High-strength wear-resistant flame-retardant water-based paint and preparation method thereof

A water-based coating, high-strength technology, used in fire-retardant coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of single function, poor strength, wear resistance and flame retardant performance, weak adhesion, etc. To achieve the effect of good scrub resistance, improved wear resistance, improved strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

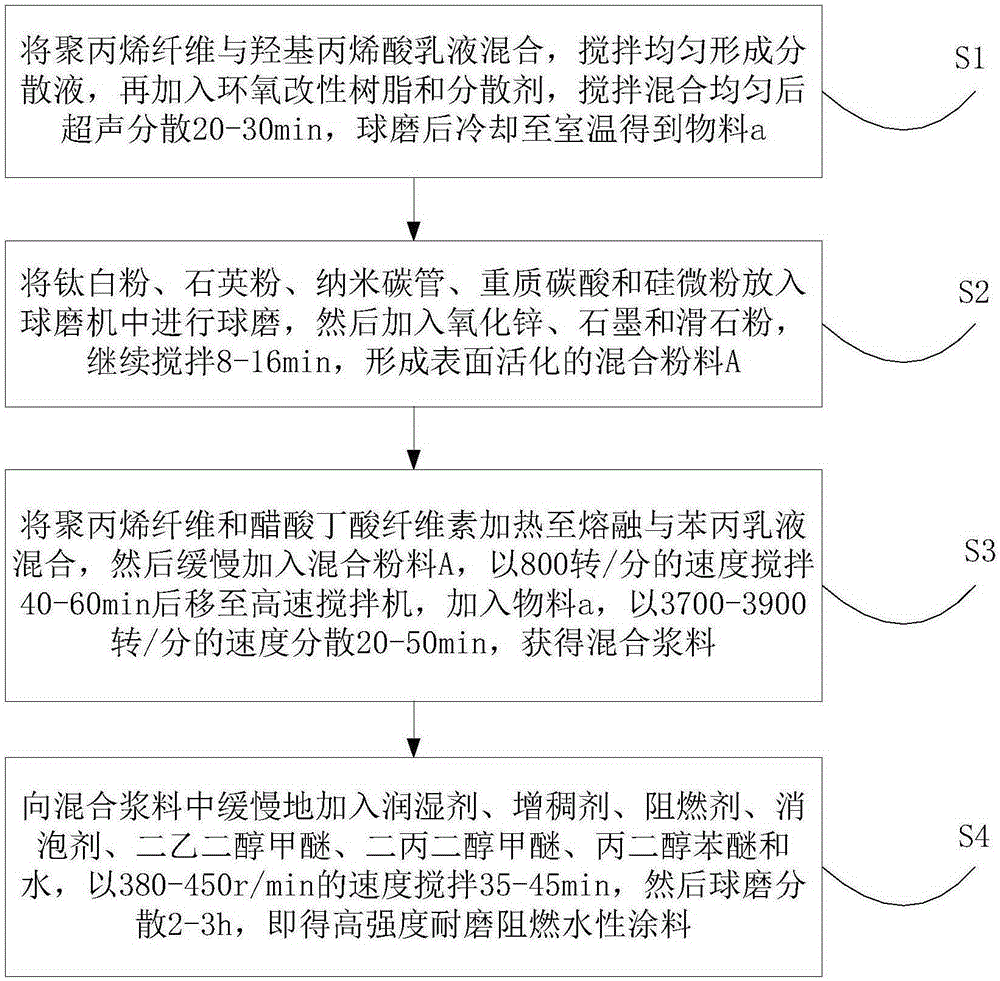

[0021] refer to figure 1 , the preparation method of a kind of high-strength wear-resistant flame-retardant water-based coating that the present invention proposes, comprises the steps:

[0022] S1. Mix polypropylene fiber with hydroxyacrylic acid emulsion, stir evenly to form a dispersion, then add epoxy modified resin and dispersant, stir and mix evenly, ultrasonically disperse for 20-30min, cool to room temperature after ball milling to obtain material a;

[0023] S2. Put titanium dioxide, quartz powder, carbon nanotubes, heavy carbonic acid and silicon micropowder into a ball mill for ball milling, then add zinc oxide, graphite and talcum powder, and continue stirring for 8-16 minutes to form a surface-activated mixed powder A ;

[0024] S3. Heat the polypropylene fiber and cellulose acetate butyrate to melt and mix them with styrene-acrylic emulsion, then slowly add the mixed powder A, stir at 800 rpm for 40-60 minutes, then move to a high-speed mixer, add material a, D...

Embodiment 1

[0028] A high-strength wear-resistant flame-retardant water-based coating proposed by the present invention, its raw materials include by weight: 100 parts of hydroxyl acrylic emulsion, 75 parts of epoxy modified resin, 50 parts of water-based polyurethane emulsion, 40 parts of silicon-acrylic emulsion, styrene-acrylic emulsion 10 parts of emulsion, 5 parts of titanium dioxide, 3.5 parts of quartz powder, 3.5 parts of polypropylene fiber, 5.5 parts of cellulose acetate butyrate, 3 parts of silicon micropowder, 4.5 parts of zinc oxide, 3.5 parts of carbon nanotubes, 3.5 parts of graphite, heavy 5 parts of calcium carbonate, 5 parts of talcum powder, 3.5 parts of wetting agent, 6 parts of thickener, 2.5 parts of dispersant, 3.5 parts of flame retardant, 2 parts of defoamer, 3 parts of diethylene glycol methyl ether, dipropylene glycol 4 parts of methyl ether, 5 parts of propylene glycol phenyl ether, and 20 parts of water.

[0029] The preparation method of a kind of high-streng...

Embodiment 2

[0035] A high-strength wear-resistant flame-retardant water-based paint proposed by the present invention, its raw materials include by weight: 80 parts of hydroxyacrylic acid emulsion, 90 parts of epoxy modified resin, 40 parts of water-based polyurethane emulsion, 60 parts of silicon-acrylic emulsion, styrene-acrylic emulsion 5 parts of emulsion, 8 parts of titanium dioxide, 1 part of quartz powder, 5 parts of polypropylene fiber, 3 parts of cellulose acetate butyrate, 5 parts of silicon micropowder, 3 parts of zinc oxide, 6 parts of carbon nanotubes, 2 parts of graphite, heavy 6 parts of calcium carbonate, 2 parts of talcum powder, 6 parts of wetting agent, 3 parts of thickener, 4 parts of dispersant, 2 parts of flame retardant, 3 parts of defoamer, 2 parts of diethylene glycol methyl ether, dipropylene glycol 5 parts of methyl ether, 4 parts of propylene glycol phenyl ether, and 15 parts of water.

[0036] The preparation method of a kind of high-strength wear-resistant fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com