Reset sample pile and sample resetting method

A reset method and sample technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve problems such as the inability to realize the reset function, and achieve the effect of satisfying repeated observations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

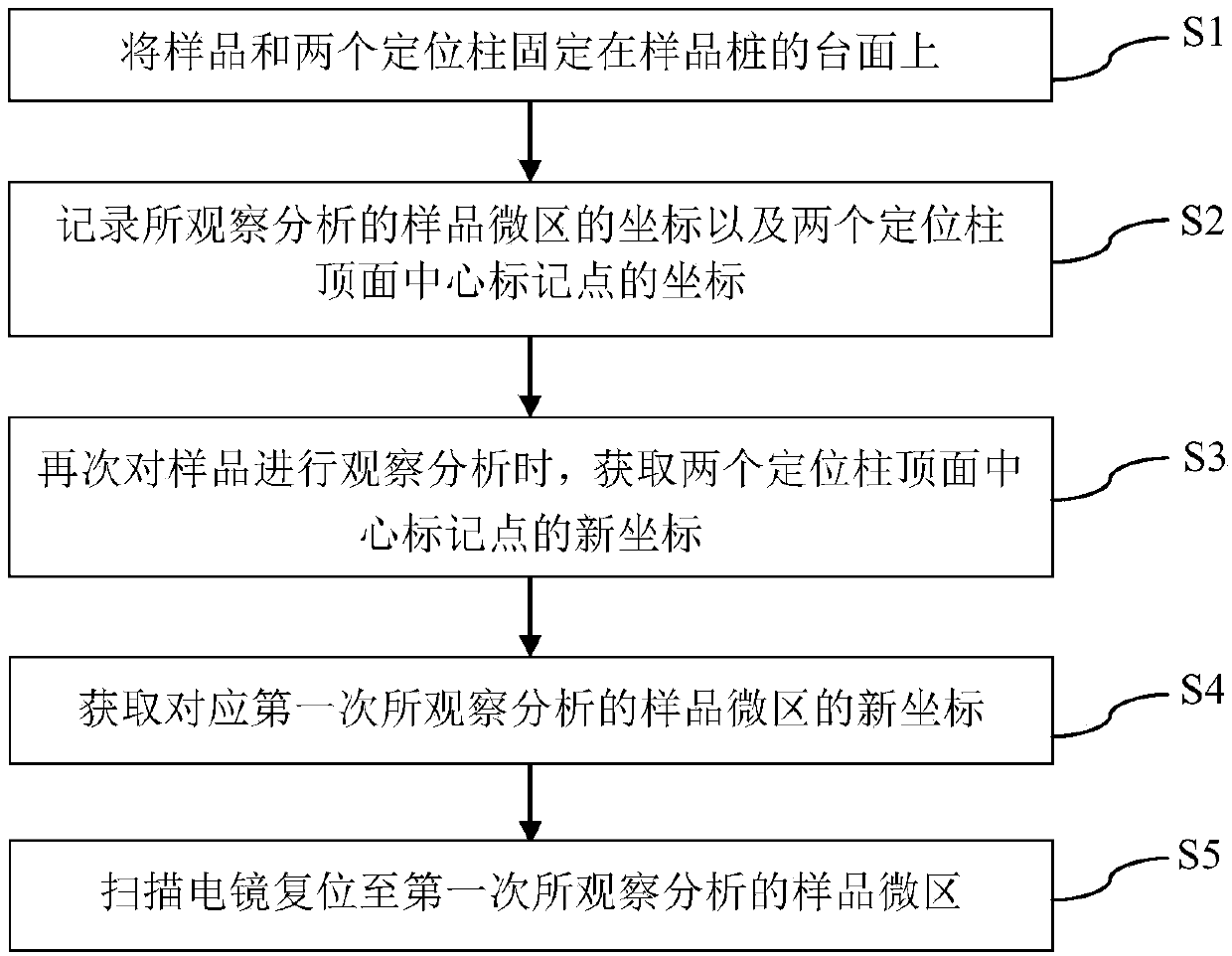

[0038] Such as figure 1 As shown, the sample resetting method according to the present invention is shown, comprising the following steps:

[0039] S1. Fix the sample and two positioning columns on the table of the sample pile;

