Neutral cleaning agent for coated optical glass

A neutral cleaning agent and optical glass technology, applied in the field of cleaning agents, can solve the problems of poor defoaming effect, etc., and achieve the effects of avoiding residue, suppressing foam generation, and solving poor defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

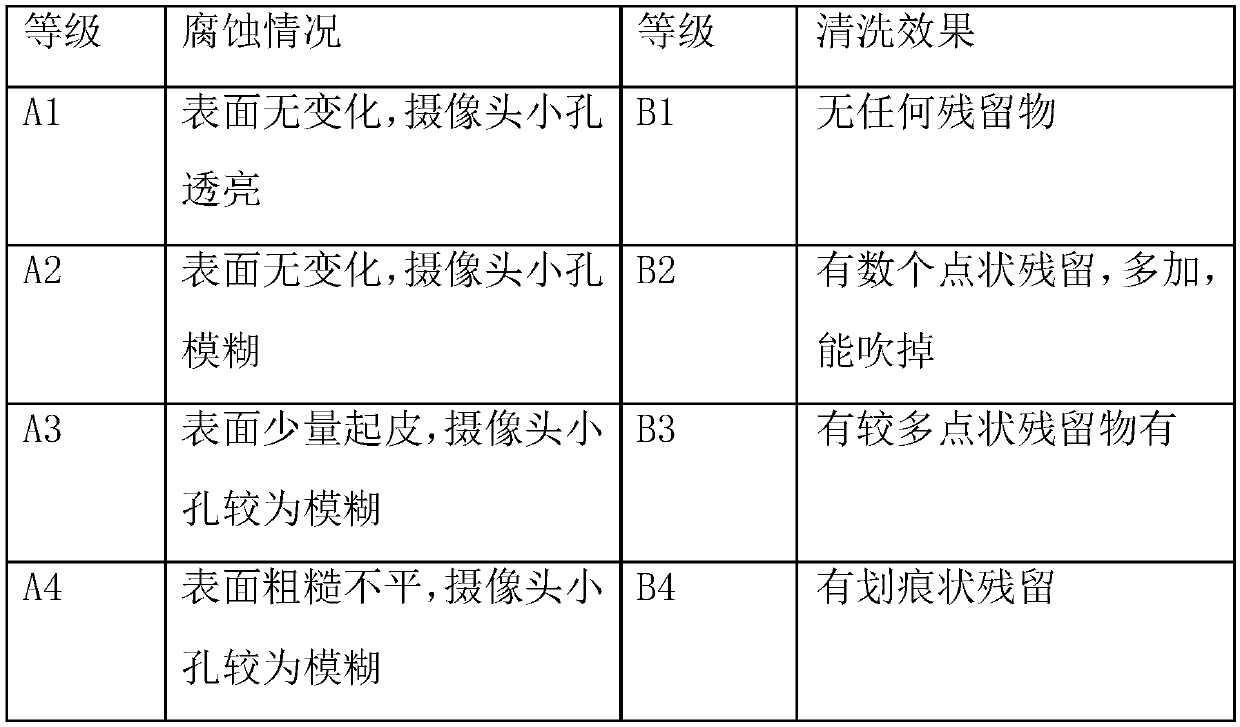

Image

Examples

Embodiment 1

[0029] Example 1 The raw material dosage (parts by weight) of the cleaning agent prepared by the above method is as follows:

[0030] 1 part of ethylenediaminetetraacetic acid (EDTA), 1 part of tetrasodium iminodisuccinate (IDS Na4), 5 parts of sodium polyacrylate, 5 parts of sodium polystyrene sulfonate, 1 part of isomeric alcohol polyoxyethylene ether, Fatty alcohol polyoxyethylene ether 1 part, and the ratio of isomeric alcohol polyoxyethylene ether and fatty alcohol polyoxyethylene ether is 8:2, ethylene glycol monobutyl ether 0.05 part, flavor 0.01 part, casson 0.02 part, supplement Water to 100 parts.

Embodiment 2

[0031] Example 2 The dosage (parts by weight) of the cleaning agent prepared by the above method is as follows:

[0032] 2 parts of sodium nitrilotriacetate (NTA), 3 parts of tetrasodium iminodisuccinate (IDS Na4), 10 parts of sodium polyacrylate, 5 parts of hydrolyzed polymaleic anhydride, isomeric alcohol polyoxyethylene ether and fatty alcohol 8 parts of polyoxyethylene ether, and the ratio of isomeric alcohol polyoxyethylene ether and fatty alcohol polyoxyethylene ether is 5:5, 1 part of diethylene glycol monobutyl ether, 0.05 part of flavor, 0.1 part of cassone, supplementary water To 100 copies.

Embodiment 3

[0033] Example 3 The raw material dosage (parts by weight) of the cleaning agent prepared by the above method is as follows:

[0034] Ethylenediaminetetraacetic acid (EDTA) 1.5 parts, diethyltriaminepentaacetic acid 2 parts, hydrolyzed polymaleic anhydride 2.5 parts, polystyrene sulfonate 10 parts, isomeric alcohol polyoxyethylene ether 3 parts, fatty alcohol 2 parts of polyoxyethylene ether, and the ratio of isomeric alcohol polyoxyethylene ether and fatty alcohol polyoxyethylene ether is 7:3, 0.5 part of ethylene glycol monomethyl ether, 0.03 part of flavor, 0.06 part of cassone, make up water to 100 copies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com