Magnetic energy car

A magnetic energy locomotive and magnetic energy technology, applied in the field of magnetic energy vehicles, can solve the problems of insignificant energy saving effect and low utilization rate of permanent magnet energy, and achieve the effects of strong fault tolerance, small loss and strong braking ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

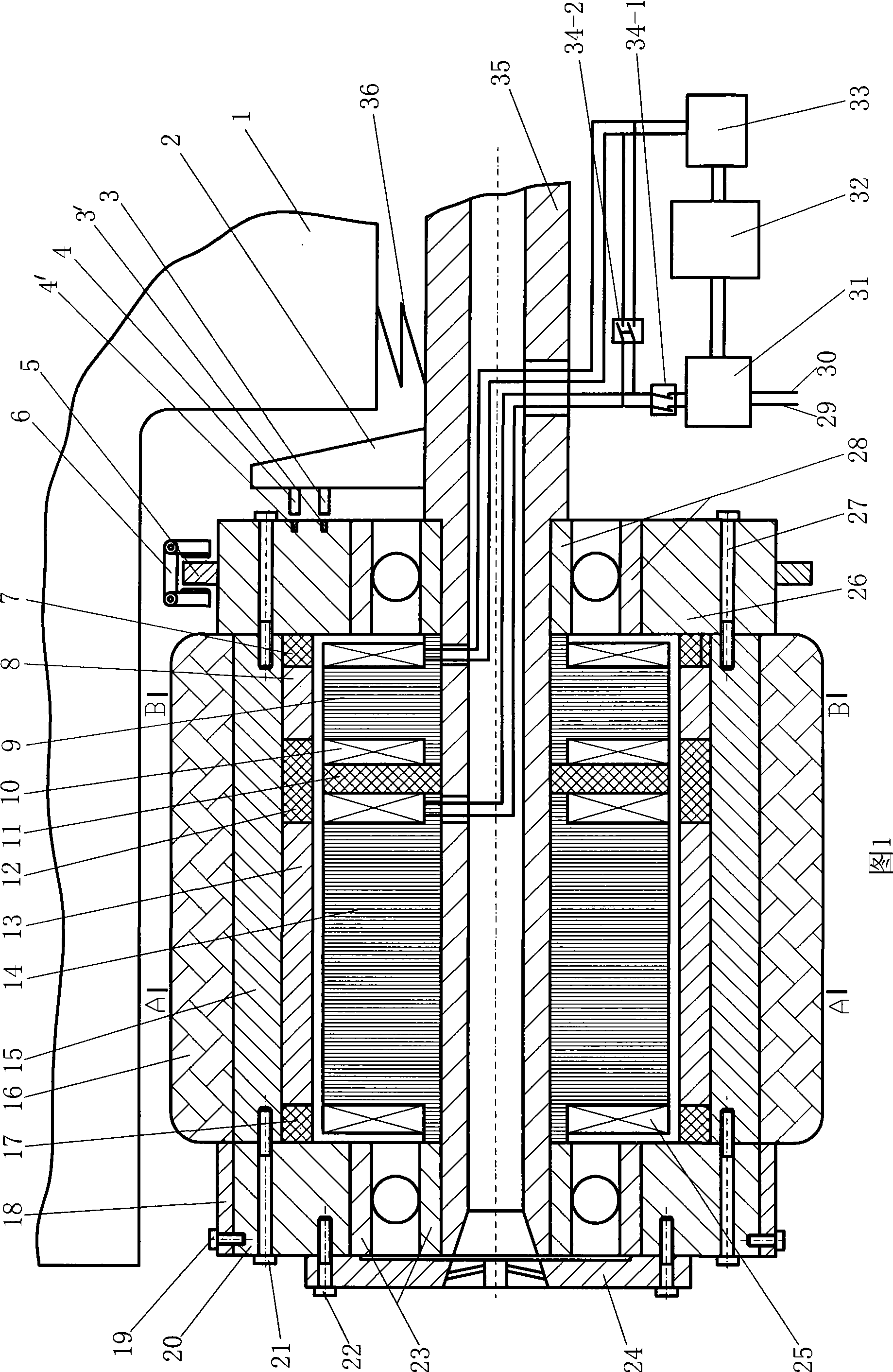

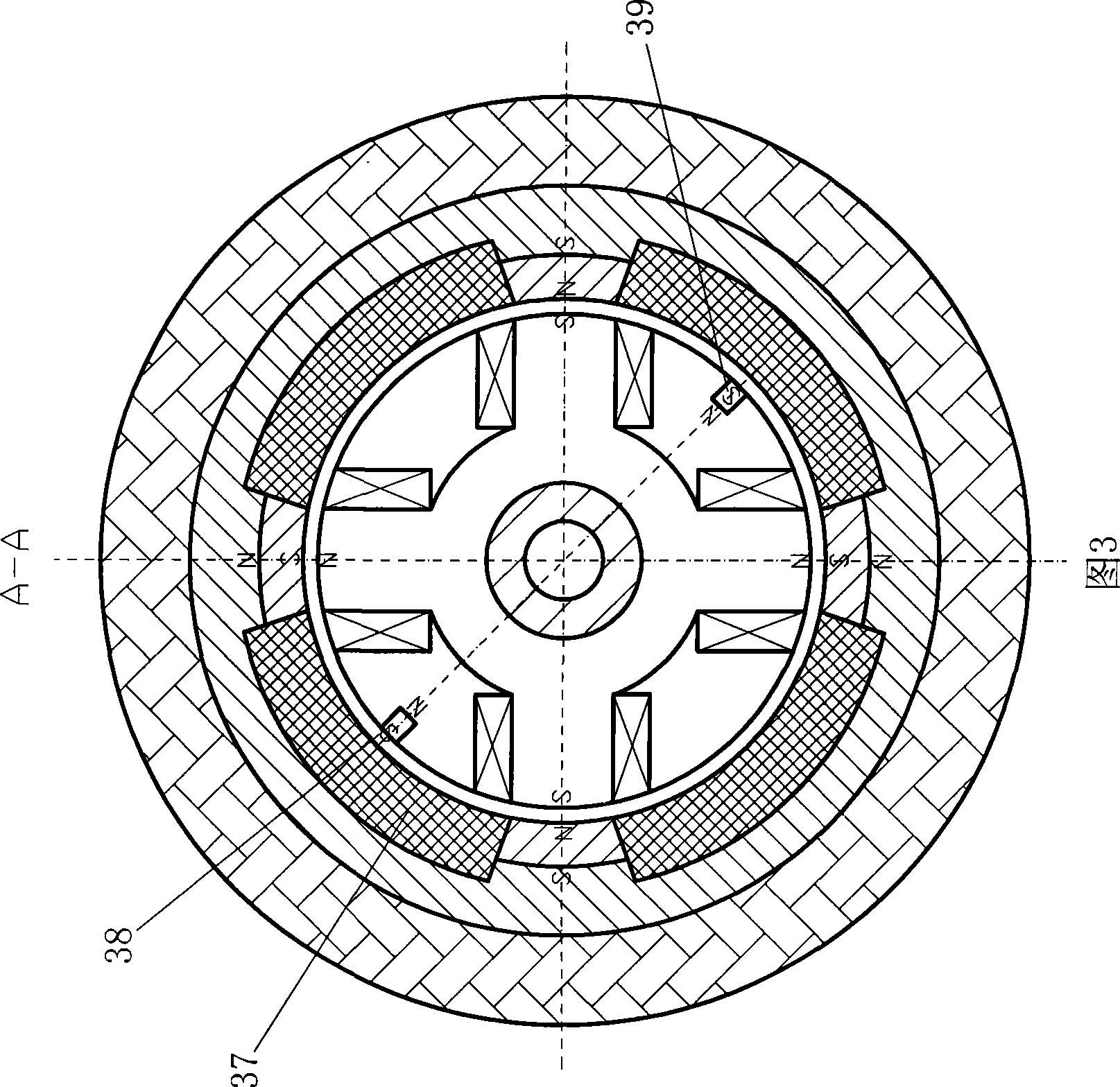

[0029] Embodiment one: as shown in Fig. 1, Fig. 2, Fig. 3, Figure 6 Show. On the fixed shaft 35 with middle hole, solidify the core 9,14 and the non-magnetic insulating spacer ring 11 of the torque gear shape that the soft magnetic sheet is stacked, coils 10,25 are respectively wound on the teeth of the core 9,14, on the stator core 14 is provided with two radially magnetized small permanent magnets 38 and 39, which form the stator.

