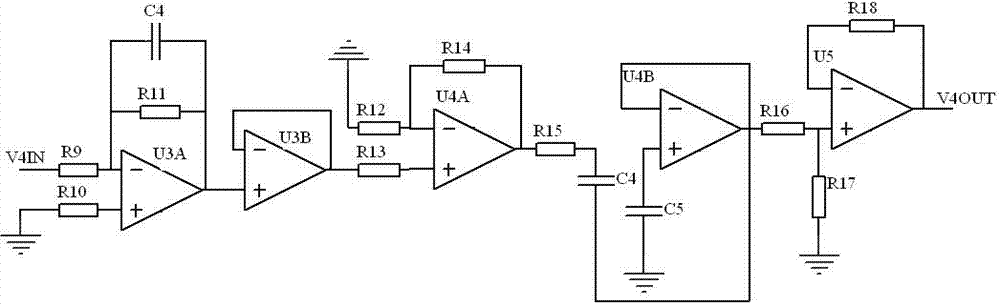

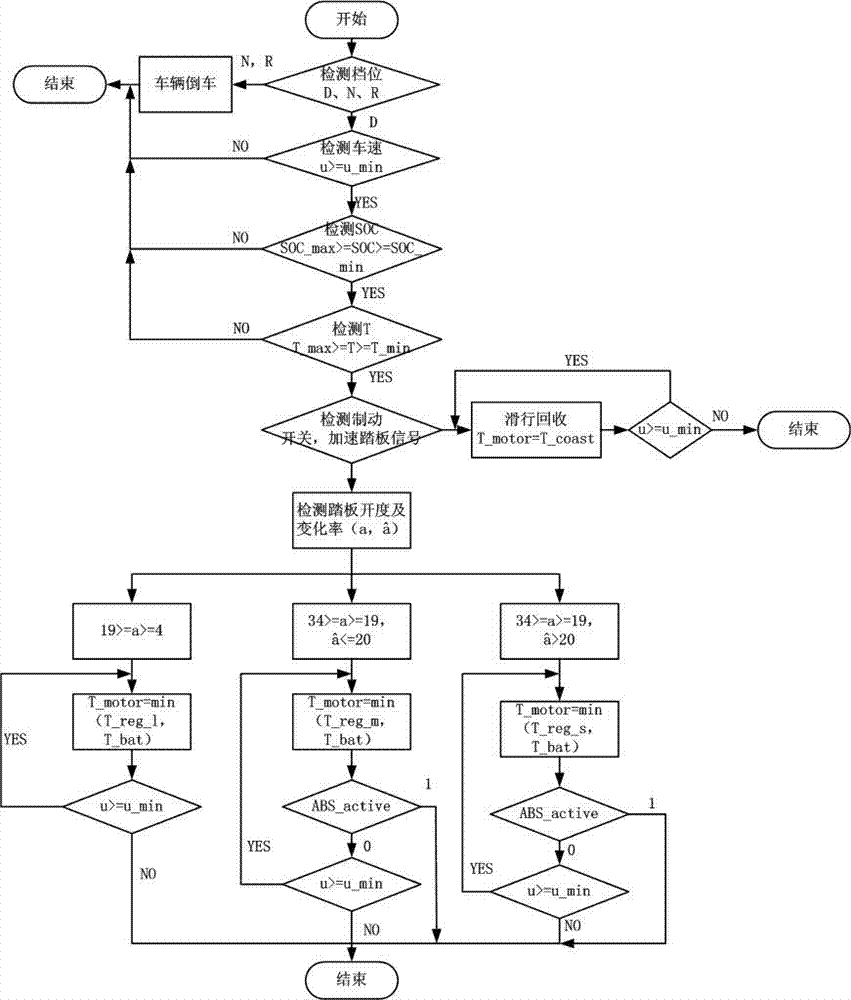

Braking energy recovery system of extended range electric vehicle

ActiveCN102774288ACharging priorityImprove energy utilizationElectrodynamic brake systemsBraking systemsStarter generatorElectrical battery

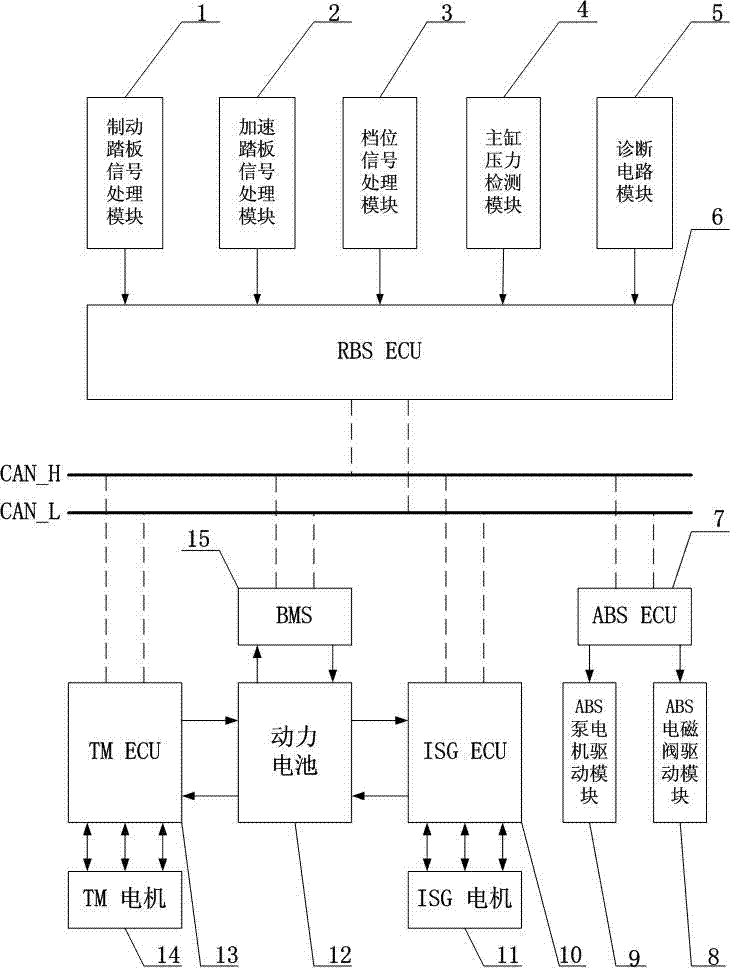

The invention discloses a braking energy recovery system of an extended range electric vehicle. The braking energy recovery system comprises a brake pedal signal processing module, an accelerator pedal signal processing module, a gear signal processing module, a main cylinder pressure signal detection module, a diagnosis circuit module, a braking energy recovery system control unit (RBSECU), an anti-lock braking control unit (ABSECU), an anti-lock braking (ABS) electromagnetic valve drive module, an anti-lock braking (ABS) pump motor drive module, an integrated starter generator control unit (ISGECU), an integrated starter generator (ISG) motor, a power battery, a battery management system (BMS), a drive motor control unit (TMECU) and a drive motor (TM). Under the premise of ensuring safe braking, the braking energy recovery system of the extended range electric vehicle can recover the braking energy furthest, and improve the vehicle energy utilization efficiency.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

