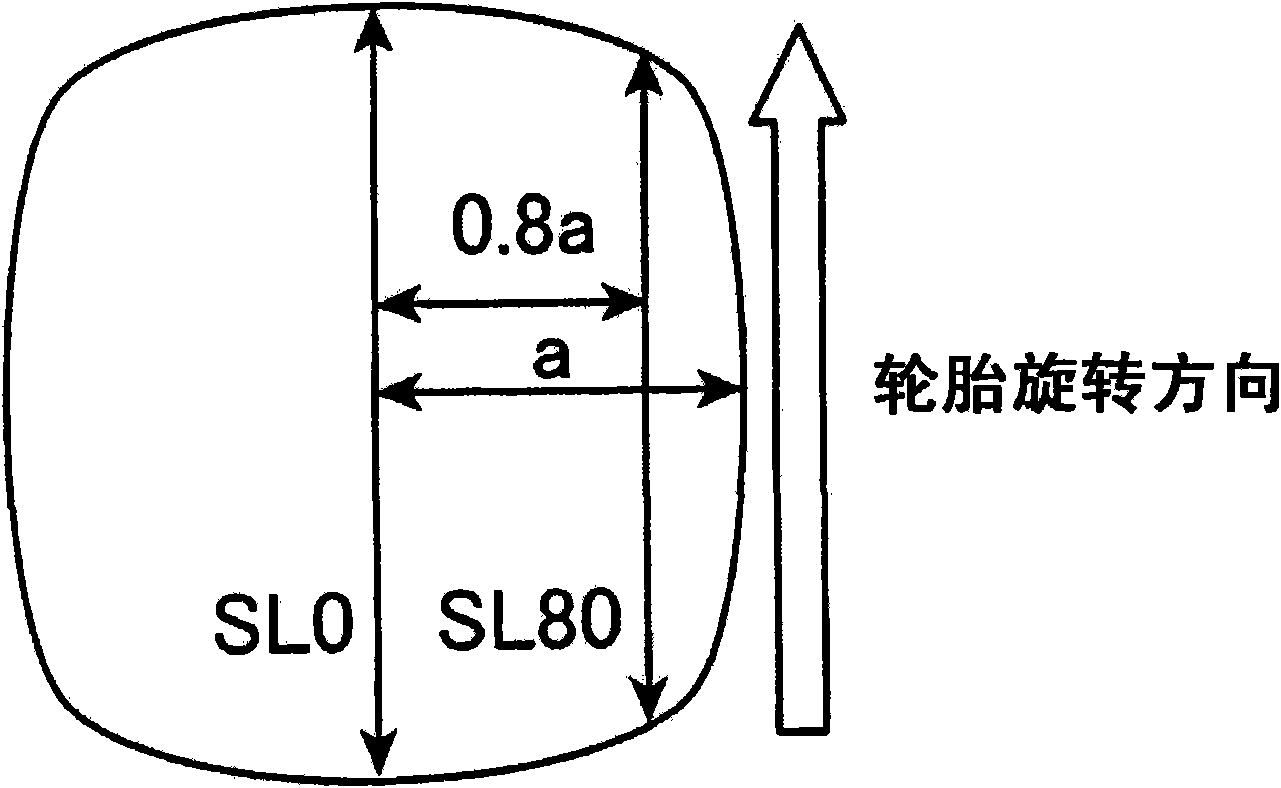

Rubber composition for studless tire and studless tire using the same

A technology of studless anti-skid tires and rubber compositions, which is applied to tire treads/tread patterns, special tires, tire parts, etc., and can solve the problems of reducing wear resistance and fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

