Patents

Literature

47 results about "N-Methylformamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-Methylformamide (NMF) is a colorless, nearly odorless, organic compound with molecular formula CH₃NHCHO, which is a liquid at room temperature. NMF is mainly used as a reagent in various organic syntheses with limited applications as a highly polar solvent.

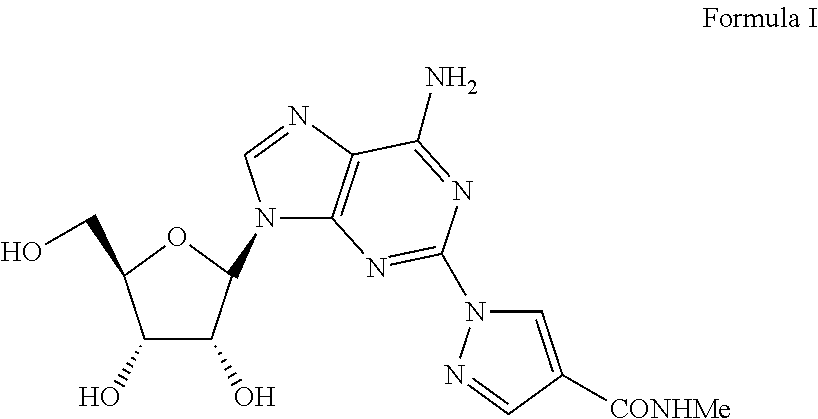

Use of A2A adenosine receptor agonists

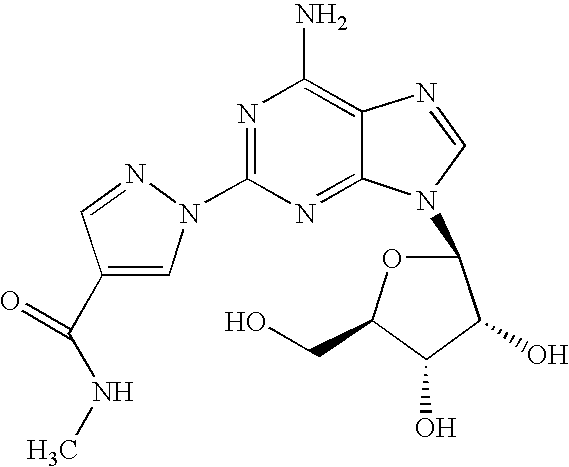

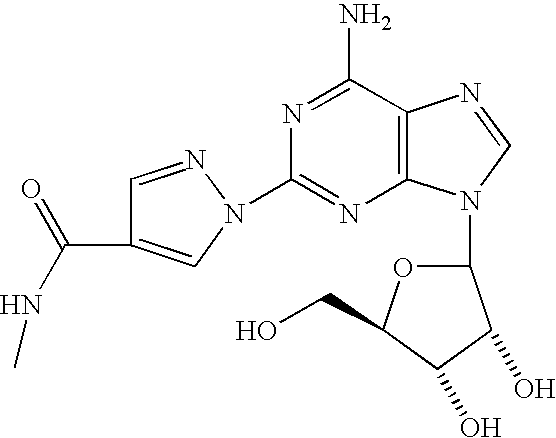

The present invention relates to methods for producing coronary vasodilation with little peripheral vasodilation by administering doses of a pharmaceutical composition including regadenoson, named (1-{9-[(4S,2R,3R,5R)-3,4-dihydroxy-5-(hydroxymethyl)oxolan-2-yl]-6-aminopurin-2-yl}pyrazol-4-yl)-N-methylcarboxamide, — an adenosine A2A receptor agonist — to a human in an amount sufficient to increase the average coronary peak flow velocity by at least about 16.5 cm / sec.