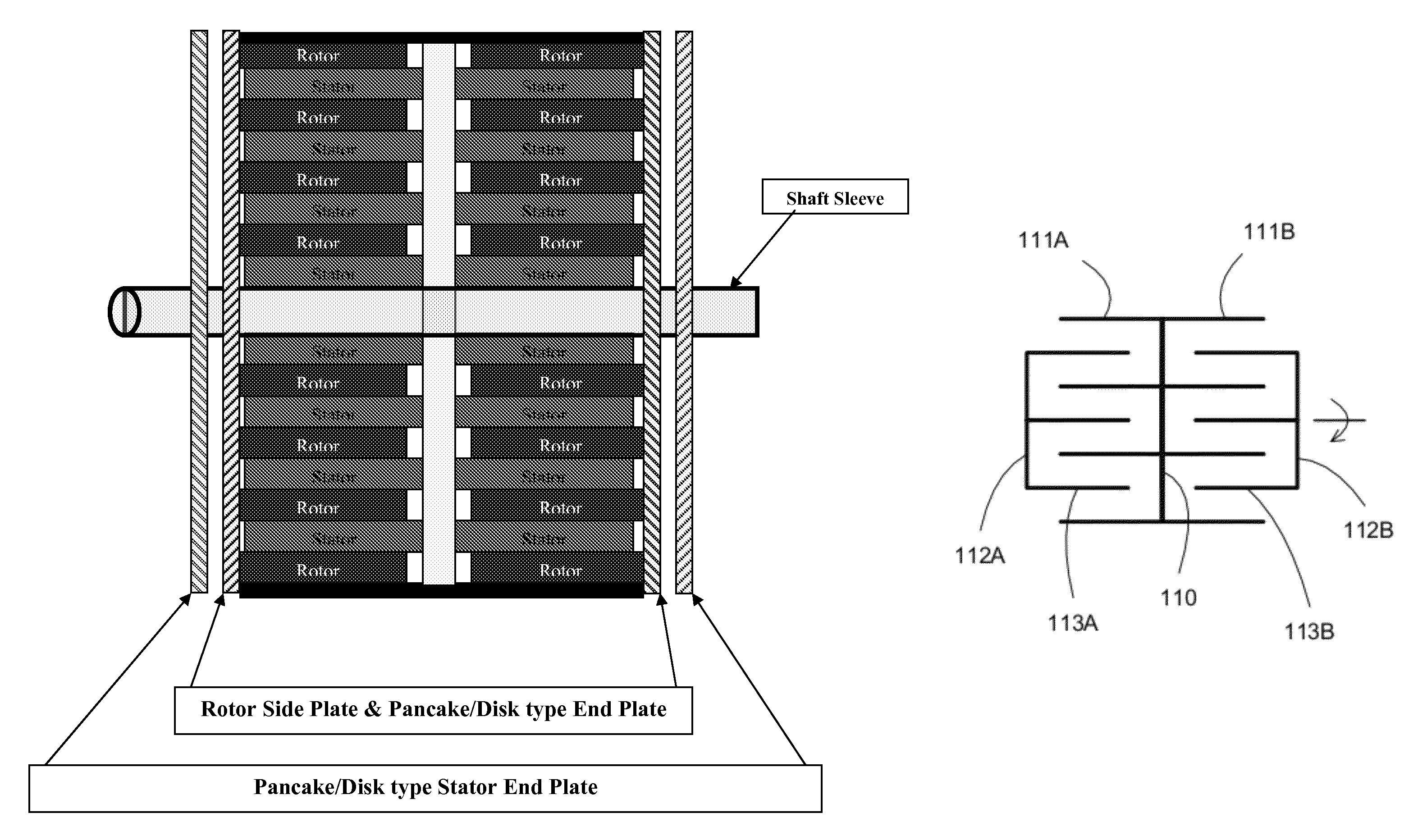

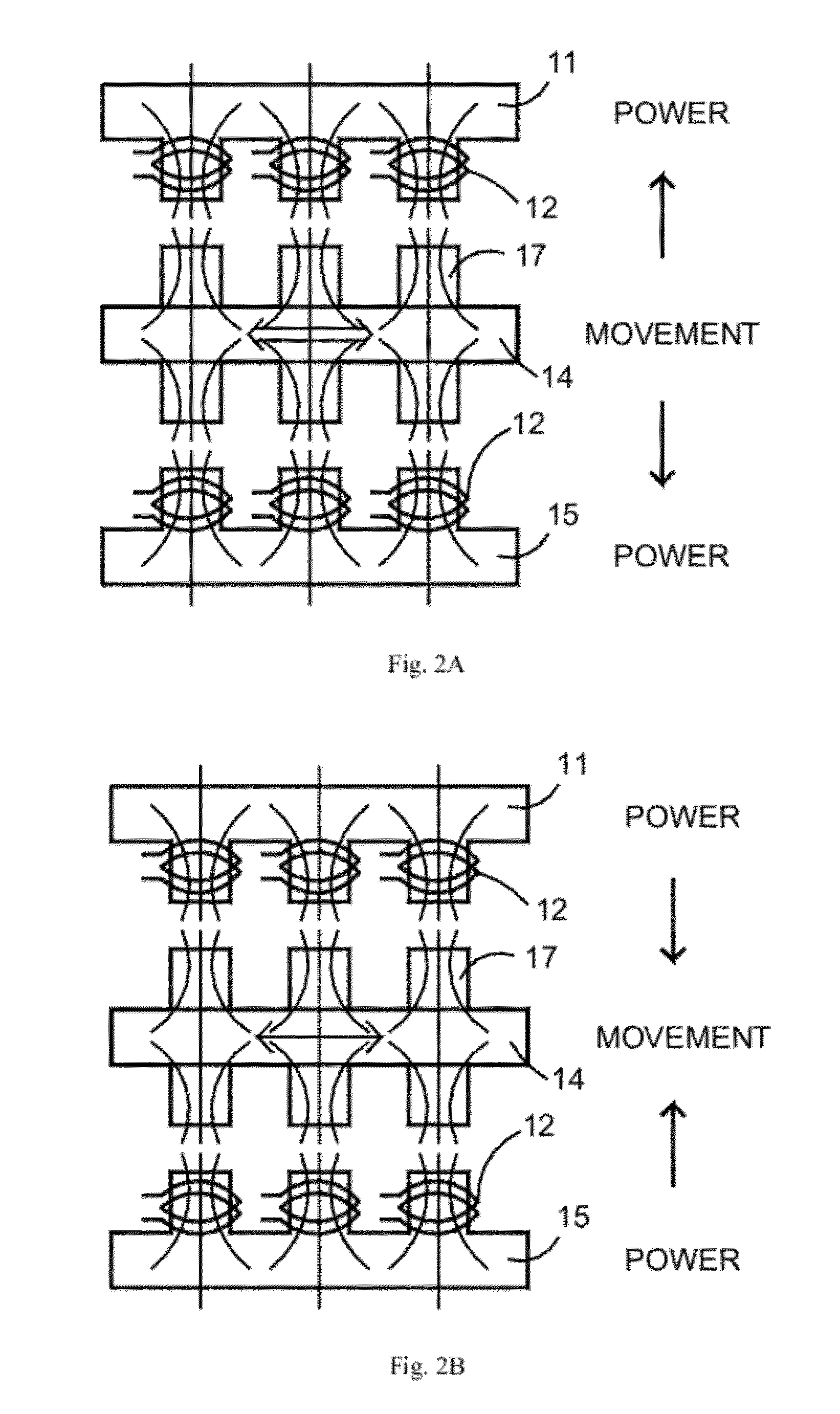

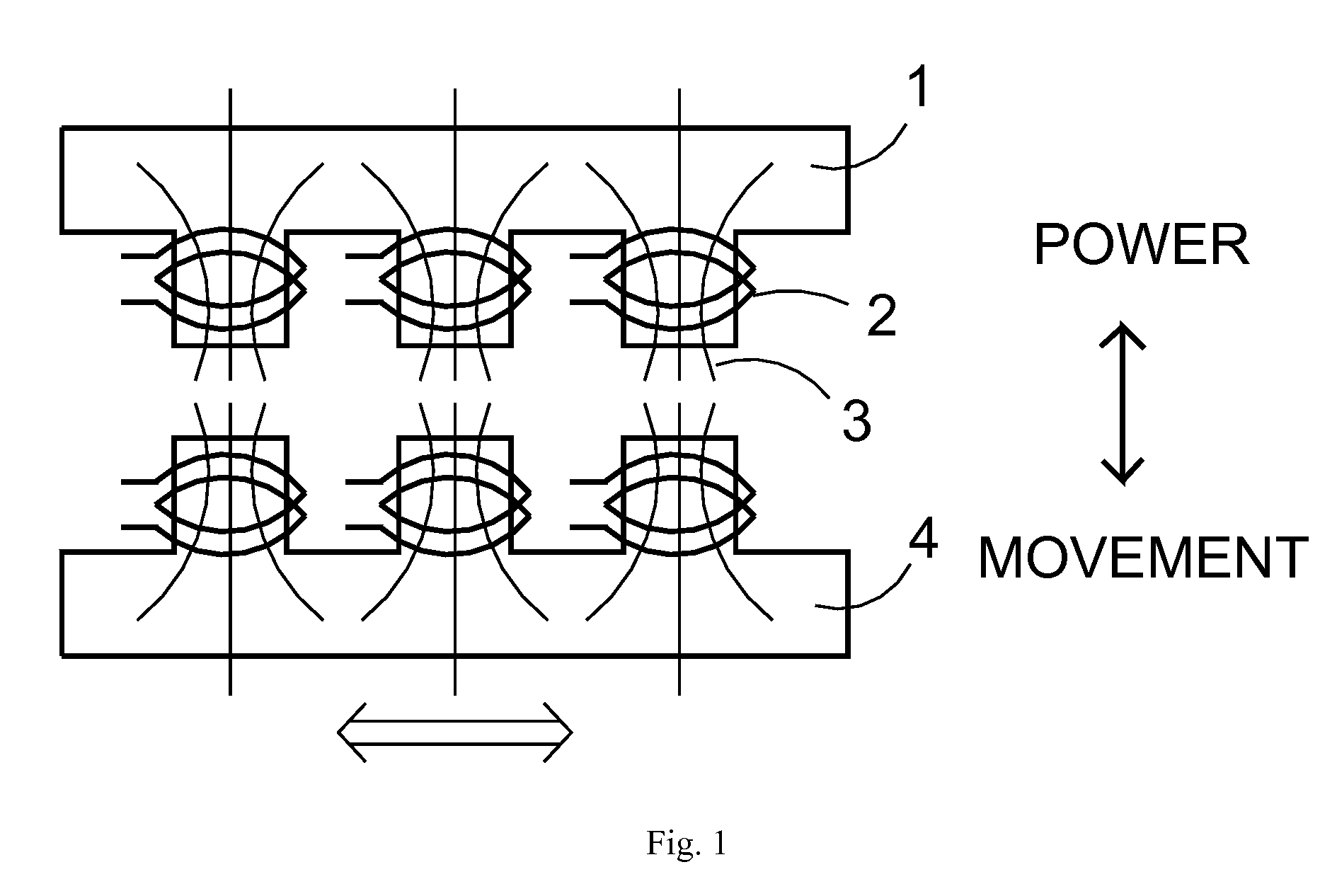

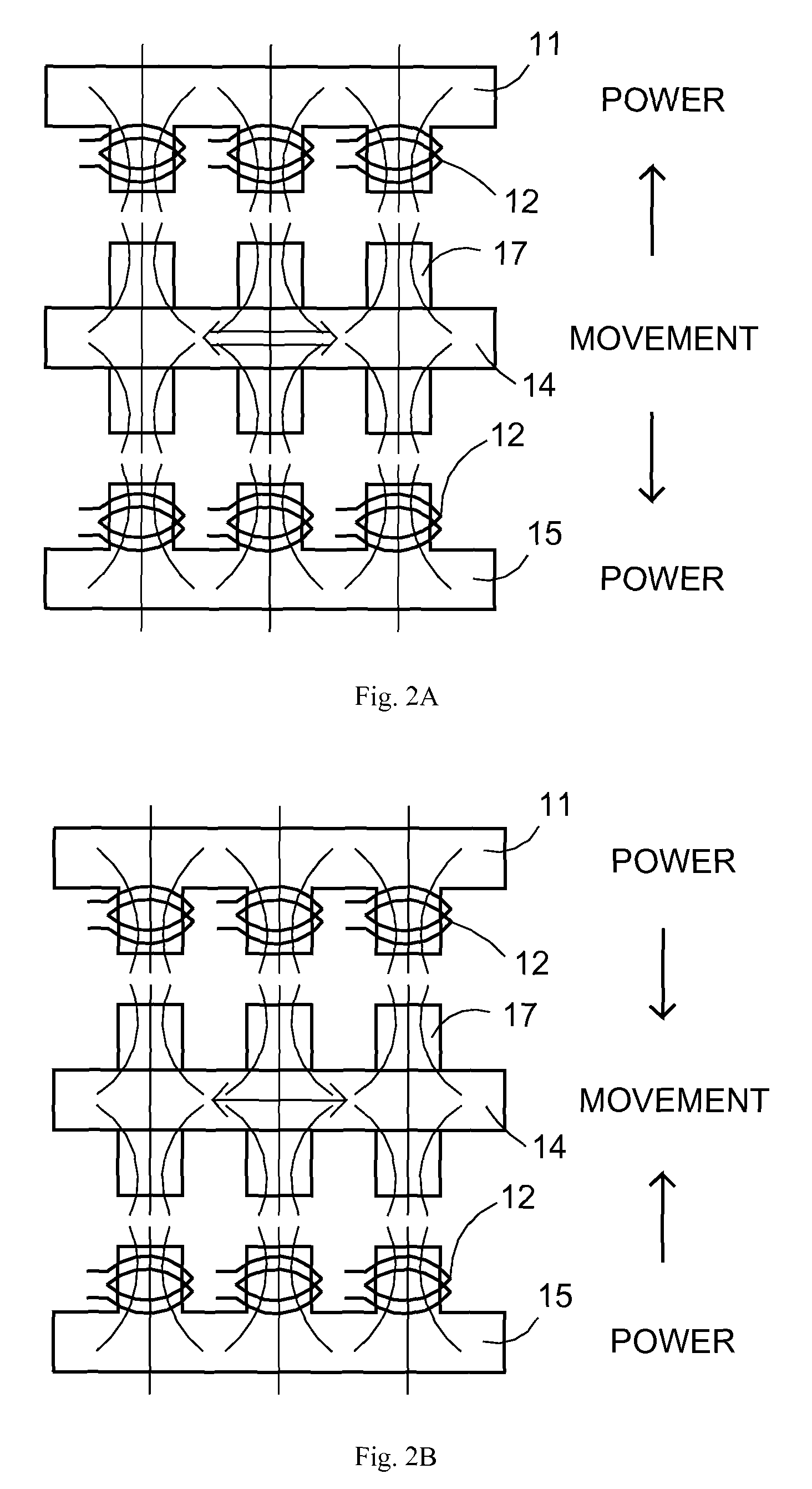

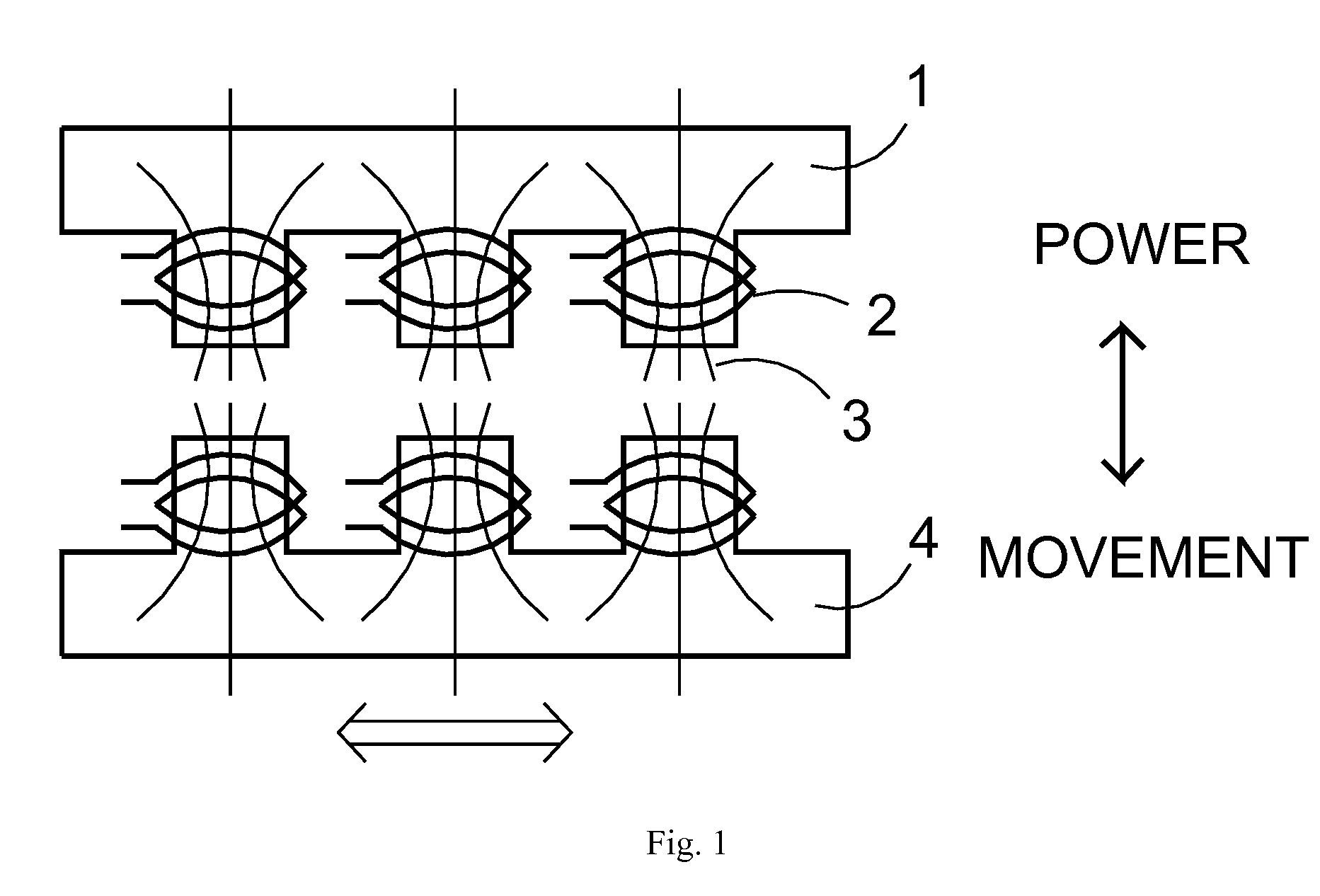

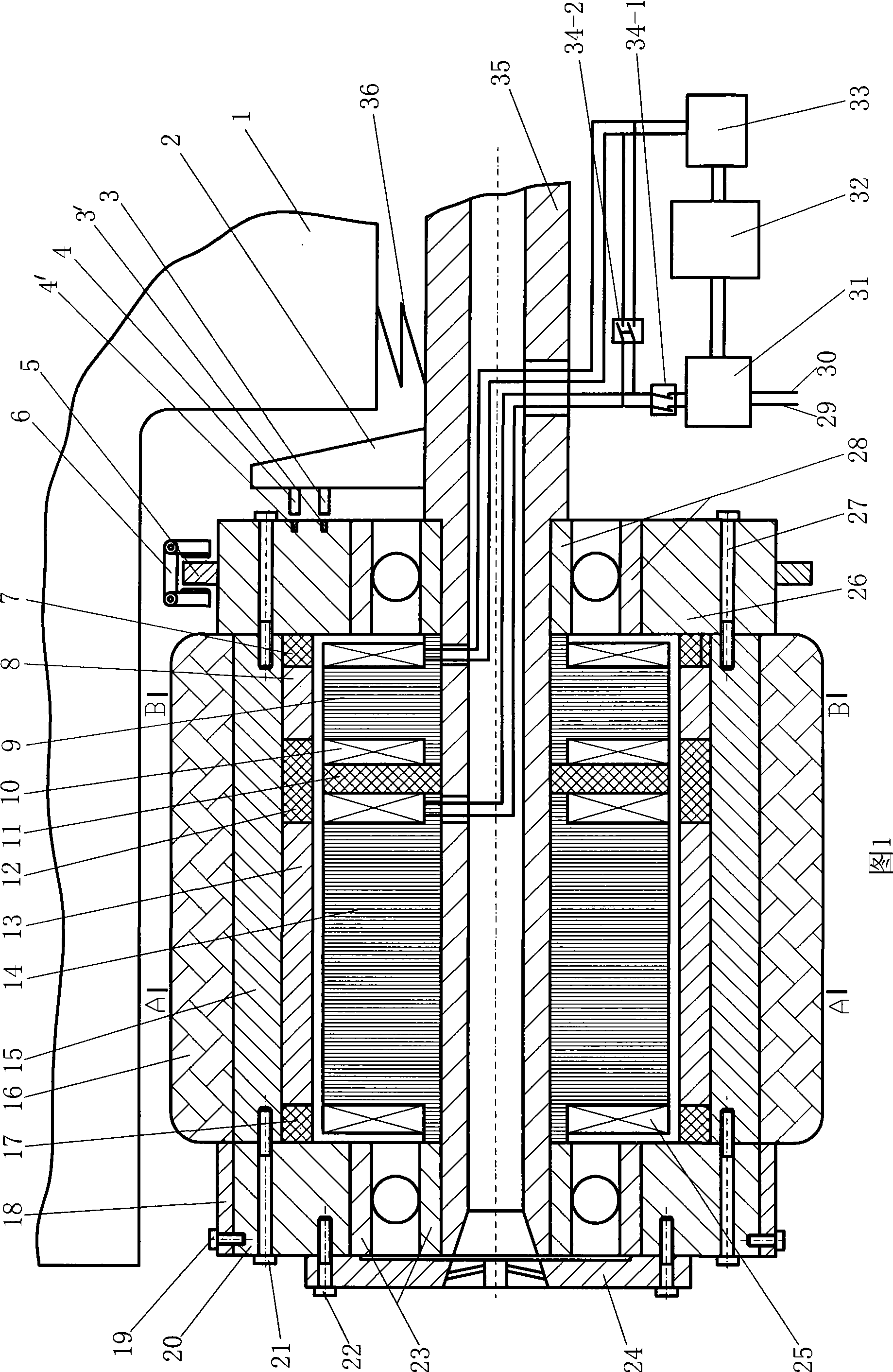

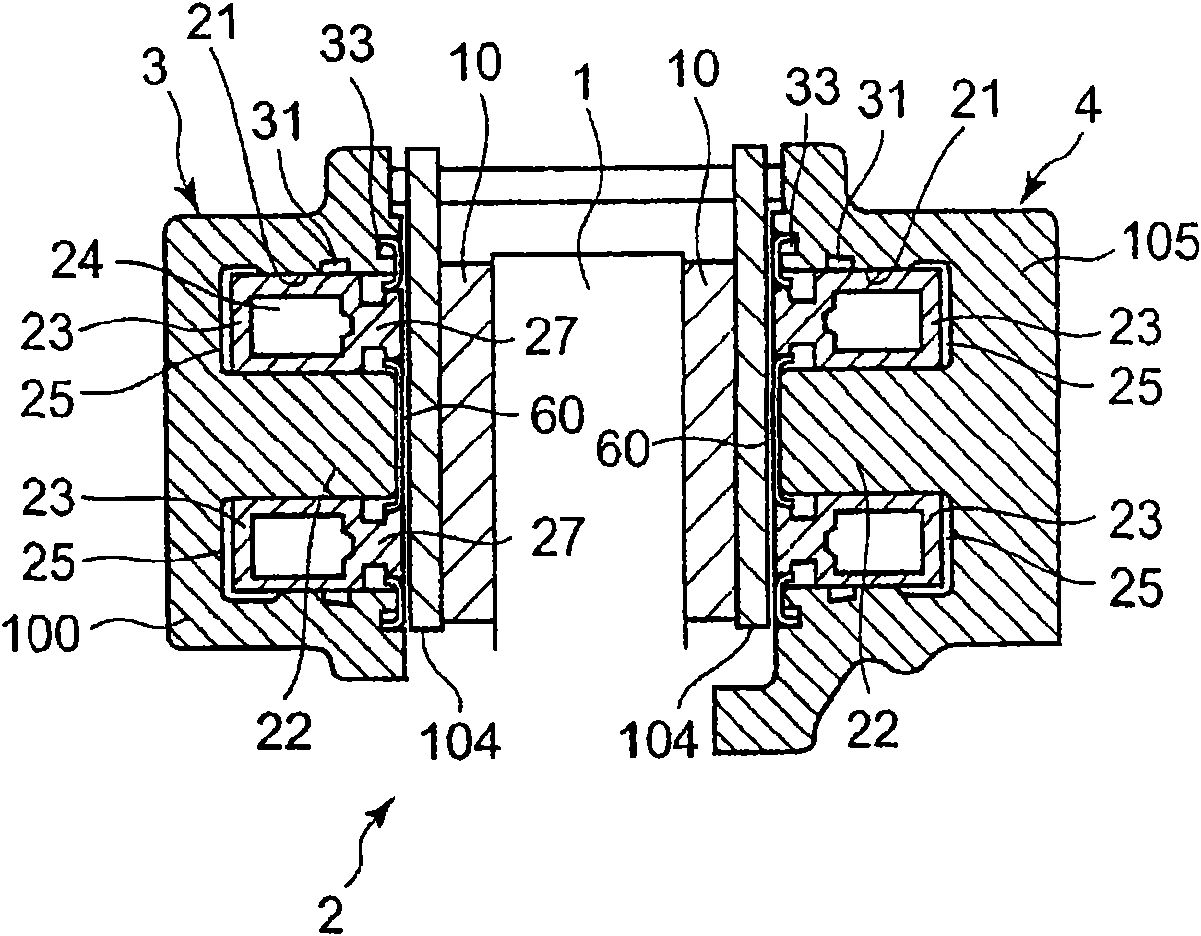

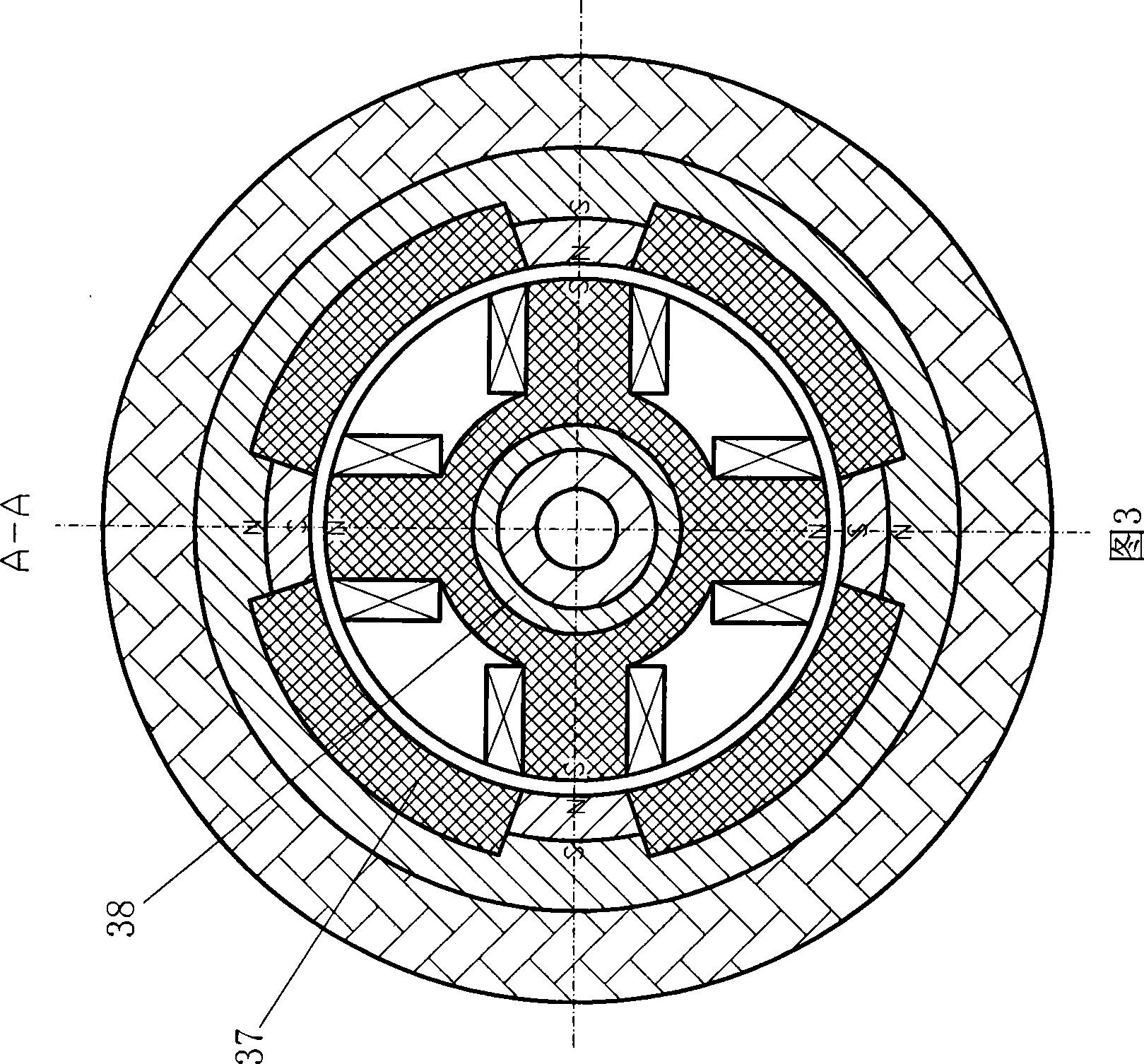

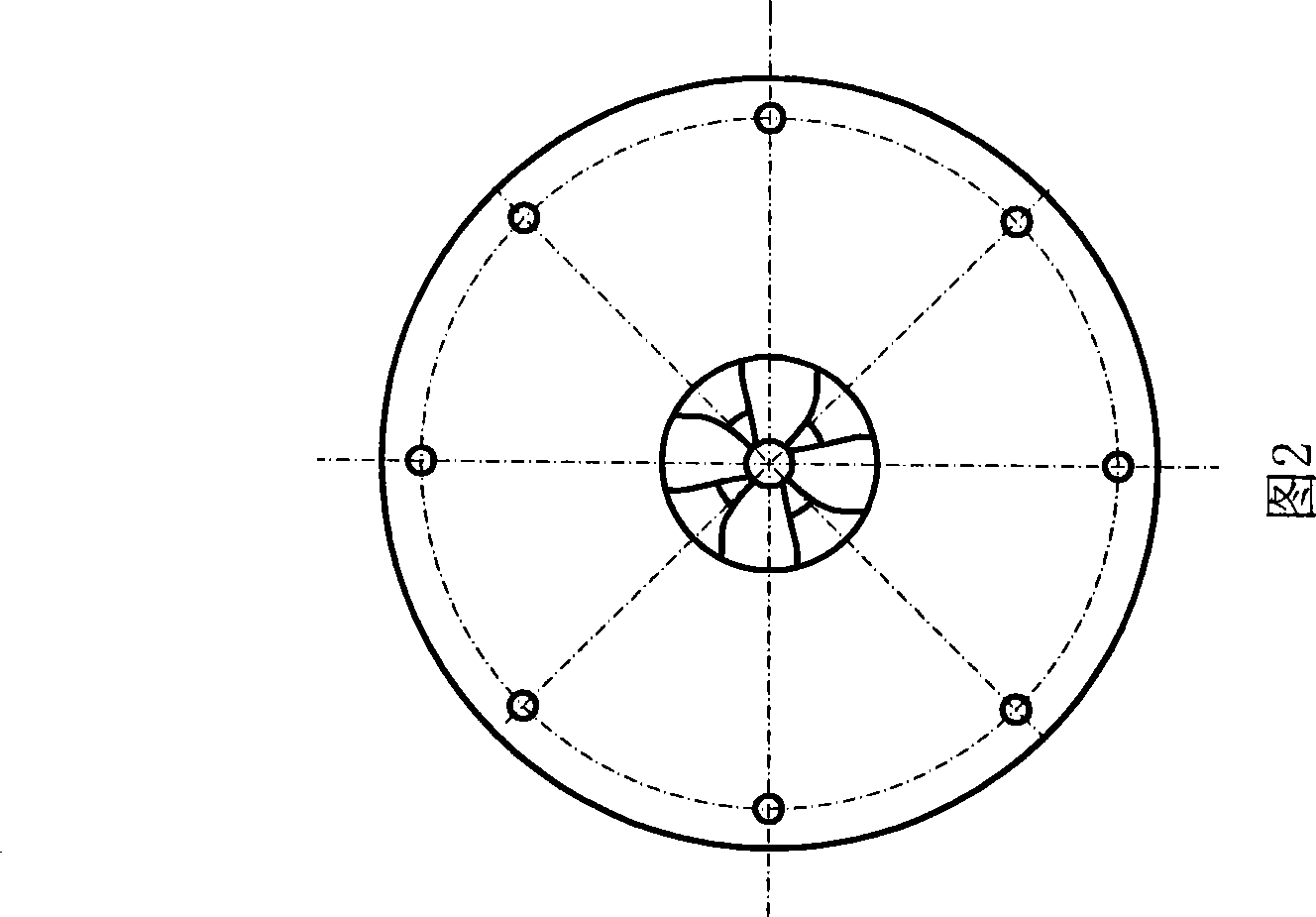

Integrated composite electromechanical machines

InactiveUS8188633B2Reduce the required powerIncrease powerSynchronous generatorsMagnetic circuit rotating partsAlternatorElectric machine

Embodiments of the present invention include a composite electromechanical machine which can operate as a motor or a generator (including dynamo or alternator). In an aspect, the present composite electromechanical machine comprises at least double-sided magnetic planes (e.g., rotor or stator) disposed on both sides of a central frames. Other embodiments can also be included.

Owner:YOSHYAMA EMIKO MRS

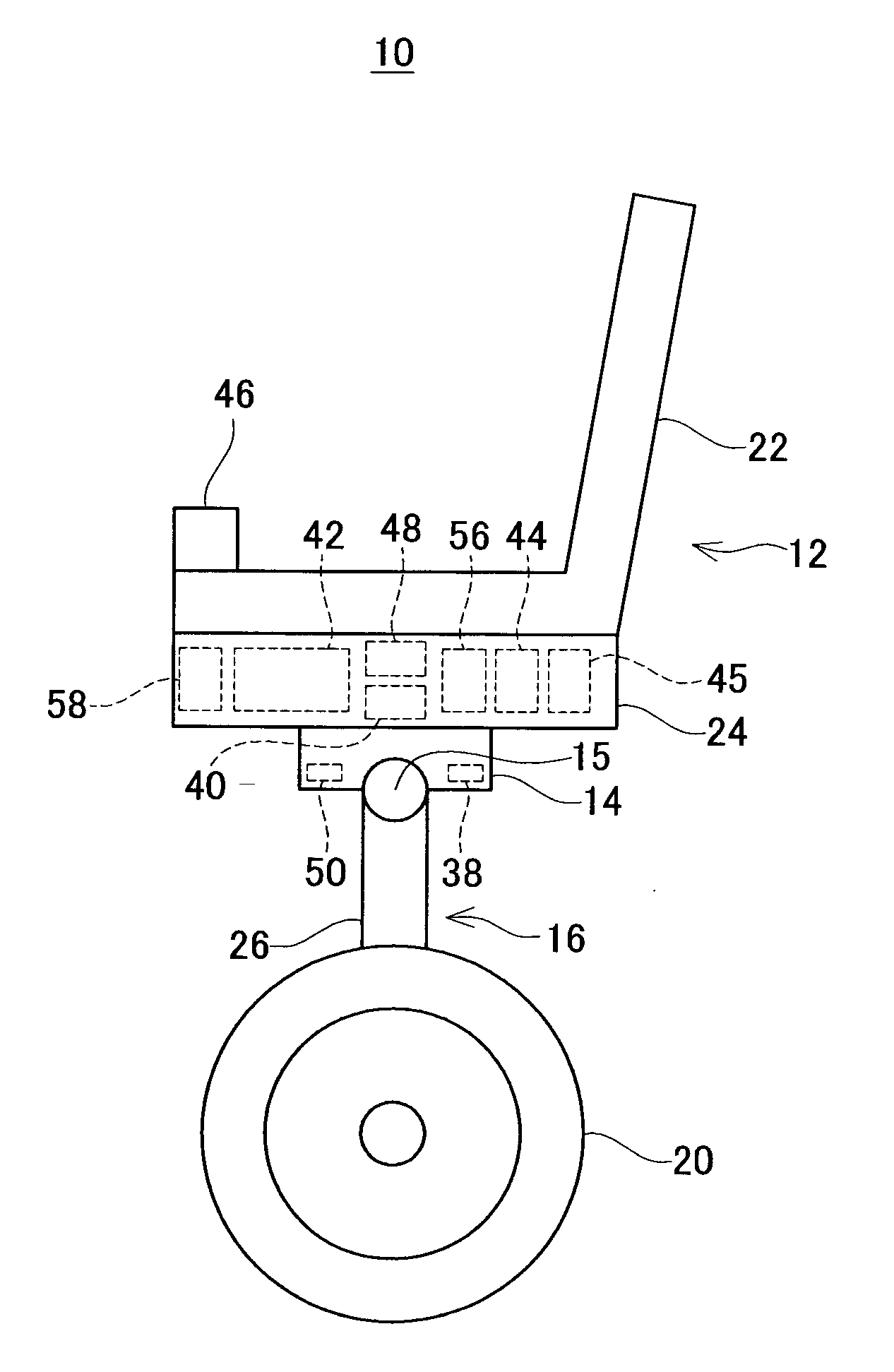

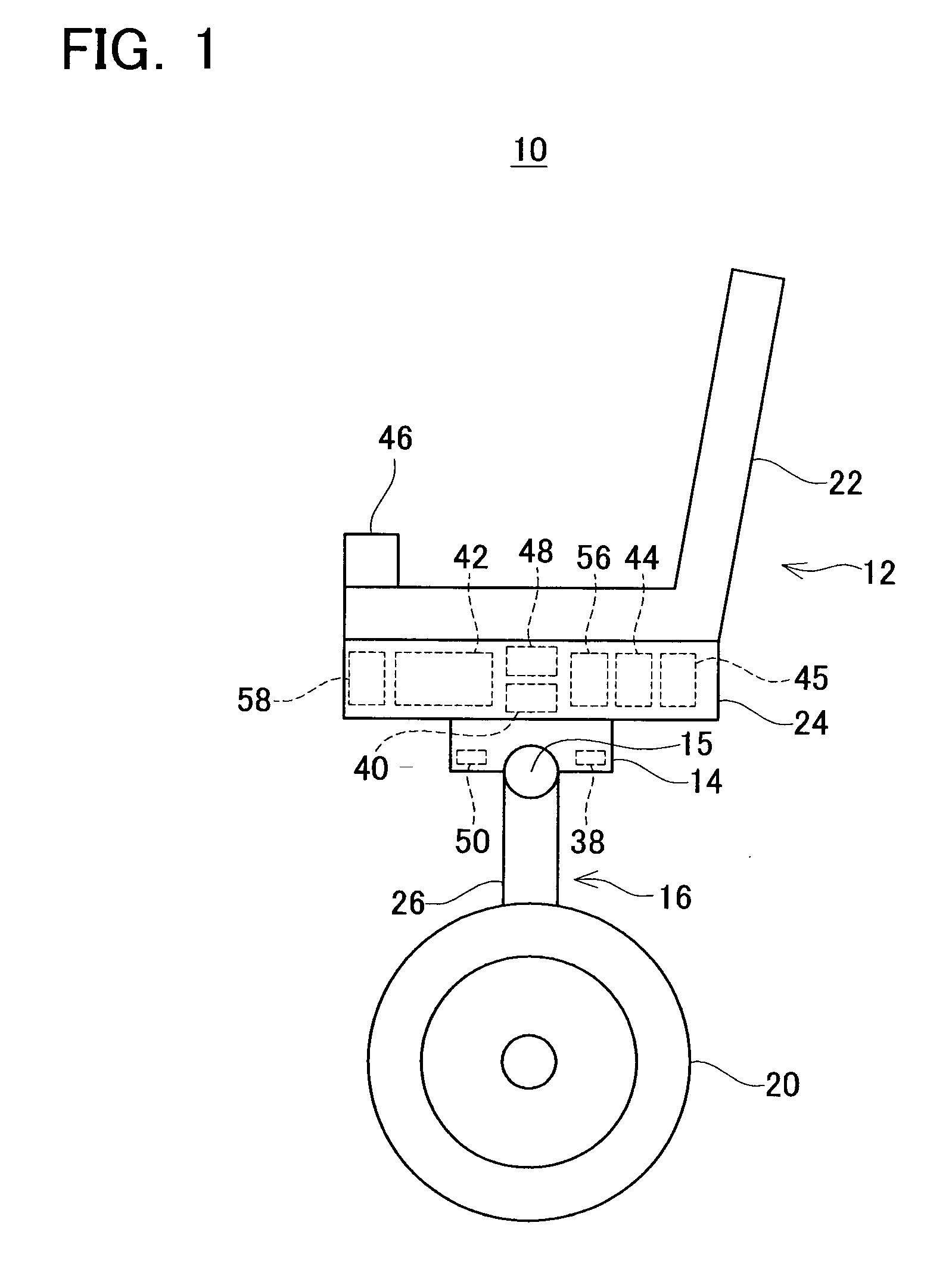

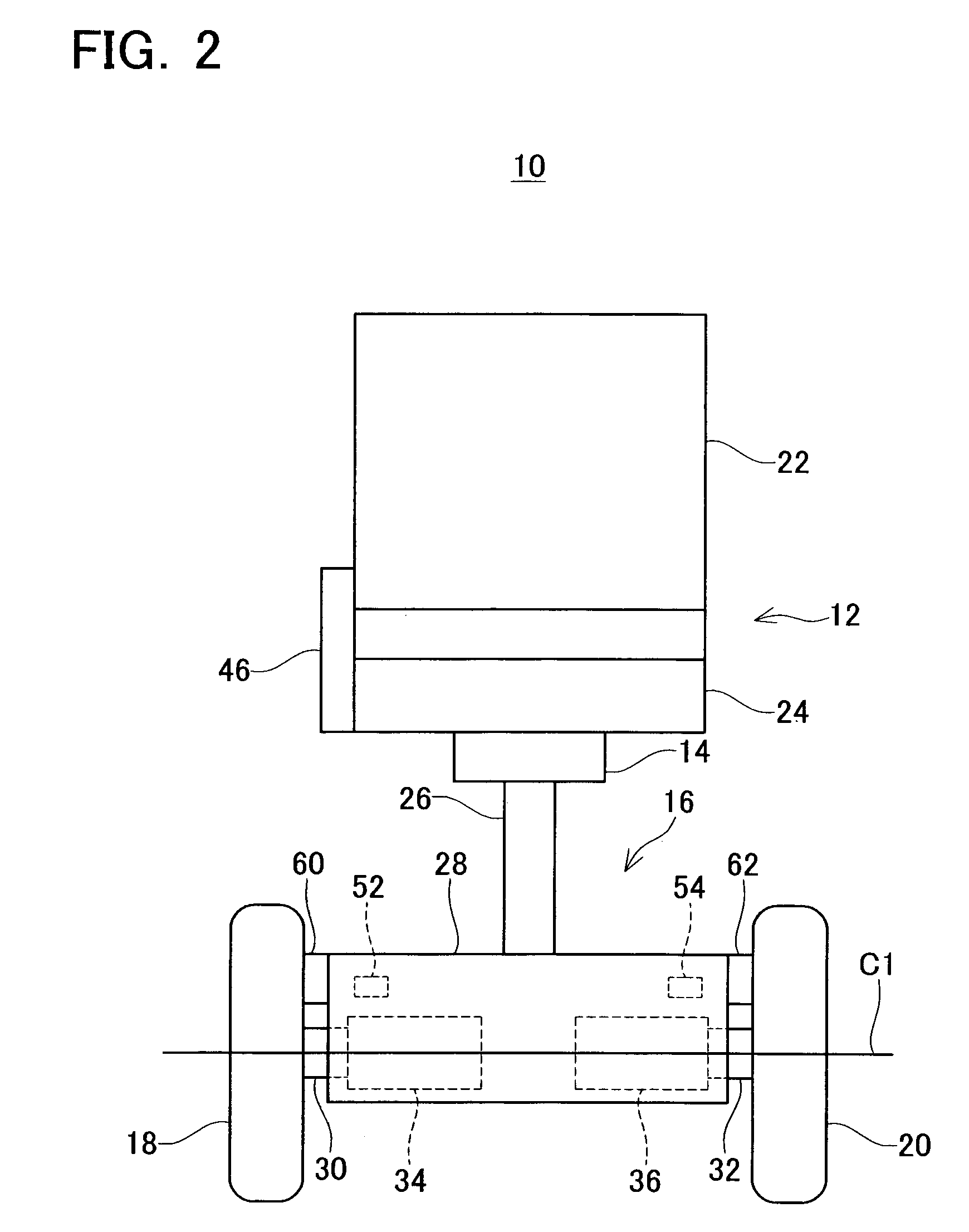

Coaxial two-wheeled inverted pendulum type moving vehicle

InactiveUS20090051136A1Strong brakingPassenger cyclesBraking element arrangementsMobile vehicleVehicle frame

The present invention provides, in connection with a coaxial two-wheeled inverted pendulum type moving vehicle, a technique which allows sudden braking without making a vehicle body to tilt significantly backward. The coaxial two-wheeled inverted pendulum type moving vehicle of the present invention comprises a pair of wheels, a chassis for supporting the pair of wheels coaxially and rotatably, wheel actuators for rotating the wheels with respect to the chassis, a vehicle body supported by the chassis, and an inverted pendulum control unit for controlling the wheel actuators so as to maintain the balanced state of the chassis. In this moving vehicle, the vehicle body is shiftable supported by the chassis in a manner that the vehicle body may shift in a direction parallel to the moving direction of the moving vehicle with respect to the chassis. The traveling body further comprises an attitude actuator for shifting the vehicle body along the moving direction of the moving vehicle with respect to the chassis, and a braking attitude control unit for controlling the attitude actuator so as to shift the vehicle body to a direction opposite to the moving direction of the moving vehicle with respect to the chassis when braking is commenced while the moving vehicle is in motion.

Owner:TOYOTA JIDOSHA KK

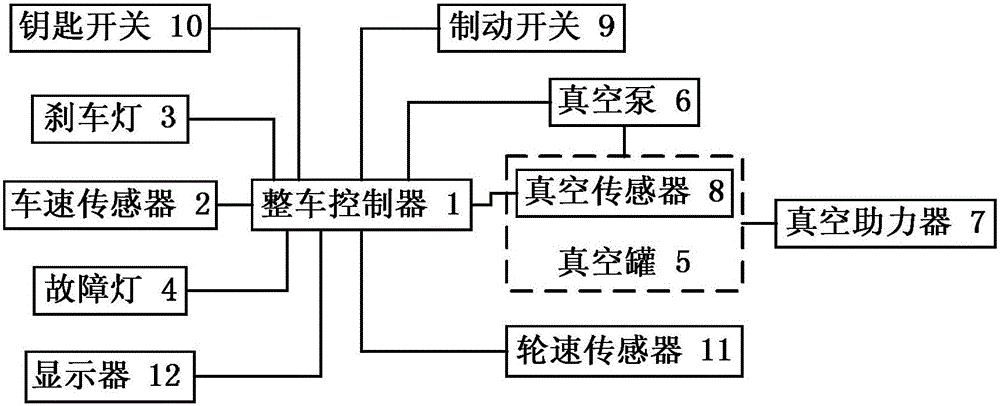

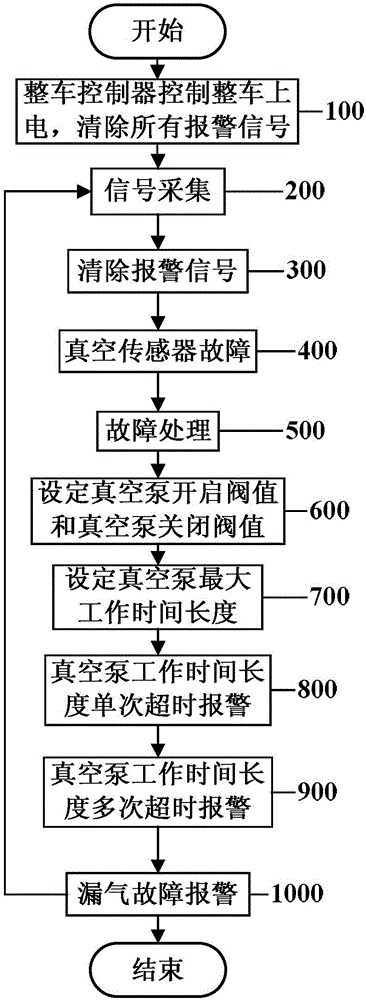

Electric vacuum pump controlling method and device

ActiveCN106812689AEasy to changeAdequate warning of potential safety hazardsBraking action transmissionPump controlWheel speed sensorVacuum pump

The invention discloses an electric vacuum pump controlling method and device. The electric vacuum pump controlling device comprises a vehicle control unit, a vehicle speed sensor, a brake light, a trouble light, a vacuum tank, a vacuum pump, a vacuum booster, a vacuum sensor arranged inside the vacuum tank, a brake switch connected with a brake pedal, a key switch, and a wheel speed sensor used for detecting the rotating speed of a vehicle tire. The vehicle control unit is electrically connected with the vehicle speed sensor, the brake light, the trouble light, the vacuum pump, the vacuum sensor, the brake switch, the key switch and the wheel speed sensor. The vacuum tank communicates with the vacuum pump and the vacuum booster through vacuum pipelines. The electric vacuum pump controlling device and method have the characteristics that power can be accurately controlled, braking force is high, electric power is saved and cost is low.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

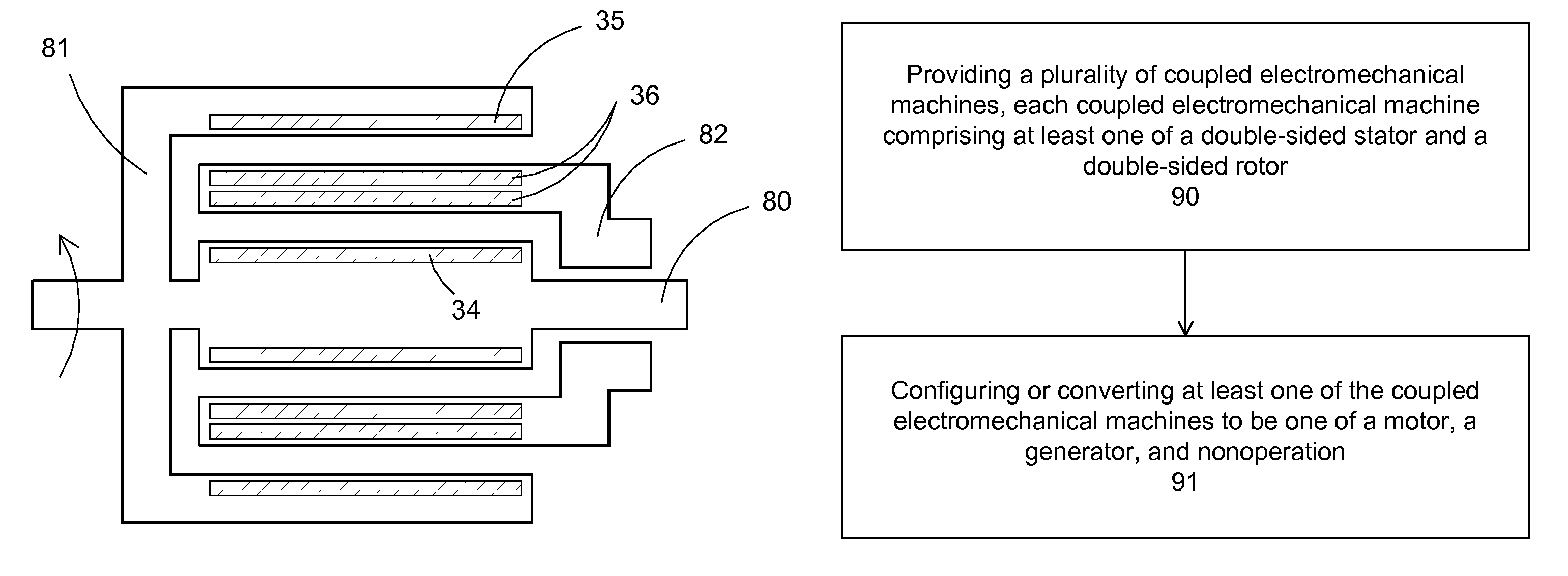

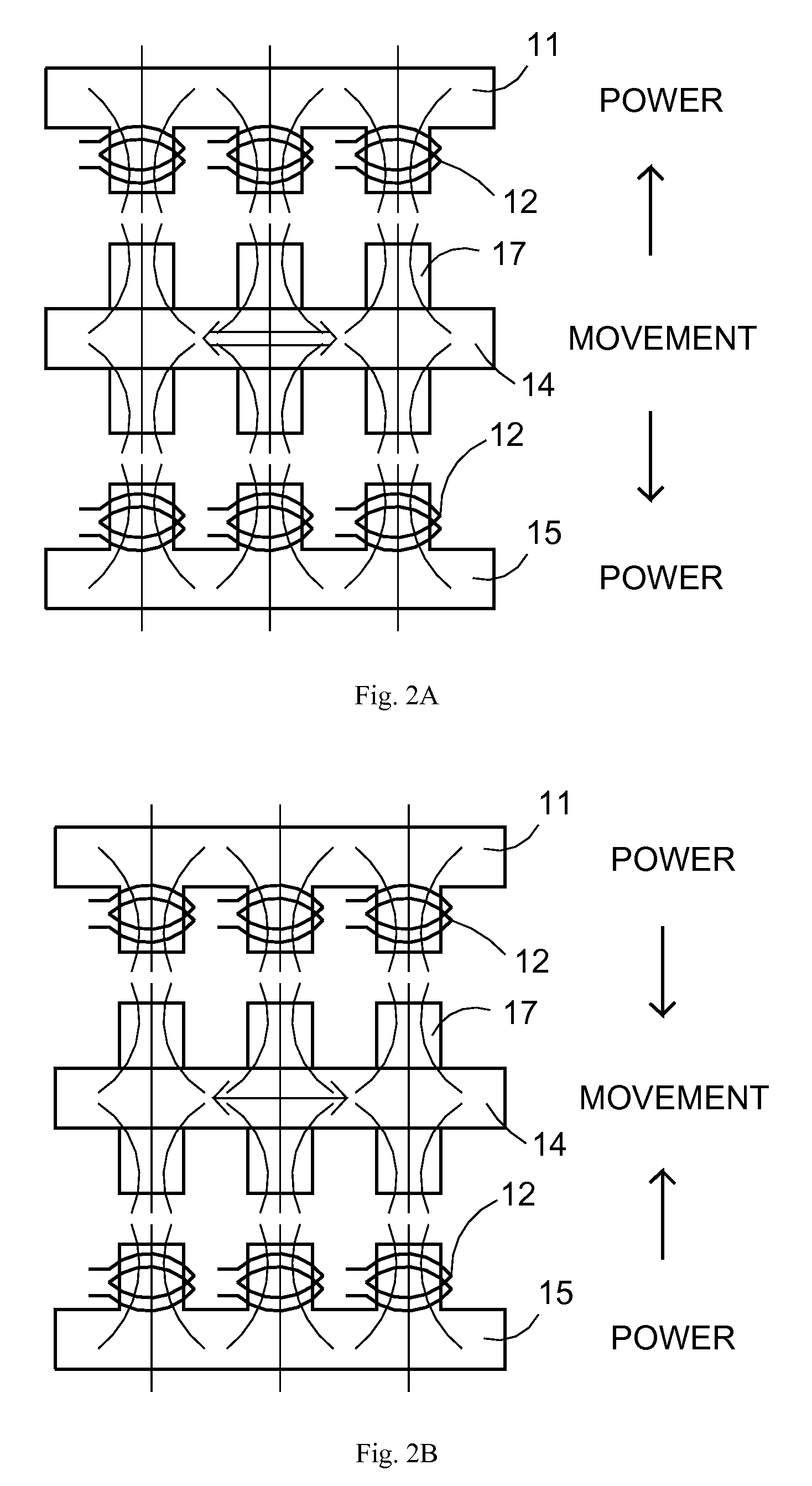

Composite electromechanical machines with controller

InactiveUS8183802B2Reduce the required powerIncrease powerDC motor speed/torque controlMultiple dynamo-motor startersAlternatorElectric machine

Embodiments of the present invention include a composite electromechanical machine which can operate as a motor, a generator (including dynamo or alternator), or any combination thereof. In an aspect, the present composite electromechanical machine comprises at least a double-sided magnetic plane (e.g., rotor or stator) to form two rotor / stator pairs, together with a controller to configure the multiple rotor / stator pair. The controller can configure or convert the multiple rotor / stator pairs into motors, generators, or nonoperation, and also can change the windings characteristics of the magnetic planes. The controller can add new functionality and characteristics to the present composite electromechanical machine. Other embodiments can also be included.

