Brake device of vacuum pipeline wheel rail train

A vacuum pipeline and braking device technology, applied in pneumatic brakes, railway braking systems, hydrostatic brakes, etc., can solve the problems of high installation accuracy, affecting driving safety, brittle fracture of brake discs, etc., and achieve energy utilization. High, simple device structure, the effect of shortening the braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

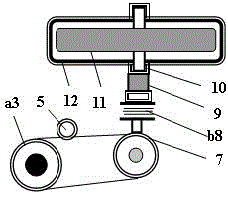

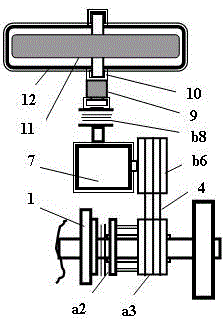

[0031] Such as figure 1 As shown, the device of the present invention at least includes: brake disc 1, clutch a2, pulley a3, transmission belt 4, tensioning mechanism 5, pulley b6, transmission gearbox 7, clutch b8, magnetic coupling 9, magnetic suspension bearing 10 , flywheel 11, vacuum chamber 12 and cooling device 13.

[0032] Assemble the brake disc 1 on the axle of the train, install the clutch a2 and the pulley a3 on the bearing of the axle, assemble the flywheel 11 in the vacuum chamber 12, install the transmission gearbox 7, the clutch b8, the magnetic coupling 9. The magnetic levitation bearing 10 and the vacuum chamber 12 are all fixed on the underframe of the train, and the pulley b6 is installed on the input shaft of the variable speed gearbox 7;

[0033] Connect one end of the clutch a2 with the pulley a3, and the other end engages with the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com