Owner:TPG AXON LEX SUB TRUST +1

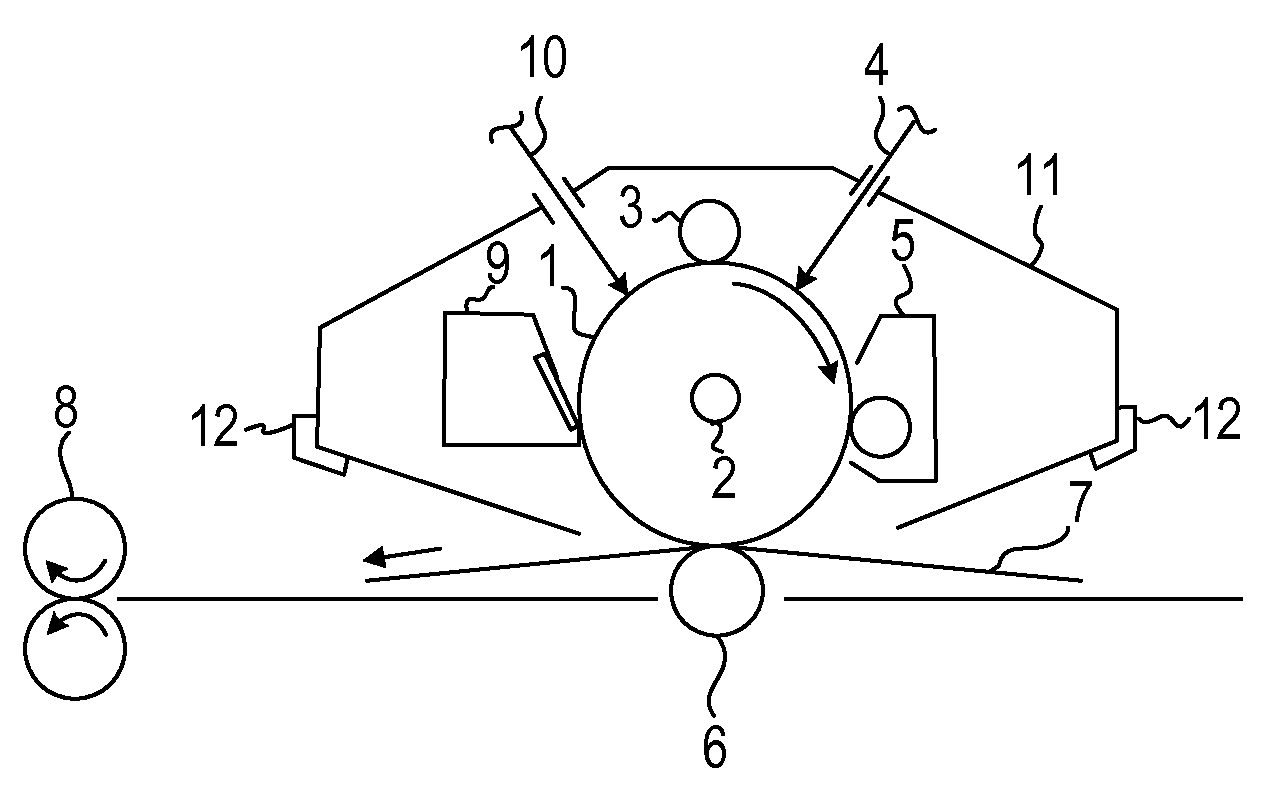

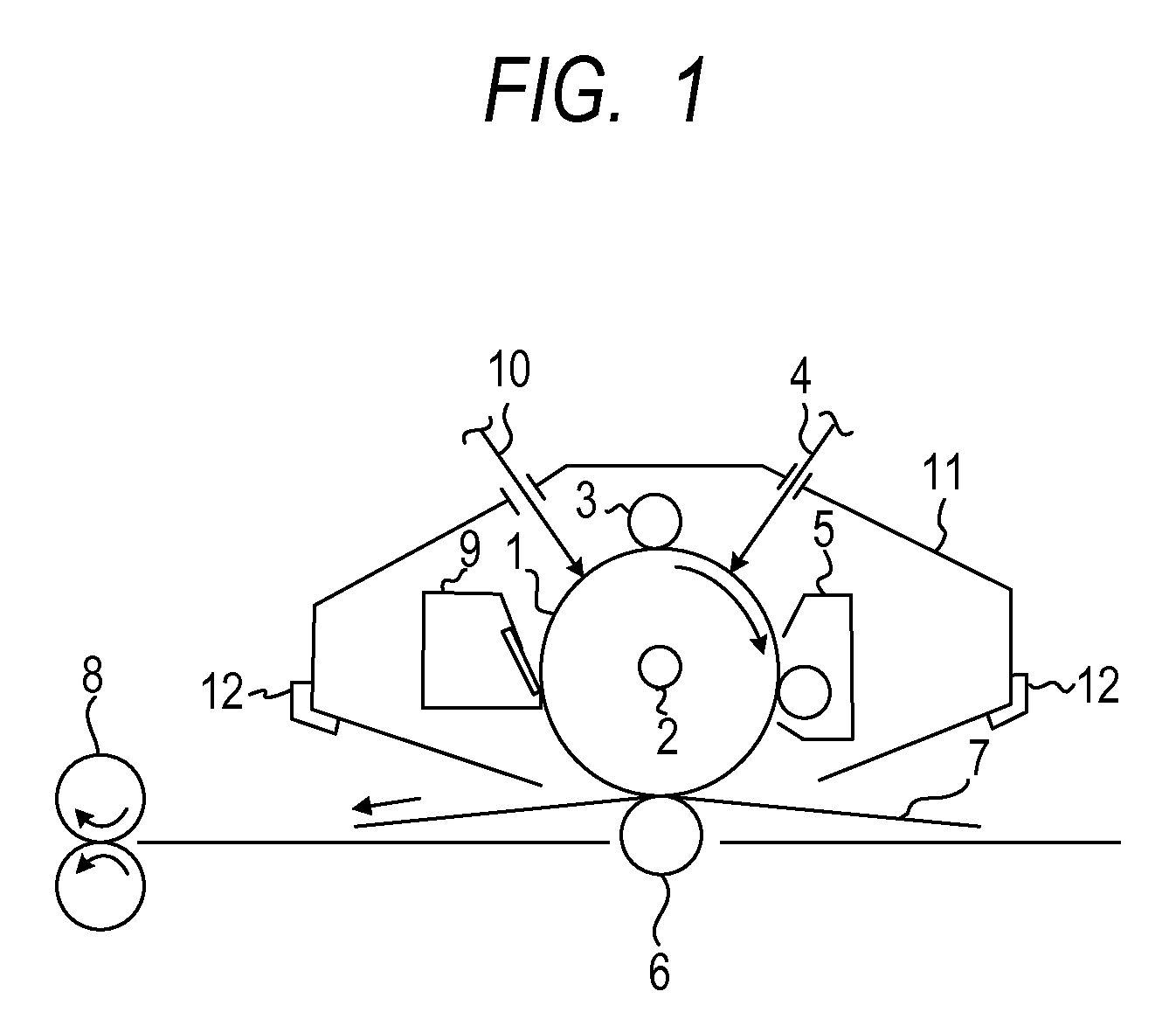

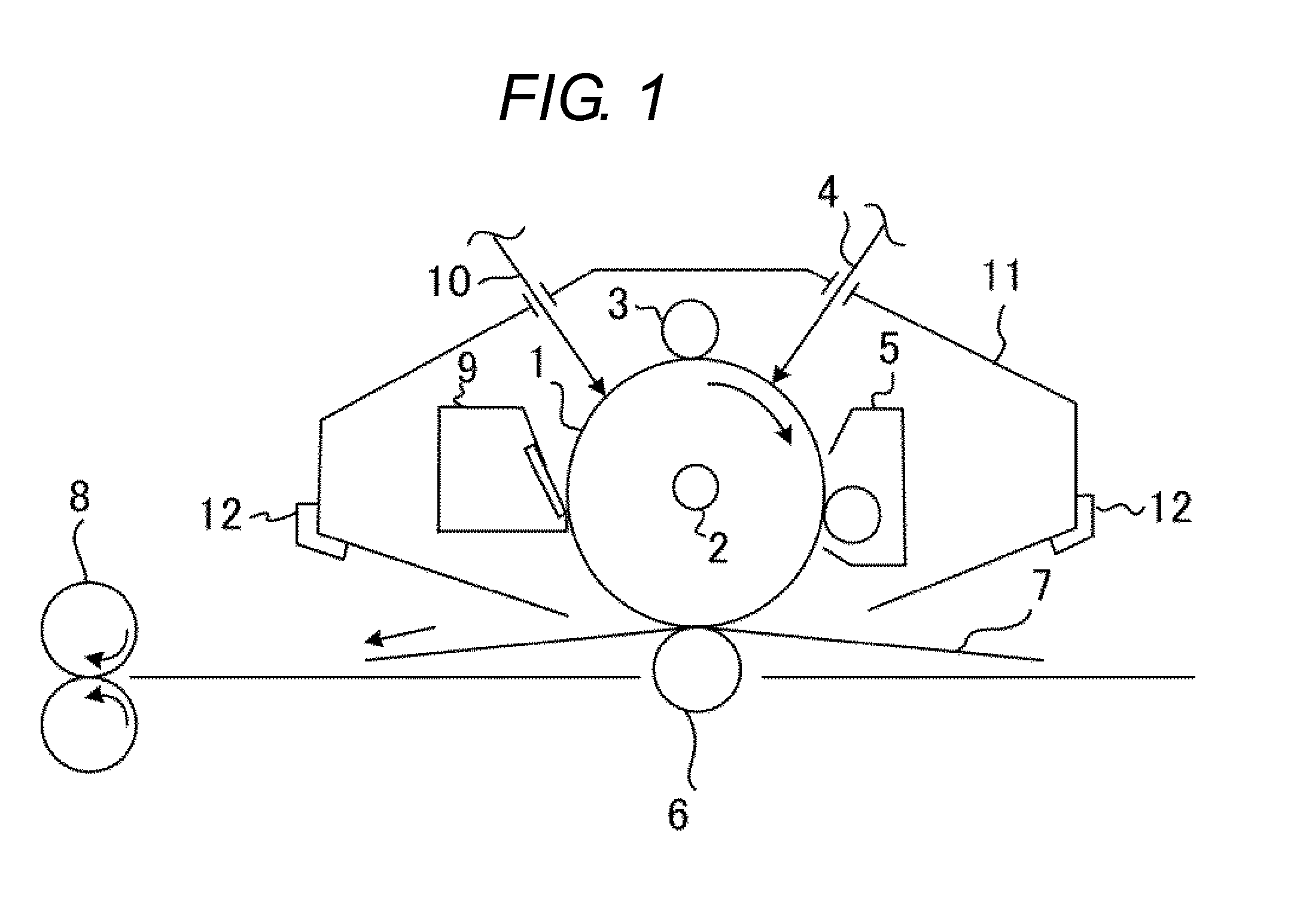