Owner:YOSHYAMA EMIKO MRS

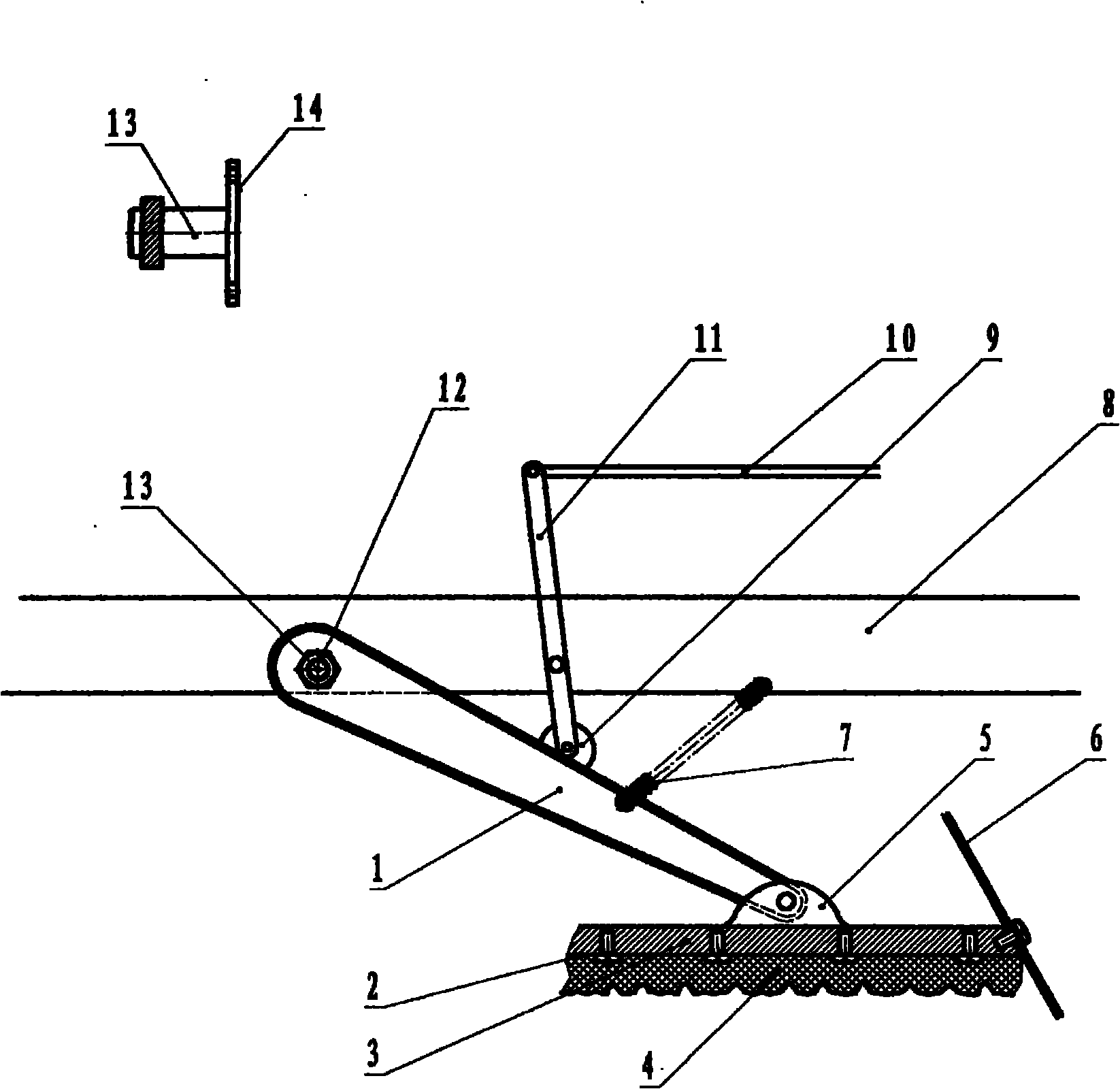

Anti-skidding brake for vehicles

InactiveCN102060007ASimple structureEasy to manufactureBraking element arrangementsLoad carryingArresting gear

The invention discloses an anti-skidding brake for vehicles, which comprises an anti-skidding plate, a connecting rod, a brake lever and the like. The anti-skidding plate comprises a plate base, anti-skidding adhesive and a snow shovel, the anti-skidding plate is provided with shaft bases towards the center, the shaft bases are connected with the connecting rod through shaft pins, another shaft base is arranged at the middle upper part of the connecting rod and connected with a brake lever through a shaft pin, and the brake lever is in braking connection with a hand brake in a cab through a pull rod. The anti-skidding brake is arranged at the forward-direction parts of rear vehicle wheels at two sides of a crossbeam of a vehicle. The anti-skidding brake for vehicles has the advantages of simple structure, low manufacturing cost, convenience of use, capability of breaking ice and shoveling snow and good anti-skidding and brake performance and is quite suitable for load-carrying vehicles.

Owner:肖德语

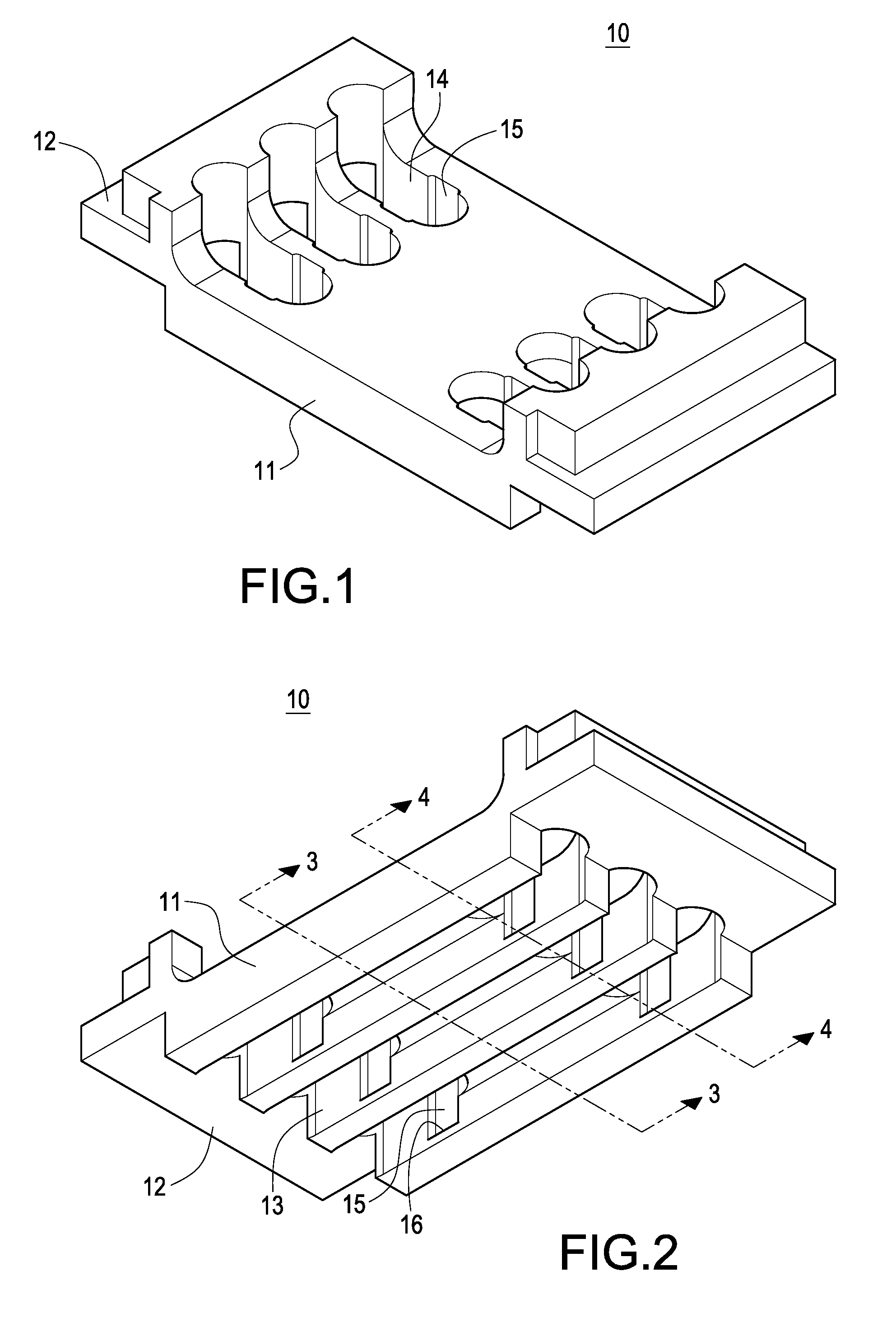

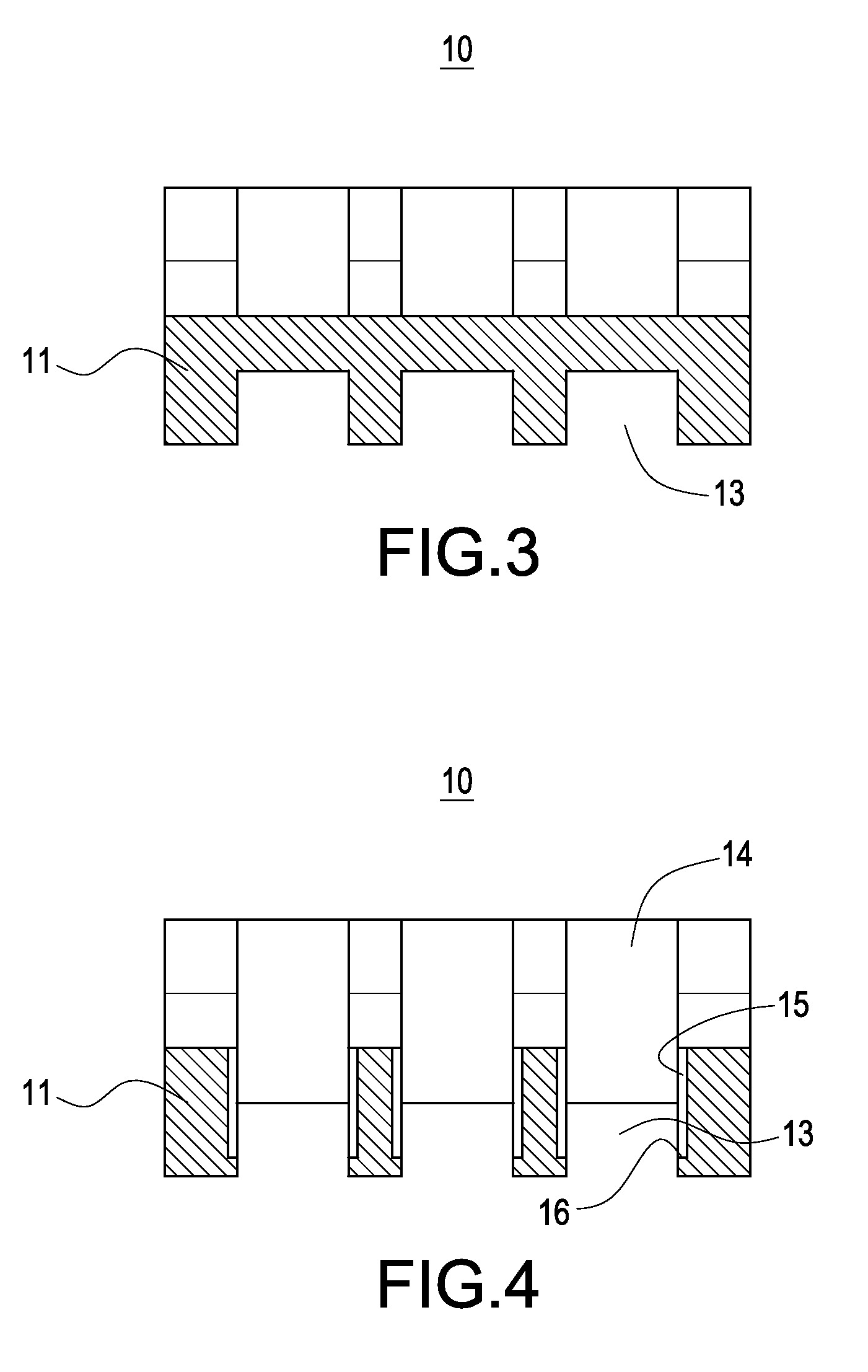

Combined assembly of fixing base and heat pipe

InactiveUS7950445B2Strong brakingEnsure stabilityIndirect heat exchangersHeat exchanger casingsEngineeringMechanical engineering

A combined assembly of a fixing base and heat pipes includes a fixing base and at least one heat pipe. The fixing base has a plate body. The bottom surface of the plate body is formed with a transverse opening trough. The opening trough is provided with a through-hole penetrating the plate body. A longitudinal groove is provided in the opening trough at a position corresponding to that of the through-hole. One end of the longitudinal groove does not penetrate the plate body and is formed into a loose-proof section on the bottom section of the opening trough. The heat pipe has a heat-absorbing section and a heat-releasing section. The heat-releasing section penetrates to the outside of the through-hole, and the heat-absorbing section is accommodated in the opening trough. A portion of the heat-absorbing section is inserted into the longitudinal groove and stopped by the loose-proof section, and the other portion thereof is formed with a plane that is in flush with the bottom surface of the plate body. Via the above arrangement, the fixing base can be combined with the heat pipes firmly and tightly.

Owner:GOLDEN SUN NEWS TECHN +1

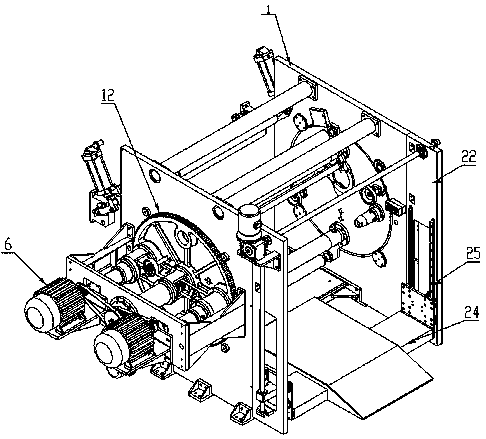

Rope-free lifting machine using lifting force as brake drive force

InactiveCN102040141AEnsure safetyAvoid flying accidentsElevatorsBuilding liftsElectric machineryArresting gear

The invention discloses a rope-free lifting machine using a lifting force as a brake drive force. The rope-free lifting machine comprises a supporting girder assembly, a cage, a linear electric motor drive device, a location guiding device, a brake device, a pair of safety tongs and a bumper. Concave strip grooves used as braking rails of the brake device and guiding rails of guiding location wheels are arranged on two side surfaces of the supporting girder assembly. A rotor of a linear electric motor is in split sliding connection with the cage and is connected with a brake push rod, the lifting force of the rotor of the linear electric motor is used as the brake releasing force of a boost type clamp brake, the down accelerated speed of the rope-free lifting machine can be automatically limited without using a special brake drive power supply, a brake driver and a controller, thus the structure of the brake is simplified. The rope-free lifting machine has the four defensive functionsof the power-off protection of the brake, the safety speed-limiting of the brake, the power-off dynamicbraking of the linear electric motor and the overspeed brake of the safety tongs, and fundamentally ensures the safety and the reliability of the lifting machine.

Owner:HENAN POLYTECHNIC UNIV

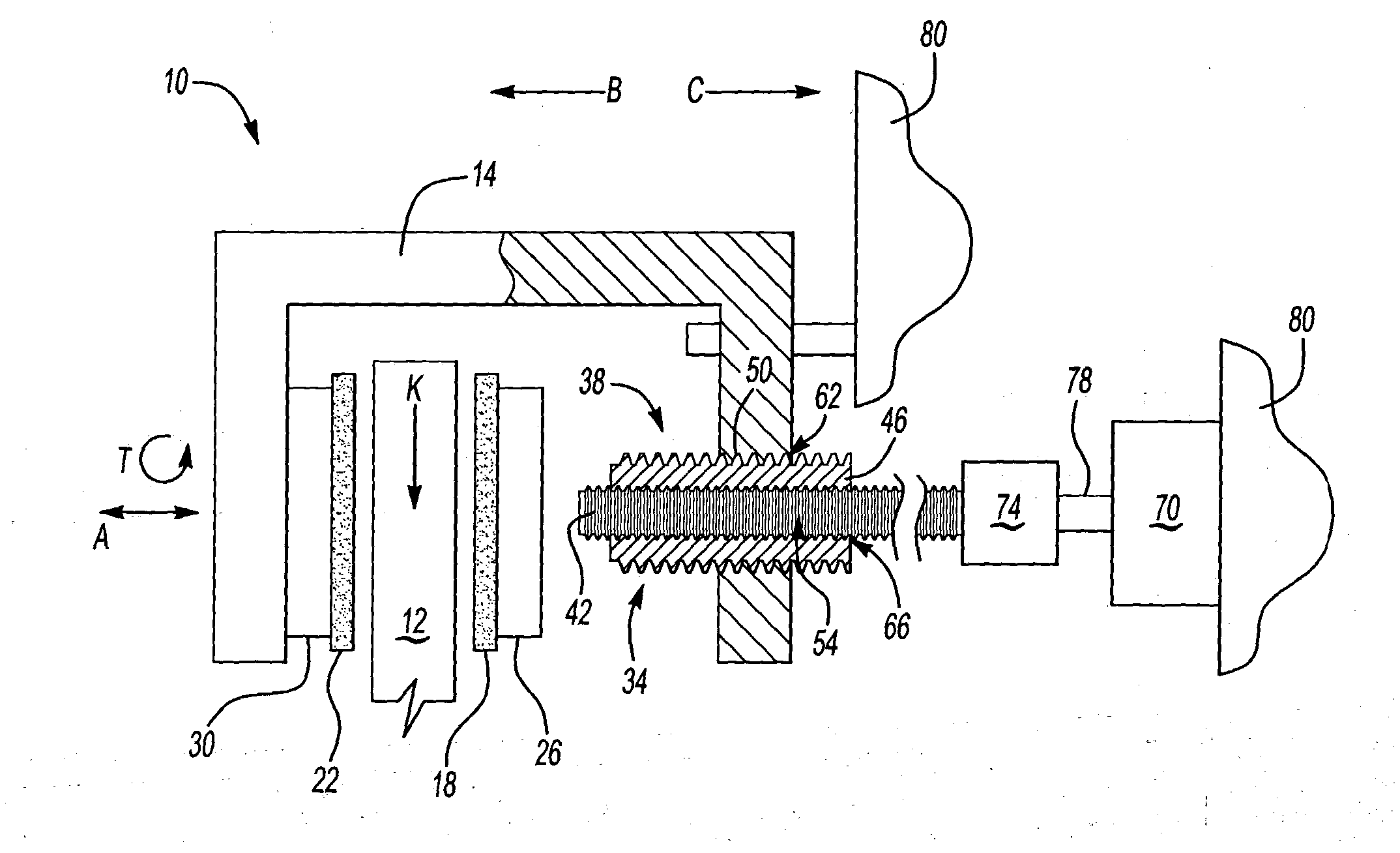

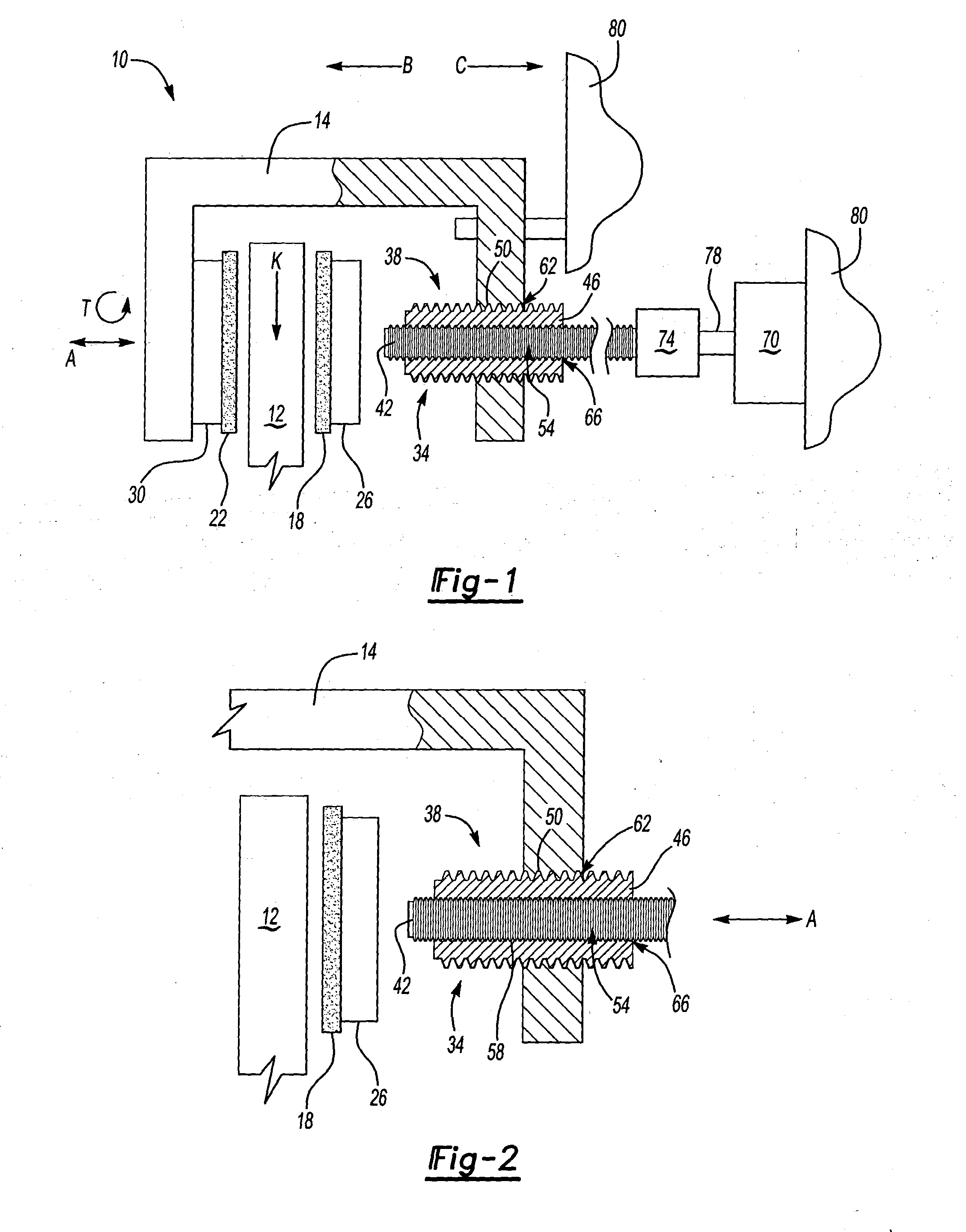

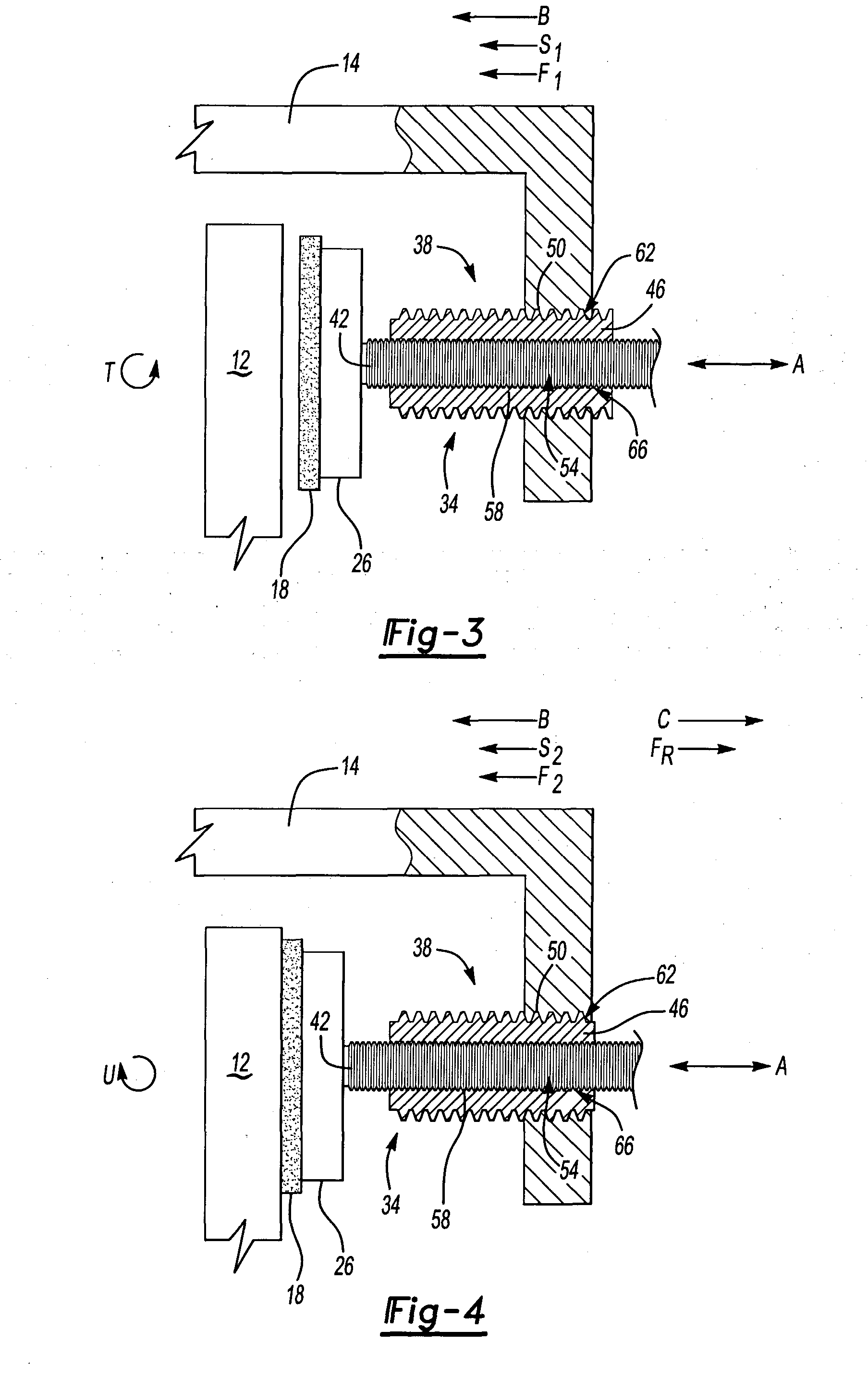

Multiple ball screw assembly with differing pitch used to optimize force and displacement of brake actuator

InactiveUS20050006187A1Strong brakingQuickly and efficiently applies braking forceMechanically actuated brakesBrake actuating mechanismsBall screwClassical mechanics

A brake assembly has a caliper with a first brake pad and a second brake pad. The first brake pad is moveable relative to the caliper. A brake actuator moves the first brake pad and has a first threaded member and a second threaded member. The first threaded member has first thread characteristics for moving the brake actuator at a first speed and a first force. The second threaded member has a second thread characteristics for moving the brake actuator at a second speed and a second force. The first speed is greater than the second speed while the first force is lower than the second force.

