A multi-size screw fastening head placement platform for mold clamping system

A technology of screw tightening and platform placement, applied in the field of mold clamping systems, can solve problems such as failure to grasp, reduce mold clamping efficiency, and mold clamping failure, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

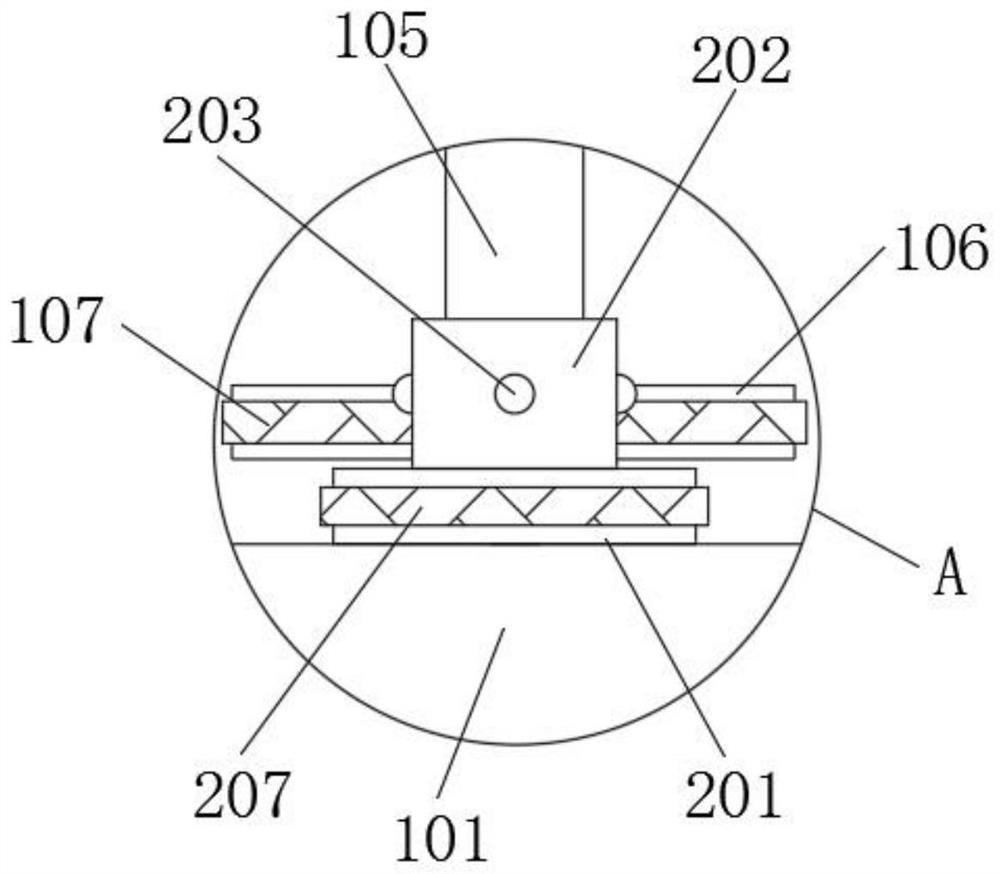

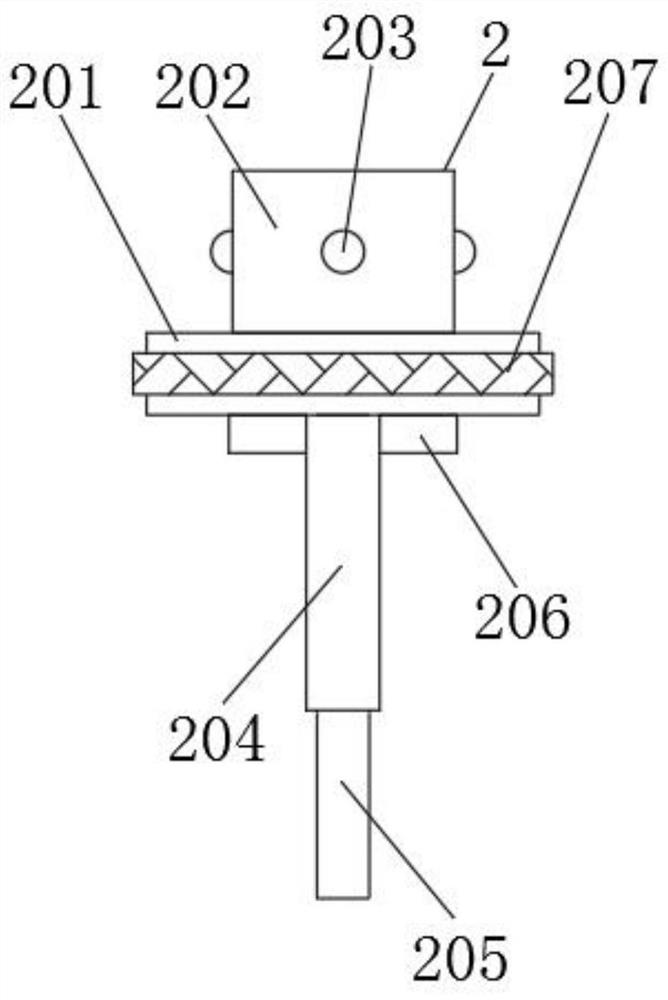

[0051] see Figure 1-3 , a multi-size screw fastening head placement platform for a mold clamping system, including a placement mechanism 1 and a plurality of screw fastening heads 2, the screw fastening heads 2 have a variety of different specifications, and the various specifications can be adapted to different The mold locking screw, the screw fastening head 2 includes a linkage wheel 201, the top of the linkage wheel 201 is fixedly connected with a connector 202, and the sides of the connector 202 are fixedly connected with a hemispherical connection block 203, and the bottom end of the linkage wheel 201 A connecting rod 204 is fixedly connected, and the bottom end of the connecting rod 204 is fixedly connected with a fastening rod 205 for fastening screws.

[0052] see figure 1 and Figure 4 The placement mechanism 1 includes a placement board 101, the bottom of the placement board 101 is fixedly connected with four support frames 102 distributed in a rectangular array,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com