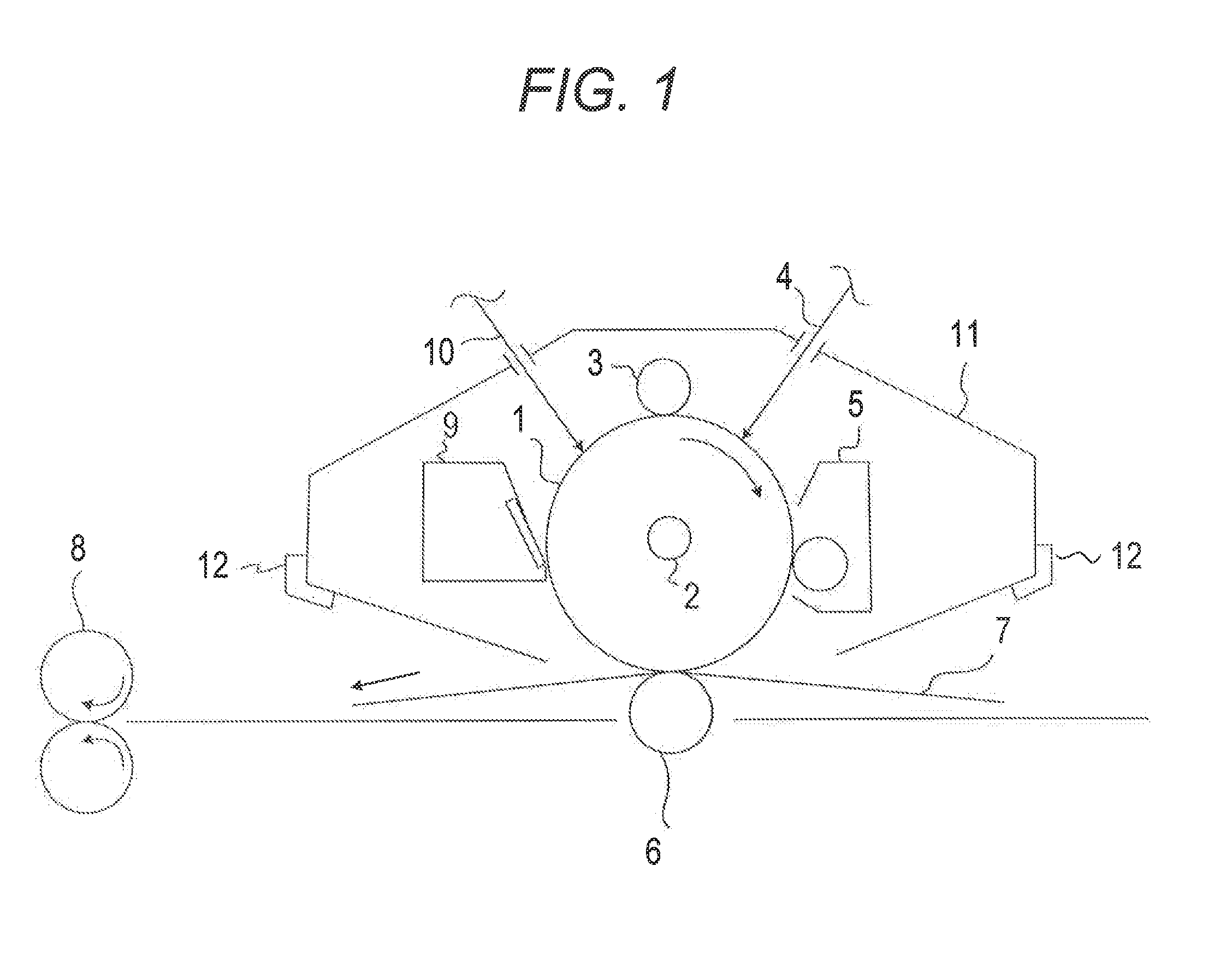

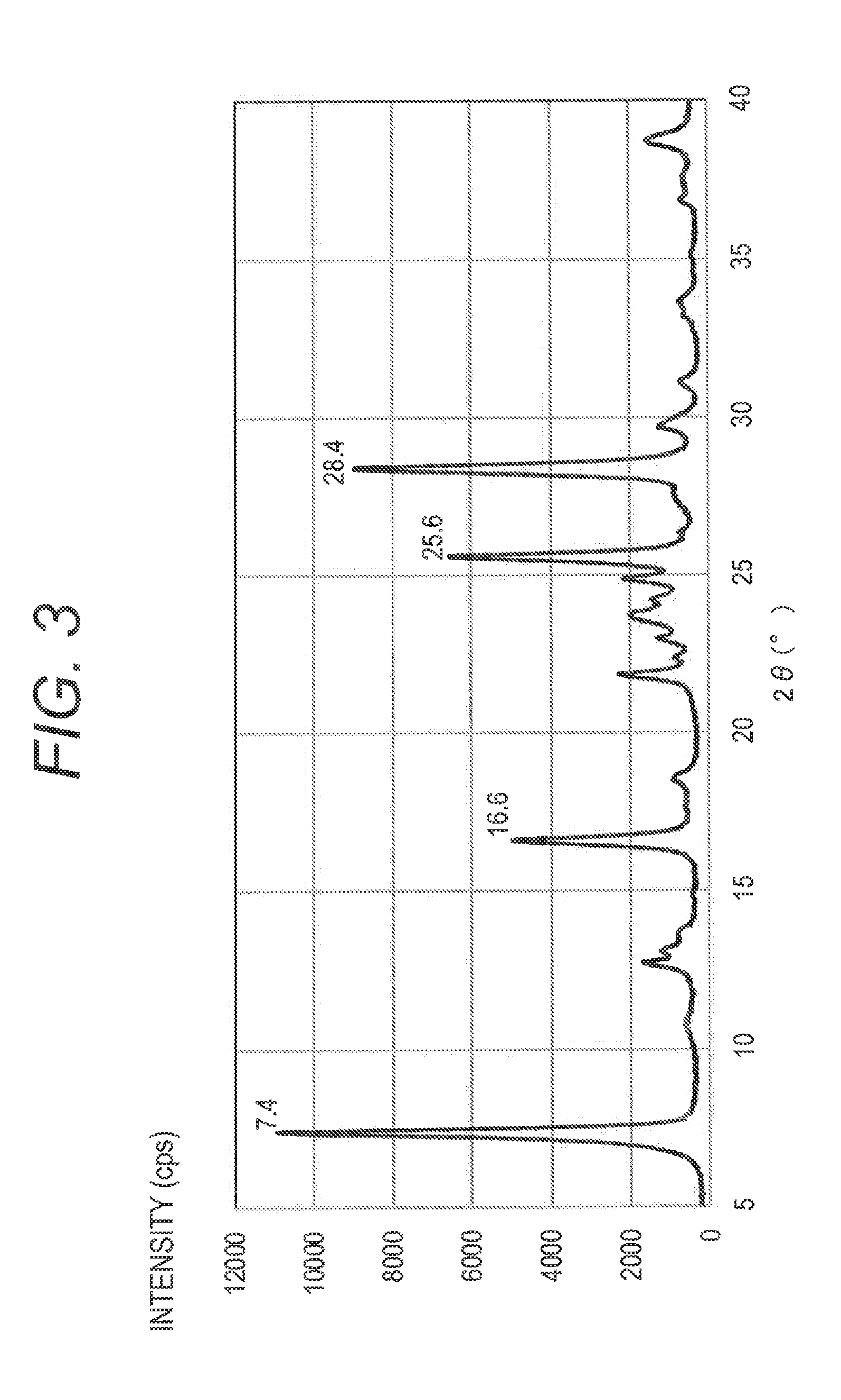

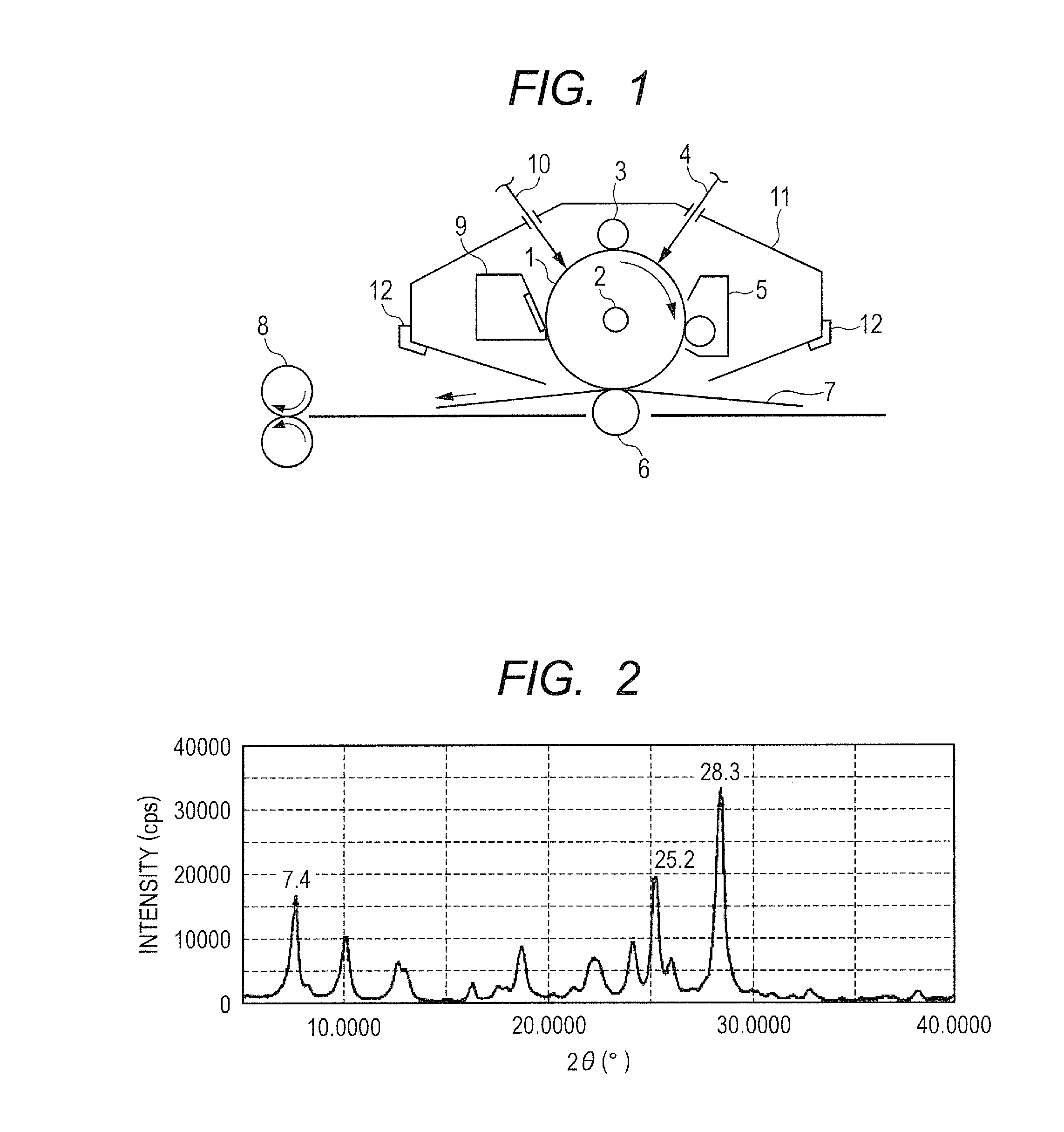

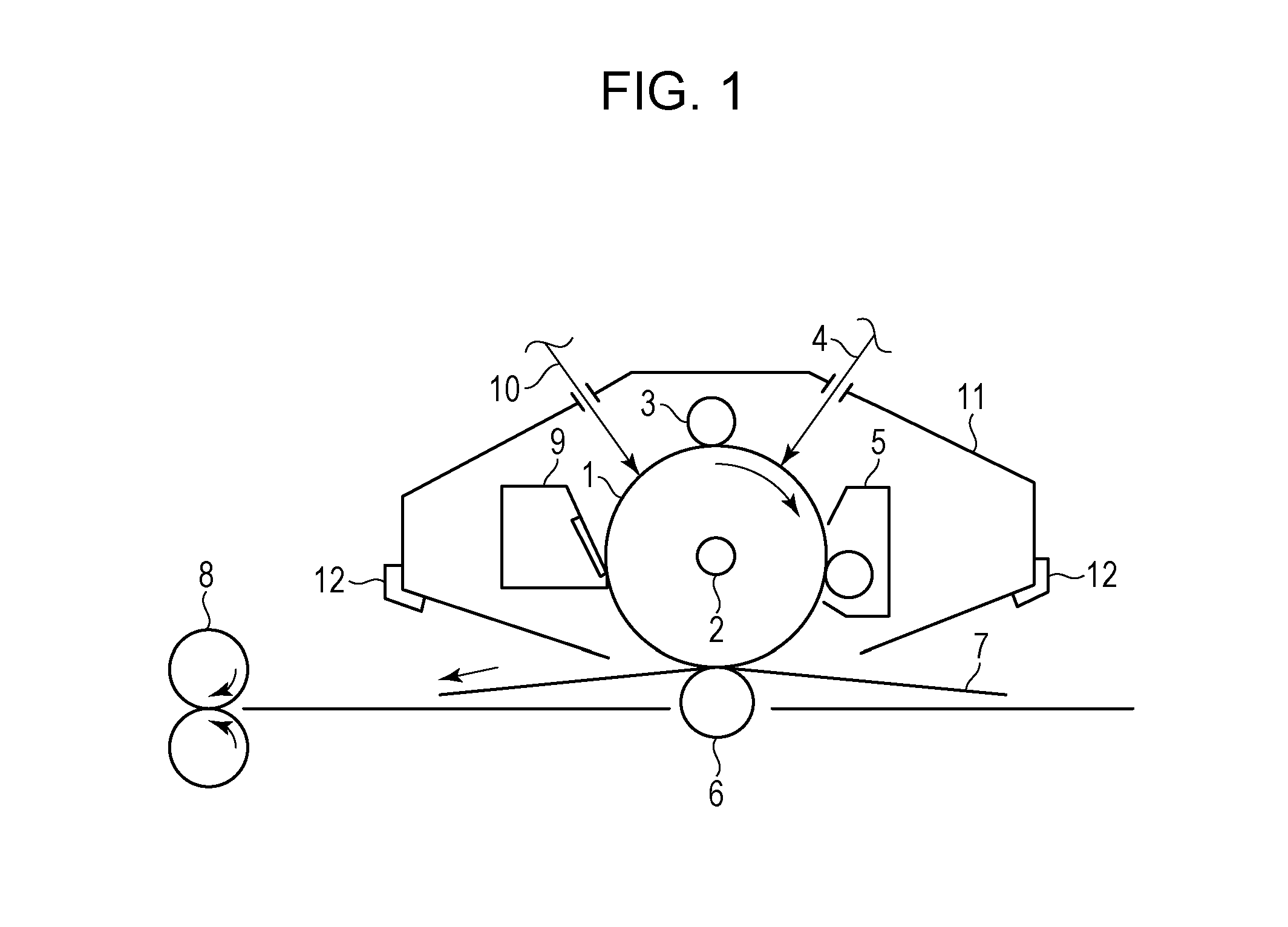

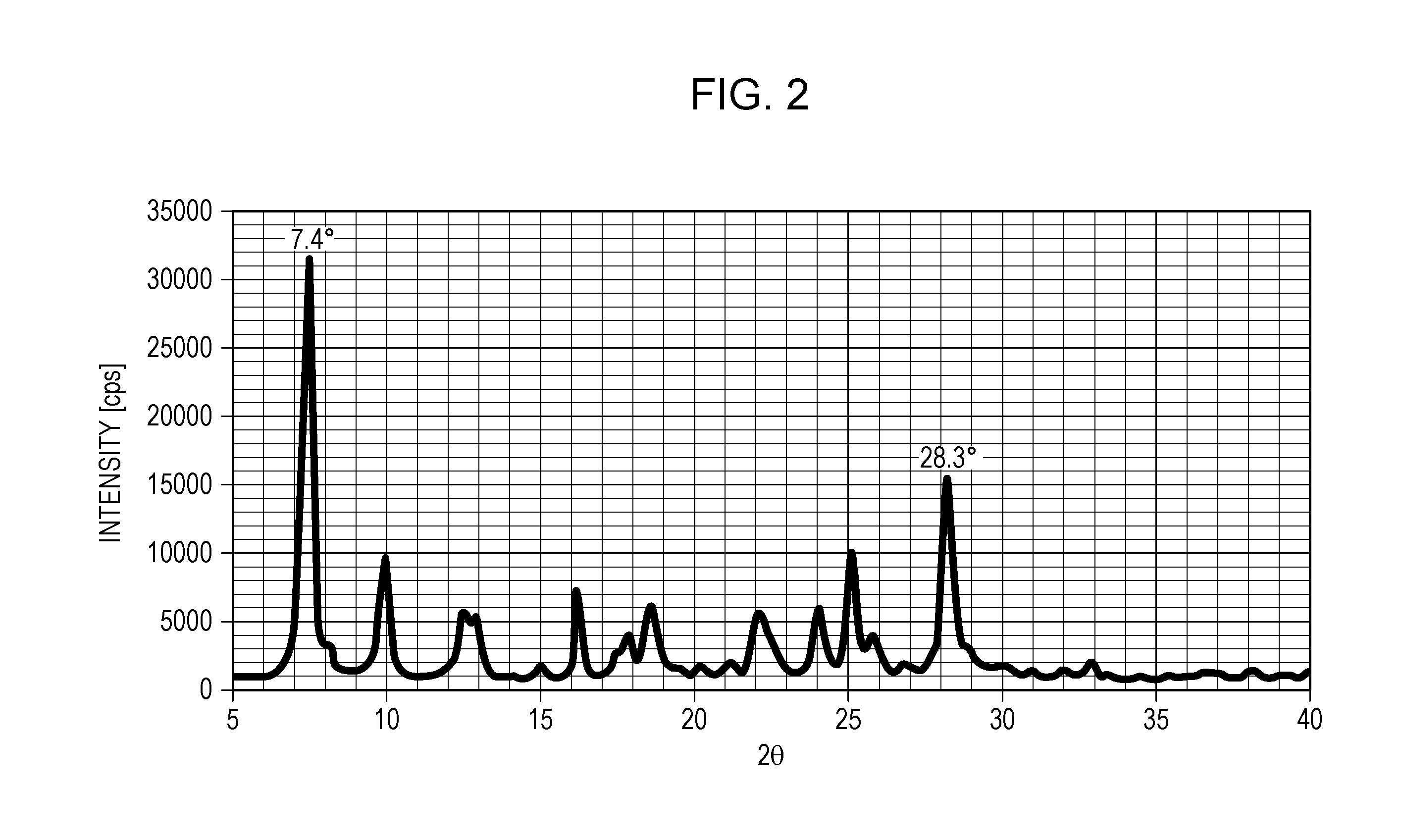

