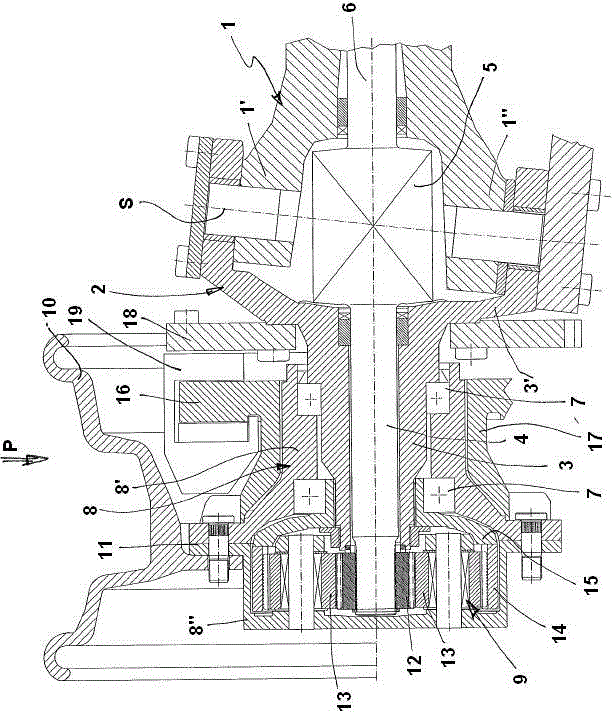

Steerable wheel side of a drive axle

A technology for driving axles and driving shafts, which is applied to steering mechanisms, steering rods, brake components, etc., can solve problems such as inability to use radially, and disc brakes are not allowed, and achieve the effect of increasing structural space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] According to the drawings, the invention relates to a drive axle with Ackermann steering. In this respect, the middle part of the axle (usually comprising the respective different axles) has axle guards at its two ends, the axle guards have an upper guard end 1' and a lower guard end 1", at these ends, The knuckle 2 is arranged steerably about a pivot S predefined by the guard ends 1' and 1", the knuckle shaft 3 of which is integrally connected to the knuckle yoke 3'. The knuckle shaft 3 is configured as a hollow body and accommodates a drive shaft part 4 in the axial center hole, wherein the drive shaft part is connected in the driving direction by a coupling joint 5 to a drive shaft 6 provided in the central shaft part , the connection head is set in the free space between the steering knuckle yoke 3' and the guard ends 1' and 1". The hub device 8 passes through the roller bearing (especially the tapered roller bearing 7) at the steering knuckle shaft 3 is rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com