Magnetic graphene oxide composite material immobilized horse radish peroxidase as well as preparation method and application thereof

A technology of horseradish peroxidase and composite materials, which is applied in biochemical equipment and methods, oxidoreductases, chemical instruments and methods, etc., can solve the problems of short catalytic life and enzyme inactivation of horseradish peroxidase. , to achieve the effect of improving the ability of reuse, improving activity and facilitating recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

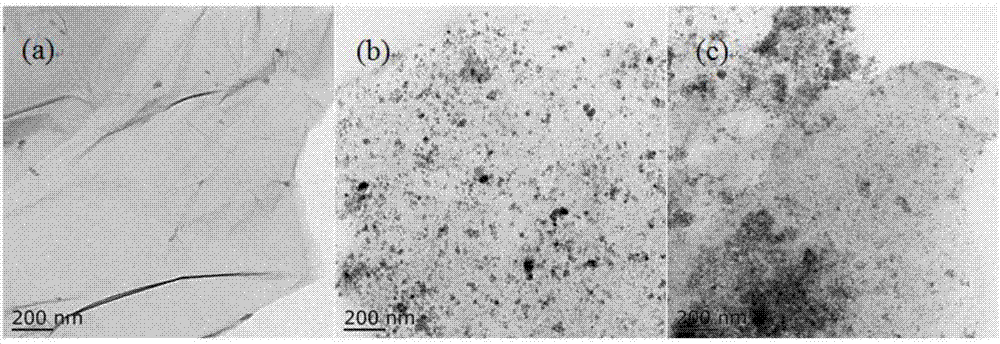

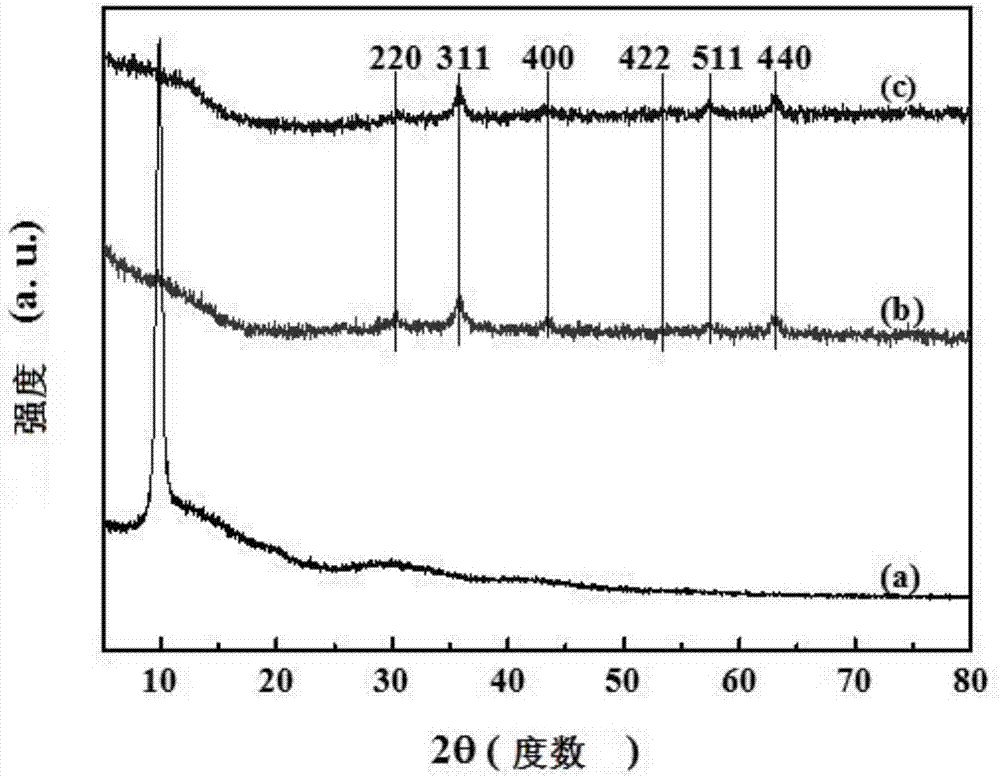

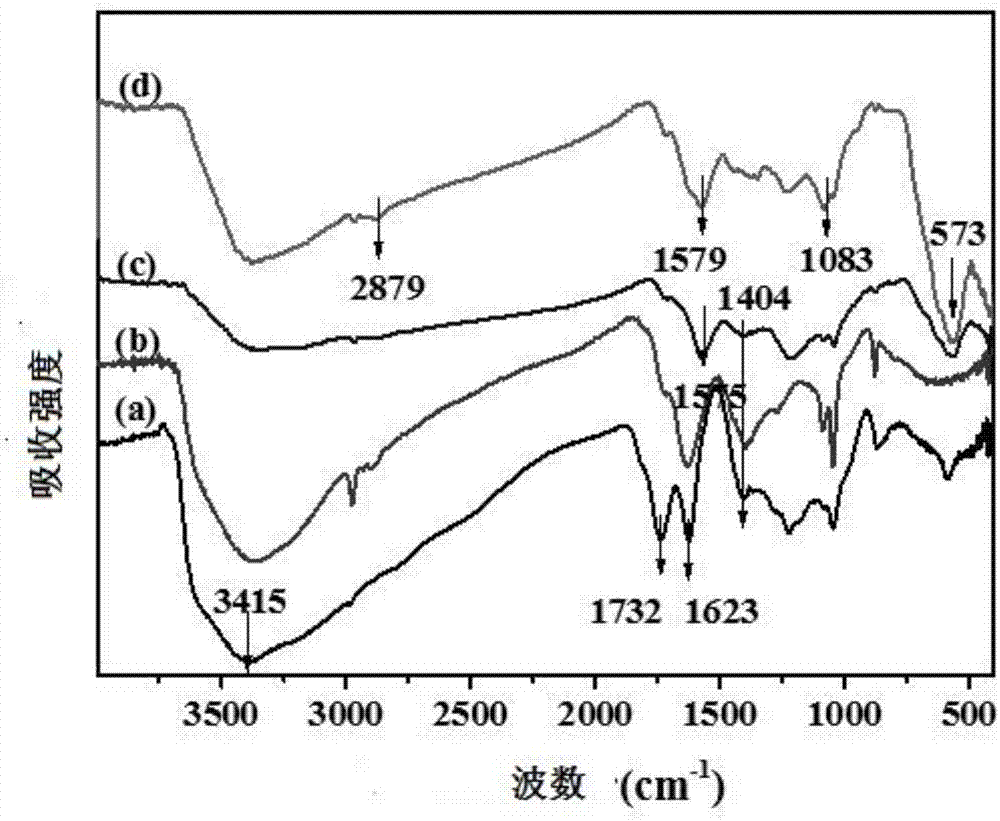

[0058] Embodiment 1: Preparation of novel magnetic graphene oxide composite material

[0059] (1) Synthesis of surface carboxylated graphene oxide GO-COOH

[0060] Graphene oxide (GO) was synthesized by the Hummers method. First, take 0.3 g graphite powder, 0.7 g sodium nitrate in 23 mL 12mol L -1 The concentrated sulfuric acid solution was stirred in an ice bath for 15 minutes. After slowly adding 2.0 g of potassium permanganate, it was transferred to a water bath at 40° C. and stirred for 90 minutes. Add 25 mL of deionized water to the reaction system for dilution and continue stirring for 10 minutes. Add 4 mL of hydrogen peroxide, the system becomes a golden yellow solution, let it stand for 24 hours, pour out the supernatant, and filter with suction to obtain the precipitate, which is washed repeatedly with 5% hydrochloric acid until it is washed with BaCl 2 Detect that there is no precipitation in the supernatant, then wash with deionized water, and centrifuge until ...

Embodiment 2

[0065] Embodiment 2: Preparation of novel magnetic graphene oxide composite material

[0066] (1) Synthesis of surface carboxylated graphene oxide GO-COOH