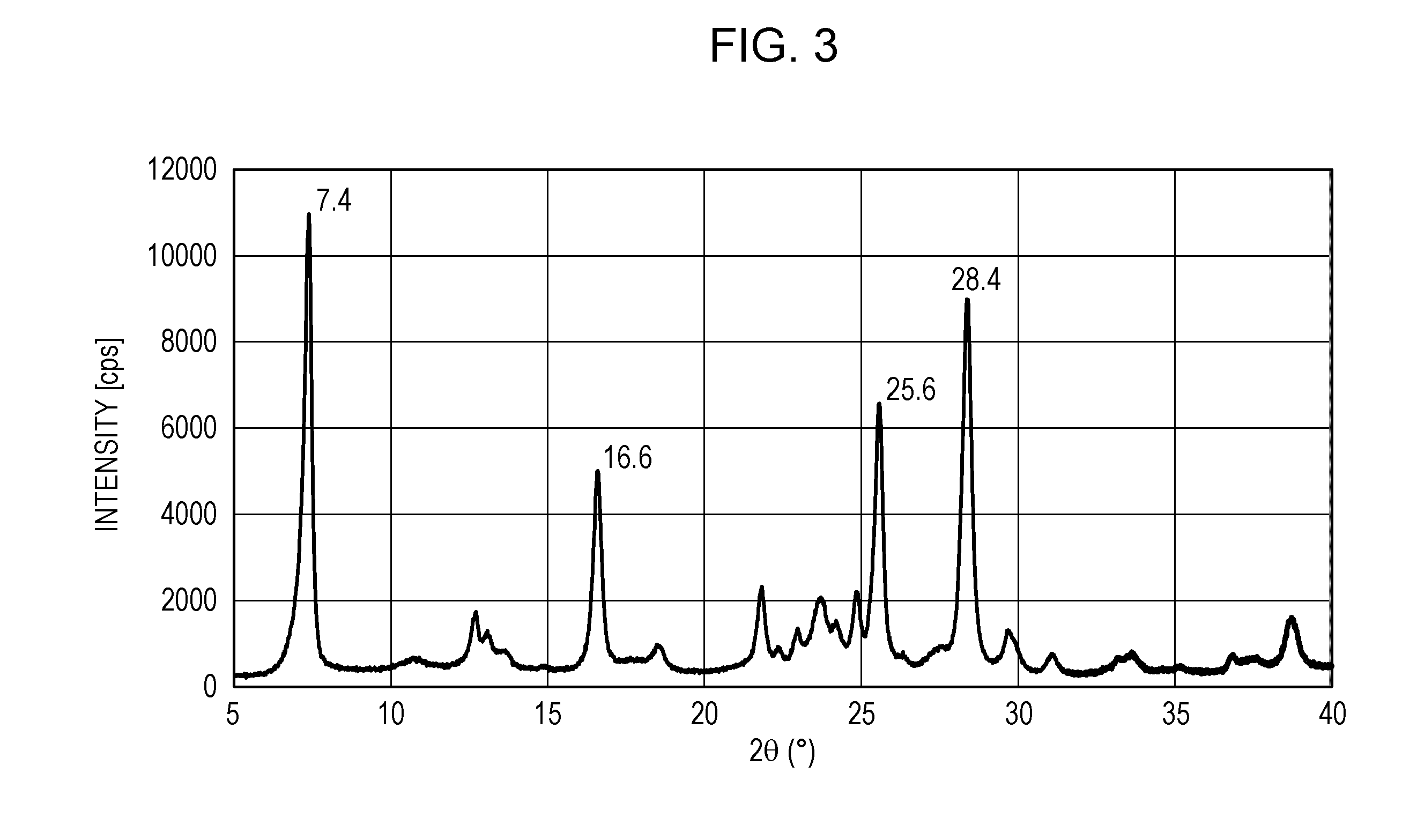

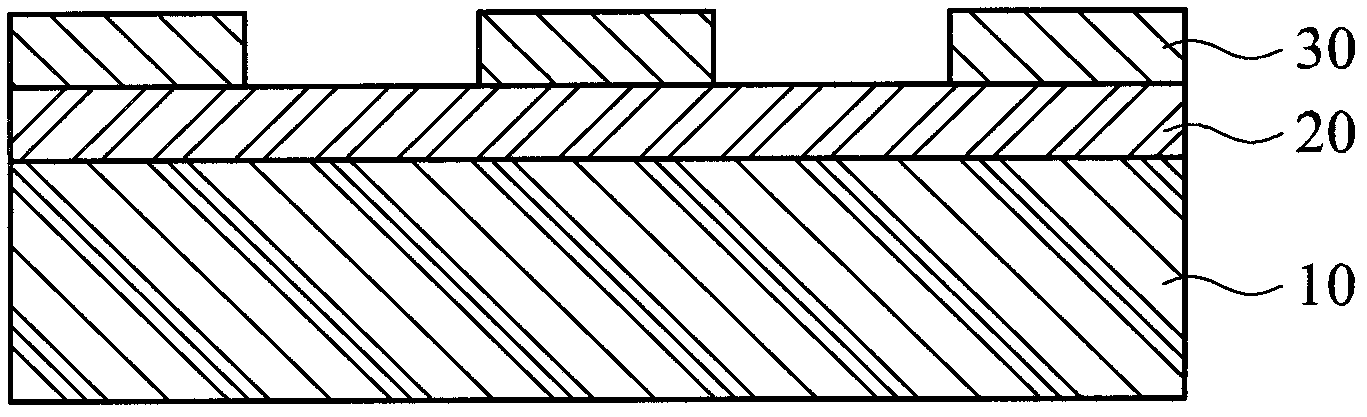

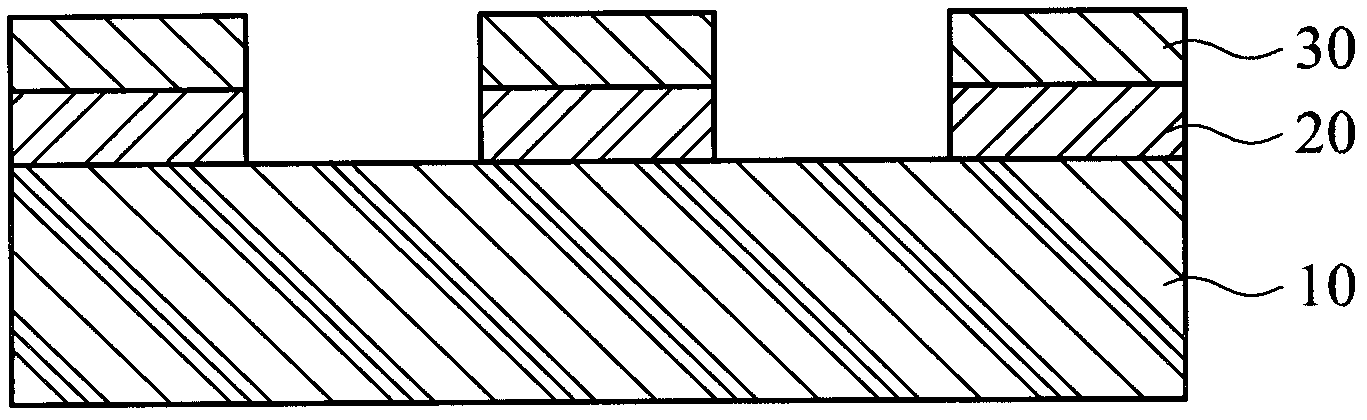

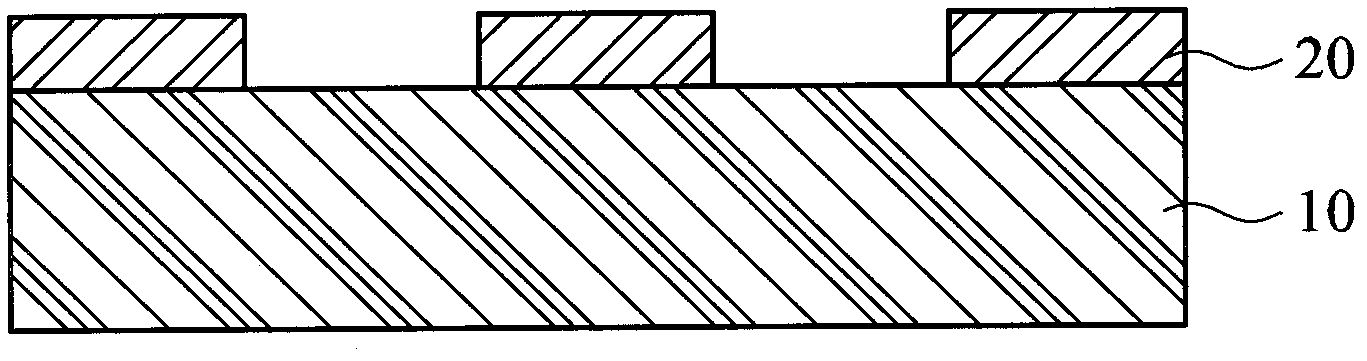

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

ActiveUS9563139B2Simple materialEnhance layeringElectrography/magnetographyN dimethylformamideTransport layer