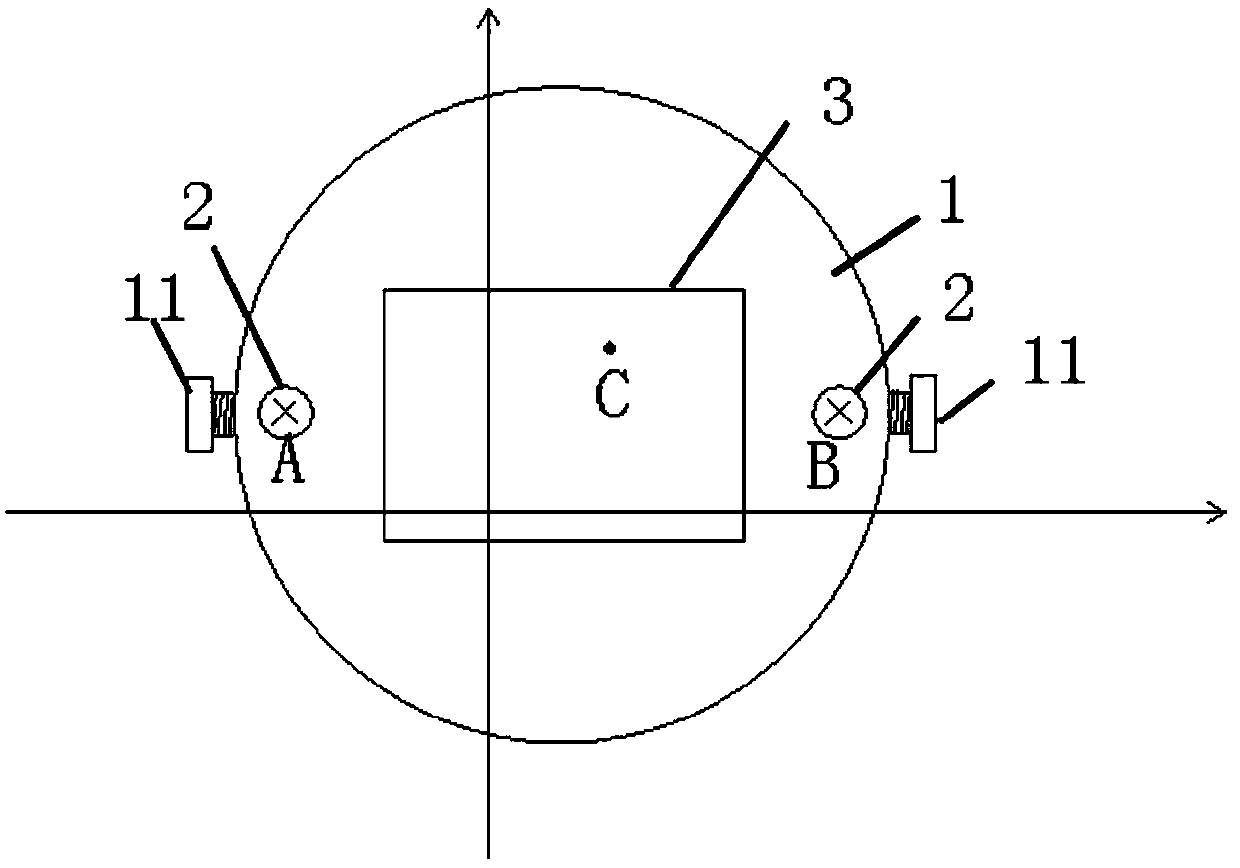

[0040] S2. Fix the sample post carrying the sample and the positioning column on the sample stage of the scanning electron microscope, use the scanning electron microscope to observe and analyze the micro-area of the sample, and record the coordinates (x, y) of the sample micro-area observed and analyzed and The coordinates (x a ,y a ) and (x b ,y b );

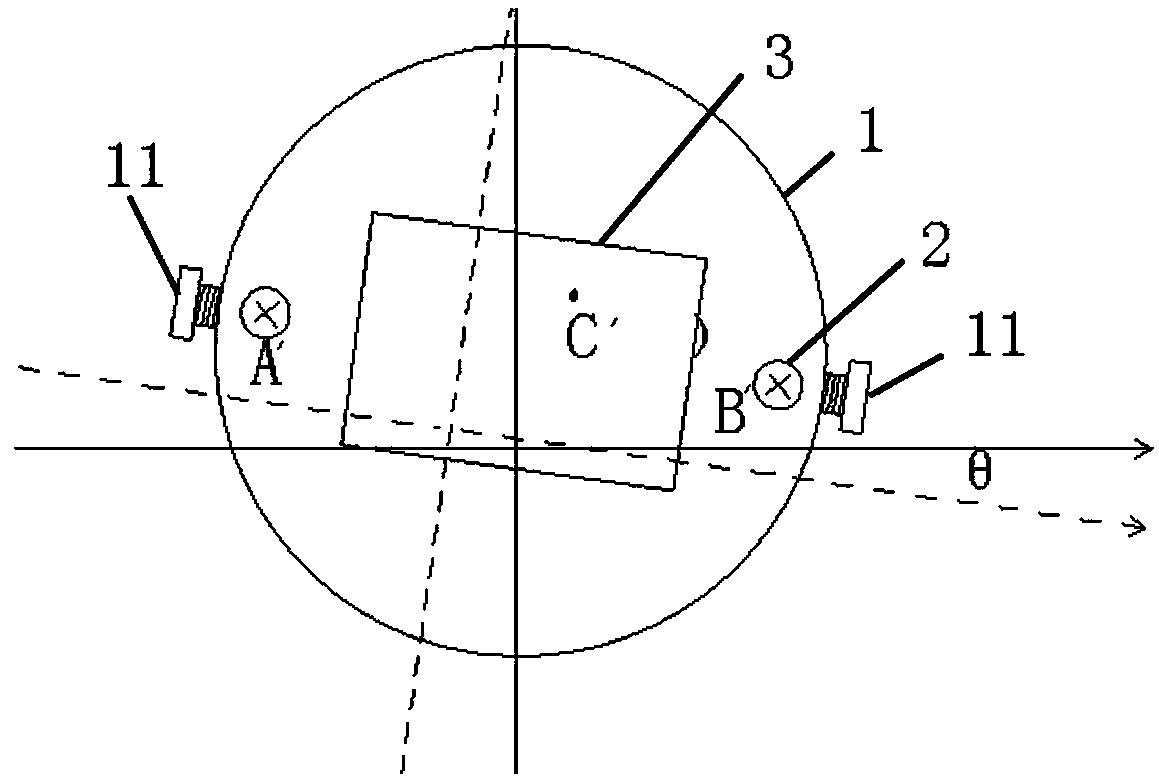

[0041] S3, when the sample is observed and analyzed again, the sample pile carrying the sample and the positioning column is fixed on the sample stage of the scanning electron microscope again, and the new coordinates (x a ',y a ') and (x b ',y b ');

[0042] S4, according to the plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com