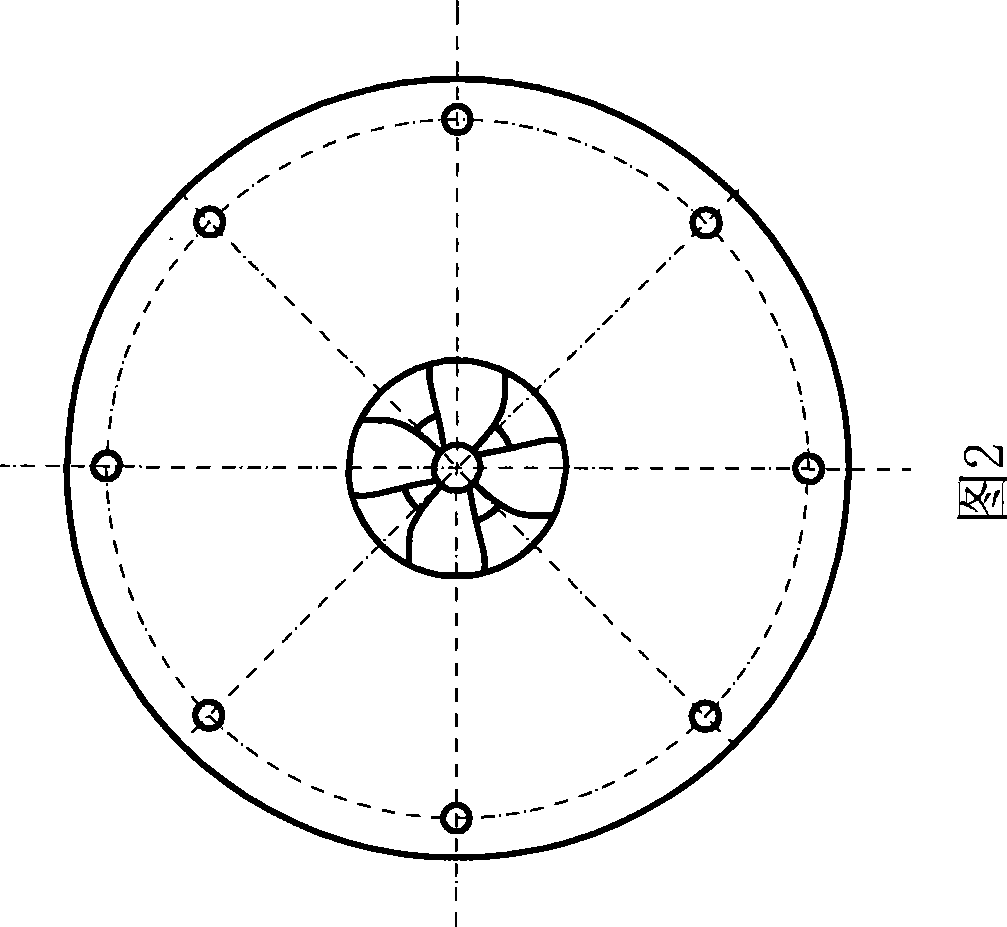

[0030] Wheel composition: radially magnetized tile-shaped permanent magnets 8, 13 and tile-shaped non-magnetic insulators 37 and non-magnetic insulating rings 7, 12, 17 form a cylinder, four permanent magnets 8, four permanent magnets The magnets 13 are alternately polarized along the circumferential direction, the cylinder is sleeved outside the stator with gaps, and the magnetically permeable hub 15 is fixed on the outer peripheral surface of the cylinder; a number of small magnets are embedded on the circular end plate 26 Columns 3' and 4' f...

Embodiment 2

[0057] Embodiment two: if the magnetic energy vehicle of the present invention often works at a low speed, or in order to reduce the volume and weight of the magnetic energy vehicle of the present invention, remove the magnet 8, stator core 9, coil 10, non-magnetic insulation in the magnetic energy vehicle wheel of the present invention Isolation ring 11, non-magnetic insulating ring 12. The battery system 32 is charged from outside the vehicle and also recovers electrical energy for regenerative braking.

Embodiment 3

[0058] Embodiment three: two magnetic energy machine wheels in front of the magnetic energy vehicle described in embodiment one are replaced with common non-powered wheels, and a four-wheeled vehicle with rear wheel drive is thus obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com