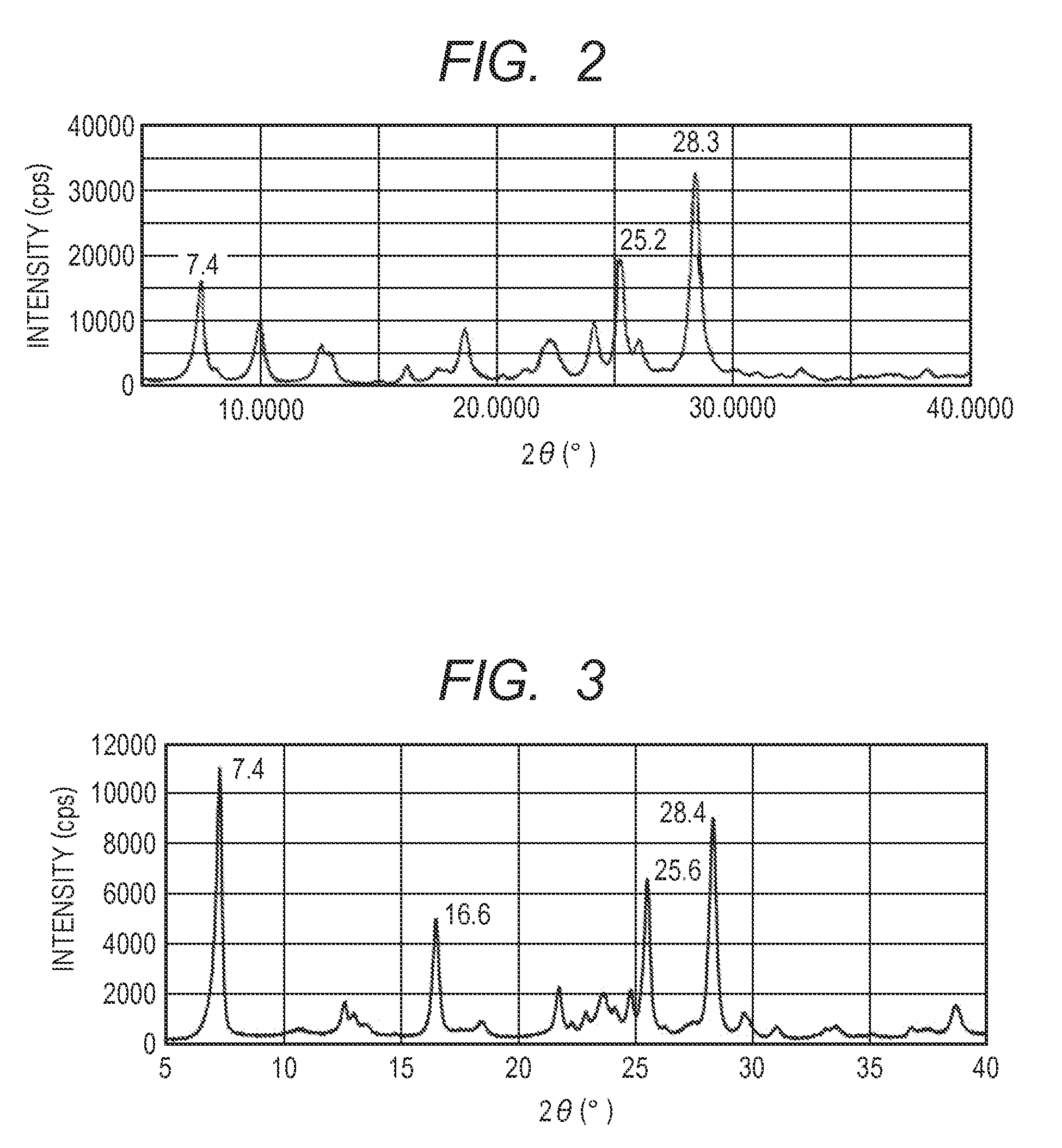

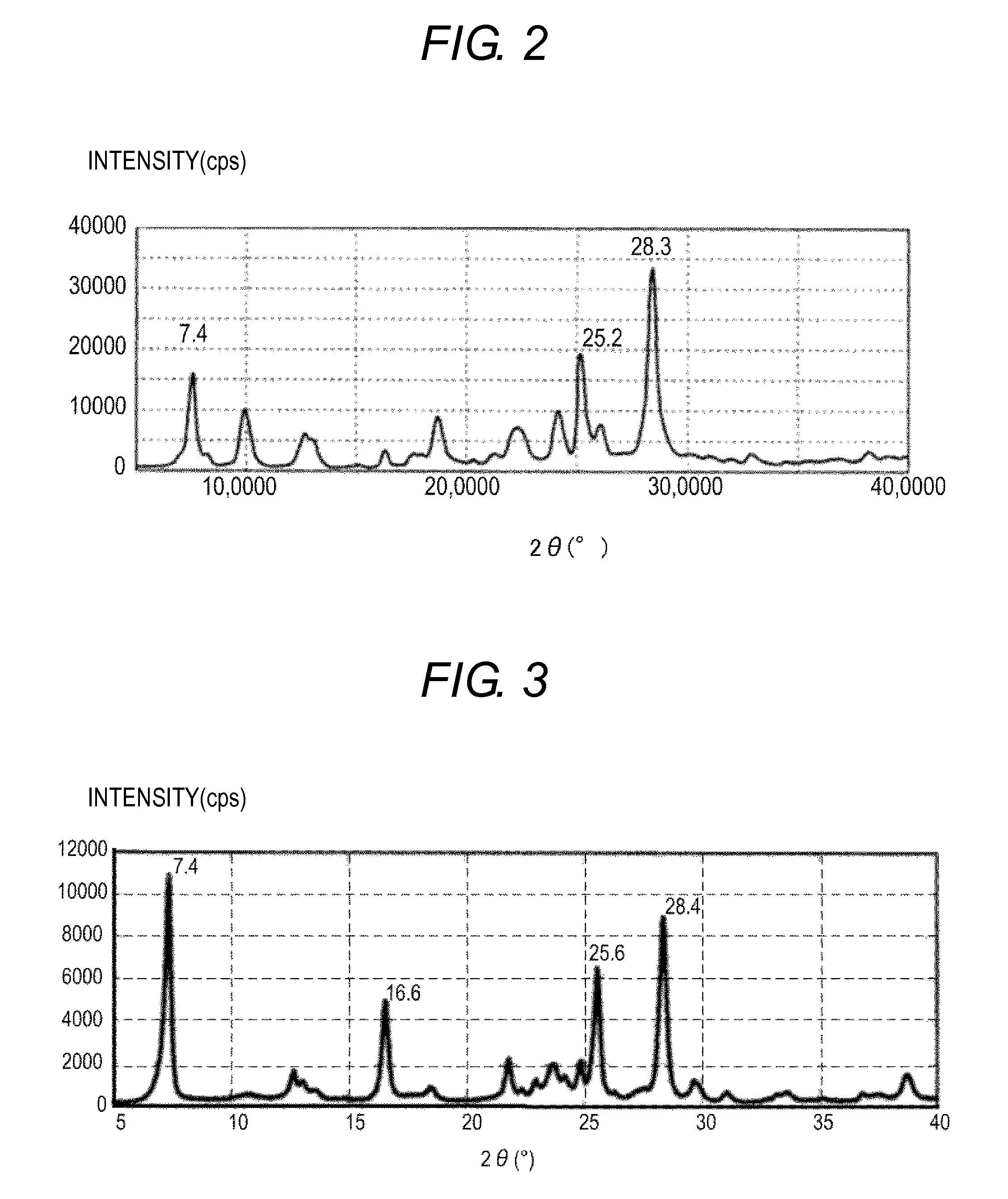

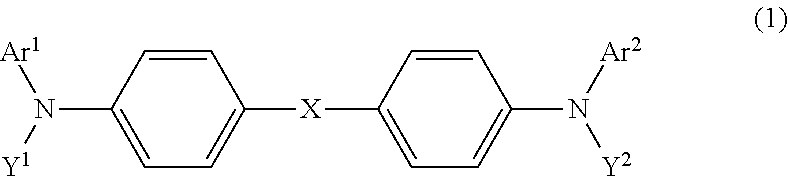

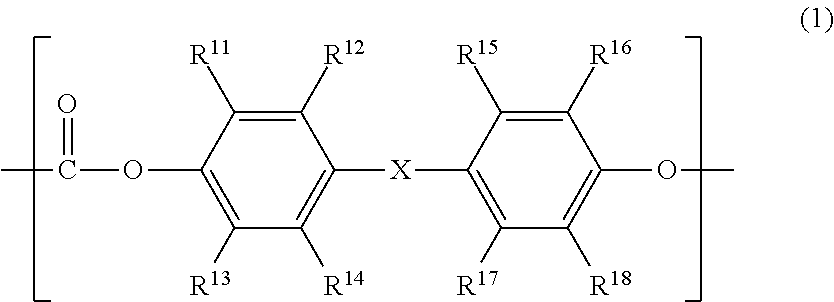

An electrophotographic photosensitive member wherein a charge generating layer of the electrophotographic photosensitive member includes a gallium phthalocyanine crystal in which an organic compound is contained, wherein the organic compound is at least one compound selected from the group consisting of dimethylsulfoxide, N,N-dimethylformamide, N-methylformamide, N-propylformamide, N-vinylformamide and N-methylpyrrolidone, the content of the organic compound is 0.1% by mass or more and 2.0% by mass or less based on a gallium phthalocyanine in the gallium phthalocyanine crystal, and a charge transporting layer of the electrophotographic photosensitive member includes a polycarbonate resin having structural units represented by formulae (1) and (2).

Owner:CANON KK

Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

InactiveUS20160131985A1Deterioration of image qualityImprove image qualityElectrographic process apparatusN dimethylformamideTransport layer

Provided is an electrophotographic photosensitive member, including in the following order: a support; a charge-generating layer; and a charge-transporting layer, in which: the charge-generating layer includes a gallium phthalocyanine crystal in which an organic compound is contained; the organic compound is at least one compound selected from the group consisting of dimethyl sulfoxide, N,N-dimethylformamide, N-methylformamide, N-propylformamide, N-vinylformamide, and N-methylpyrrolidone; a content of the organic compound is 0.1% by mass or more and 1.5% by mass or less with respect to a mass of gallium phthalocyanine in the gallium phthalocyanine crystal; and the charge-transporting layer comprises at least one compound selected from the group consisting of a compound represented by the formula (1), a compound represented by the formula (2), a compound represented by the formula (3), and a compound represented by the formula (4).