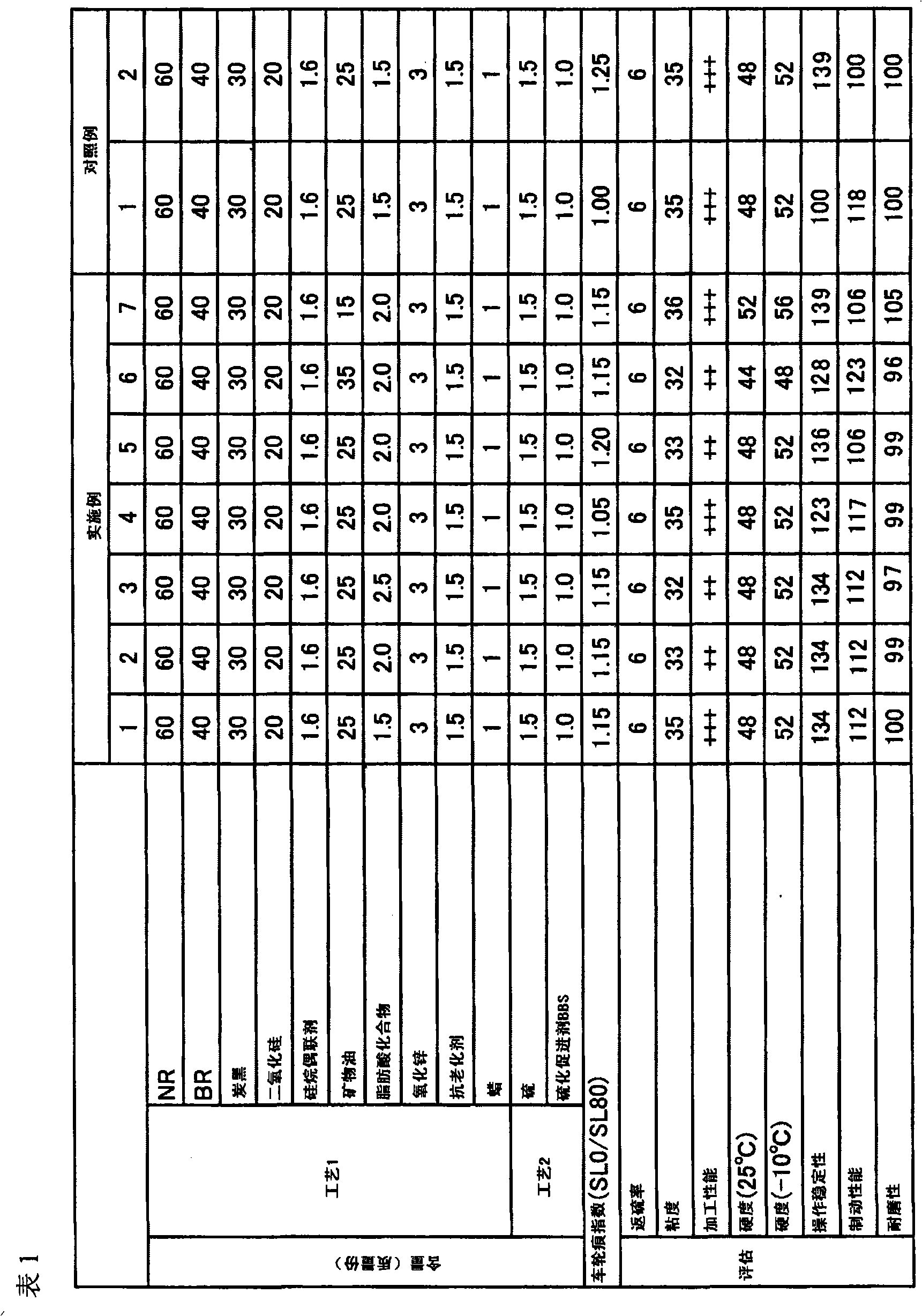

Examples

Embodiment

[0086] Although the present invention has been described more specifically based on examples, the present invention is not limited to these examples.

[0087] Various chemicals used in Examples and Comparative Examples are as follows.

[0088] Natural Rubber (NR): RSS #3.

[0089] BR: BR 150B (cis 1,4 binding capacity: 97%, ML 1+4 (100° C.): 40, viscosity of 5% toluene solution at 25° C.: 48 cps, Mw / Mn: 3.3), manufactured by Ube Industries, Ltd.

[0090] Carbon black: DIABLACK I (ISAF carbon black, average particle diameter: 23 nm, DBP oil absorption: 114 ml / 100 g), manufactured by Mitsubishi Chemical Corporation.

[0091] Silica: Ultrasil VN3 (N 2 SA: 175m 2 / g), manufactured by Degussa

[0092] Silane coupling agent: Si-69, manufactured by Degussa Corporation.

[0093] Mineral oil: PS-32 (paraffin process oil), manufactured by Idemitsu Kosan Co., Ltd.

[0094] Fatty acid compound (fatty acid derivative: mixture of zinc salt of aliphatic carboxylic acid and zinc salt o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com