Owner:ARVINMERITOR TECH

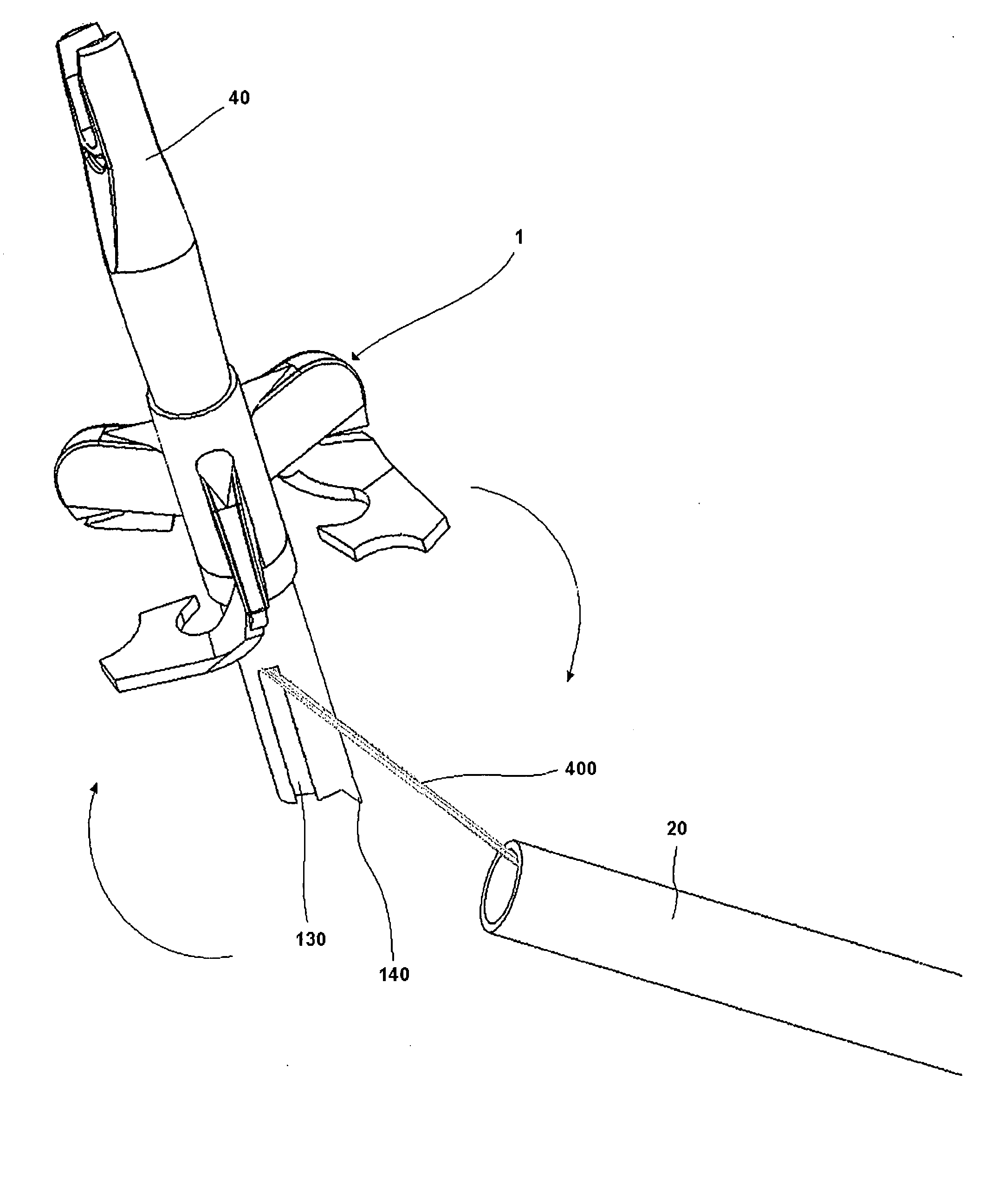

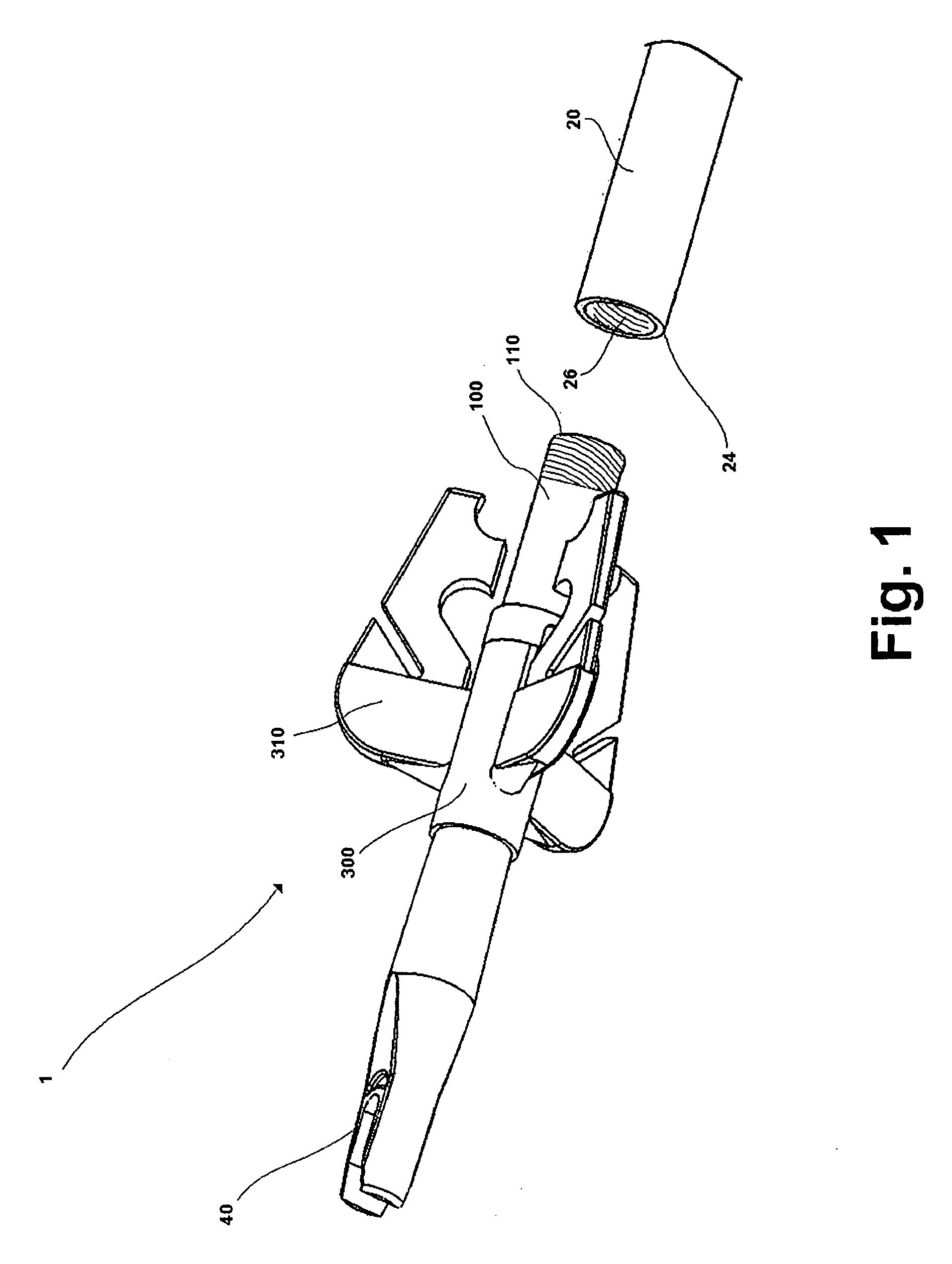

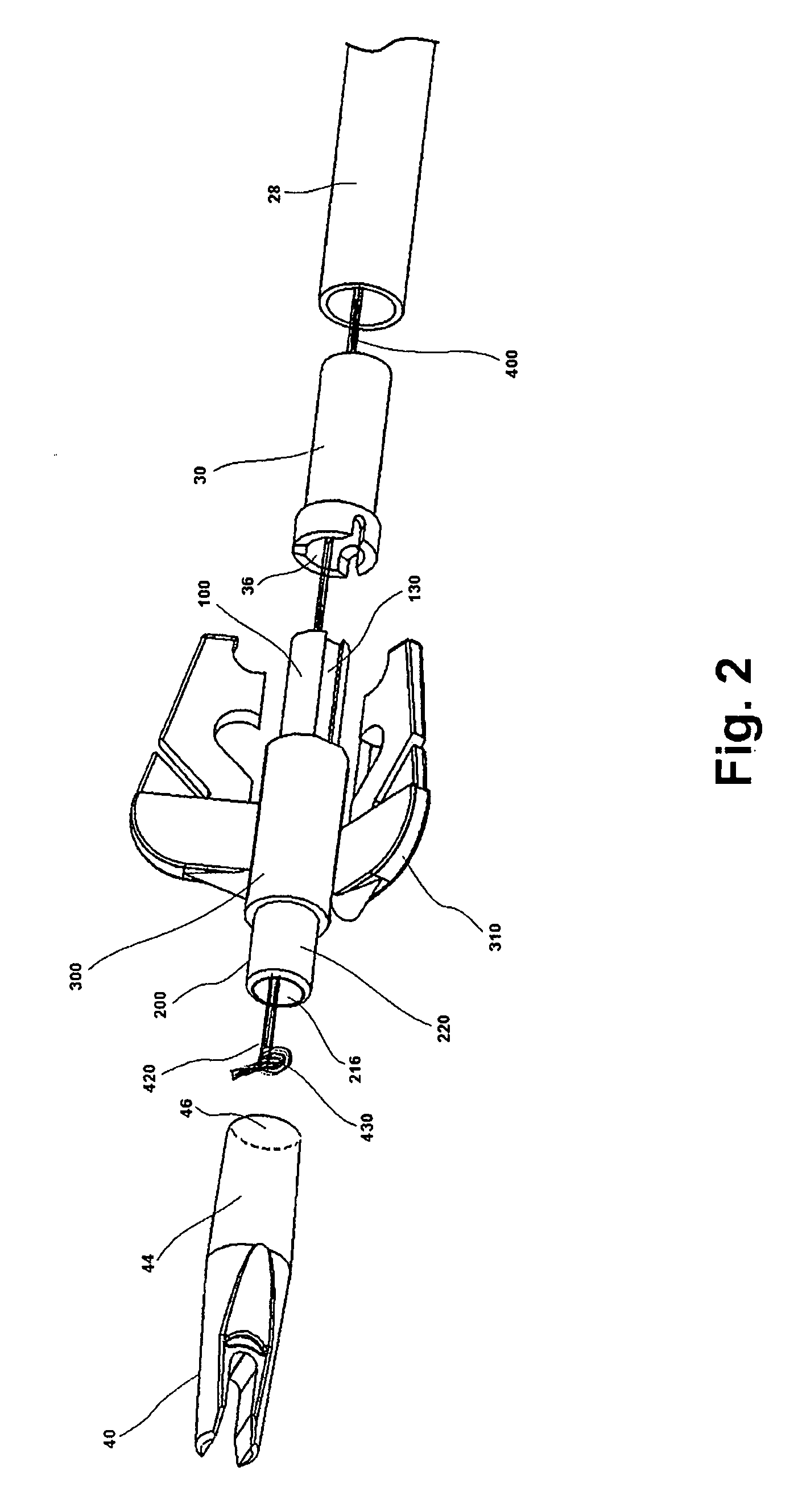

Rear mounted penetration limiter for bow-fired projectiles

A rear mounted penetration limiter for bow-fired projectiles for use in combination with a projectile and a nock, wherein said projectile is an arrow or a crossbow bolt, said penetration limiter comprising an attachment component, a nock securing component, and an engagement component having one or more engagement members, with said penetration limiter suitably adapted to limit the penetration of the projectile through a game animal once the front end of the projectile has struck and passed through the game animal, thereby allowing the creation of an exit wound while retaining the projectile within the game animal. In one embodiment the penetration limiter is adapted to detach from the projectile, remaining secured thereto by a short tether, thereby allowing the detached penetration limiter to reorient itself within the game animal to create greater drag on the projectile.

Owner:CYR MAURICE MR

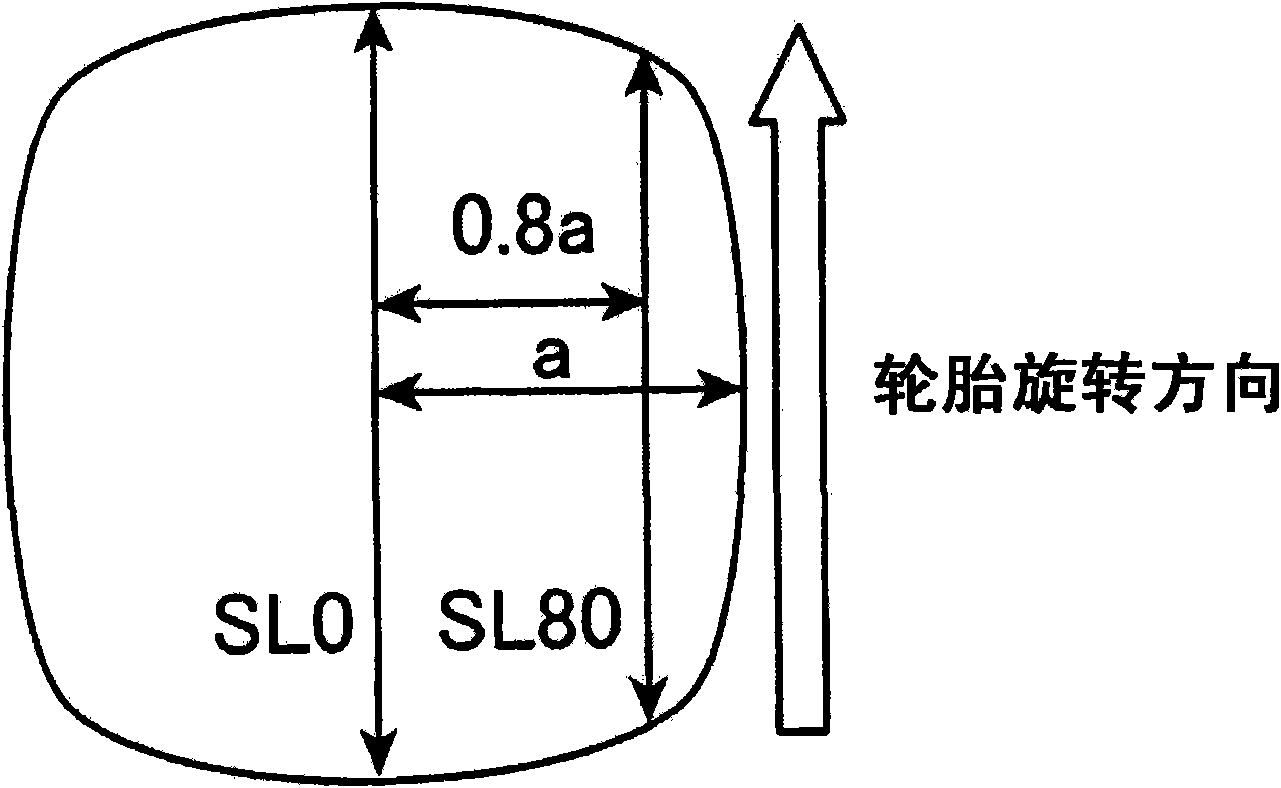

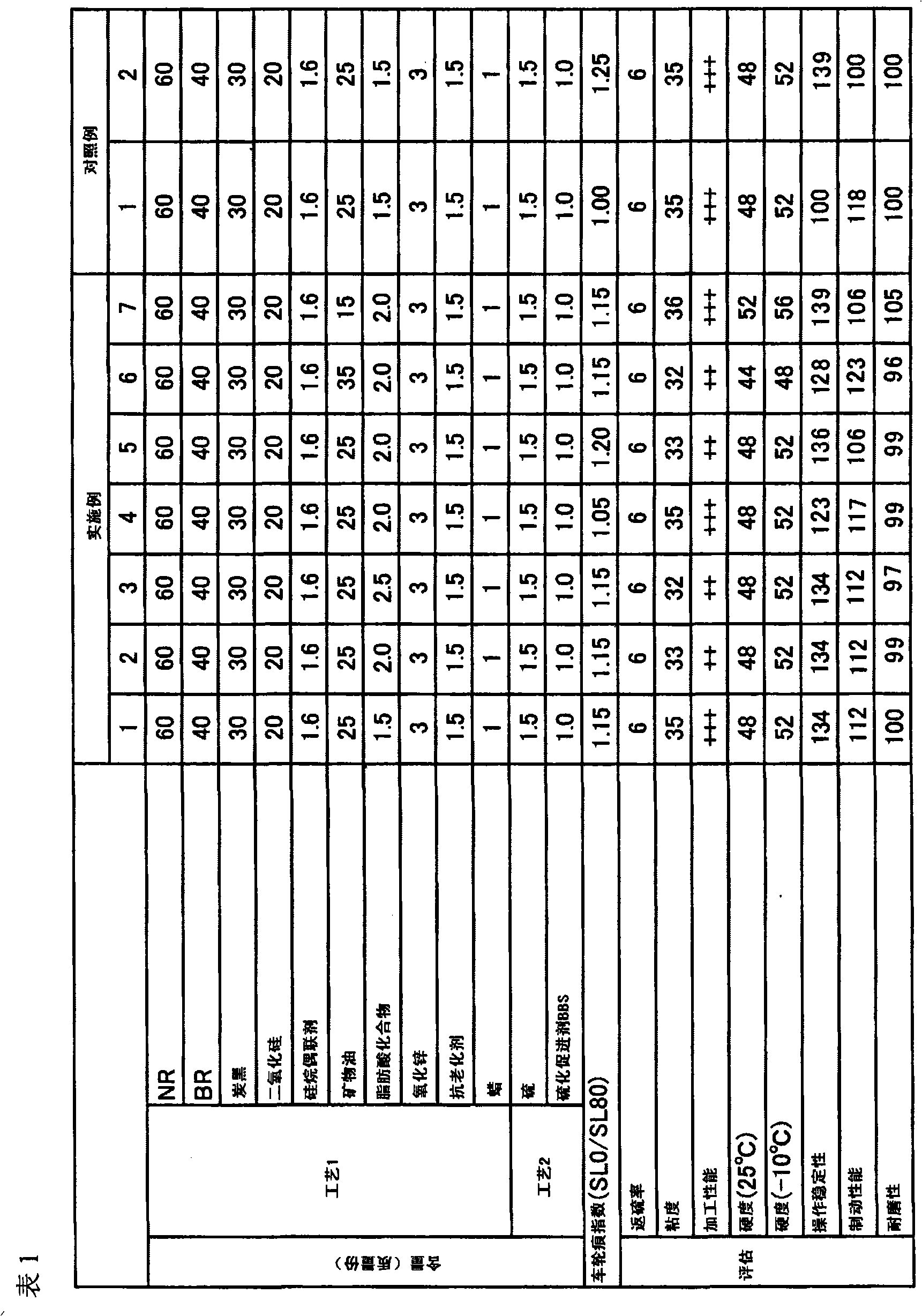

Rubber composition for studless tire and studless tire using the same

InactiveCN101665063AImprove operational stabilityImprove productivitySpecial tyresTyre tread bands/patternsProduction rateOperational stability

The present invention has its object to provide a high performance studless tire, which has both good braking force and high handling stability on ice or snow, at higher productivity and at a lower price for customers. The studless tire comprises a tread made of a rubber composition that contains 0.5 to 5.0 parts by mass of a fatty acid and / or a derivative of the fatty acid per 100 parts by mass of a rubber component.

Owner:SUMITOMO RUBBER IND LTD

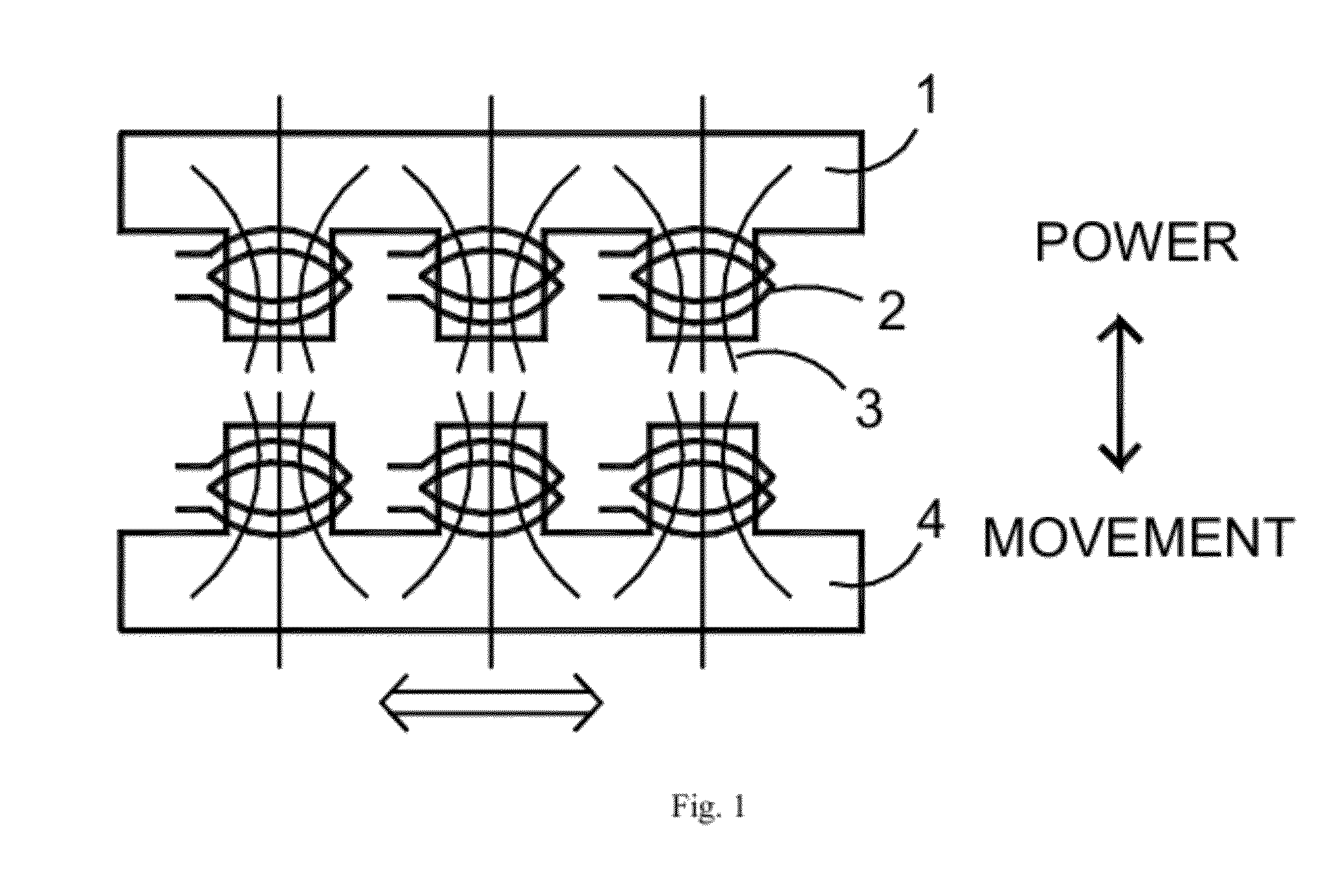

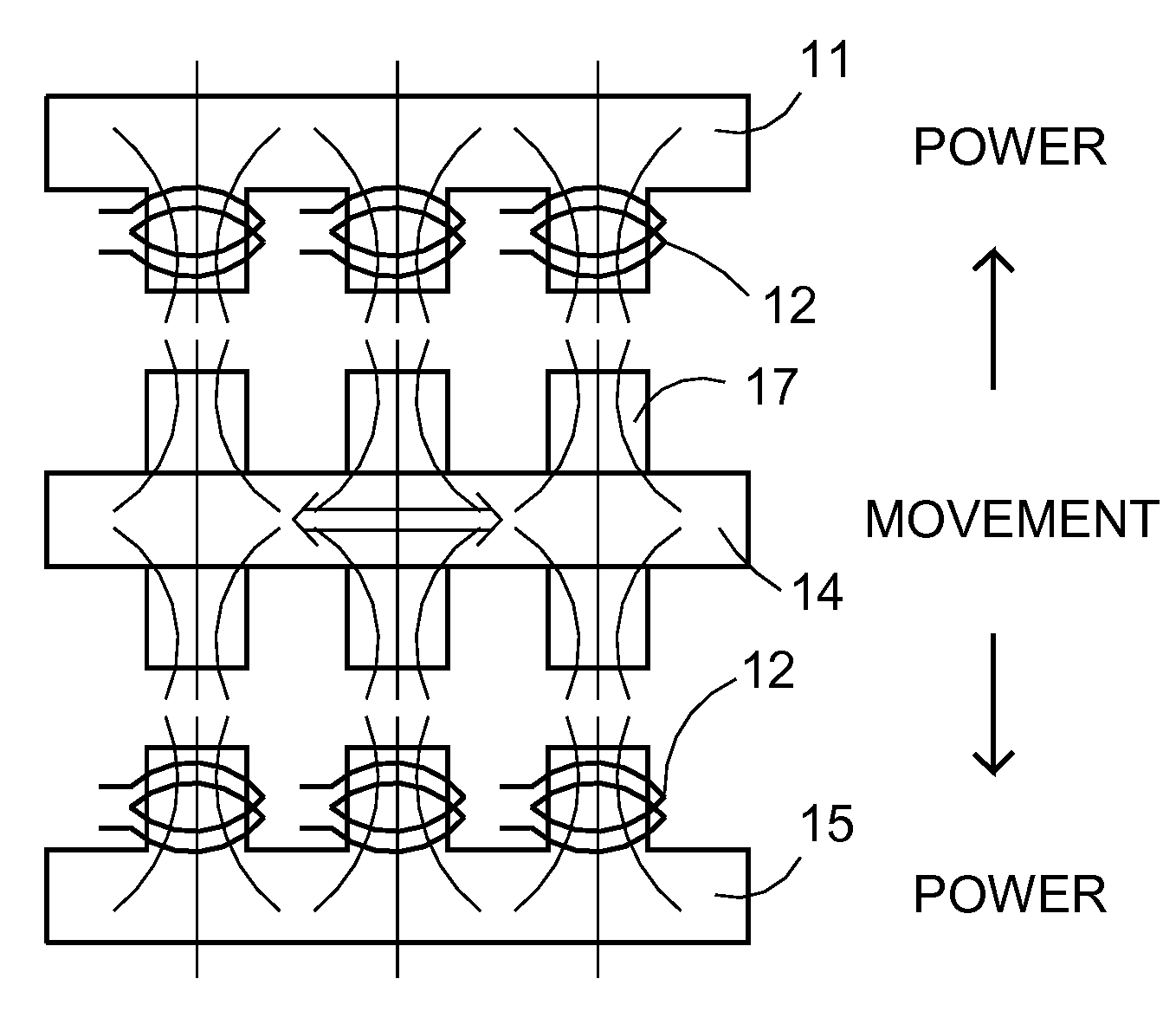

Composite electromechanical machines with controller

InactiveUS20100171450A1Reduce the required powerIncrease speedSynchronous motors startersAC motor controlAlternatorElectric machine

Embodiments of the present invention include a composite electromechanical machine which can operate as a motor, a generator (including dynamo or alternator), or any combination thereof. In an aspect, the present composite electromechanical machine comprises at least a double-sided magnetic plane (e.g., rotor or stator) to form two rotor / stator pairs, together with a controller to configure the multiple rotor / stator pairs. The controller can configure or convert the multiple rotor / stator pairs into motors, generators, or nonoperation, and also can change the windings characteristics of the magnetic planes. The controller can add new functionality and characteristics to the present composite electromechanical machine. Other embodiments can also be included.

Owner:YOSHYAMA EMIKO MRS

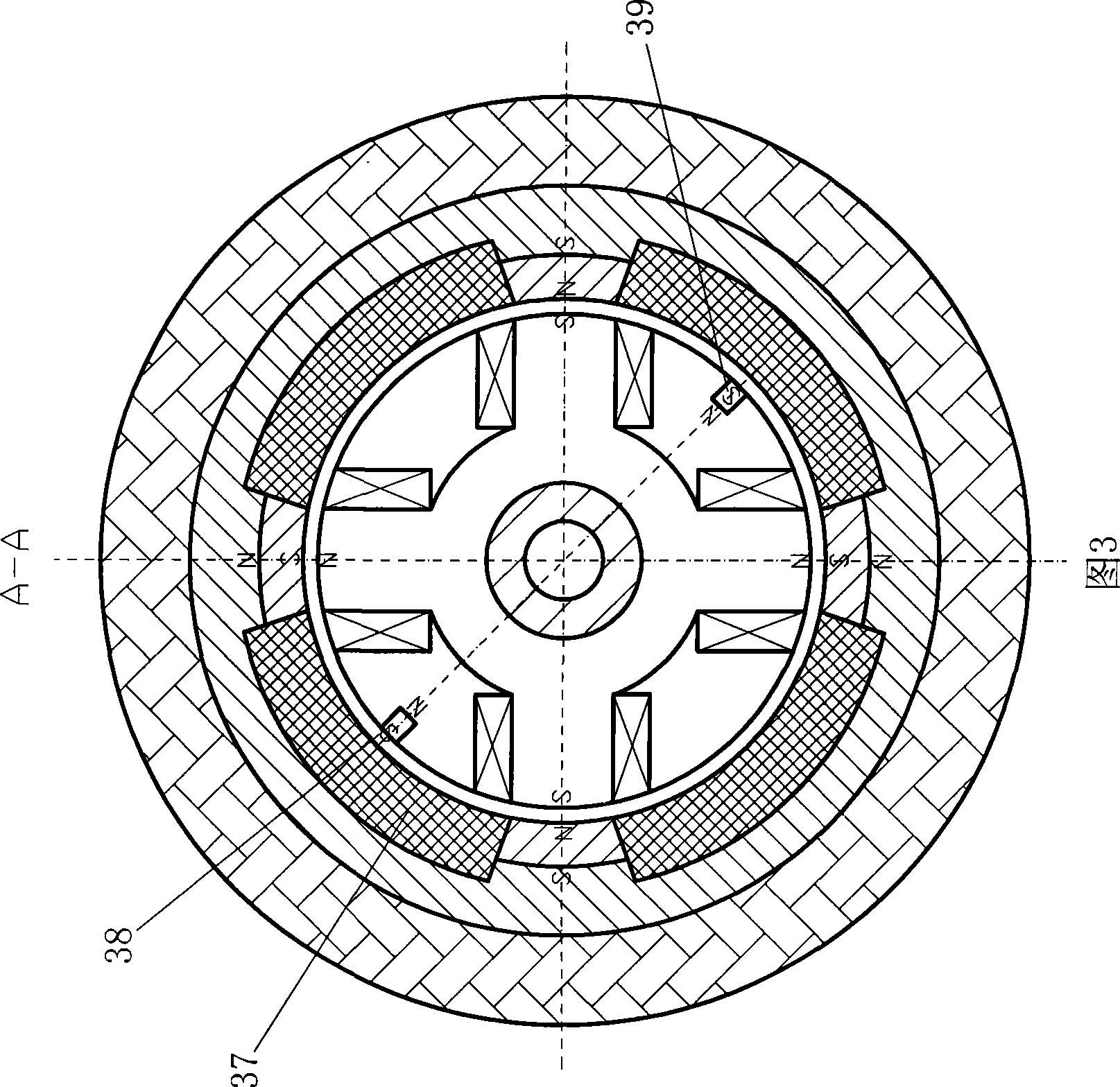

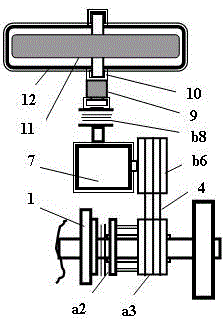

Magnetic energy car

InactiveCN101362440AAchieve driving speedAchieve direct controlElectric machinesMechanical energy handlingElectrical batteryMagnetic poles

The invention is composed of a vehicle main body and a control system. The vehicle main body is composed of a vehicle body and a magnetic energy machine wheel, and the control system is composed of a control computer, a bus, a power electronic device, a sensor, a battery system and software. The magnetic energy machine wheel is composed of a stator, a wheel and a bearing, wherein, the wheel rotates around the stator, the stator core is a rectangular gear shape, and the tooth is winded with a coil; a tire, a wheel hub, a magnetizer, a non-magnetic body and a permanent magnet form a multipolar wheel with alternate polarities along the circumference of a circle. The magnetic energy machine wheel comprises two parts: an electric motor and an electric generator. The electric generator is connected with the battery system through a rectifier voltage regulator, and a stator coil is connected with the battery system through a frequency modulator. The control system acquires the position signal of the rotor pole to the stator core tooth according to the sensor, the stator coil is energized with current with different directions alternately, and the wheel is rotated under the actions of the attractive torque and the repulsive torque of the electromagnetic poles of the stator teeth. The invention has the advantages of extremely high efficiency, energy conservation and environmental protection.