Owner:CANON KK

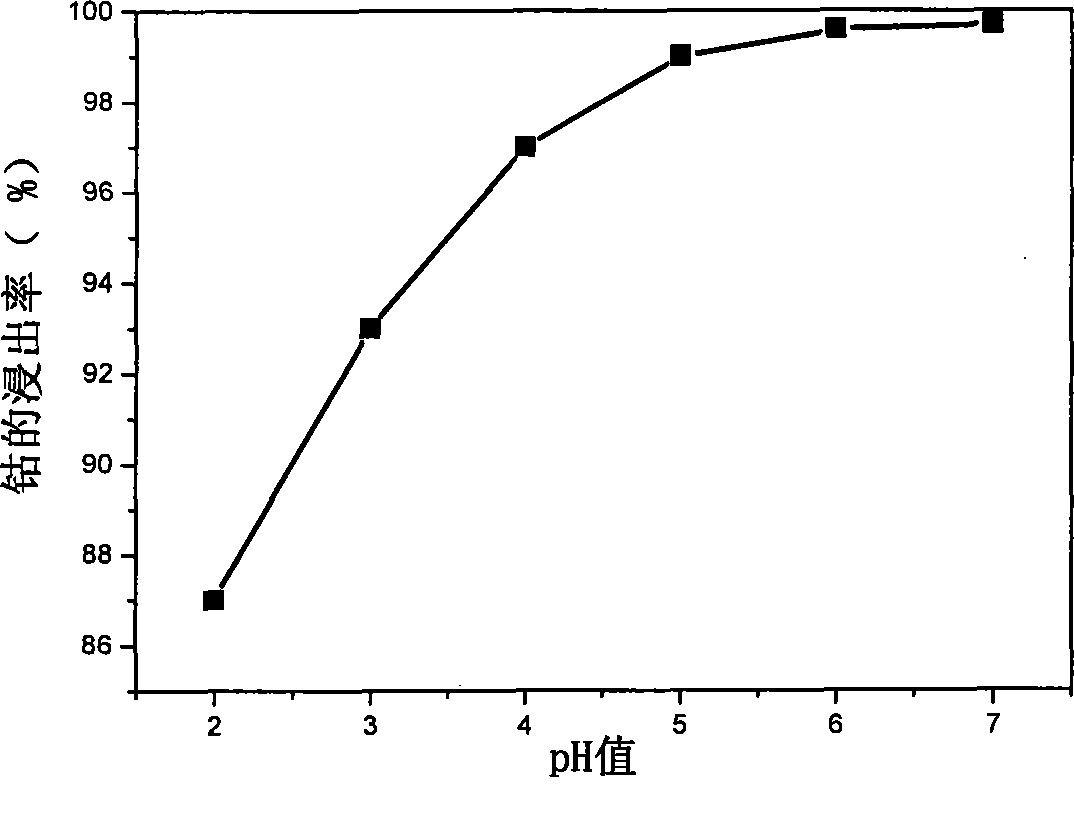

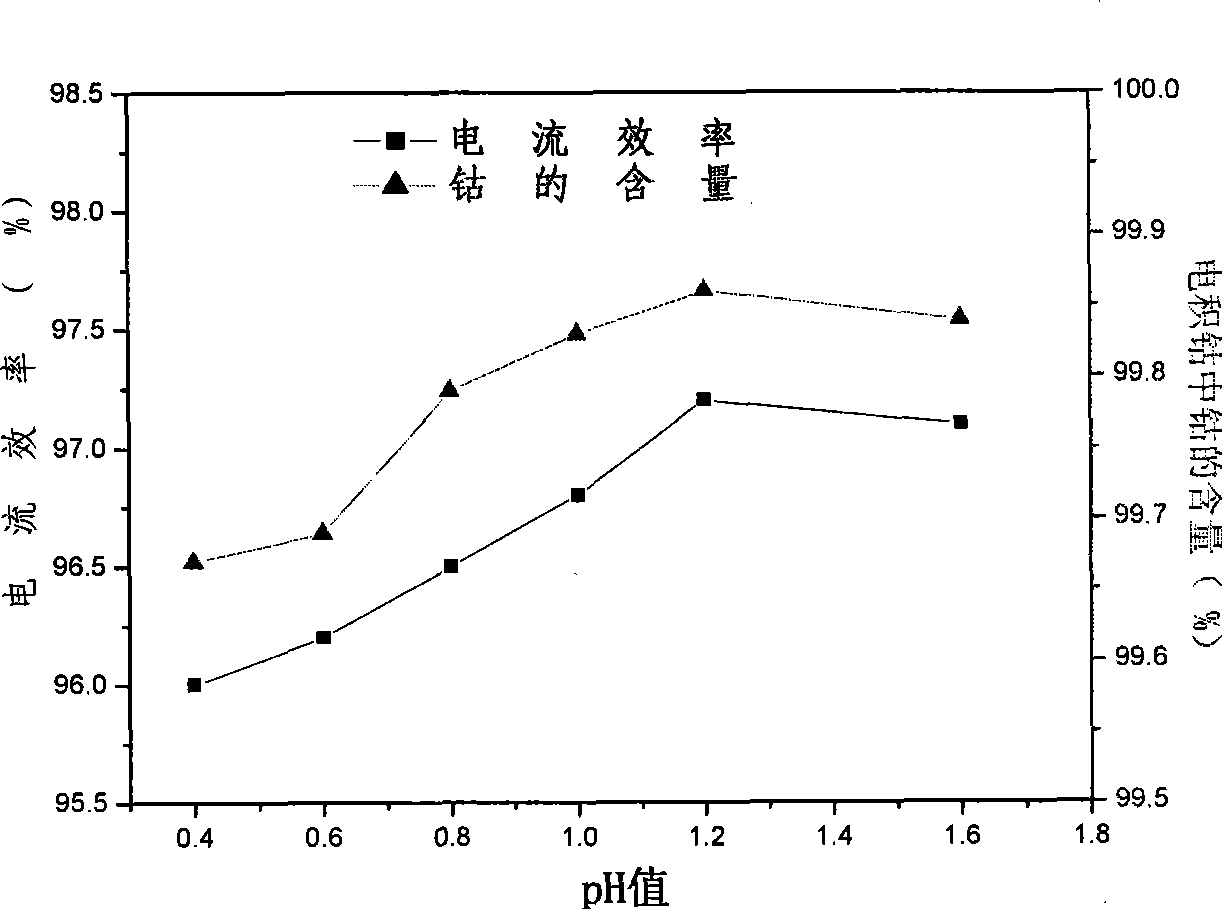

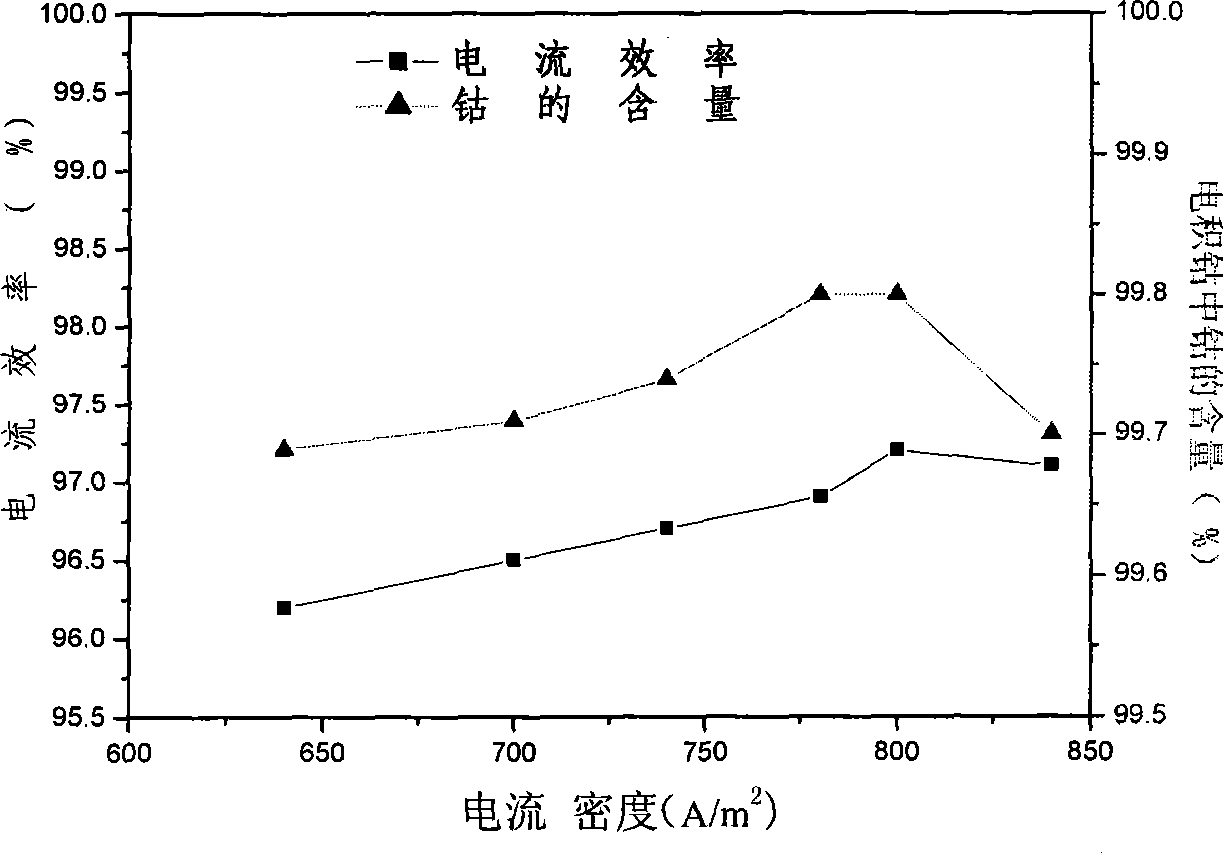

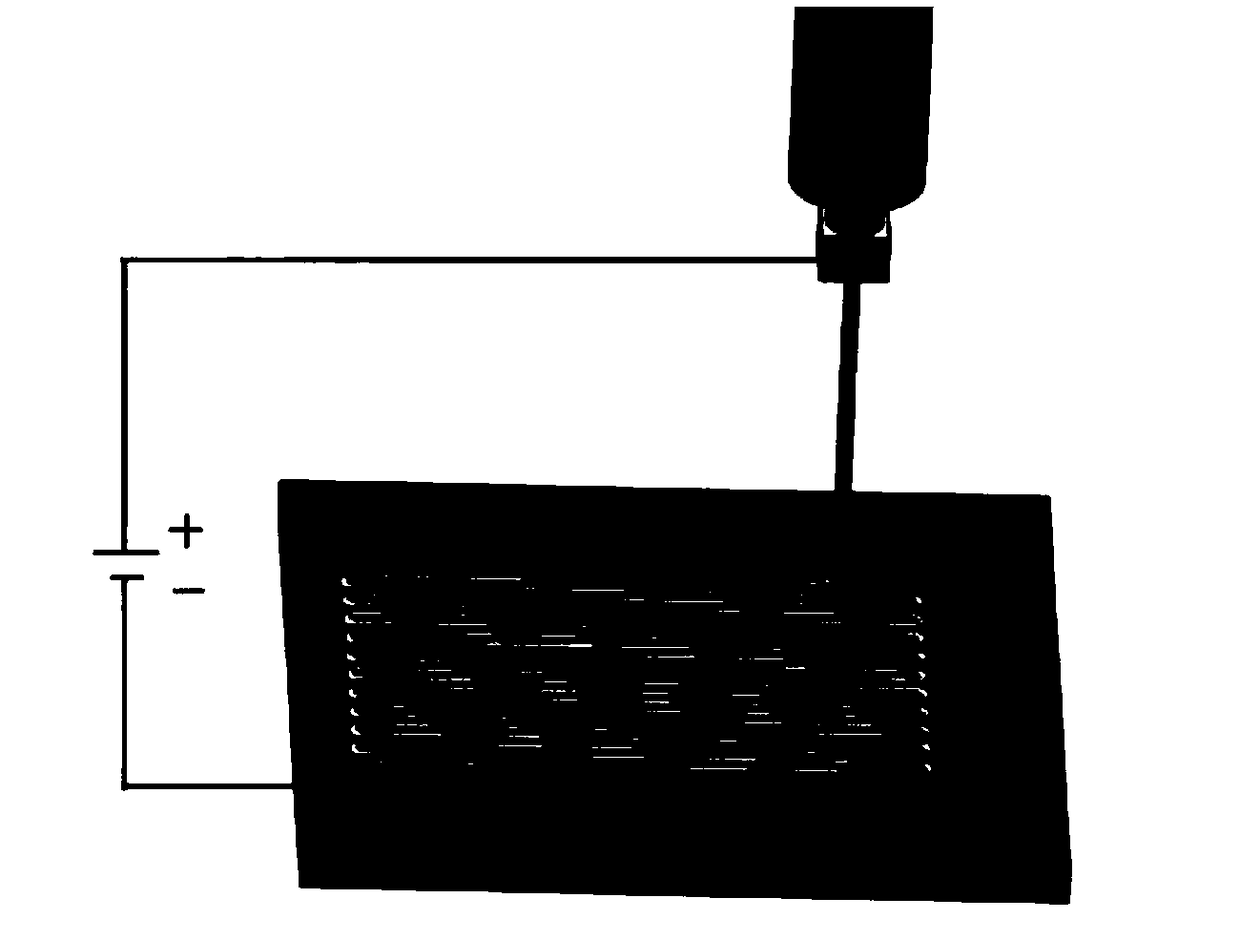

Method for directly recovering and producing electrowinning cobalt from waste and old lithium ionic cell

InactiveCN101381817ALow priceHigh recovery ratePhotography auxillary processesProcess efficiency improvementLithiumOrganic solvent

The invention discloses a method for directly recovering and producing electro deposited cobalt from waste lithium ion cells. The method is mainly characterized in that: firstly, the waste lithium ion cells are disassembled and separated to obtain positive plates; secondly, the positive plates are immersed by an organic solvent N-methylformamide (NMP), and aluminum foils and anode materials of a current collector are separated; thirdly, the anode materials which contain lithium cobaltate are leached out by a hydrochloric acid and hydrogen peroxide system, and undissolved substances are filtered and separated; and fourthly, the electro deposited cobalt is obtained after electrodeposition of filtrate. By adoption of the method, the recovery rate of the cobalt in the waste lithium ion cells can be about 97.0 percent, and the purity of the electro deposited cobalt can be more than 99.8 percent.

Owner:GUANGDONG BRUNP RECYCLING TECH +4

Electrophotographic photosensitive member, method for producing electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

InactiveUS20160154326A1Excellent sensitive characteristicEasily image defectElectrographic process apparatusCoatingsN dimethylformamidePhthalocyanine

Owner:CANON KK

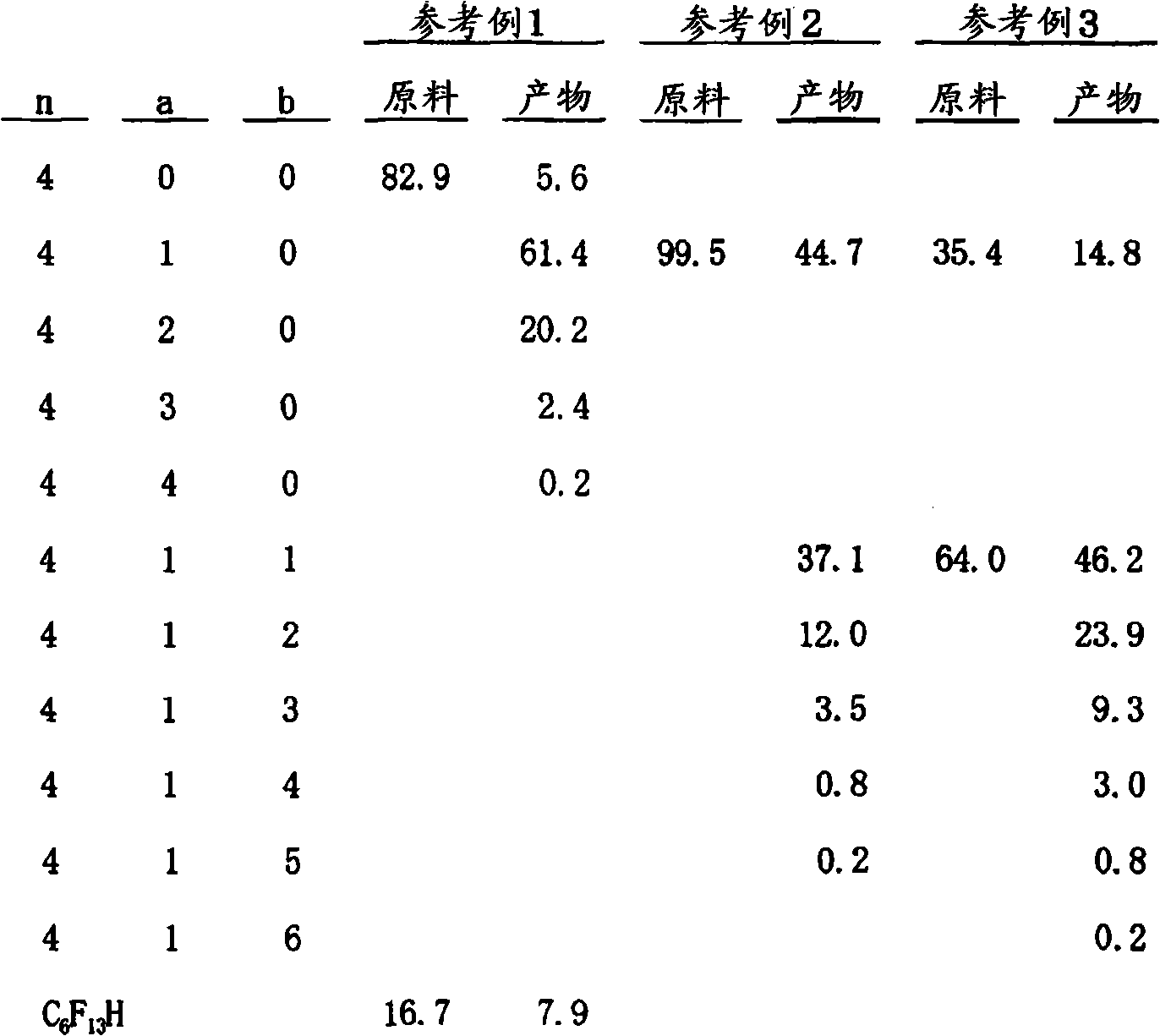

Polyfluoroalkyl alcohol or (meth)acrylic acid derivative thereof, and their production methods

ActiveCN101400633AEasy to usePromote decompositionOrganic compound preparationOrganic chemistry methodsMeth-Hydrogen atom