[0067] Graphene oxide (GO) was synthesized by the Hummers method. First, take 0.7 g graphite powder, 0.3 g sodium nitrate in 23 ml 12mol L -1 The concentrated sulfuric acid solution was stirred in an ice bath for 15 minutes. After slowly adding 6.0 g of potassium permanganate, it was transferred to a water bath at 40° C. and stirred for 90 minutes. Add 75 ml of deionized water to the reaction system for dilution and continue stirring for 10 minutes. Add 8 ml of hydrogen peroxide, the system becomes a golden yellow solution, let it stand for 24 hours, pour out the supernatant, and filter with suction to obtain the precipitate, which is washed repeatedly with 5% hydrochloric acid until it is washed with BaCl 2Detect that there is no precipitation in the supernatant, then wash with deionized water, and centrifuge until t...

Embodiment 3

[0072] Embodiment 3: Preparation of novel magnetic graphene oxide composite material

[0073] (1) Synthesis of surface carboxylated graphene oxide GO-COOH

[0074] Graphene oxide (GO) was synthesized by the Hummers method. First, take 0.5 g graphite powder, 0.5 g sodium nitrate in 23 ml 12mol L -1 The concentrated sulfuric acid solution was stirred in an ice bath for 15 minutes. After slowly adding 4.0 g of potassium permanganate, it was transferred to a water bath at 40° C. and stirred for 90 minutes. Add 50 ml of deionized water to the reaction system for dilution and continue stirring for 10 minutes. Add 6 ml of hydrogen peroxide, the system becomes a golden yellow solution, let it stand for 24 hours, pour out the supernatant, and filter with suction to obtain the precipitate, which is washed repeatedly with 5% hydrochloric acid until it is washed with BaCl 2 Detect that there is no precipitation in the supernatant, then wash with deionized water, and centrifuge until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Fixed capacity | aaaaa | aaaaa |

| Fixed capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com