Rope-free lifting machine using lifting force as brake drive force

A technology for brakes and hoists, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of difficulty in realization, large lifting load and large volume, and achieve the effect of preventing flying accidents and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

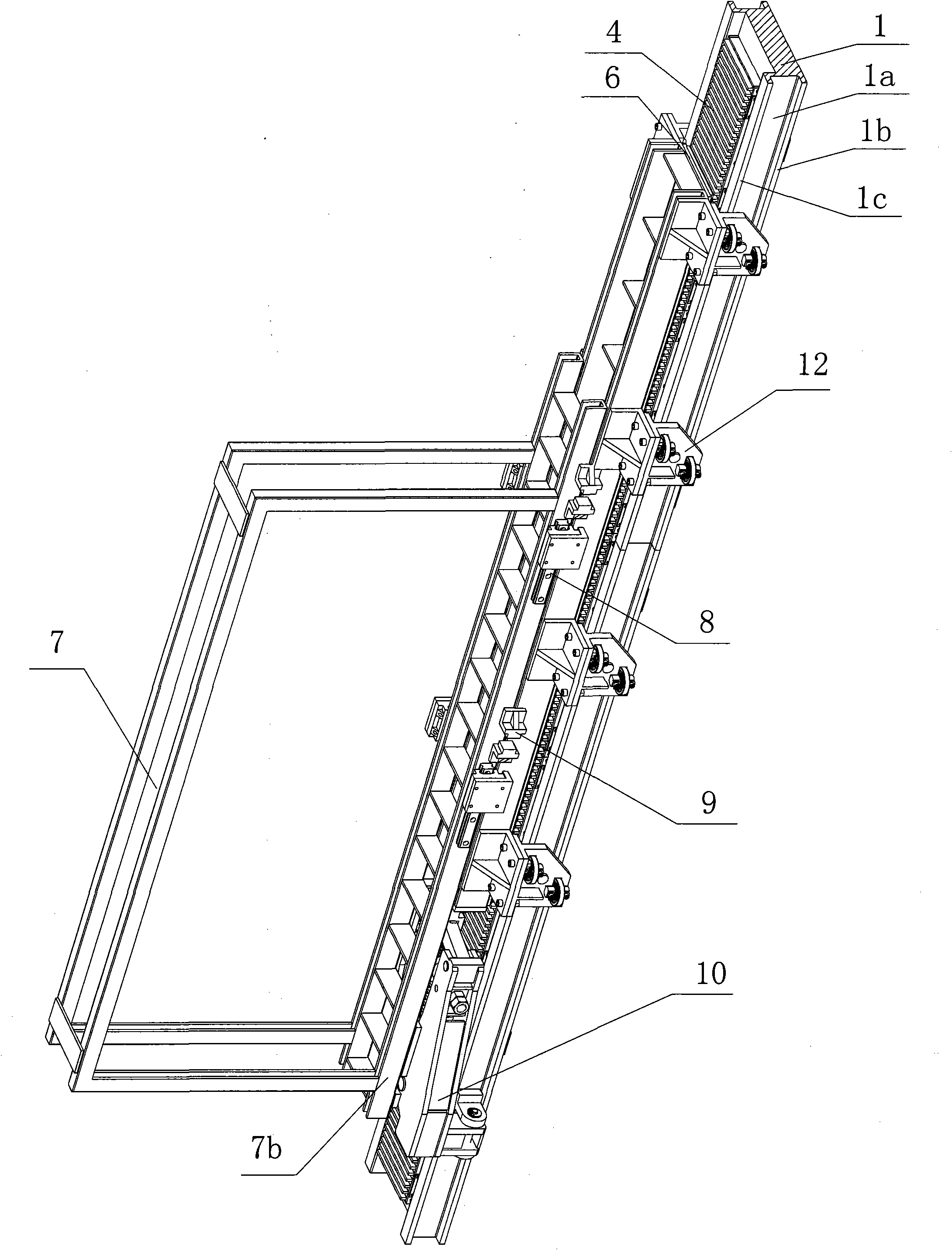

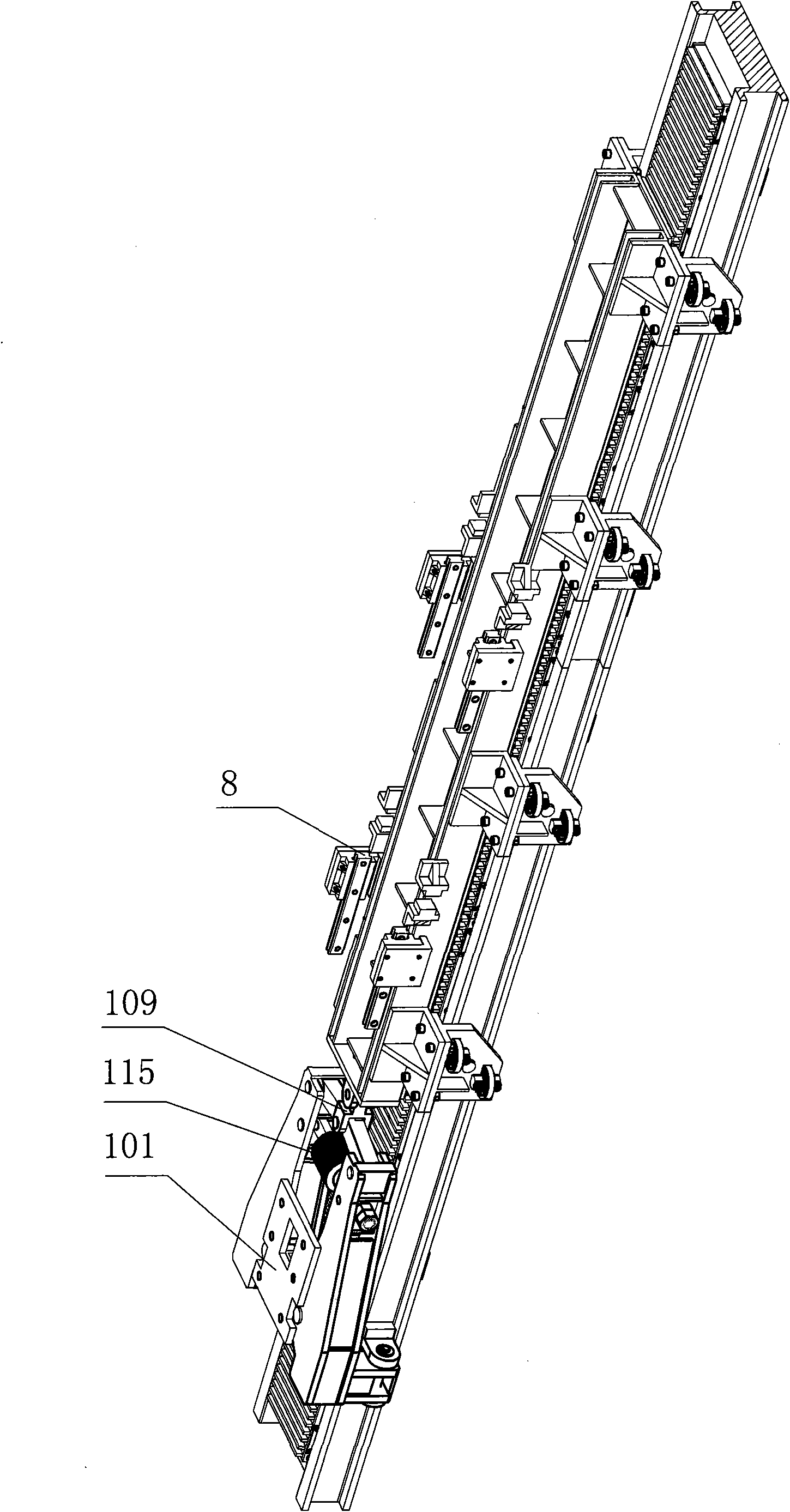

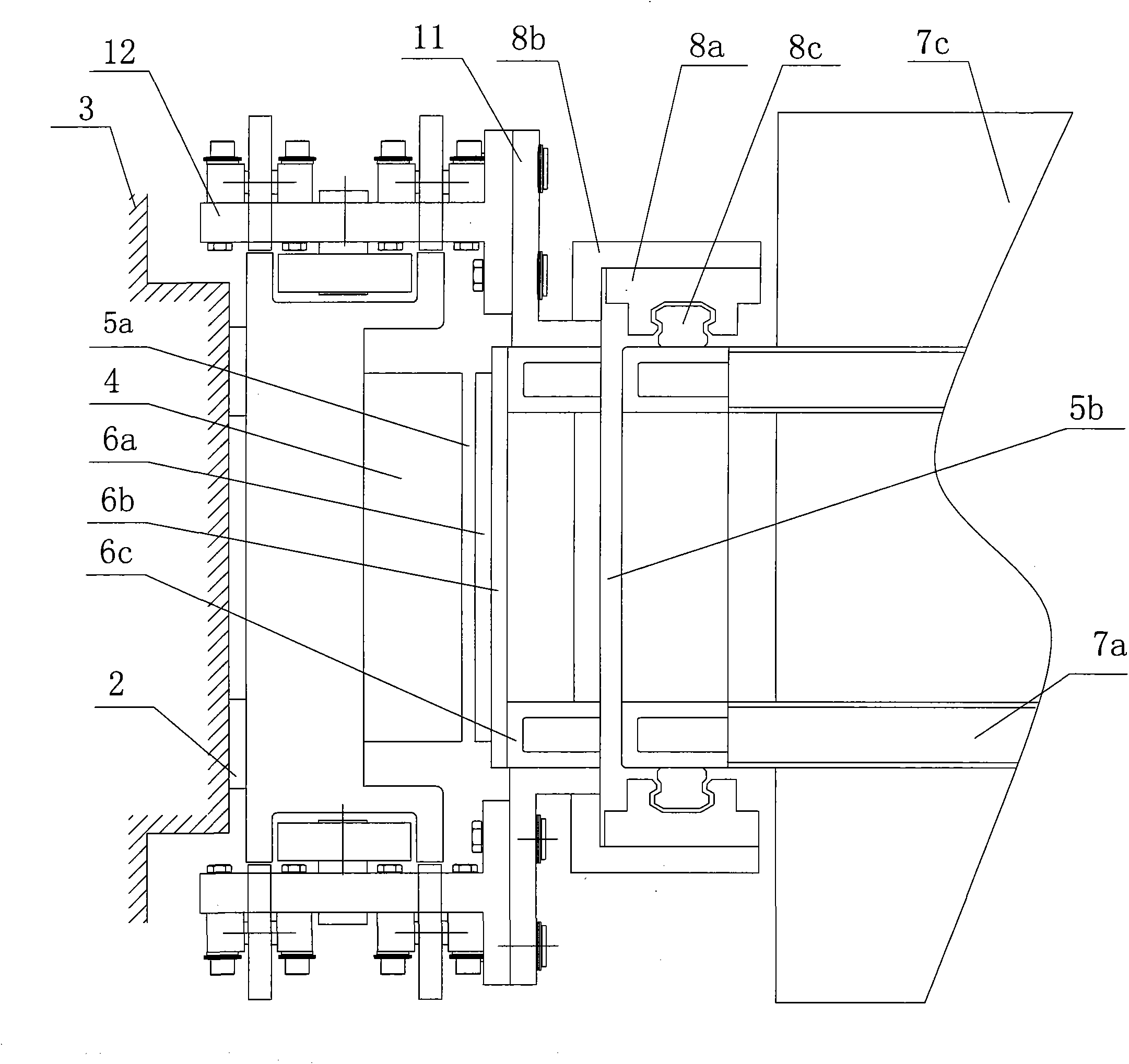

[0037] Such as figure 1 , figure 2 , image 3 As shown, the cordless hoist using the lifting force as the brake driving force of the present invention mainly includes a supporting steel beam assembly, a car, a linear motor driving device, a positioning guide device, and a braking device.

