Method for refining isoprene by extractive distillation

A technology for extractive distillation and isoprene, which is applied in the field of isoprene purification by extractive distillation, can solve the problems of unsatisfactory dissolving and dispersing properties of polymerization inhibitors, and achieves improved dissolving and dispersing properties and good polymerization inhibiting properties. Effect

Inactive Publication Date: 2011-12-28

CHINA PETROLEUM & CHEM CORP +1

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The invention provides a method for refining isoprene by extractive distillation, which adds components including piperidine oxygen free radicals and / or nitrophenol polymerization inhibitors to the system during the extractive distillation process. By adding an auxiliary component to the polymerization inhibitor, the technical problem of the unsatisfactory dissolution and dispersion of the polymerization inhibitor in the system is solved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~10

[0025] Components A and B each take a suitable compound, put it into the solvent dimethylformamide (DMF) according to the required amount, and stir until completely dissolved to prepare a polymerization inhibitor solution for later use. See Table 1 for the proportions of component A and component B, component A and component B, and solvents used in each embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

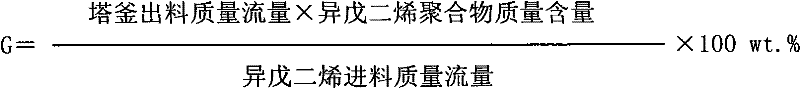

A method for refining isoprene by extraction and rectification, in which isoprene is subjected to extraction and rectification in the presence of solvent dimethylformamide, and a polymerization inhibitor that inhibits the polymerization of isoprene is added to the system, and its components Contains Part A and Part B. Wherein component A is piperidine oxygen free radical and / or nitrophenol, and component B is diethylene glycol monomethyl ether and / or diethylene glycol monobutyl ether; In parts by weight, component A: component B= 1: (0.5-2.0). The polymerization inhibitor is first prepared into a solution with solvent dimethylformamide and then added to the extractive distillation system, in parts by weight, (component A+component B): dimethylformamide=(2~8): 10; The addition amount of the polymerization inhibitor is 0.3-3.0wt.‰ based on the amount of component A based on isoprene. The invention greatly improves the solubility and dispersibility of the polymerization inhibitor in the extraction and rectification system by adding an auxiliary component to the polymerization inhibitor, so that the polymerization inhibitor has better polymerization inhibition performance.

Description

technical field [0001] The invention relates to a method for refining isoprene, in particular to a method for refining isoprene by extractive distillation using dimethylformamide as a solvent. Background technique [0002] Isoprene is a fine chemical raw material with a wide range of uses. It can be used to synthesize many fine chemical products such as spices, pesticides, and pharmaceuticals, such as pyrethroid pesticides, linalool, isophytol, and vitamin E. At the same time, isoprene is also a monomer of many synthetic rubbers, plastics and other synthetic materials. The basic source of isoprene is the extraction and separation of petroleum C5 fractions. At present, the isoprene obtained directly from petroleum C5 fractions can reach the purity of chemical grade, which can meet the requirements of synthesizing most fine chemical products , but if it is used as a monomer for synthetic rubber, plastics and other synthetic materials, it should be further refined to remove im...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C11/18C07C7/08C07C7/20

Inventor 郭世卓秦技强谢家明蒋芳红郑金达

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com