A kind of active roller car

A roller car, active technology, used in transportation and packaging, load hanging components, walking mechanisms, etc., can solve problems such as unreasonable technology and economy, strict requirements for pile foundations, and difficulty in guaranteeing sliding surfaces. Large range, compact structure, small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

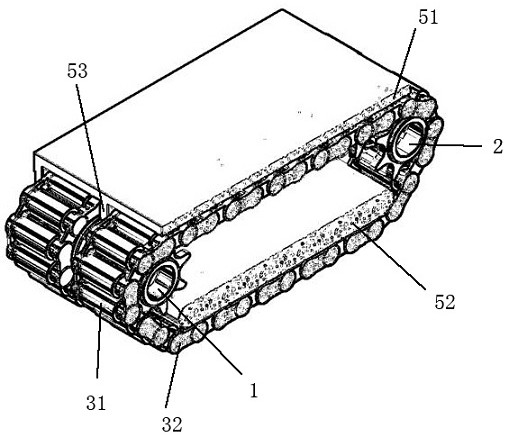

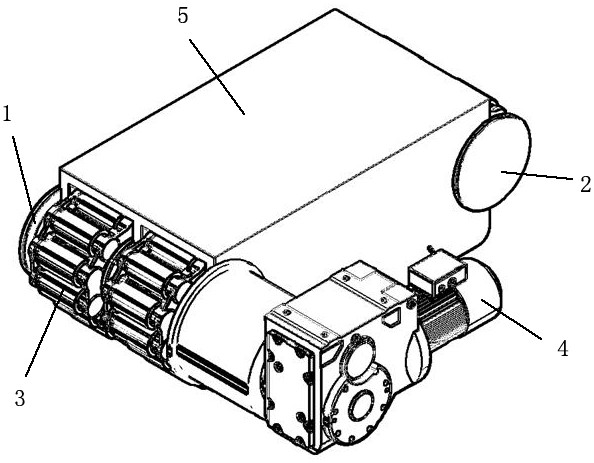

[0013] An active roller vehicle, comprising a driving sprocket 1 and a guide wheel 2, two driving sprocket 1 and a guide wheel 2 are provided, the driving sprocket 1 and the guide wheel 2 are connected by a roller chain 3, and the roller chains 3 are arranged side by side There are two, the driving sprocket 1 is connected to the reduction motor 4 through the transmission shaft, the roller chain 3 includes a roller 31 and a roller pin 32, the roller pin 32 is connected with the roller 31 through the holes provided at both ends, and the roller is connected by the roller pin 32 31 are connected in series to form an endless roller chain 3.

[0014] The drive sprocket 1 and the guide wheel 2 are all fixed on the vehicle frame 5, coaxial between the two drive sprockets 1, and coaxial between the two guide wheels 2, and the vehicle frame 5 includes an upper panel 51 and a lower panel 52 , the driving sprocket 1 and the guide wheel 2 are located between the upper panel 51 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com