Industrial separation method of N-methylformamide and diethylene glycol monomethyl ether

A separation method and industrial technology, applied in carboxylic acid amide separation/purification, ether separation/purification, ether preparation, etc., can solve the problem of high energy consumption of NMF and MDG mixture, achieve green energy consumption, low energy consumption, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

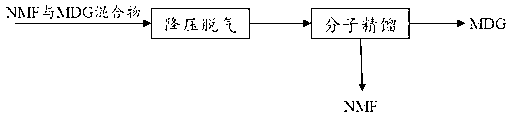

Method used

Image

Examples

Embodiment 1

[0012] The mixture of NMF and MDG is fed at a flow rate of 360 kg / h at room temperature, and the pressure of the decompression degassing tower is 5000-10000 Pa. According to Henry's law, in a sealed container at a certain temperature, the partial pressure of the gas is the same as the gas dissolved in the solution. Proportional to the molar concentration within. After treatment in the decompression degassing tower, more than 90% of the gas content in the material is removed. It reduces the mist splash caused by the sudden pressure drop after the material enters the molecular distillation tower. After the material enters the molecular distillation tower, the molecules fly out of the liquid surface continuously and rapidly through heating and depressurization and the continuous renewal of the liquid film. MDG with a long average free path of molecules can fly to the condensation surface for enrichment, while the average free path of molecules is short NMF can only be enriched a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com