Owner:刘新广

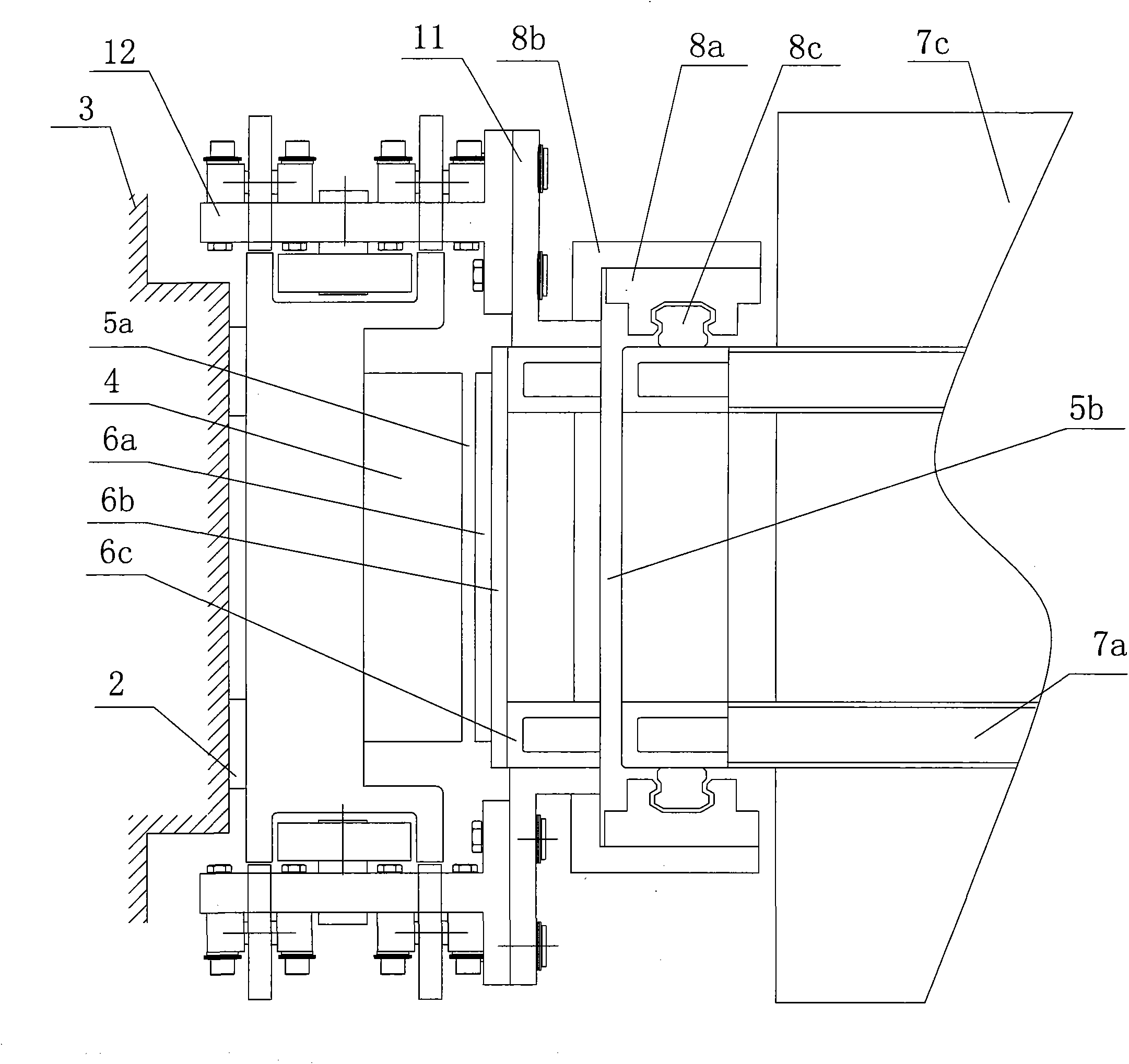

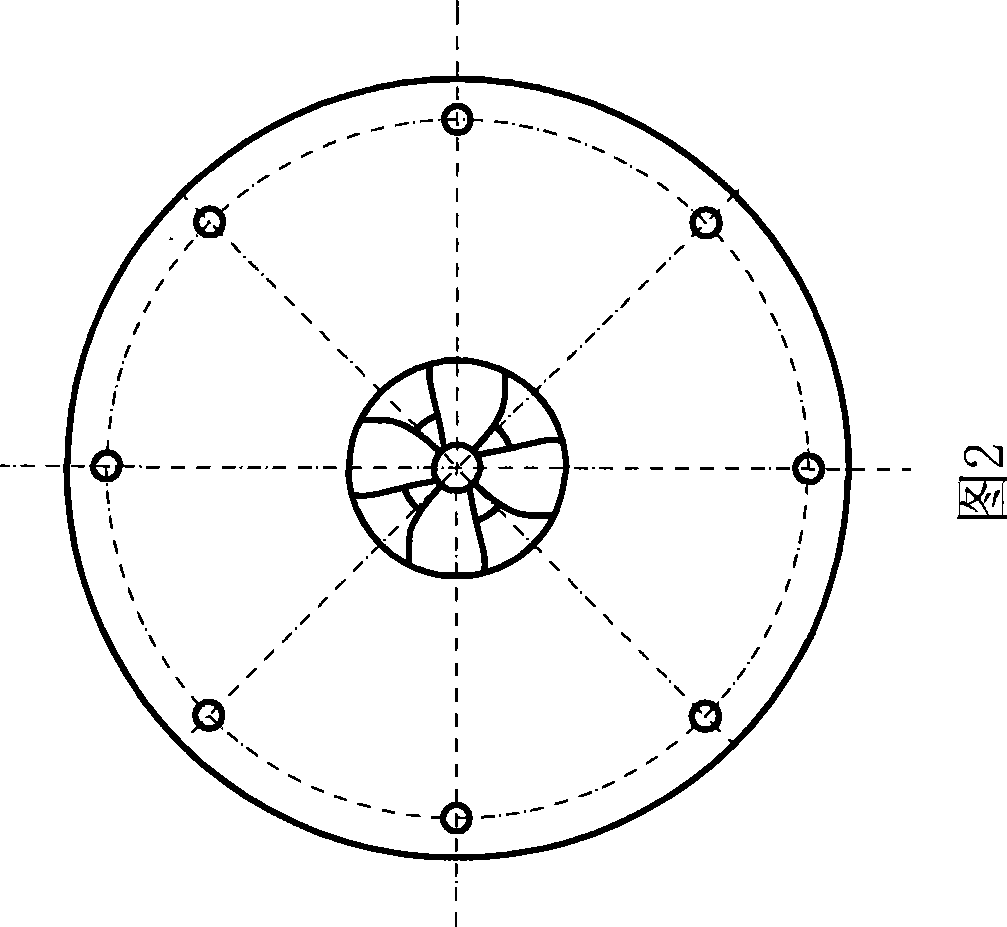

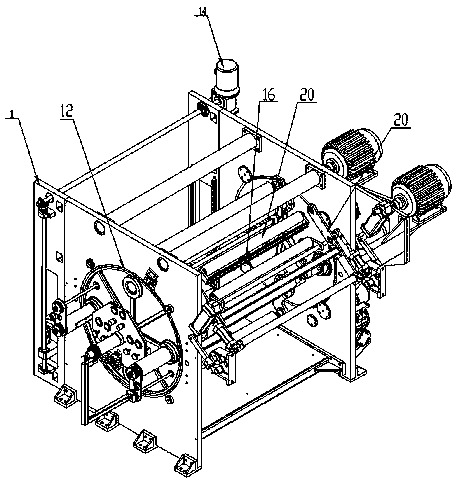

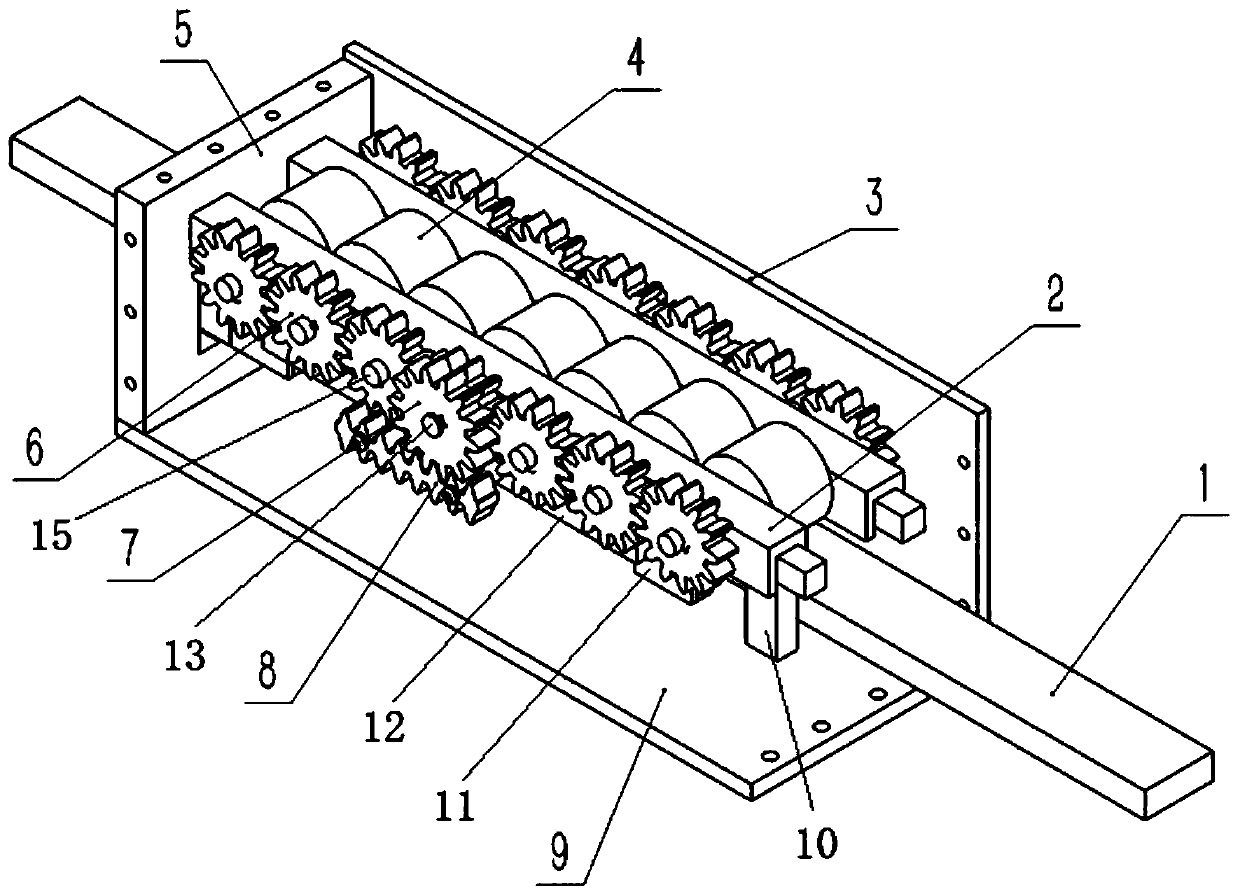

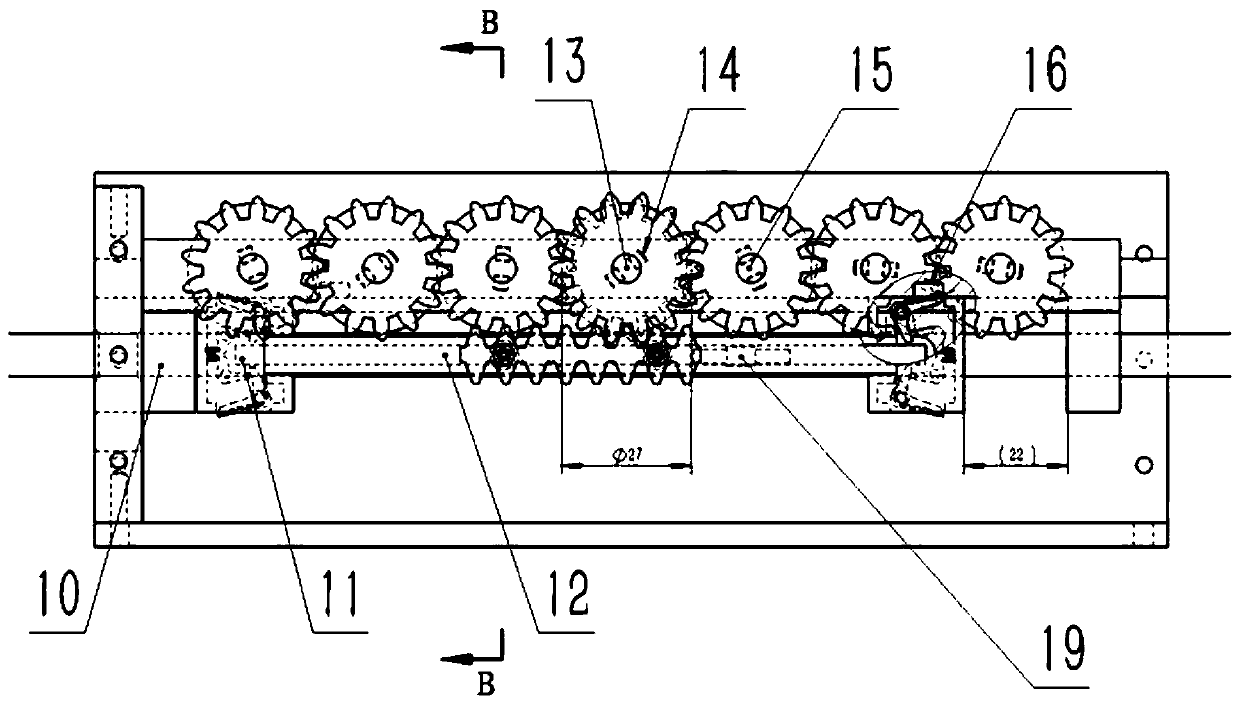

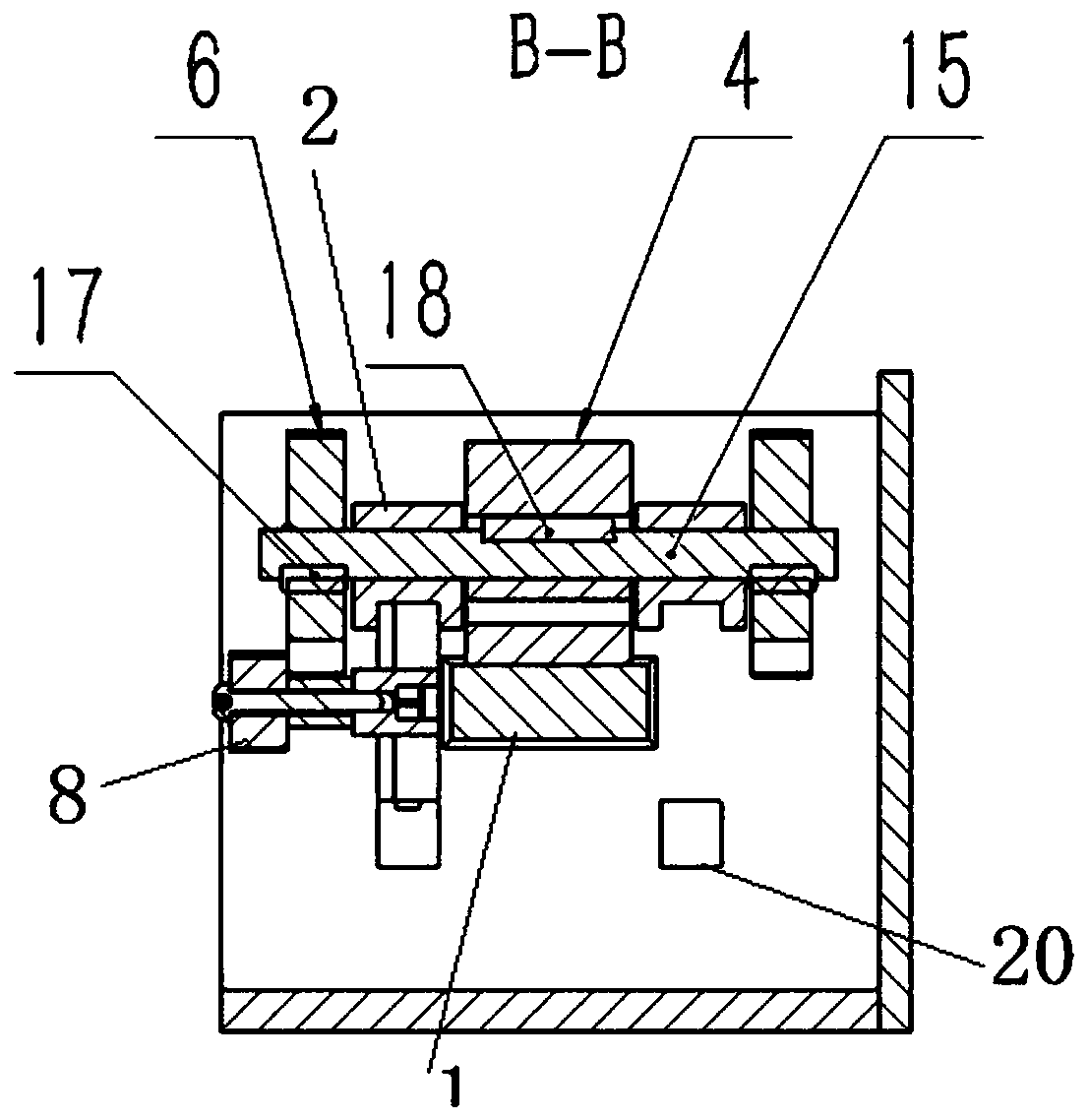

High-speed disc gear non-shaft loading rolling and unrolling device

The invention discloses a high-speed disc gear non-shaft loading rolling and unrolling device which comprises an installation frame, a transmission mechanism, an overturning mechanism, a cutting mechanism and an unrolling lifting mechanism, wherein the transmission mechanism, the overturning mechanism, the cutting mechanism and the unrolling lifting mechanism are installed on the installation frame. Multi-stage transmission of a worm gear reduction motor and a disc large gear is adopted for the overturning mechanism, and a non-shaft loading structure is adopted for the device. By means of thehigh-speed disc gear non-shaft loading rolling and unrolling device, multi-stage transmission of the worm gear reduction motor and the disc large gear is adopted for the overturning mechanism, the transmission torque is large, rigidity is good, the braking capability is high, the problems of jittering, sliding and the like cannot happen in the high-speed material collecting and releasing process,the overturning material changing process and the cutting process of the equipment, and stable running is ensured; and the non-shaft loading structure is adopted, the stretching and contracting distance of end stoppers on the left and right side of the equipment is long, a gas expansion shaft or a mechanical shaft or the like does not need to be additionally arranged for aiding during new materialroll installation, the end stoppers on the two edges directly abut against a material roll paper core, unnecessary parts are reduced, precision is higher, and the labor intensity of workers is also greatly lowered.

Owner:广东汕樟轻工股份有限公司

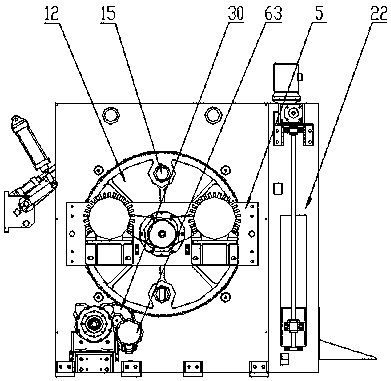

Steerable wheel side of a drive axle

ActiveCN105050828ASmall diameterSolve insufficient storage spaceSteering linkagesBraking discsDrive wheelClassical mechanics

The invention relates to the wheel side of a drive axle with wheel member steering. A drop centre rim, preferably made of steel, is provided on the wheel hub and is combined with a disc brake, which is axially inwardly offset relative to the wheel plane and which preferably has compressed air actuation. The necessary space for the disc brake arrangement is guaranteed by the sufficiently low diameter of the wheel hub in the region of the brake disc and by a comparatively large axial space for the brake system, which is created by an axially narrow design of the wheel hub transmission and a by a new design of the steering knuckle bearing and of the pertaining axle guard.

Owner:KESSLER & CO GMBH CO KG

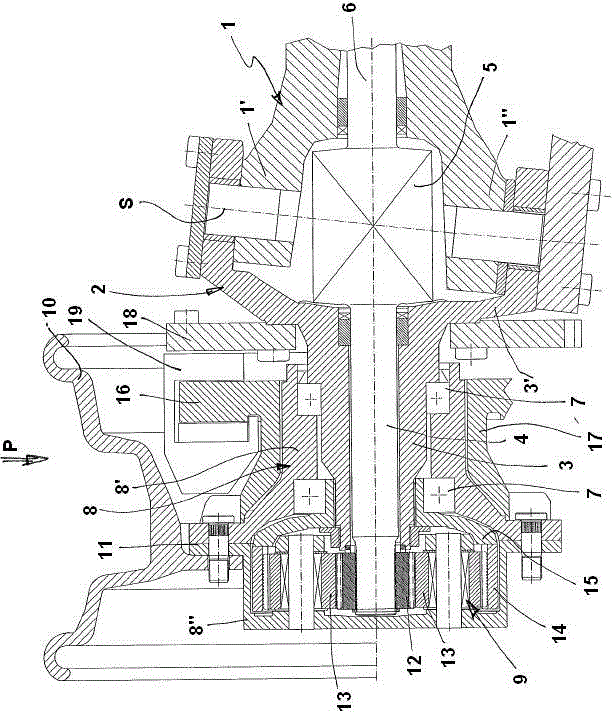

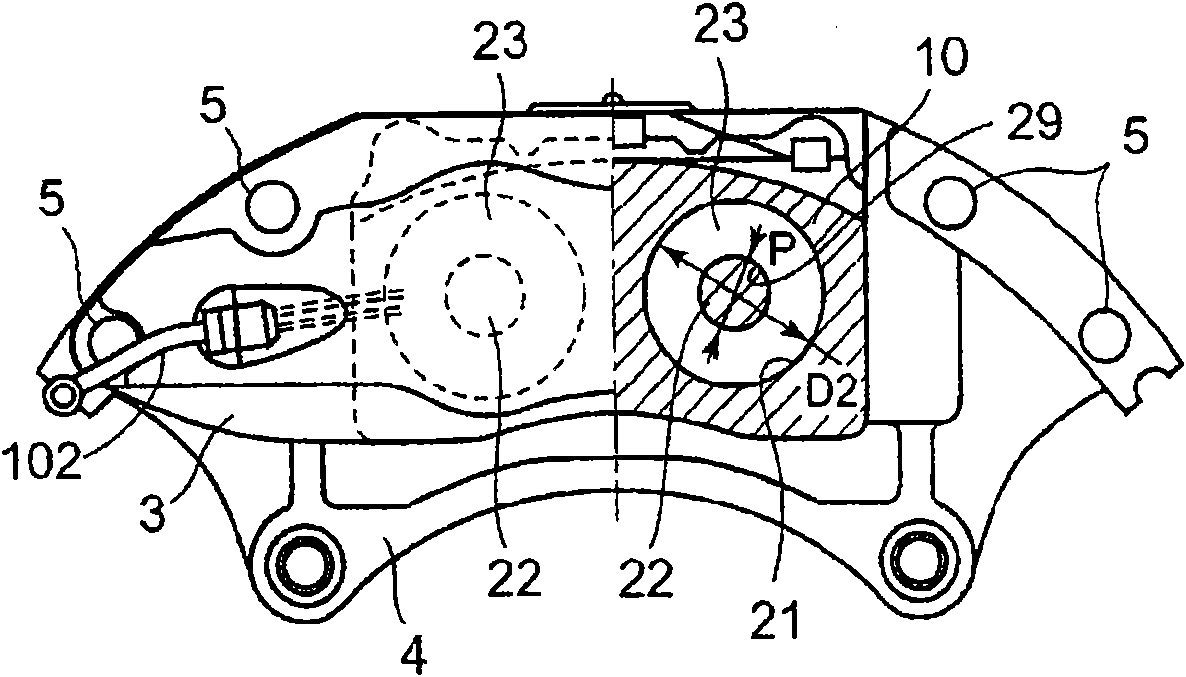

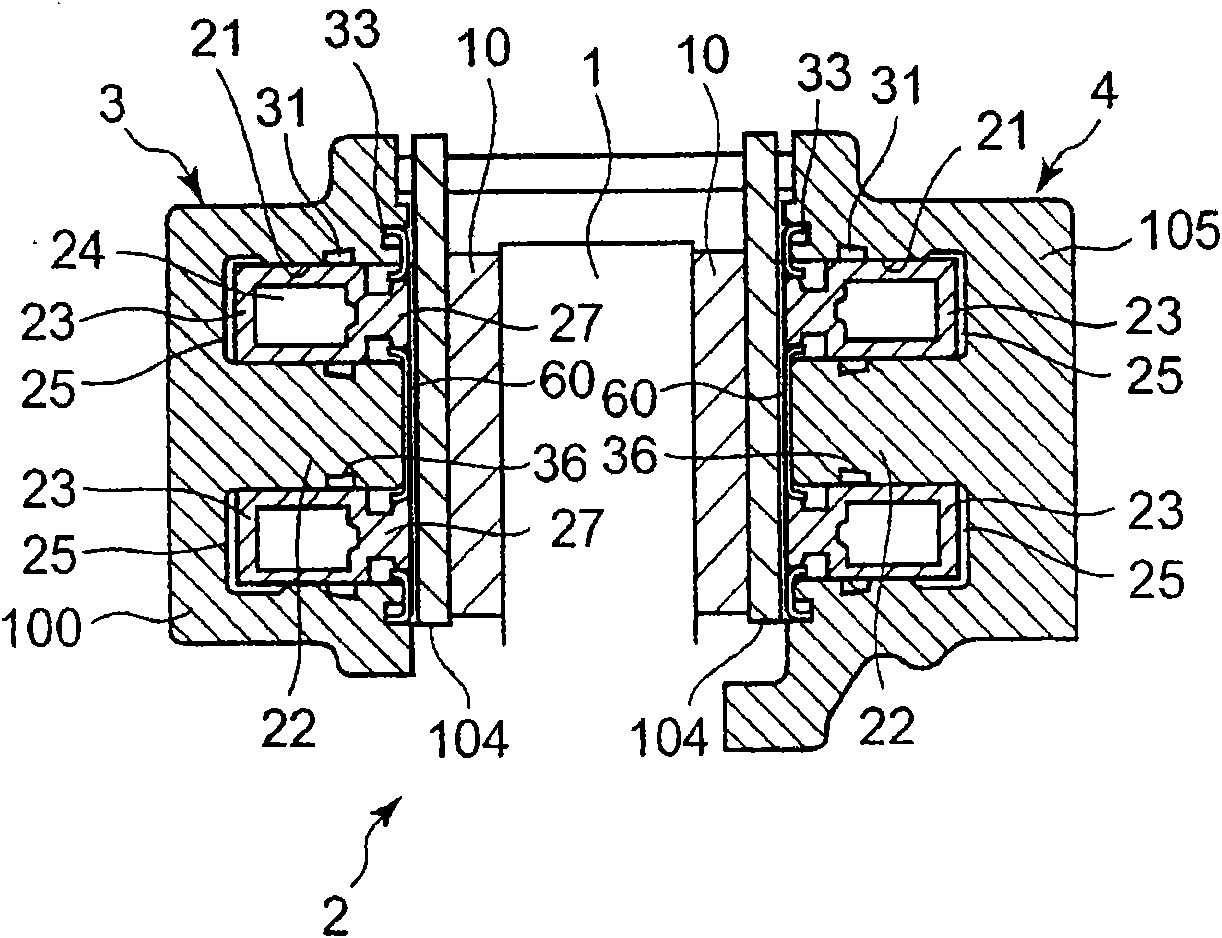

Brake caliper for disk brake

InactiveCN101529115APrevent slippingImprove sealing propertiesBrake actuating mechanismsEngineeringCalipers

A brake caliper that has the same performance as a brake caliper with multiple pistons despite its compact structure, in which drag resistance between a brake pad and a brake disk is minimized, that is less likely to produce non-uniform wear of brake pad and brake squealing, and whose weight and cost are suppressed. Pistons (23) are formed in a circular hollow cylindrical shape, and apply pressing force to a disk rotor (1) by circular pressing parts. Piston-containing holes (21) recessed in a circular shape and containing the pistons (23) so that they can slide in the axial direction of the pistons are formed in caliper bodies (100, 105).

