Slip vibration isolation support

A seismic isolation bearing and sliding technology, which is applied in the direction of earthquake resistance, bridge parts, building components, etc., can solve the problems of poor tensile performance, significant impact effect, weak self-resetting ability, etc., and achieve small impact effect and energy consumption performance Outstanding, strong self-resetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

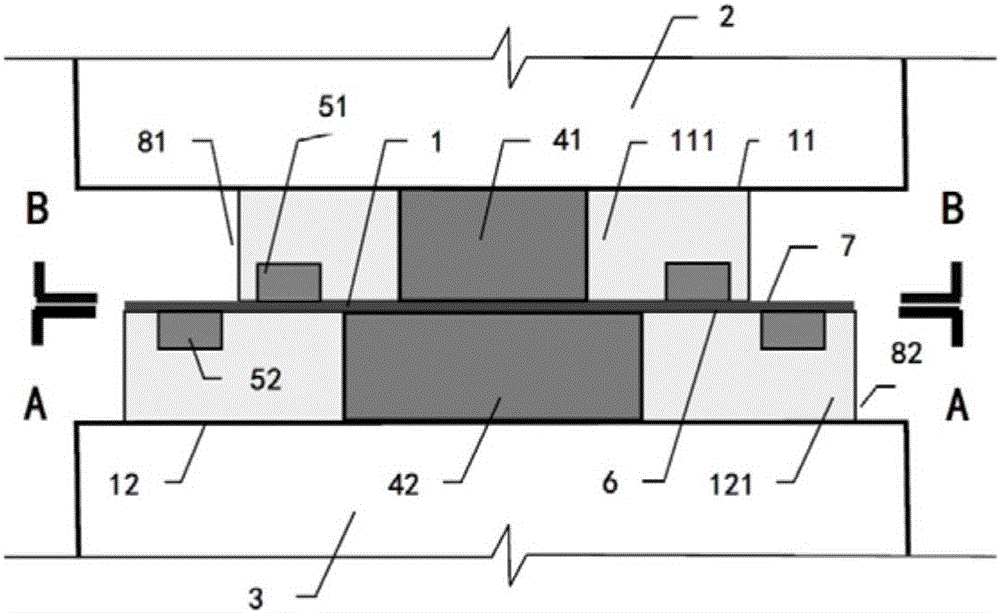

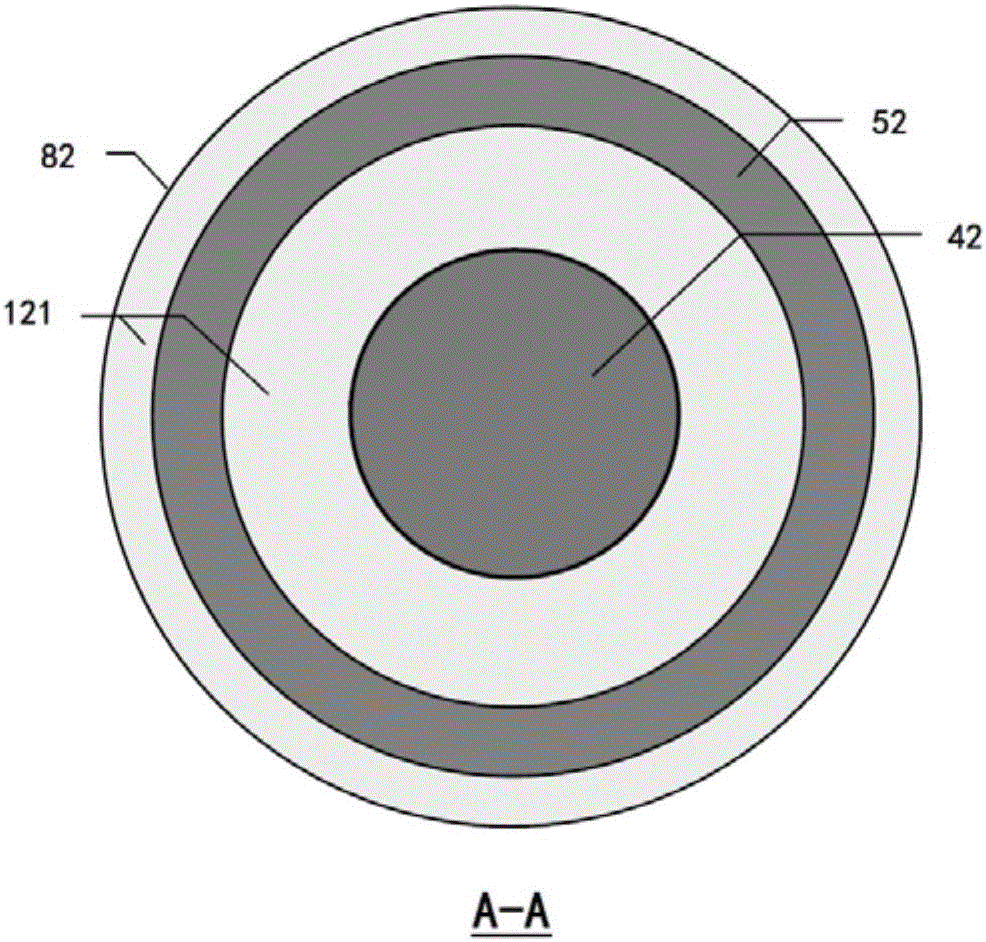

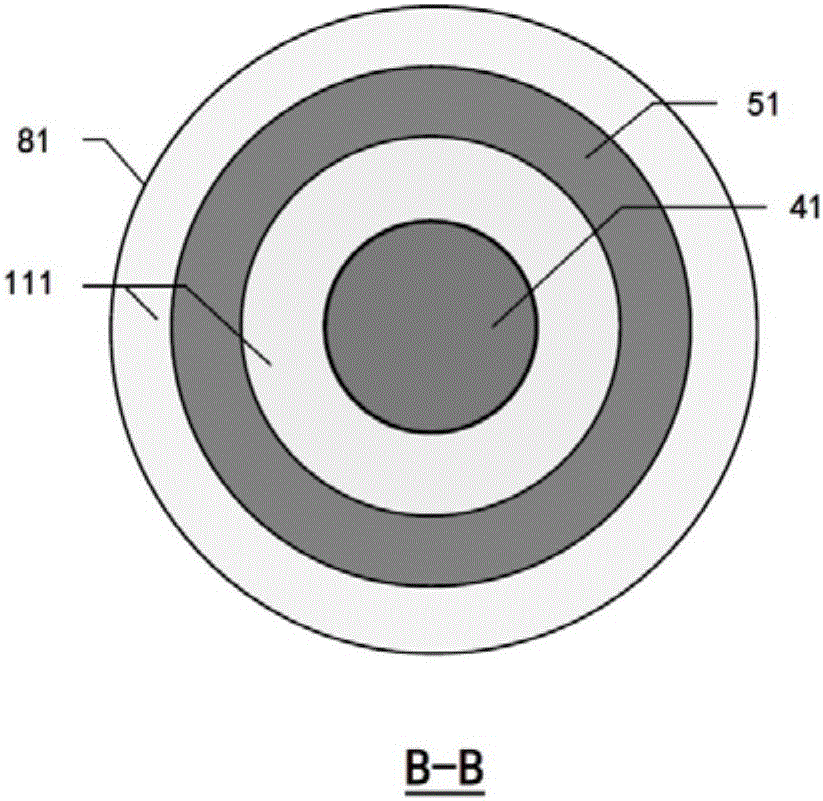

[0039] like figure 1 As shown, a sliding shock-isolation bearing 1 of the present invention includes upper and lower bearings, the upper bearing 11 is supported by the lower bearing 12; an interlayer pad 6 is provided between them, including The upper layer interlayer pad on the support 11 that is integrally linked with it, and the lower layer interlayer pad fixed on the lower support 12 that is integrally linked with it (not shown in the figure for the sake of simplicity); the material of the interlayer pad 6 is made of weak Magnetic permeability and high electrical conductivity materials, specifically, materials with relative magnetic permeability less than 1 and relative electrical conductivity greater than 50 are used; preferably, aluminum plates are used; the outer surfaces of the upper interlayer pad and the lower interlayer pad are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com