A method of manufacturing a sliding shock-isolation bearing

A seismic isolation bearing and manufacturing method technology, applied in the engineering field, can solve the problems of complex design, significant impact effect, amplifying seismic waves, etc., and achieve the effects of inhibiting relative slip between layers, outstanding energy dissipation performance, and small impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

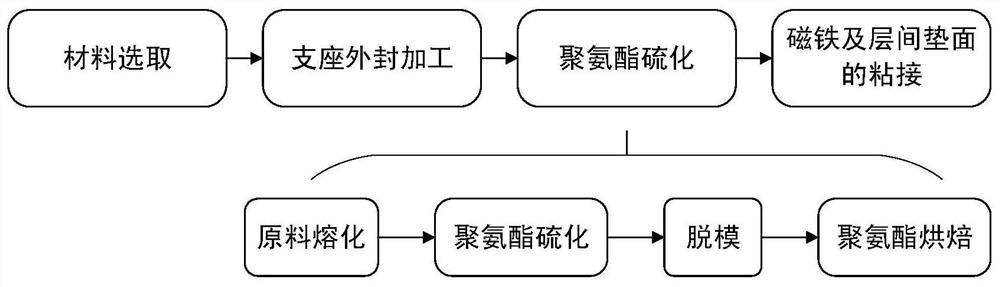

[0048] Such as figure 1 As shown, the present invention is a manufacturing process for forming a sliding shock-isolation bearing.

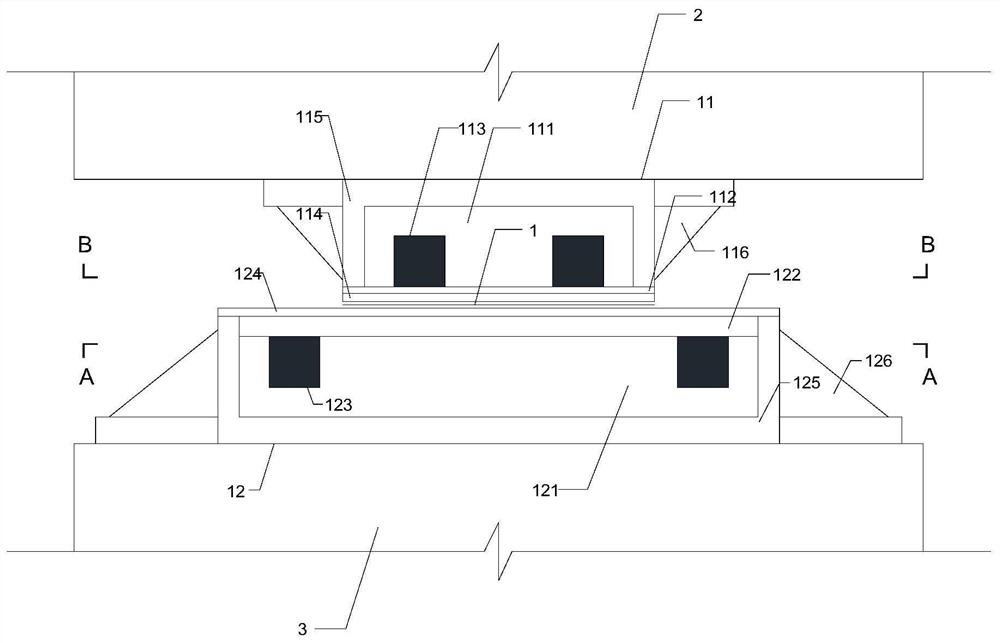

[0049] First of all, the outer seal of the support is made of steel with higher strength, such as Q345 steel, the inner filling is made of polyurethane material with higher hardness, such as Shore hardness above 80, and the magnet is the most magnetic NdFeB N52 magnet, and the interlayer pad surface The materials with weak magnetic permeability and high electrical conductivity are selected as aluminum plate with relative magnetic permeability less than 1, relative electrical conductivity greater than 50 and polytetrafluoroethylene plate with friction coefficient less than 0.05.

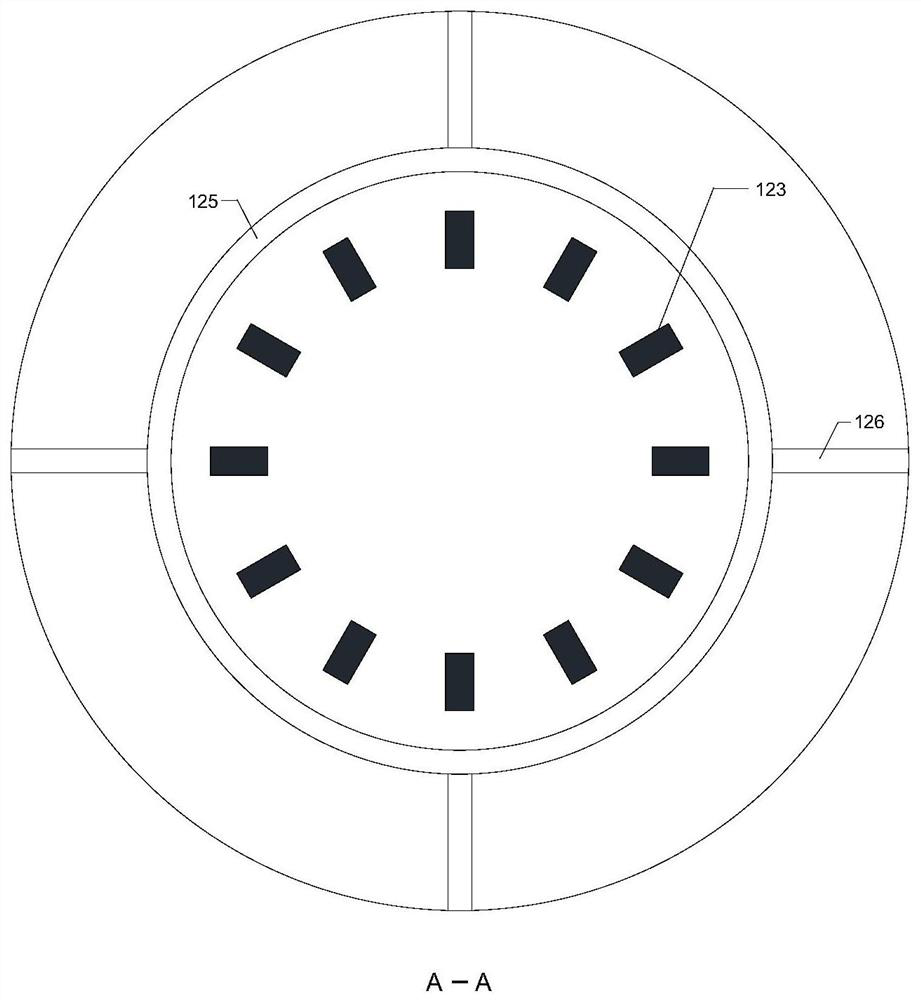

[0050] Secondly, the outer seal is processed, and the annular steel channel is arranged with stiffeners around the outer side. The stiff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com