Manufacturing process of ball valve ball

A manufacturing process and technology of spheres, applied in the field of ball valve sphere manufacturing process, can solve problems such as difficulty in taking out rough spheres, low production efficiency, and sphere damage, and achieve the effects of facilitating rough spheres, improving service life, and increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

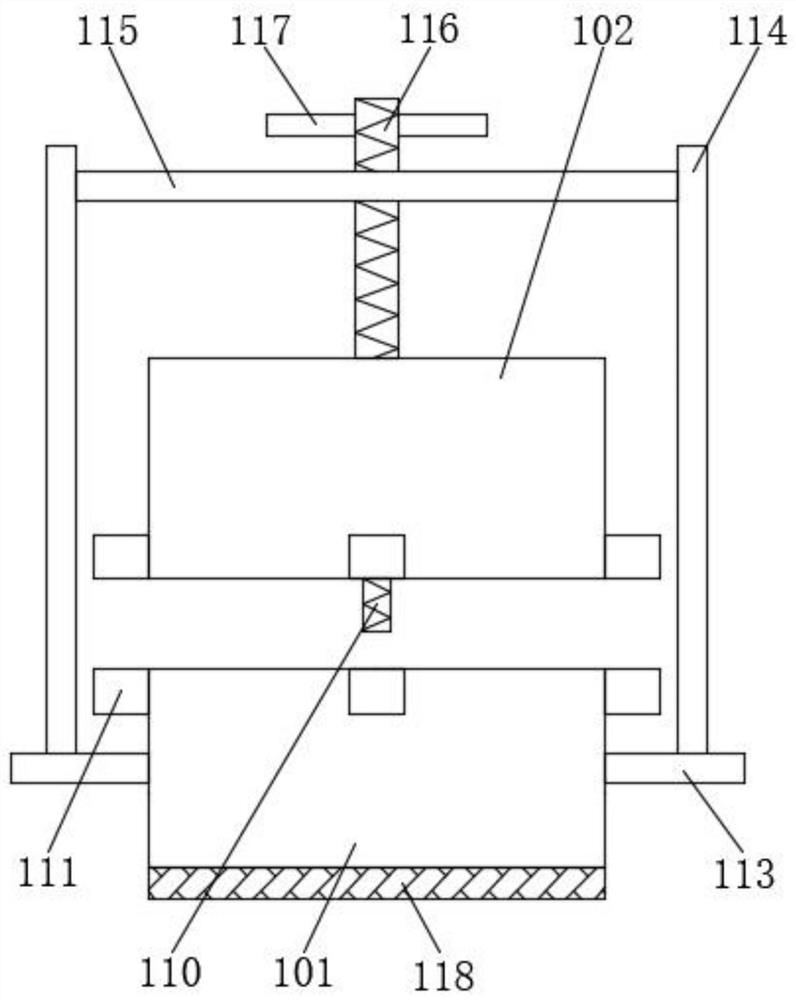

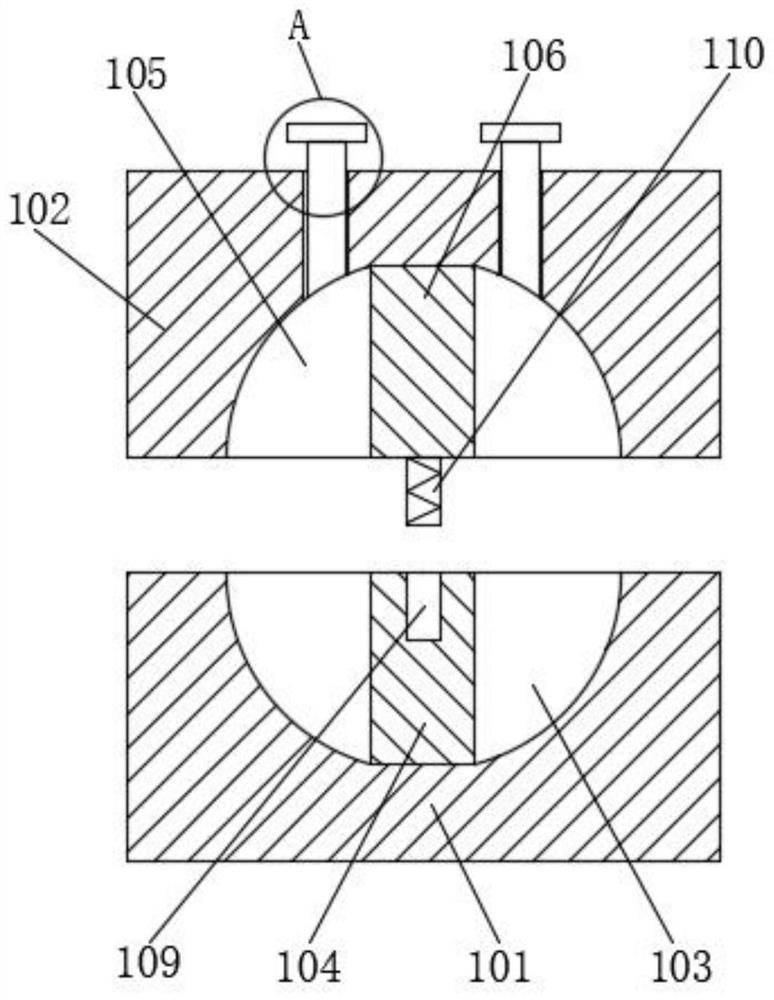

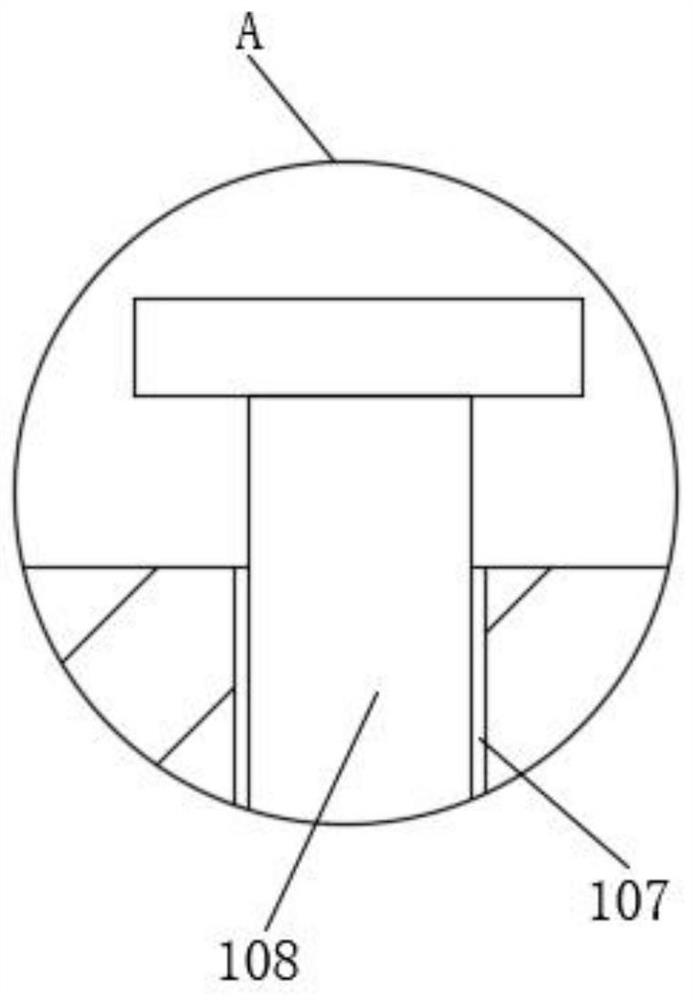

[0048] see Figure 1-8 , a manufacturing process of a ball valve spheroid, comprising the following steps:

[0049] S1. Pouring molding: Apply an appropriate amount of release agent on the inner wall of the mold cavity of the mold mechanism, then close the mold mechanism, take an appropriate amount of stainless steel water into the mold mechanism, and make the stainless steel water in the mold mechanism, forming a shape with A blank sphere with a through hole;

[0050] S2, mold opening and taking out: open the mold mechanism, and use the extraction mechanism to take out the blank sphere in step S1 from the mold mechanism;

[0051] S3, slotting: slotting the blank sphere in step S2 by a milling machine, and opening a valve stem groove for connecting the valve stem on the outer wall of the blank sphere;

[0052] S4, grinding: surface treatment is carried out to the rough sphere in step S3, use sandpaper to grind and polish the surface of the sphere, the inner wall of the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com