Owner:株式会社努卡贝

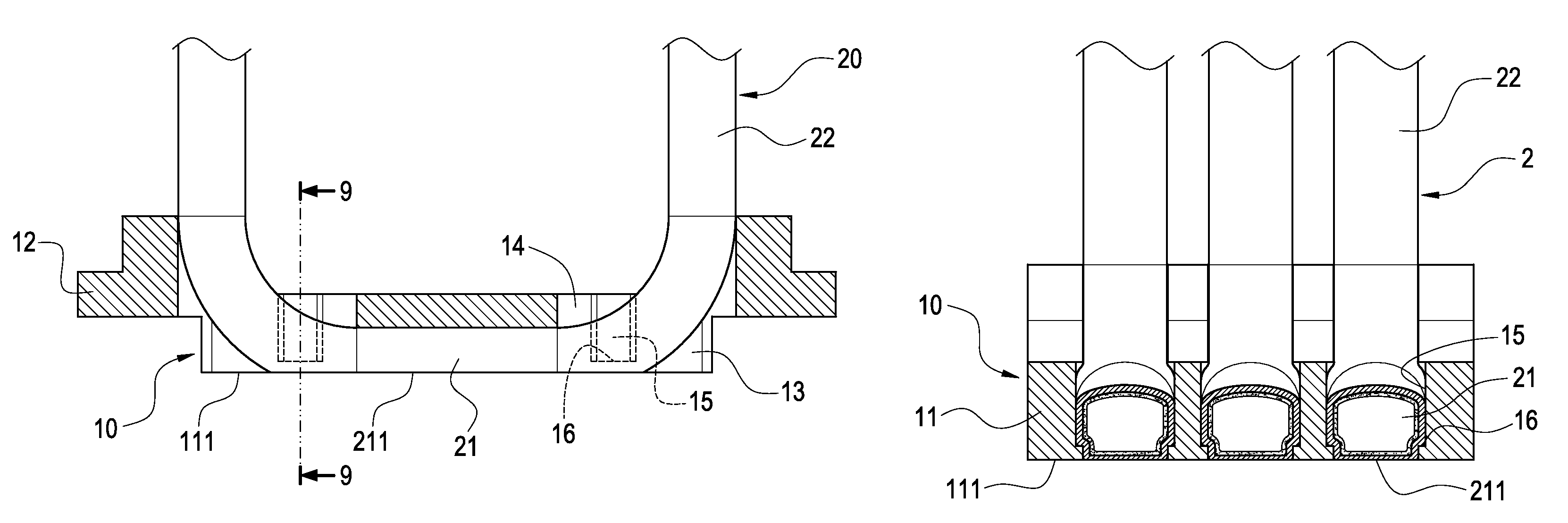

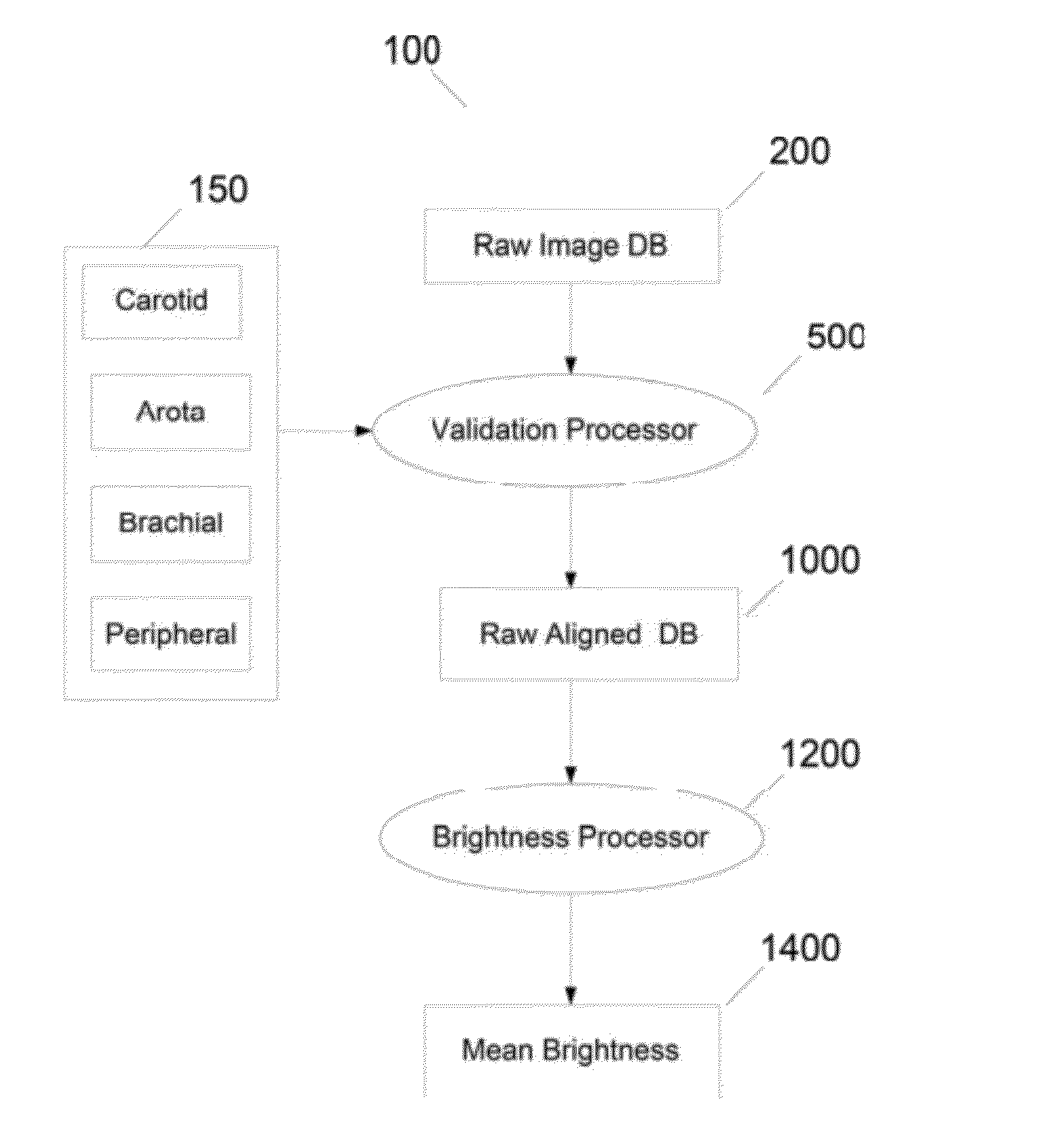

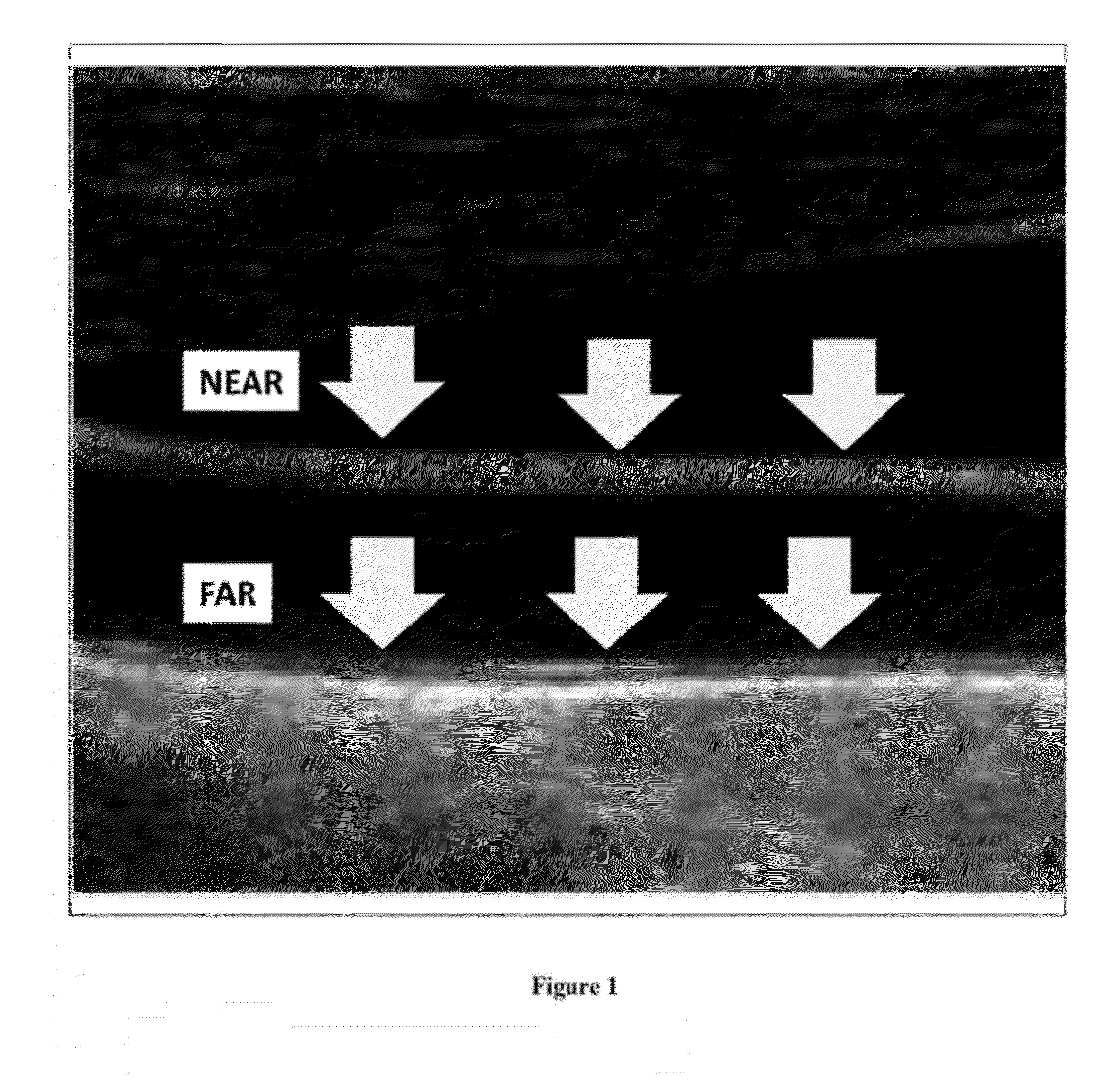

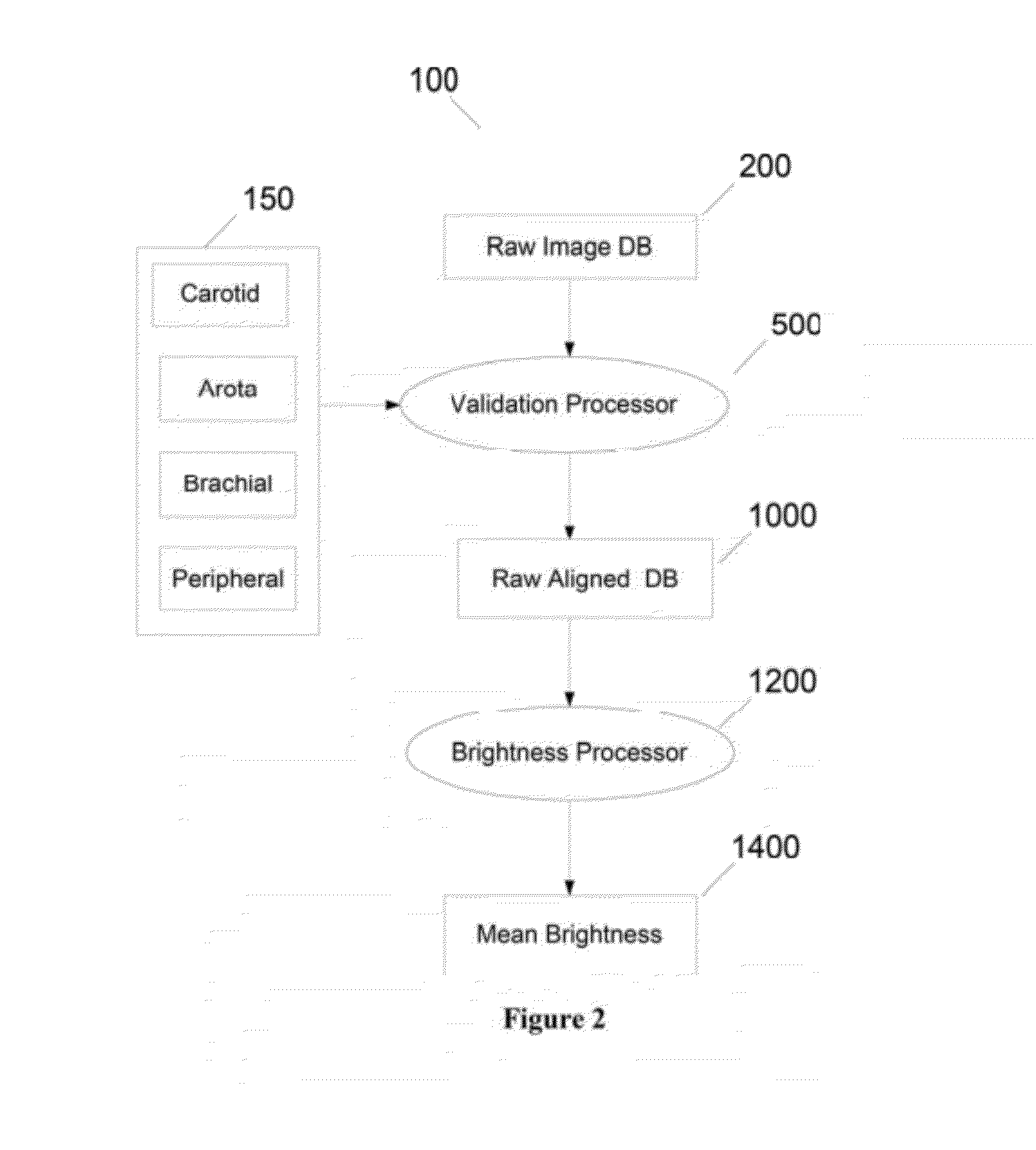

Hypothesis Validation of Far Wall Brightness in Arterial Ultrasound

InactiveUS20120316442A1Strong brakingIncrease speedUltrasonic/sonic/infrasonic diagnosticsImage enhancementSonificationHypothesis verification

Automated IMT system hypothesize that far wall of the common carotid artery has the highest intensity. In this current application, we verify that this hypothesis holds true for B-mode or RF-mode longitudinal ultrasound images of the carotid wall. The methodology consists of generating the composite image (arithmetic sum of images) from the database by first registering the carotid image frames with respect to a nearly straight carotid artery frame from the same database using (a) B-spline based non-rigid registration and (b) affine registration. Prior to registration, we segment the carotid artery lumen using a level set based algorithm followed by morphological image processing. The binary lumen images are registered and the transformations are applied to the original grayscale CCA images. These B-mode or RF-mode ultrasound images are then used for IMT computation using automated methods which hypothesize that far wall has the brightest intensity distribution.

Owner:ATHEROPOINT

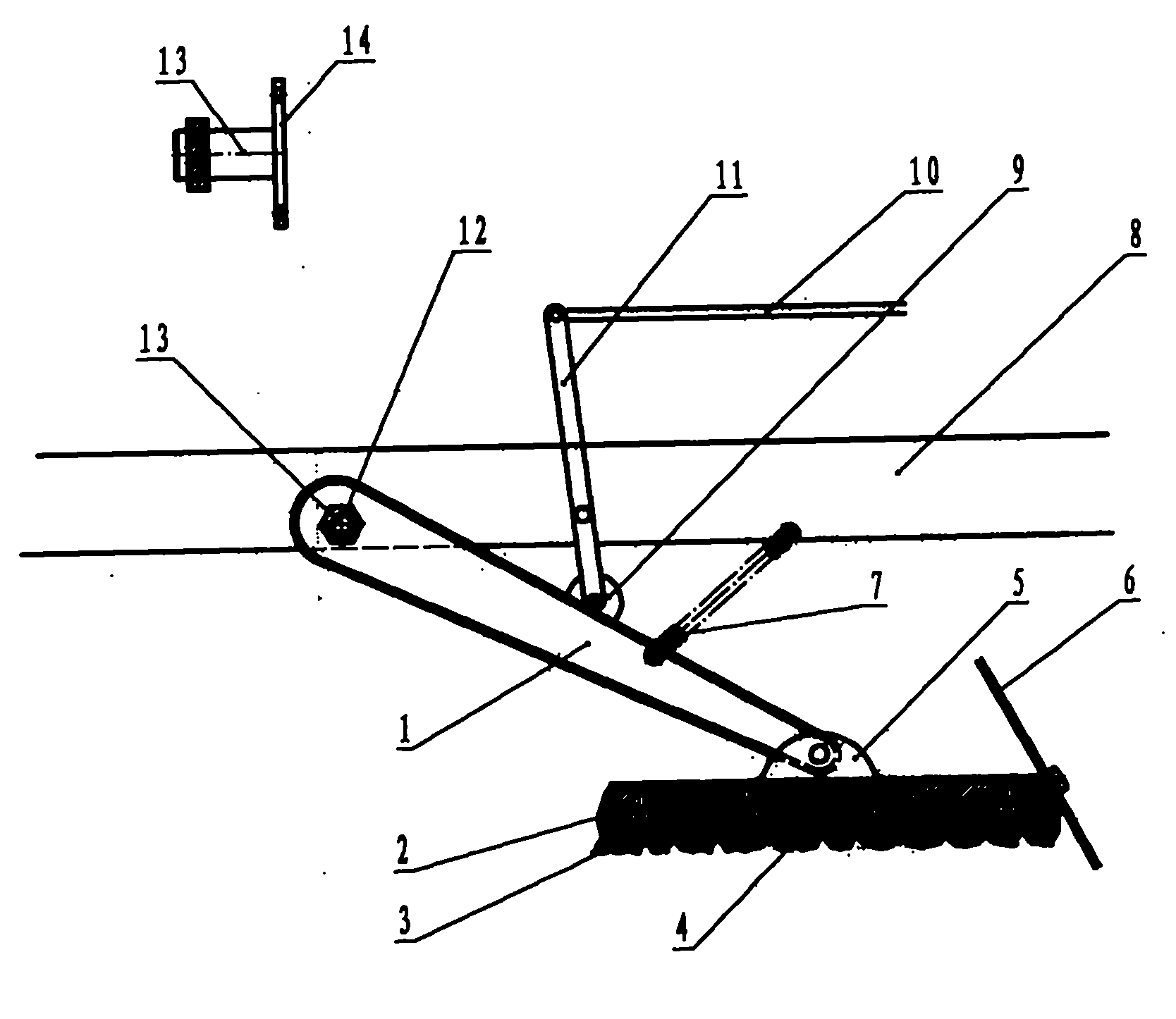

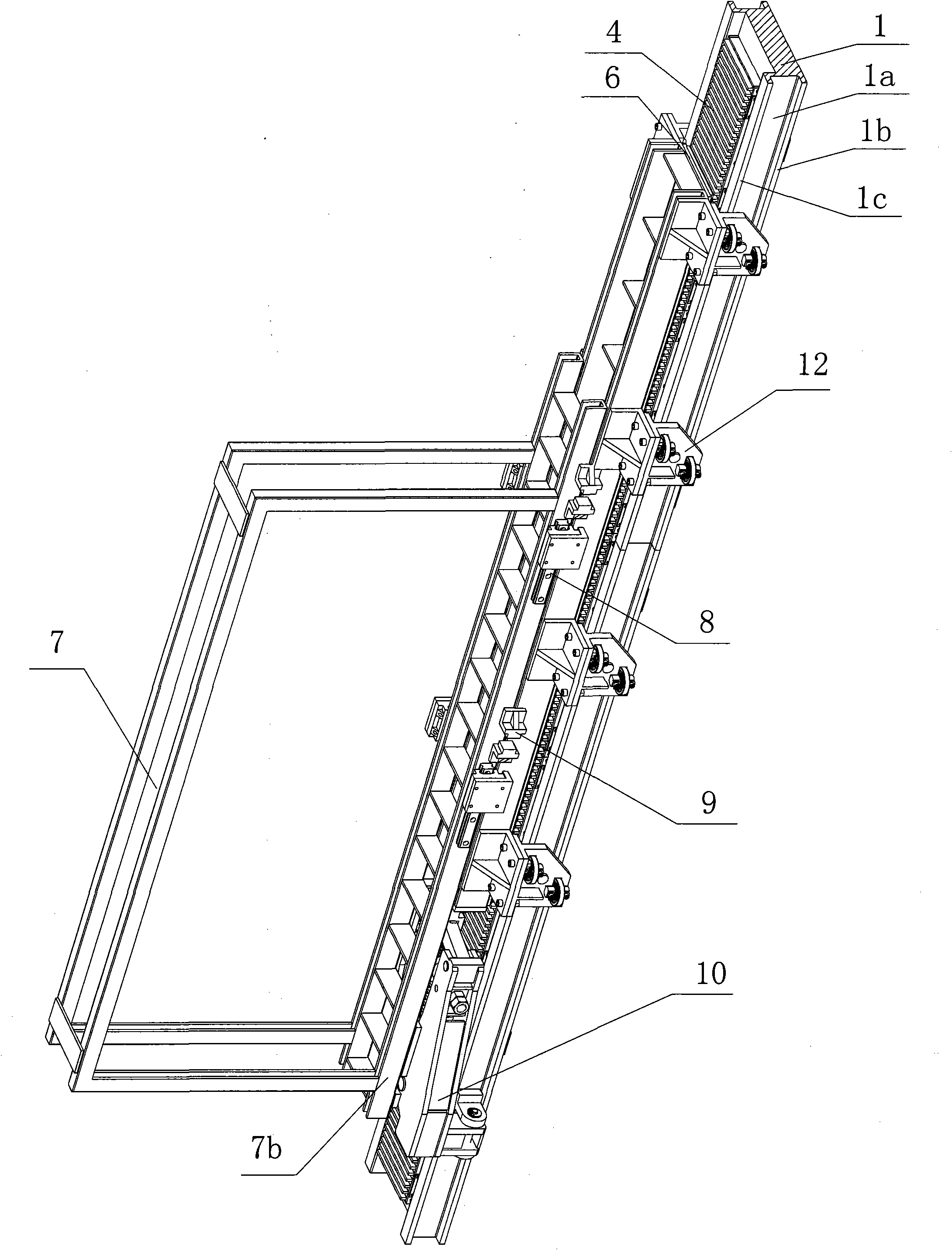

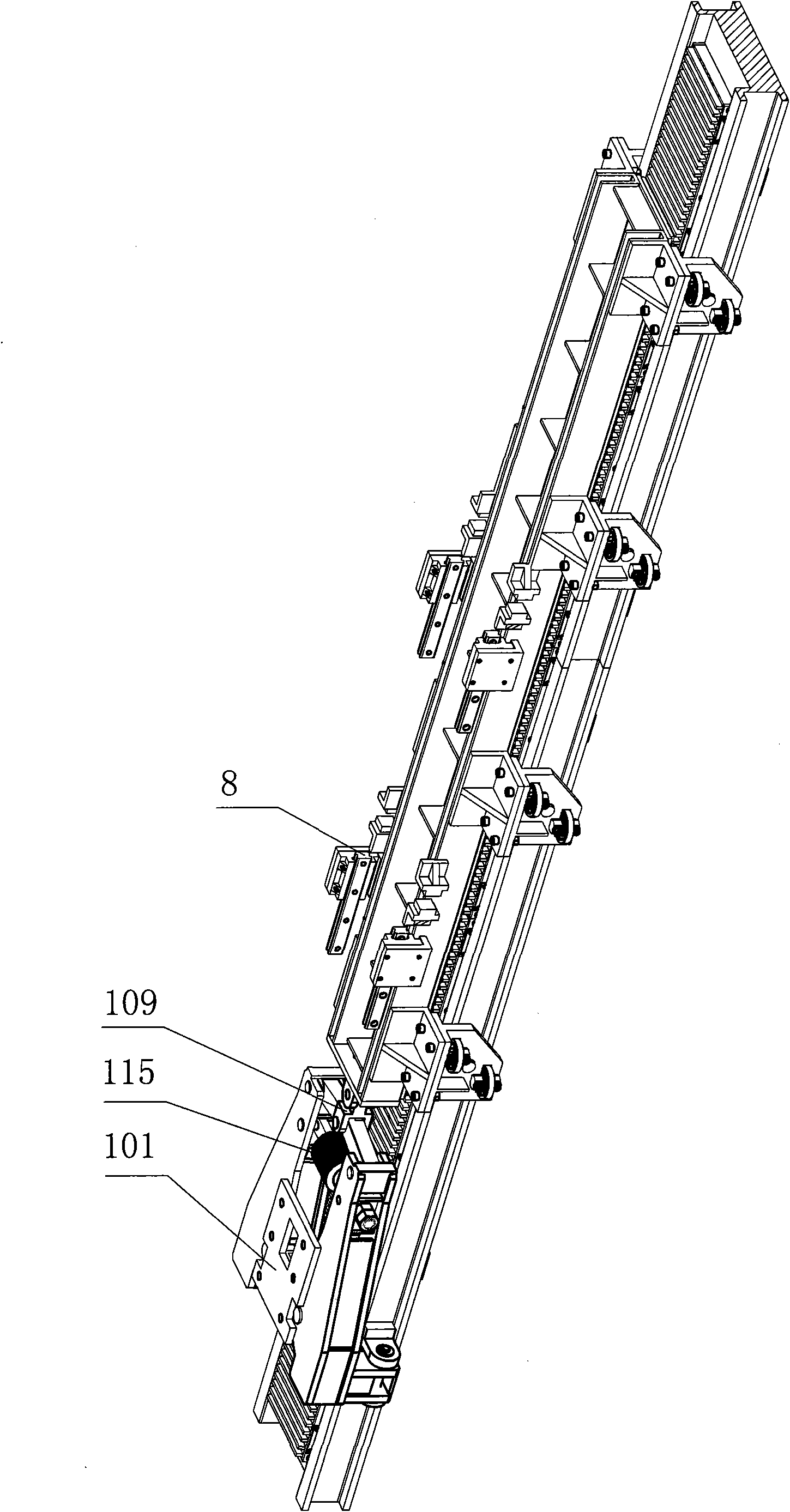

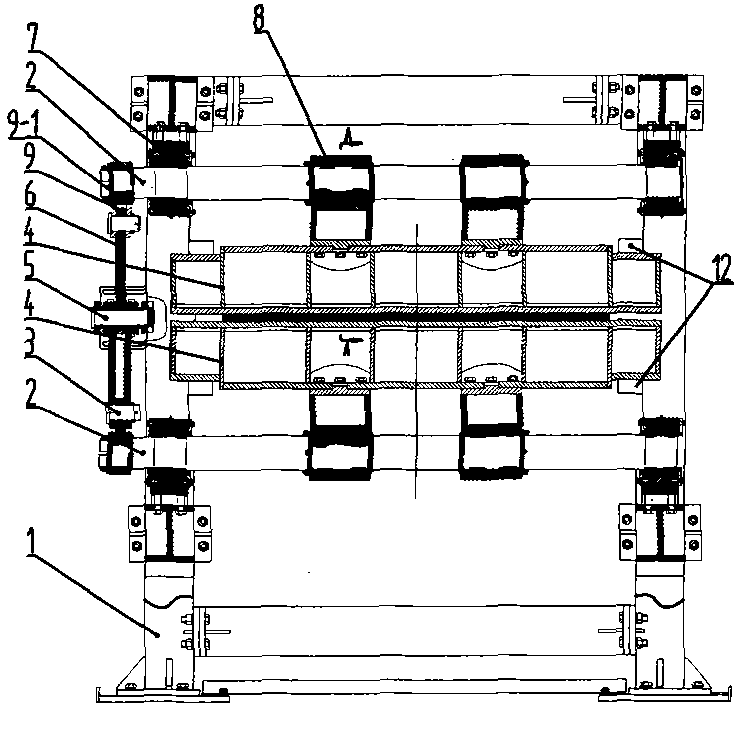

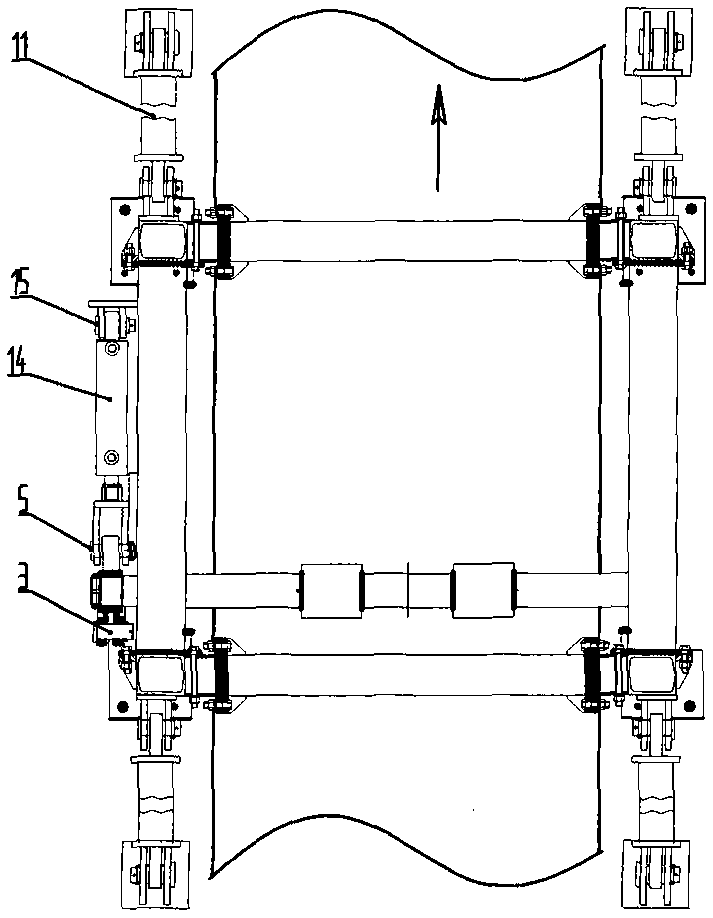

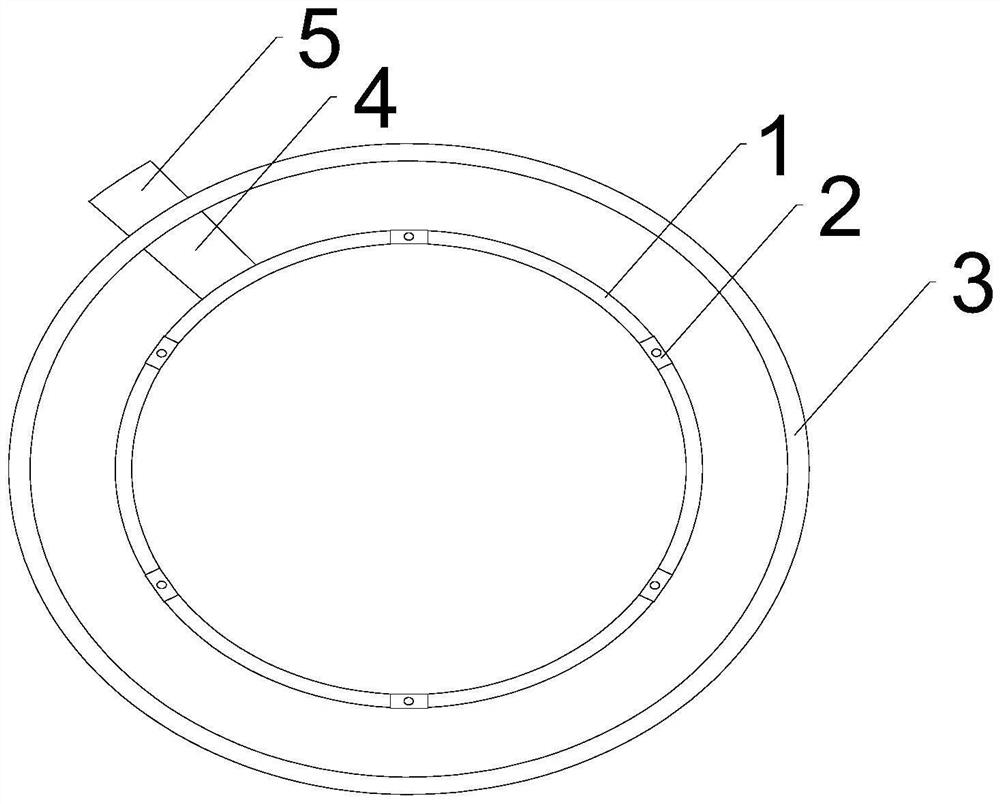

Broken belt protecting device of gantry belt conveyor

InactiveCN101879983AFlexible brakingEasy to installControl devices for conveyorsEngineeringPiston rod

The invention discloses a broken belt protecting device of a gantry belt conveyor and relates to a broken belt protecting device of a mine gantry belt conveyor. The broken belt protecting device comprises a frame 1, a broken belt braking system and a driving system, wherein the broken belt braking system comprises a brake beam 4, a main shaft 2 and a drive cylinder 14; the main shaft 2 contains an upper shaft and a lower shaft, the both ends of the main shaft 2 are separately arranged on the frame 1 through a bearing seat 7; the brake beam 4 contains two beams, the middle of the brake beam 4 is arranged on the main shaft 2 through two positioning sleeves; one end of the main shaft 2 extends out of the frame 1, a drive lug 9 is arranged on the extending part of the main shaft 2; the drive lug 9 is hinged with one end of a drive connecting rod 6 through a pin I3, the other end of the drive connecting rod 6 is hinged with the piston rod of the drive cylinder 14 through a pin II5; and the cylinder body of the drive cylinder 14 is hinged with the frame 1 through a cylinder pin 15. The brake surface of the brake beam is an inclined plane, the braking force is powerful, and the overall height of the device is low so that the device is applicable to the smaller roadway.

