Belt-breaking hydraulic protection device for belt conveyor

A belt conveyor and hydraulic protection technology, which is applied in the direction of mechanical equipment, conveyor objects, conveyor control devices, etc., can solve problems such as small contact surface, secondary broken belt, and false braking, and achieve strong braking force, The effect of increasing the friction factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

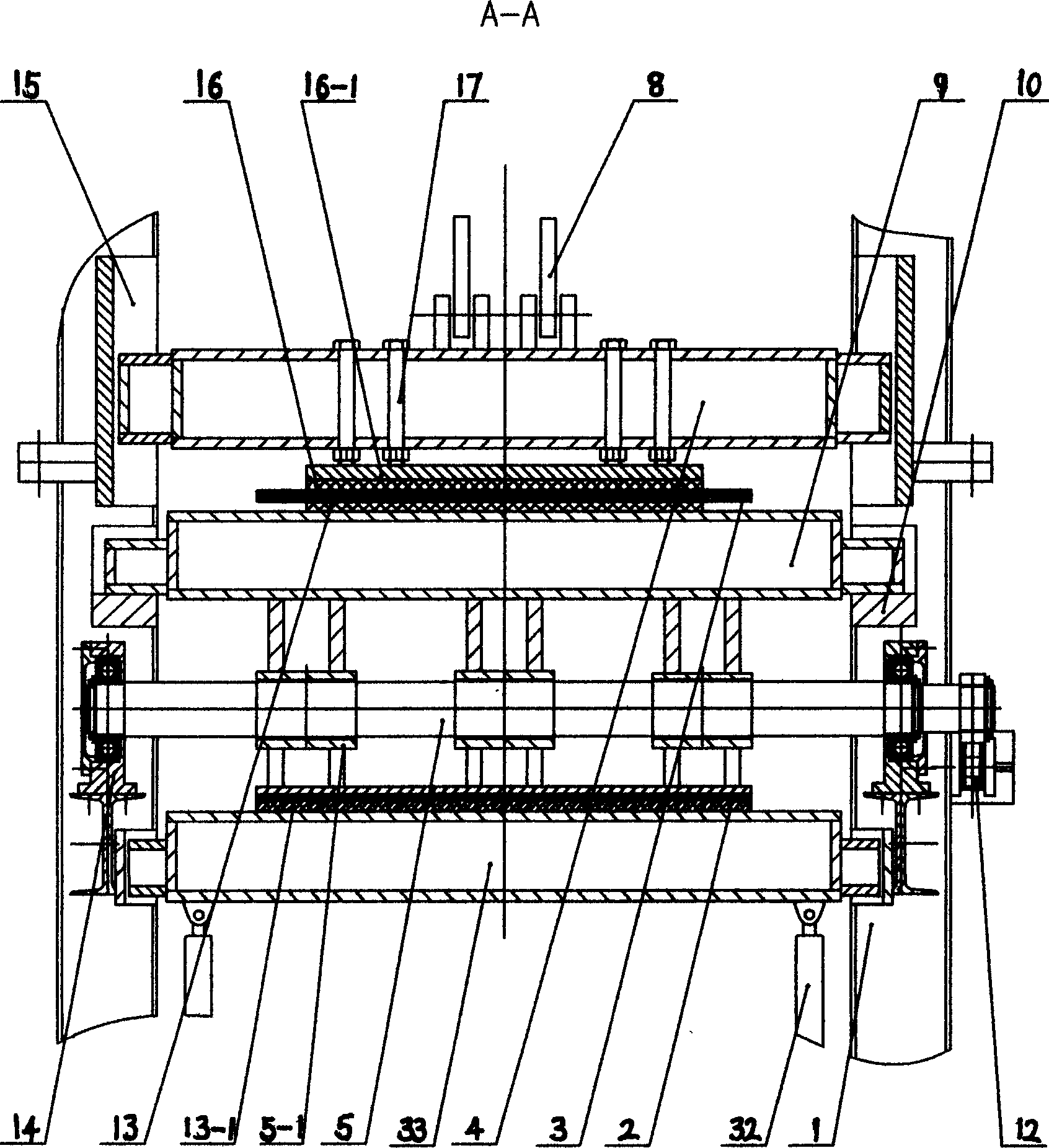

[0026] Such as Figure 5 As shown, on the belt conveyor upper adhesive tape (3) and the lower adhesive tape (2), the catcher device (30) and sensor (31) are installed at multiple points, and the general station PLC programming program controller (28) and substation (1# , 2#, 3#, etc.) three control modes, under these three control modes, there are centralized automatic, centralized manual and decentralized local operation control.

[0027] Such as Figure 5 As shown, its sensor (31) is an incremental rotary encoder, which is characterized in that there is no signal output in the positive phase [the normal working direction of the upper tape (3)], and in the reverse phase [the upper tape (3) slides or conveys after the tape is broken. When the machine is normally shut down, the tape (3) runs in reverse for a certain distance] to collect signals. When the encoder rotates in the opposite direction, the number of pulses per revolution (ppr) is 1000. The diameter of the measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com