High-speed disc gear non-shaft loading rolling and unrolling device

A technology for rewinding and unwinding of rolls and gears, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of short service life of spare parts, high structural complexity, and high labor intensity of workers, and achieve transmission torque The effect of large size, reduced precision of parts and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

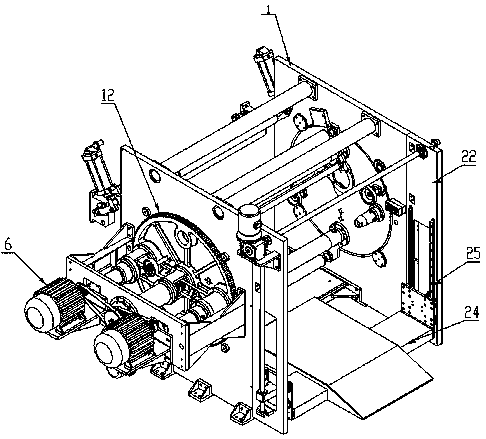

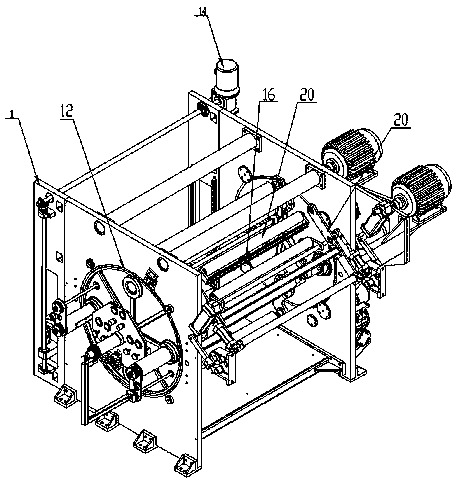

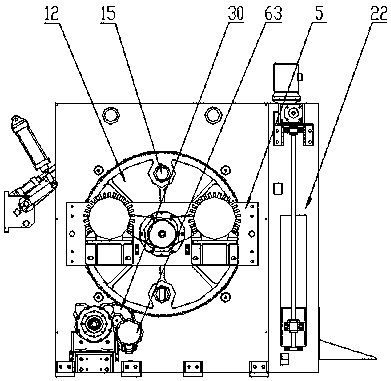

[0036] Example: such as Figure 1-7 As shown, a high-speed disc gear shaftless loading and unwinding device of the present invention includes:

[0037] The mounting frame is composed of wall panels 1 on both sides, an upper beam 2 and a lower beam 3, the upper beam 2 and the lower beam 3 are arranged between the wall panels 1 on both sides, and the bottom of the wall panels 1 is provided with a support base plate 4, A motor mounting frame 5 is arranged on the outside of one side of the wall panel 1;

[0038] Transmission mechanism, the transmission mechanism is composed of two motors 6, main transmission rod 7, two non-cylinder cone plug telescopic mechanisms 8 and two tensioning wheels 9, the two motors 6 are symmetrically installed on the outside of the motor mounting frame 5, the main transmission The rod 7 runs through the middle of the motor mounting frame 5, and the two motors 6 are connected to the main transmission rod 7 through the motor pulley 10. The transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com