Owner:徐州中部矿山设备有限公司

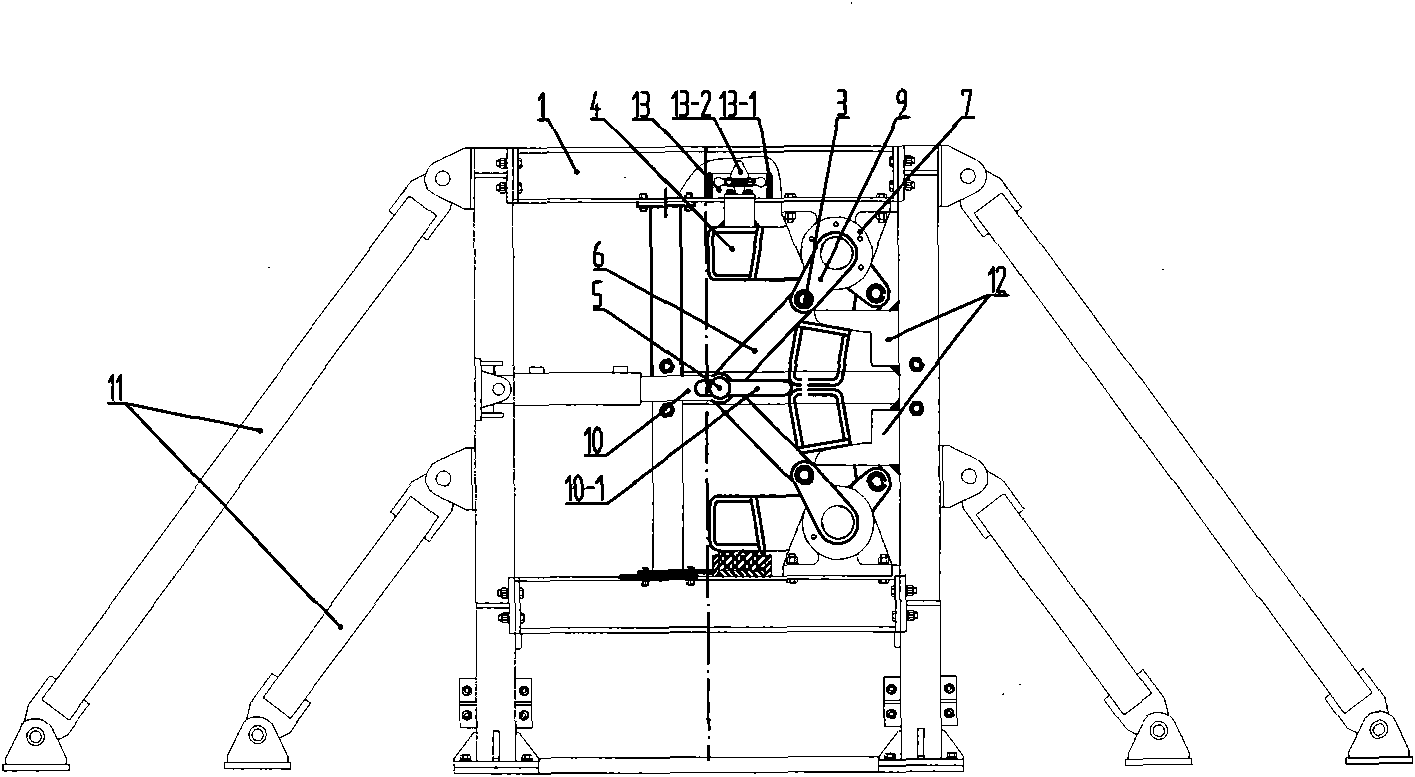

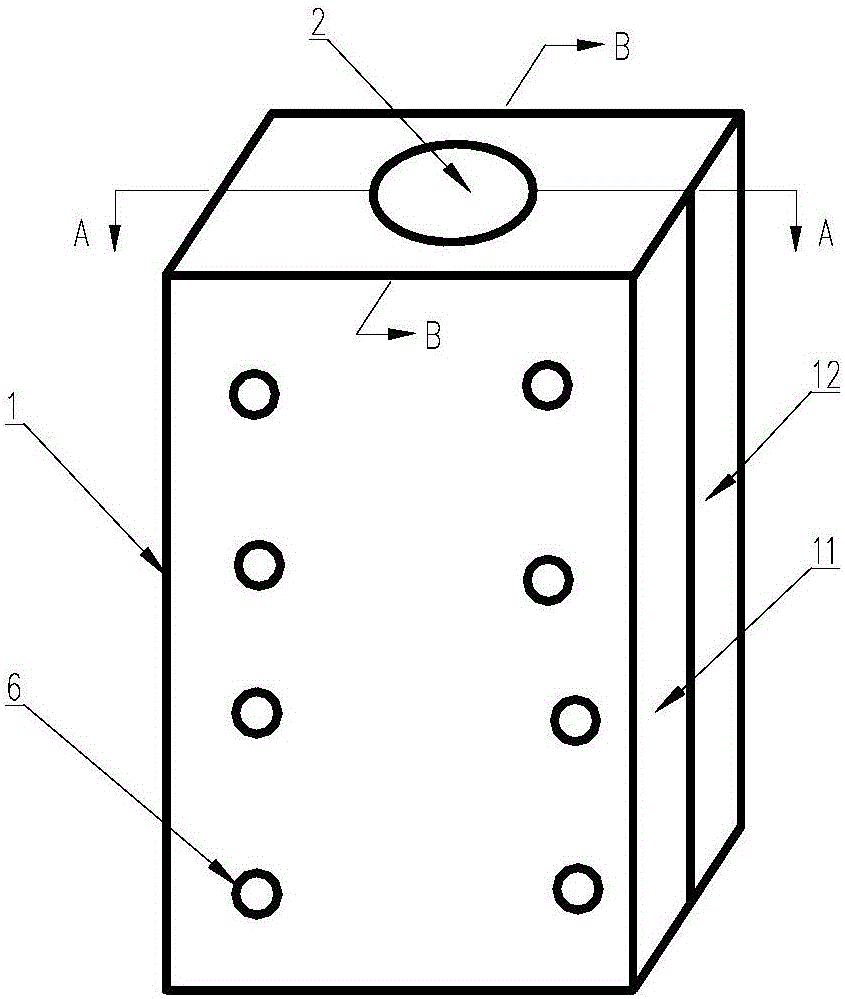

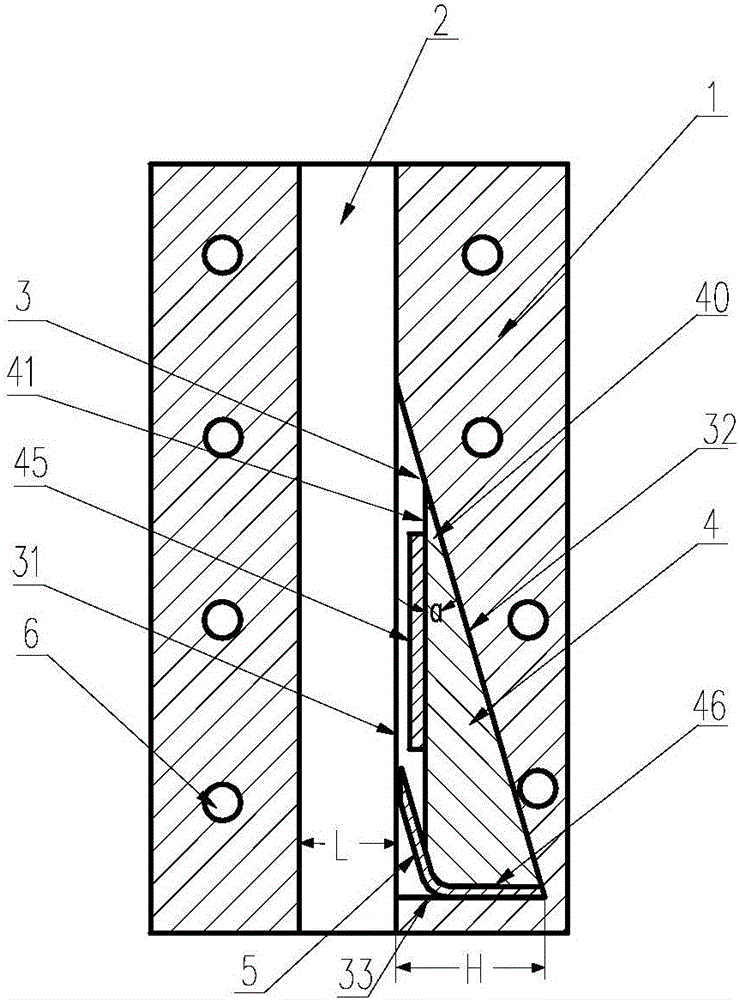

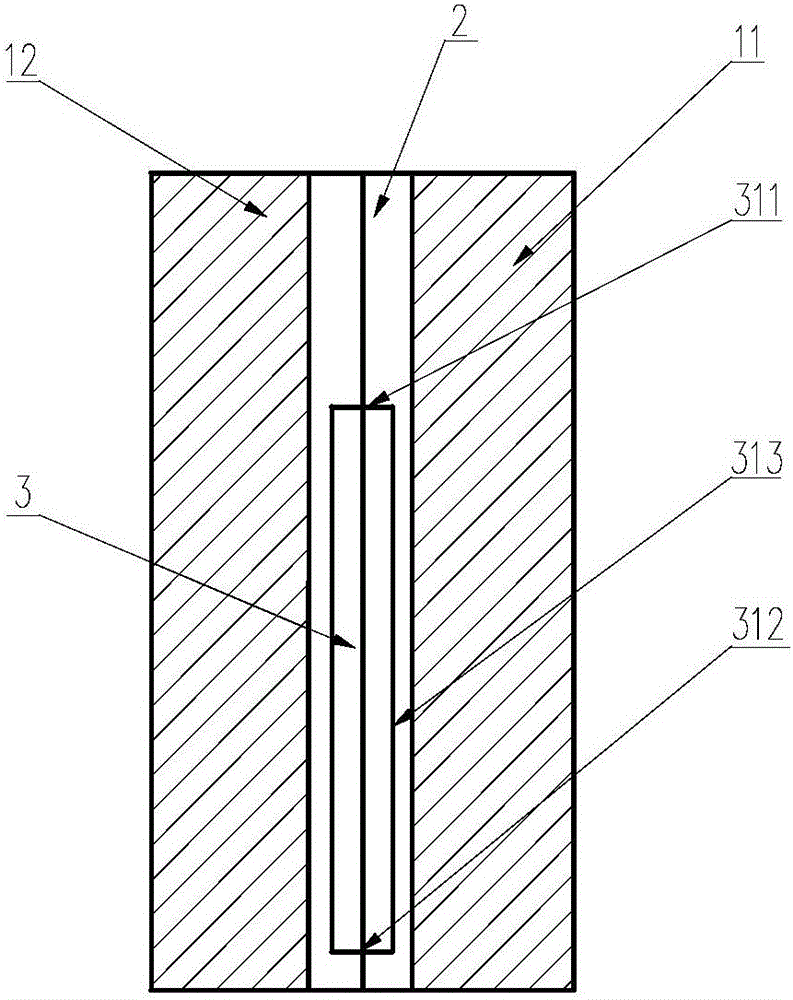

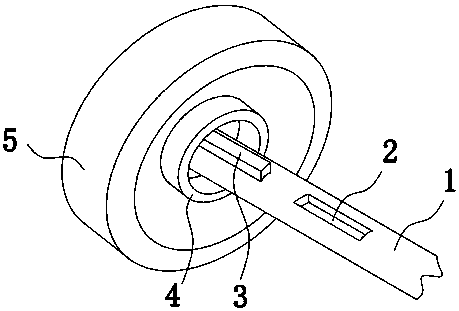

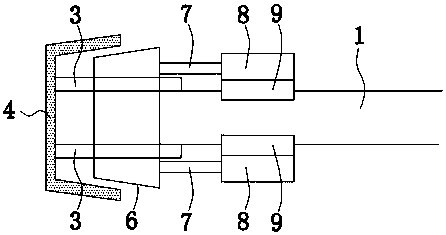

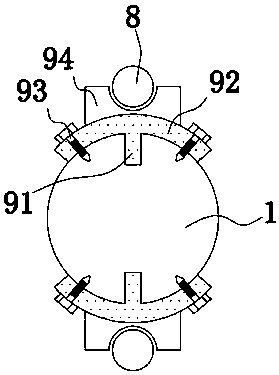

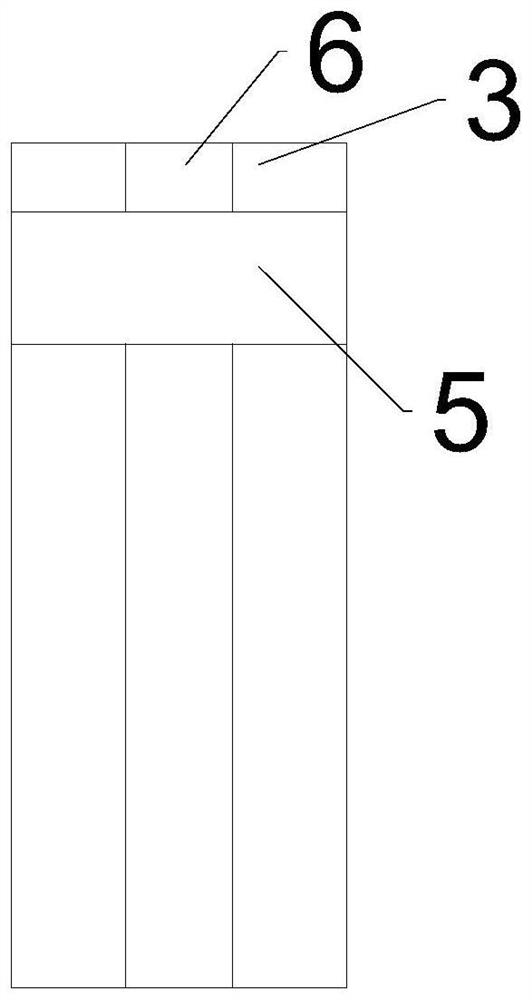

Safety lock for high-altitude operation device and use method of safety lock

PendingCN105731319ASimple structureNo need for frequent inspection and maintenanceSafety devices for lifting equipmentsClassical mechanicsStructural engineering

The invention provides a safety lock for a high-altitude operation device and a use method of the safety lock. The safety lock comprises a columnar lock body (1) and a sliding block (4), wherein the columnar lock body (1) is provided with a vertical through hole (2) and an inclined groove (3); the sliding block (4) is arranged in the inclined groove (3) and is matched with the inclined groove (3); when the safety lock is in use, a block head (40) of the sliding block (4) in the safety lock is upwards and fixedly arranged on an outer wall (8) of the high-altitude operation device, a traction suspension rope (7) and / or a guiding suspension rope (7) of the high-altitude operation device are / is vertically arranged in the through hole (2) of the safety lock in a penetrating manner; under the normal condition, the safety lock is only a guiding device of the traction suspension rope (7) and / or the guiding suspension rope (7); when the high-altitude operation device falls suddenly and rapidly, gravity is generated, and the sliding block is thrown out reversely to clamp the suspension rope (7) in the through hole (2), so that the purpose of locking the high-altitude operation device is achieved. The safety lock provided by the invention has the advantages of simple structure, low cost, good safe and reliable effects, convenience in installation and use, long service life, no maintenance, high universality, great promotion and application value and wide market prospect.

Owner:SHANGHAI DONGHAN WIND POWER EQUIP CO LTD

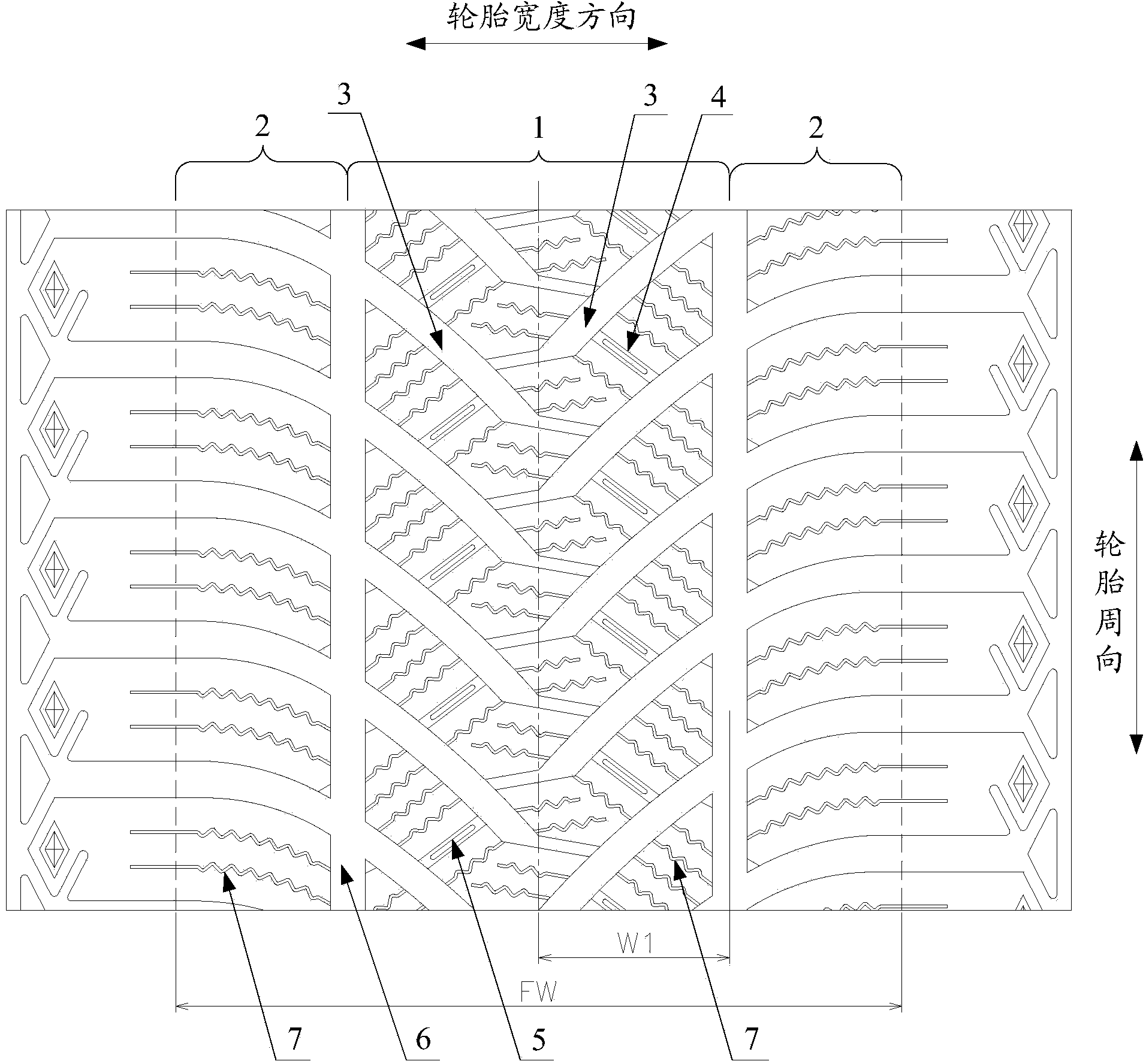

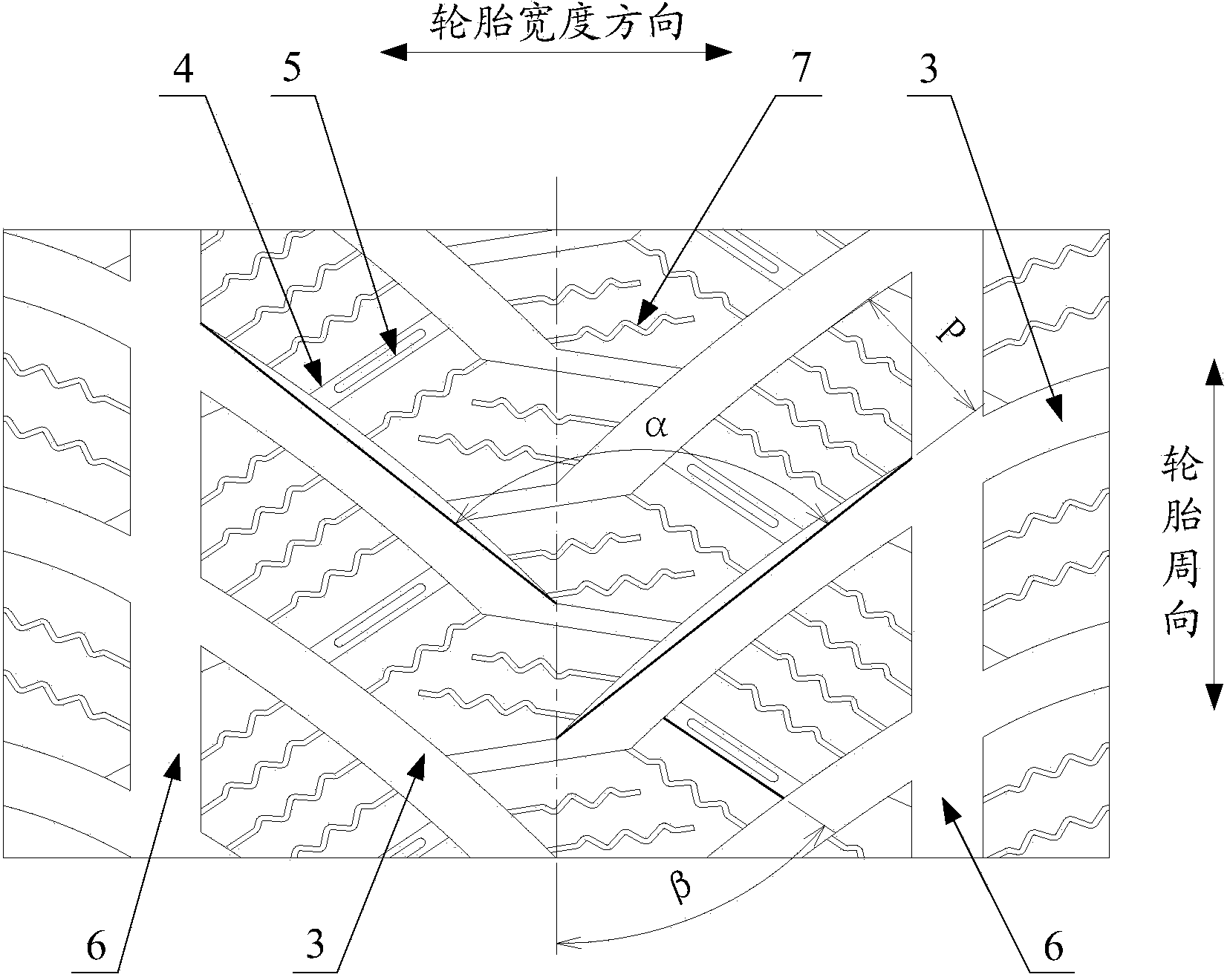

Pneumatic tyre

The invention provides a pneumatic tyre. The pneumatic tyre comprises a tread part and tyre shoulder parts positioned on the two sides of the tread part, wherein a V-shaped groove is formed in the tread part; two troughs of the V-shaped groove extend to different tyre shoulder parts and extend out of the tyre shoulder parts in the width direction of the pneumatic tyre. The pneumatic tyre has the advantages that as traditional sipes or cut grooves are replaced with the V-shaped groove formed in the pneumatic tyre, the pneumatic tyre has better brake performance on ice snow covered pavements, and the control stability of the pneumatic tyre can not be affected.

