Method for purifying ethylenediamine

A purification method, ethylenediamine technology, applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problems of equipment corrosion and low purity of ethylenediamine, and achieve the effect of avoiding equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

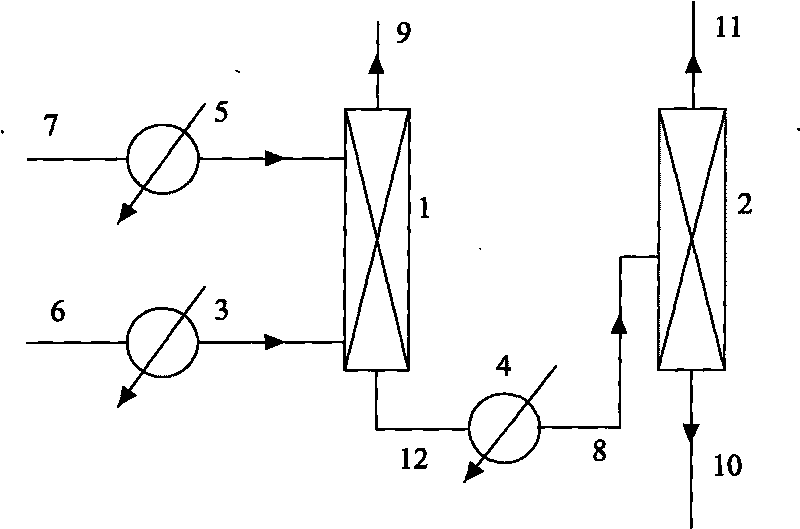

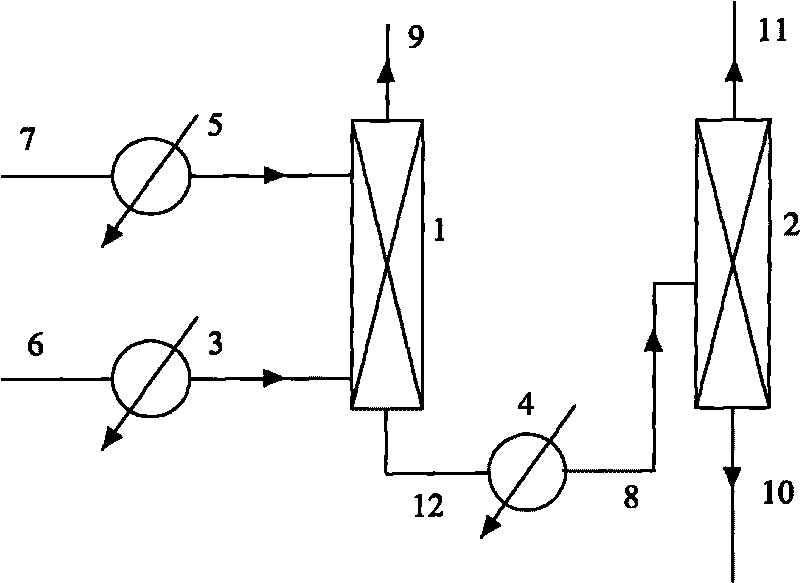

Image

Examples

Embodiment 1

[0025] Heat and vaporize water-containing ethylenediamine with a concentration of 85.0%, and enter the lower part of the extraction tower at a flow rate of 48.68g / h. Diethylene glycol monomethyl ether enters the extraction tower at a flow rate of 162.22g / h through a heater to 80°C In the upper part, the two are in reverse contact in the extraction tower filled with packing. The temperature at the top of the extraction tower is 61°C, the temperature at the bottom of the tower is 140°C, and the pressure is 20.3kPa. The water separated from the top of the extraction tower is discharged at a flow rate of 7.29g / h. The mixture of ethylenediamine and diethylene glycol monomethyl ether flows out at the bottom of the extraction tower at a flow rate of 203.61g / h, which is heated to 90°C by a heater and enters the middle of the rectification tower, where it is rectified. The temperature at the top of the rectification tower is 45°C, the temperature at the bottom of the tower is 150°C, and...

Embodiment 2

[0027] Heat and vaporize the water-containing ethylenediamine with a concentration of 92.0%, and enter the lower part of the extraction tower at a flow rate of 32.44g / h. Diethylene glycol monobutyl ether enters the extraction tower at a flow rate of 162.22g / h through a heater to 79°C In the upper part, the two are in reverse contact in the extraction tower filled with packing. The temperature at the top of the extraction tower is 63°C, the temperature at the bottom of the tower is 150°C, and the pressure is 16.3kPa. The water separated from the top of the extraction tower is discharged at a flow rate of 5.90g / h. The mixture of ethylenediamine and diethylene glycol monobutyl ether flows out at the bottom of the extraction tower at a flow rate of 188.74g / h, which is heated to 102°C by a heater and enters the middle of the rectification tower, where it is rectified , the temperature at the top of the rectifying tower is 48°C, the temperature at the bottom of the tower is 160°C, an...

Embodiment 3

[0029] Heat and vaporize the water-containing ethylenediamine with a concentration of 75.5%, and enter the lower part of the extraction tower at a flow rate of 40.55g / h, and triethylene glycol dimethyl ether enter the extraction tower at a flow rate of 162.22g / h through a heater to 85°C In the upper part, the two are in reverse contact in the extraction tower filled with packing. The temperature at the top of the extraction tower is 60°C, the temperature at the bottom of the tower is 138°C, and the pressure is 19.5kPa. The water separated from the top of the extraction tower is discharged at a flow rate of 9.55g / h. The mixture of ethylenediamine and triethylene glycol dimethyl ether flows out of the bottom of the extraction tower at a flow rate of 193.22g / h, which is heated to 90°C by a heater and then enters the middle of the rectification tower, and is rectified in the rectification tower. The temperature at the top of the rectification tower is 46°C, the temperature at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com