[0038] The supporting steel beam assembly 1 is a long strip and is installed on the mounting support 2 on the inner wall of the wellbore along the vertical direction. The linear motor stator 4 of the linear motor driving device is installed on the front of the supporting steel beam assembly 1. A concave strip groove 1a with an opening facing outward is provided along the vertical direction;

[0039] On both sides of the concave strip groove 1a are convex bars I 1b and convex bars II 1c, and the convex bars I 1b or convex bars II 1c are used as the brake rails of the safety gear protection device;

[0040] The concave strip groove 1a contains the brake block 103 of the booster caliper brake 10. Whe...

Embodiment 2

[0084] The base of the booster caliper brake (5) is installed on the linear motor mover (6), the brake push rod (109) is hinged or solidified with the car frame back plate (7b), and the brake block (103) ) Acting on the bottom surface (1d) of the concave strip groove supporting the steel beam assembly (1). Others are the same as in Example 1.

Embodiment 3

[0086] The positioning and guiding device of the linear motor mover 6 of the present invention can also be realized by linear guide rails and sliders. The linear guide rails are installed on the two sides of the supporting steel beam assembly 1, and the sliders are installed on the back of the linear motor mover. The iron 6b corresponds to the side surface and is aligned with the linear guide rail. The slider can slide freely on the linear guide rail to ensure that the linear motor mover 6 moves up and down in the vertical direction on the supporting steel beam assembly 1. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com