Owner:CHENG SHIN RUBBER CHINA

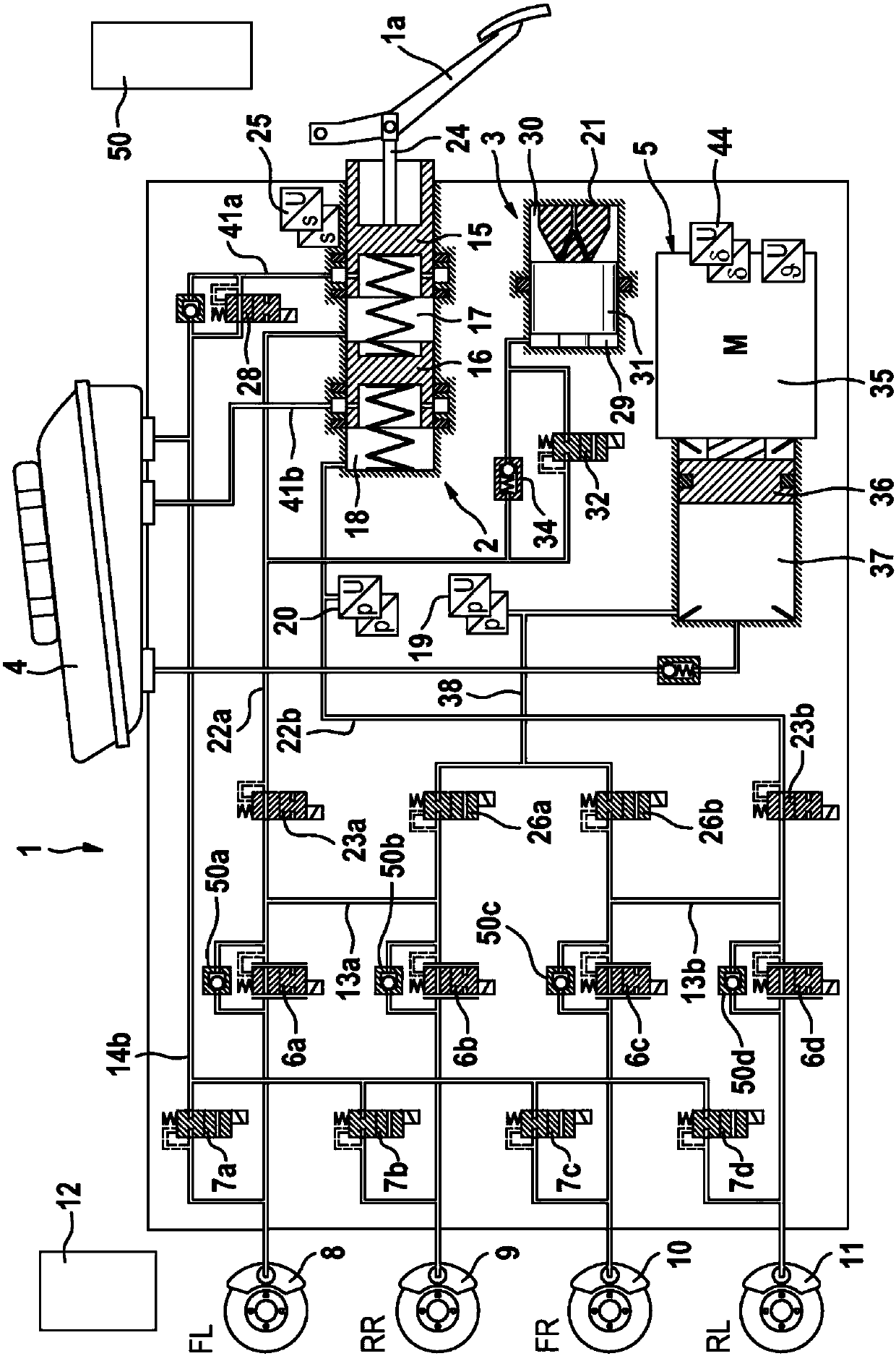

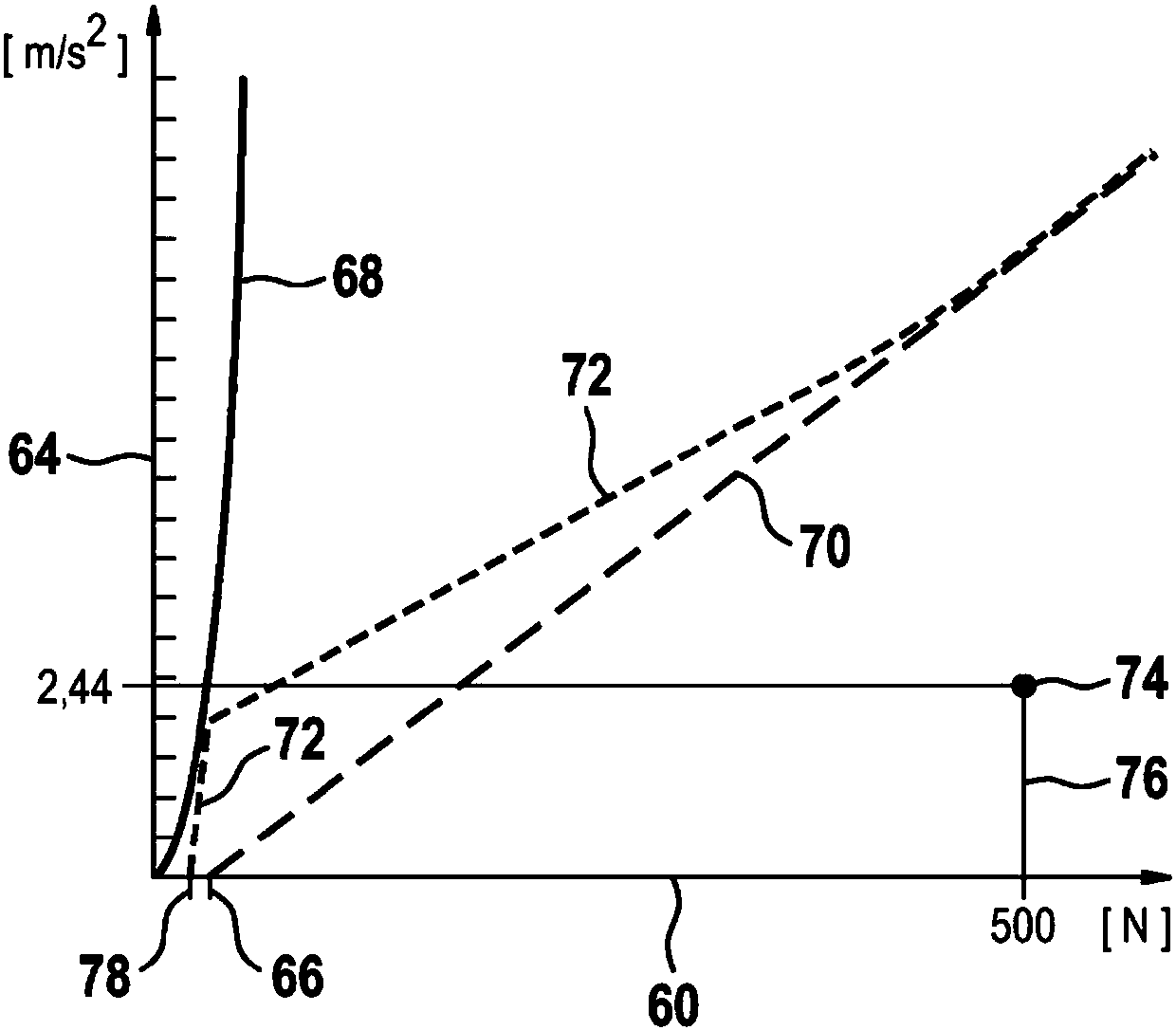

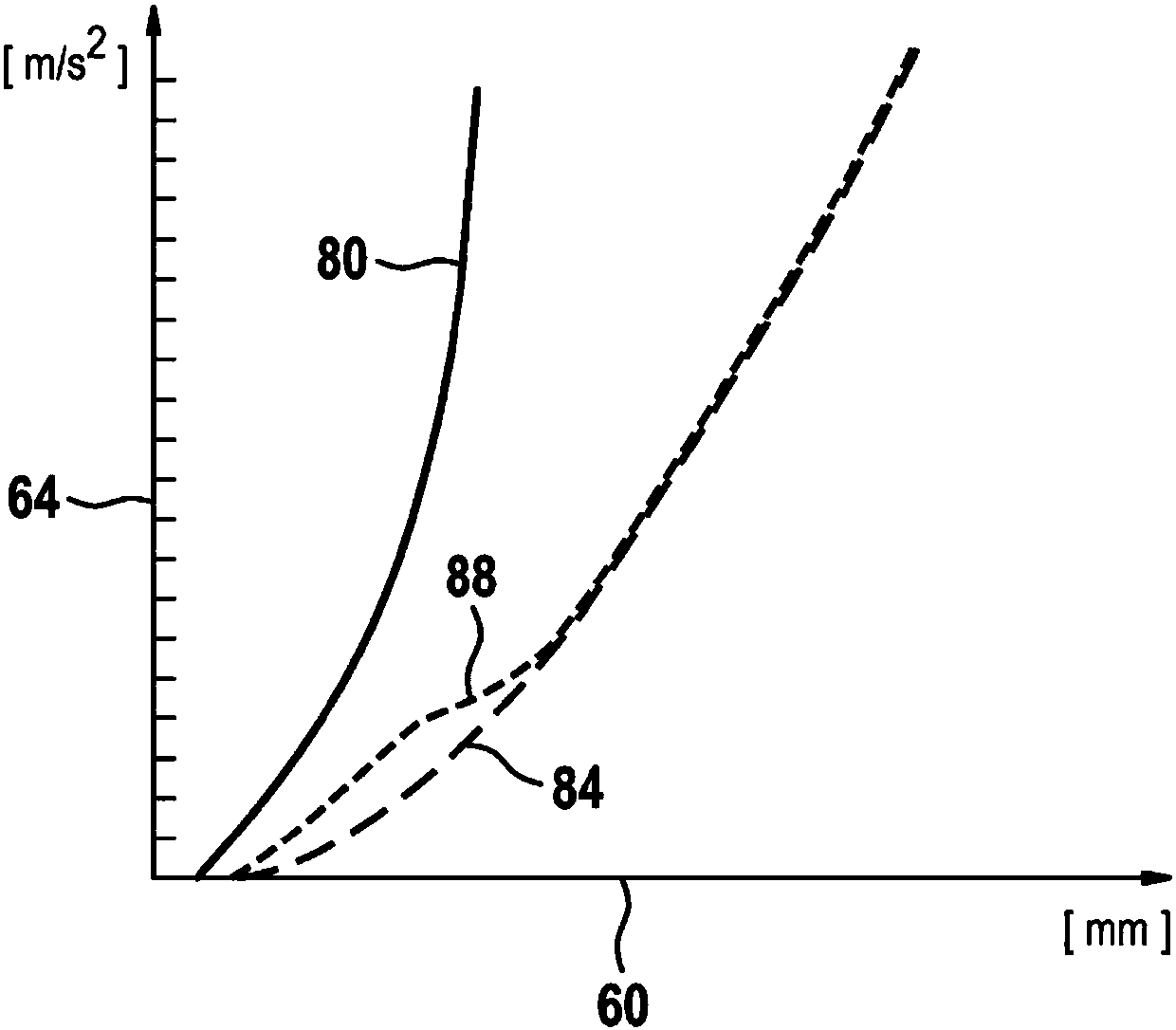

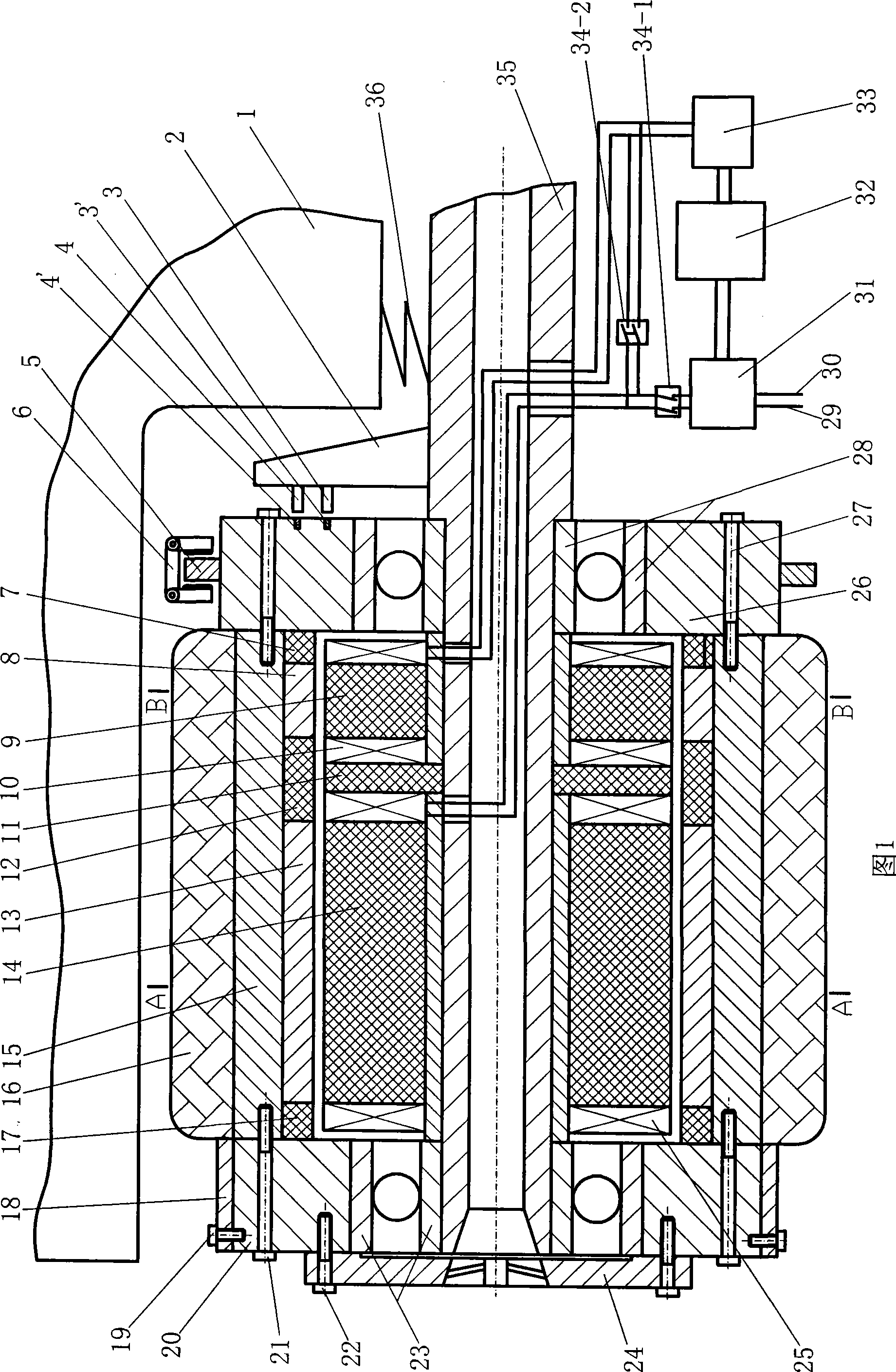

Brake system and method for operating a brake system

ActiveCN108025718AWon't get the wrong impressionStrong brakingVehicle sub-unit featuresBrake action initiationsBrake torqueDriver/operator

The invention relates to an electro-hydraulic brake system (1) for a motor vehicle, comprising a main brake cylinder (2) which can be actuated by a brake pedal (1a) for actuating wheel brakes (8, 9, 10, 11), a pressure generating device (5) which can be activated electronically, an additional brake actuator (50) which can be activated electronically, an open and closed-loop control unit (12), wherein in a normal mode of operation the open and closed-loop control unit (12) detects a requirement for braking on the basis of the actuation of the brake pedal (1a) by the driver and activates the pressure generating device (5) to build up braking torque on the wheel brakes (8, 9, 10, 11), wherein, if the pressure generating device (5) is not activated or cannot be activated, the driver gains direct access to the wheel brakes (8, 9, 10, 11) and the open and closed-loop control unit (12) controls the additional brake actuator (50) to build up braking torque, wherein as a backup the open and closed-loop control unit (12) monitors the brake pedal travel and, when a predetermined pedal travel threshold value (120) is reached, activates the additional brake actuator to build up braking torque,and wherein, in the event of a succession of brake pedal actuations by the driver, the pedal travel threshold value (120) is increased at least once. The invention further relates to a method for operating an electro-hydraulic brake system.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

An auxiliary brake system for reversing a vehicle

InactiveCN109017717AEasy to moveImprove braking effectBraking element arrangementsContact failureDistance sensors

The invention discloses an auxiliary braking system for reversing a vehicle. The auxiliary braking system comprises a service computer for receiving an alarm signal of a distance sensor so as to control the extension and retraction of a telescopic rod of an electric telescopic rod. The electric telescopic rod is fixed to the upper and lower ends of the wheel connecting shaft through a mounting seat, the end of the wheel connecting shaft is connected with an auxiliary brake disc, the auxiliary brake disc is arranged in the middle of the wheel, A brake pad is sleeved on the wheel connecting shaft, As that bottom of the fix arc plate is provided with a protrusion, the protrusion is slidably connected with the second sliding groove of the upper end and the lower end of the wheel connecting shaft, When the brake pads are worn, the position of the fixed arc plate can be adjusted so that the fixed arc plate is close to the auxiliary brake disc, and the position of the electric telescopic lever can be adjusted so that the telescopic lever can push the brake pads into close contact with the auxiliary brake disc, thereby preventing poor contact between the brake pads and the auxiliary brakedisc and poor braking effect.

Owner:HEFEI ZHIXIN AUTOMOTIVE TECH CO LTD

Novel magnetic energy vehicle

InactiveCN101442235AAchieve driving speedAchieve direct controlElectric propulsion mountingMechanical energy handlingElectrical batteryControl system

The invention discloses a novel magnetic energy vehicle, which consists of a vehicle main body and a control system. The vehicle main body consists of a vehicle body and a magnetic energy locomotive wheel; and the control system consists of a control computer, a bus, a power electronic device, a sensor, a battery system and software. The magnetic energy locomotive wheel consists of a stator, a wheel and a bearing, wherein the wheel surrounds the stator, a stator core is in shape of a rectangular gear made of a nonmagnetic insulating material, and coils are wound on teeth; and a tyre, a hub, a magnetizer, a nonmagnetic body and a permanent magnet form a multi-polar wheel of which the polarity is alternate along the circumference. The magnetic energy locomotive wheel is divided into two parts, wherein one part is an electric motor, while the other part is a generator. The generator is connected with the battery system through a rectification voltage regulator, and a stator coil is connected with the battery system through a frequency modulator. The control system measures position signals of a rotor pole relative to stator teeth according to the sensor, alternates current in different directions for the stator coil, and the wheel is rotated because a permanent-magnet pole thereof is subjected to attraction moment and exclusion moment of a pole of the stator teeth. The novel magnetic energy vehicle is energy-saving and environment-friendly.

Owner:刘新广

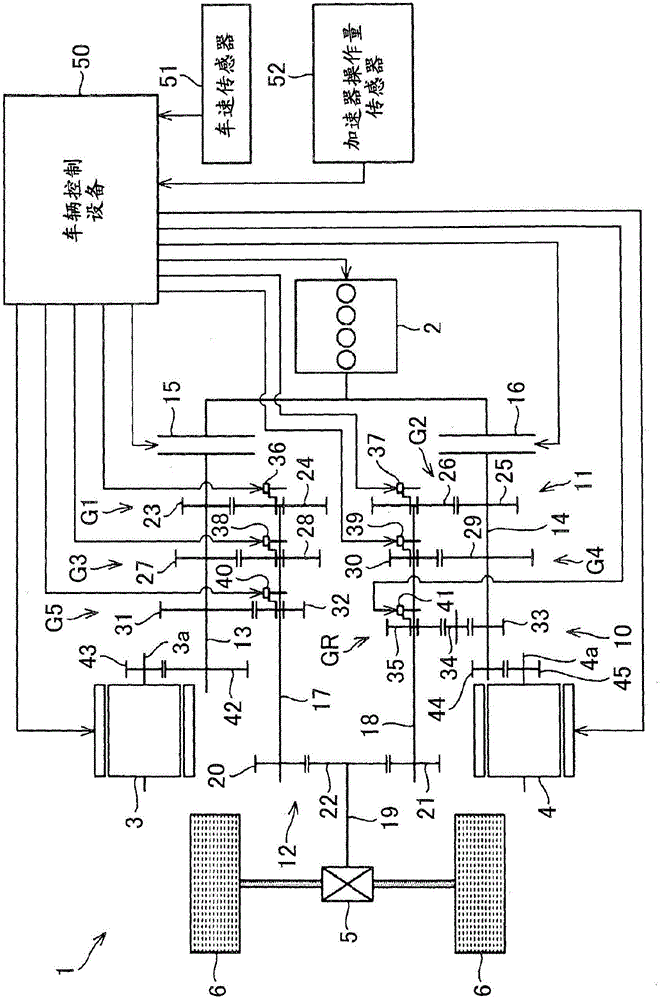

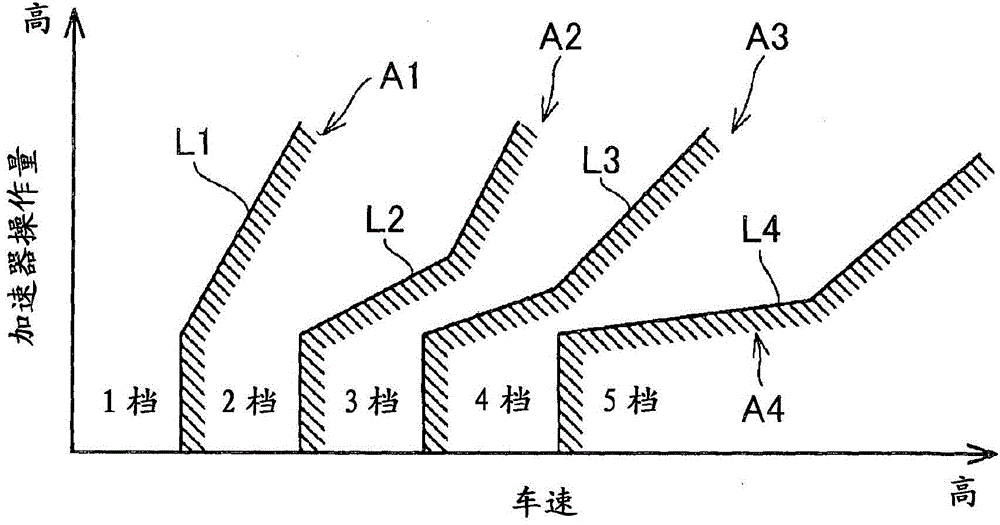

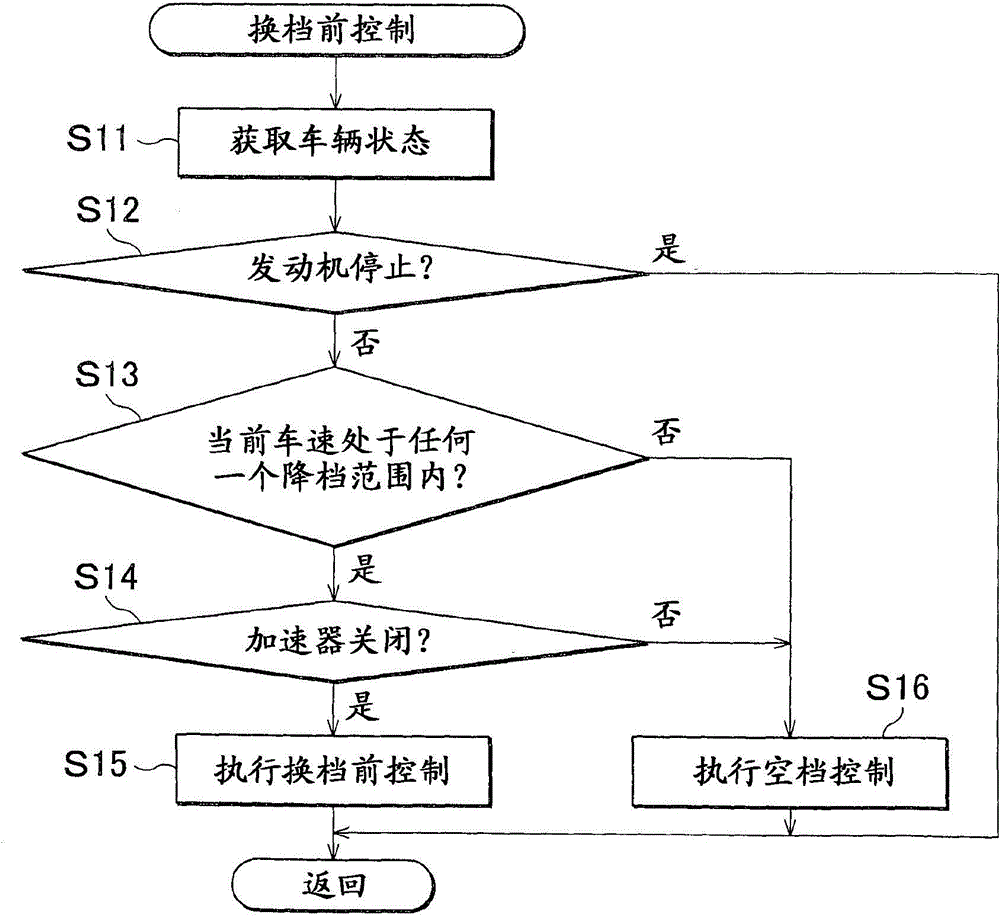

Control device for hybrid vehicle

InactiveCN104640730APrevent wasteful consumptionImprove fuel economyHybrid vehiclesGas pressure propulsion mountingExternal combustion engineEngineering

In a control device for a hybrid vehicle (1) including a dual-clutch transmission (10), a first MG (3) connected to a first input shaft (13) of the transmission (10) in a power transmittable manner and a second MG (4) connected to a second input shaft (14) of the transmission (10) in a power transmittable manner, while the vehicle (1) is travelling with the use of an internal combustion engine (2), the transmission (10) is controlled such that power transmission between the input shaft, which is interrupted in power transmission from the internal combustion engine (2), and an output system (12) is interrupted when an accelerator pedal is depressed, and the transmission (10) is controlled such that power transmission between the input shaft, which is interrupted in power transmission from the internal combustion engine (2), and the output system (12) is established by a gear train of a speed position lower than a current speed position when depression of the accelerator pedal is released.

Owner:TOYOTA JIDOSHA KK

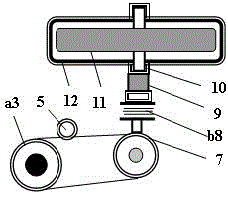

Variable damping permanent magnet eddy current retarder

ActiveCN110195755ASolve the problem that different damping is required for positive and negative strokesReasonable and efficient allocationMagnetic springsDrive wheelPhase control

The invention discloses a variable damping permanent magnet eddy current retarder. The variable damping permanent magnet eddy current retarder comprises a displacement-eddy current generating assembly, a phase control assembly, a fixing supporting assembly and a positioning-dead-locking assembly, wherein the phase control assembly comprises a supporting phase guide rail, a plurality of driven gears, a driving wheel and a rack, wherein the plurality of driven gears, the driving wheel and the rack are sequentially arranged on the supporting phase guide rail and are meshed with one another; a phase sliding groove is formed in the bottom of the supporting phase guide rail, two limiting groove holes are formed in the bottom surface of the phase sliding groove, the displacement-eddy current generating assembly comprises a conductor plate and a plurality of permanent magnets; and an unlocking sliding block is arranged on at least one side of the conductor plate, the magnetizing directions ofthe plurality of permanent magnets are arranged according to the Halbach array, the positioning-dead-locking assembly comprises a limiting travel guide rail and a clamping and tenon device, a travel sliding groove is formed in the inner side of the limiting travel guide rail, and the clamping and tenon device can realize locking and unlocking of the limiting groove holes through the movement of the unlocking sliding block. According to the variable damping permanent magnet eddy current retarder, the problem that the forward stroke and the reverse stroke of the linear permanent magnet eddy current retarder need different damping, and energy can be more reasonably and efficiently distributed.

Owner:NANJING UNIV OF SCI & TECH

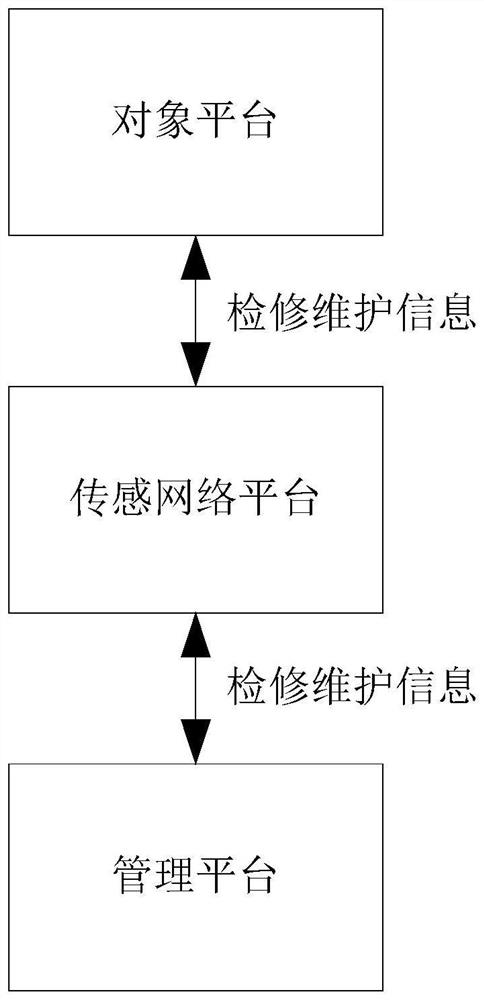

Natural gas station equipment overhaul and maintenance management system and method based on Internet of Things

PendingCN114548440AAvoid interactionAvoid influenceData processing applicationsPipeline systemsThe InternetMaintenance management

The invention discloses a natural gas station equipment overhaul and maintenance management system based on the Internet of Things, which comprises an object platform, a sensing network platform and a management platform, the object platform and the management platform are in communication connection through the sensing network platform, the object platform is used for inputting field data and generating equipment maintenance records, and the management platform is used for storing the field data. Storing the equipment maintenance record in a database, converting the equipment maintenance record into repair and maintenance information, and sending the repair and maintenance information to a sensing network platform; the sensing network platform is used for receiving the overhaul and maintenance information of the object platform and sending the overhaul and maintenance information to the management platform; and the management platform is used for acquiring the overhaul and maintenance information, establishing a mapping relation between the overhaul and maintenance information and time, and forming overhaul early warning according to a preset overhaul period. According to the invention, the maintenance information and the preset maintenance cycle and maintenance content are compared and analyzed in the management platform, the maintenance early warning information is formed, and the maintenance work is adjusted in time according to the maintenance information.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

Brake device of vacuum pipeline wheel rail train

ActiveCN105480253AImprove reliabilityShorter braking distanceRailway hydrostatic brakesRailway hydrodynamic brakesBrakeCoupling

The invention discloses a brake device of a vacuum pipeline wheel rail train, which at least comprises a brake disc, a clutch a, a belt pulley a, a transmission belt, a tensioning mechanism, a belt pulley b, a speed change gear box, a clutch b, a magnetic coupling, a magnetic suspension bearing, a flywheel, a vacuum cavity and a cooling device, wherein the clutch a and the clutch b are automatically controlled by a computer; during braking, the clutch b is jointed with the magnetic coupling firstly, then the clutch a is combined with the brake disc, an axle drives the flywheel to rotate through the transmission belt and the speed change gear box, and the kinetic energy of the axle is changed to the kinetic energy of the flywheel; when the rotating speed of the flywheel reaches the maximum value, the clutch a is disconnected from the brake disc, the clutch b is disconnected from the magnetic coupling, and the flywheel still rotates at a high speed; and when the train starts, the clutch a is combined with the brake disc firstly, then the clutch b is jointed with the magnetic coupling, the kinetic energy of the flywheel is transferred to the axle through the gear box and the transmission belt, and thus the braking energy is changed to traction power.

Owner:上海洲跃生物科技有限公司

Environmental protection type asbestos less friction magnetic powder

An environmental protection type non-asbestos magnetic friction powder as braking material with high friction coefficient is proportionally prepared from 16 raw materials including sepiolite, iron oxide powder, copper oxide powder, barite powder, magnesium oxide powder, steel wool, etc.

Owner:吴传良

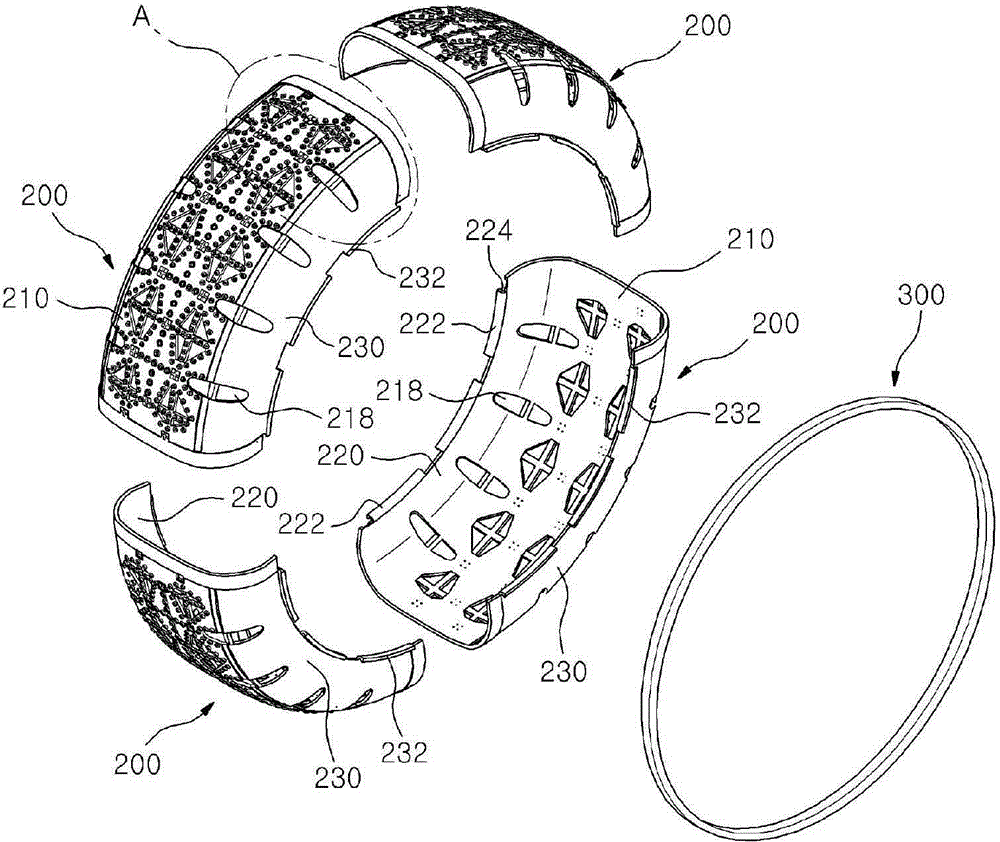

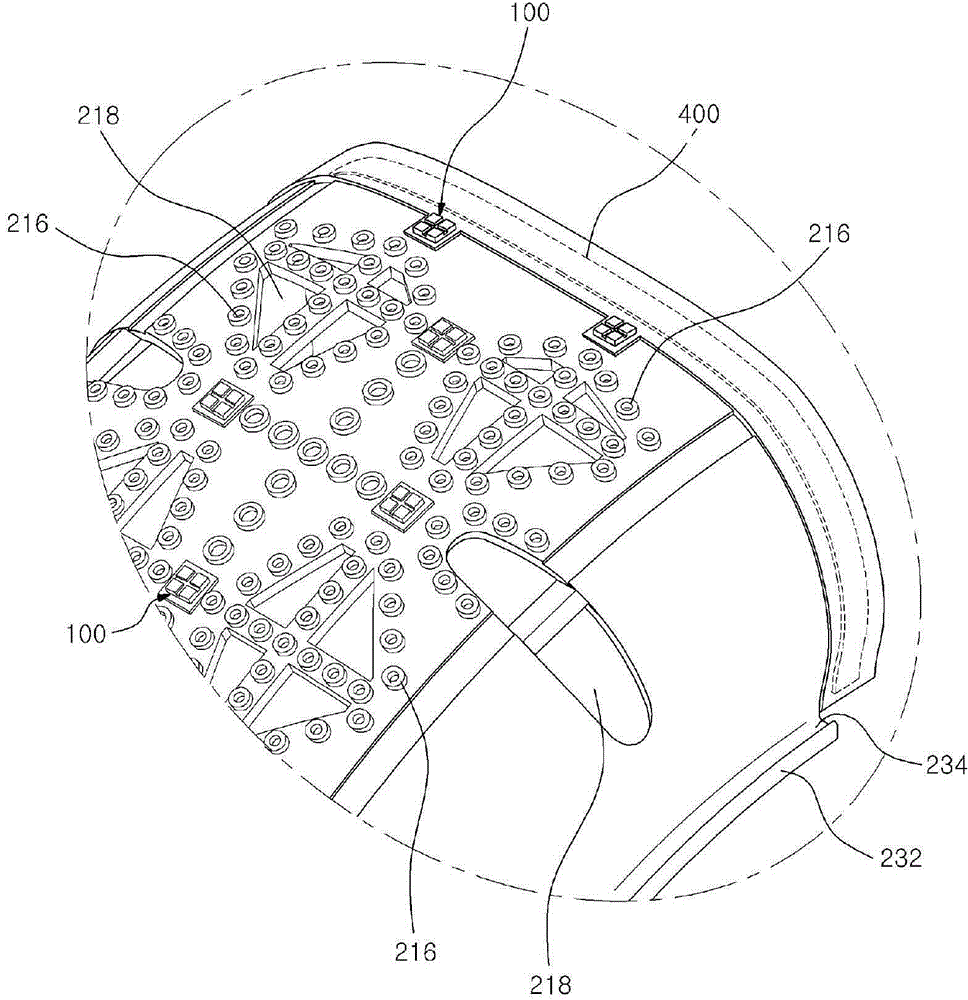

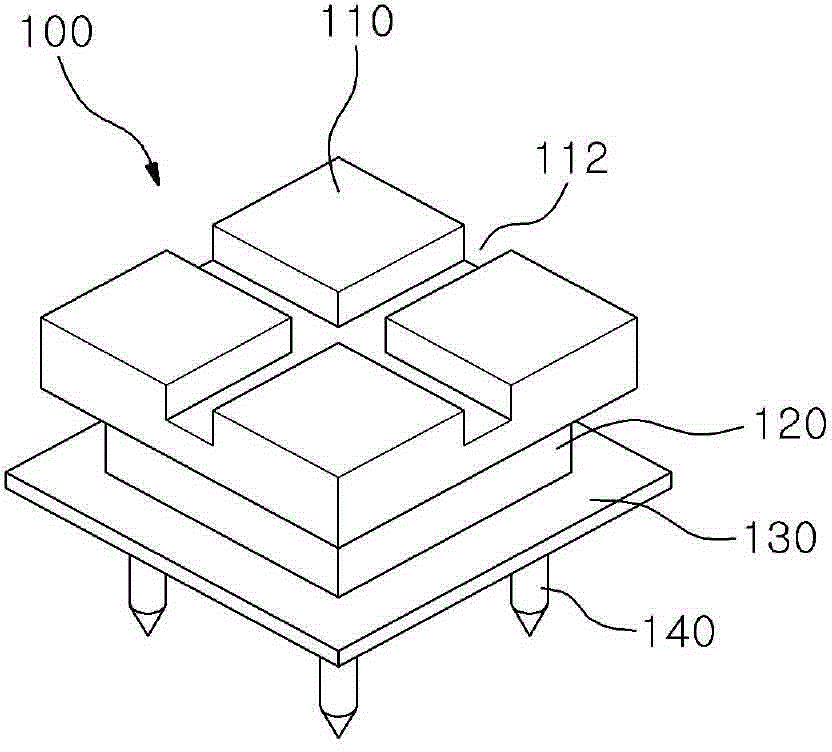

Snow tire cover

The present invention relates to a snow tire cover of a new configuration which is easily fitted to and separated from a tire, causes no concern about road breakage and does not degrade ride comfort, the snow tire cover comprising: a metal brake pin (100) consisting of a head (110), a neck (120) protruding from the rear surface of the head (110) at a width narrower than the head (110), a stopper plate (130) protruding from the rear surface of the neck (120) at a width wider than the neck (120), and pins (140) protruding from the rear surface of the stopper plate (130); and a plurality of synthetic resin cover bodies (200) which are injection-molded so as to have a tread cover (210) for covering the tread of the tire (2), and inside and outside covers (220, 230) for covering the inside and outside of the tire (2) by extending from both sides of the tread cover (210), and which are elastically fitted into the tire (2) so as to cover the tire (2), wherein the brake pin (100) is inserted into the tread cover (210) at the time of the injection-molding of the cover bodies (200) so that the head (110) protrudes toward the outside of the tread cover (210) and the stopper (130) and the pins (140) protrude toward the inside of the tread cover (210), whereby if the cover bodies (200) are fitted into the tire (2), the pins (140) of the brake pin (100) are pressed in the tire (2).

Owner:李洙荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com