Disclosed is a polyfluoroalkyl alcohol represented by the following general formula: CnF2n+1(CH2CF2)a(CF2CF2)b(CH2CH2)cOR (R: H, a (meth)acrylic acid group; n:1-6; a:1-4; b:1-3; c:1-3), or a (meth)acrylic acid derivative thereof. A polyfluoroalkyl alcohol (R: a hydrogen atom) can be produced by reacting a fluoroalkyl iodide represented by the following general formula: CnF2n+1(CH2CF2)a(CF2CF2)b(CH2CH2)cI with N-methylformamide, and then hydrolyzing the resulting in the presence of an acid catalyst. A (meth)acrylic acid derivative of such a polyfluoroalkyl alcohol (R: a (meth)acrylic acid group) can be produced by reacting a (meth)acrylic acid with the polyfluoroalkyl alcohol.

Owner:UNIMATEC CO LTD

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

InactiveUS20160154328A1SpeedHigh quality imagingElectrographic process apparatusCorona dischargeN dimethylformamideTransport layer

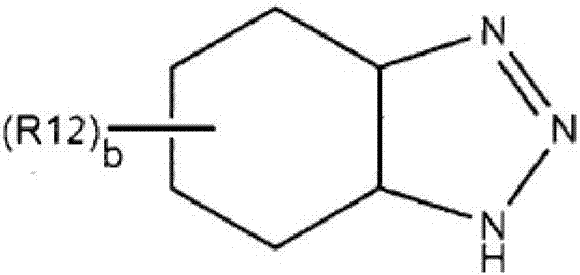

To provide an electrophotographic photosensitive member that can allow a high-quality image, in which photomemory after repeated use in a high-speed process is suppressed, to be output, as well as a process cartridge and an electrophotographic apparatus including the electrophotographic photosensitive member. An electrophotographic photosensitive member wherein a charge generating layer includes a gallium phthalocyanine crystal in which an organic compound is contained, wherein the organic compound is at least one compound selected from the group consisting of dimethylsulfoxide, N,N-dimethylformamide, N-methylformamide, N-propylformamide, N-vinylformamide and N-methylpyrrolidone, the content of the organic compound is 0.1% by mass or more and 2.0% by mass or less based on a gallium phthalocyanine in the gallium phthalocyanine crystal, and a charge transporting layer includes a polycarbonate resin having structural units represented by the following formula (1).

Owner:CANON KK

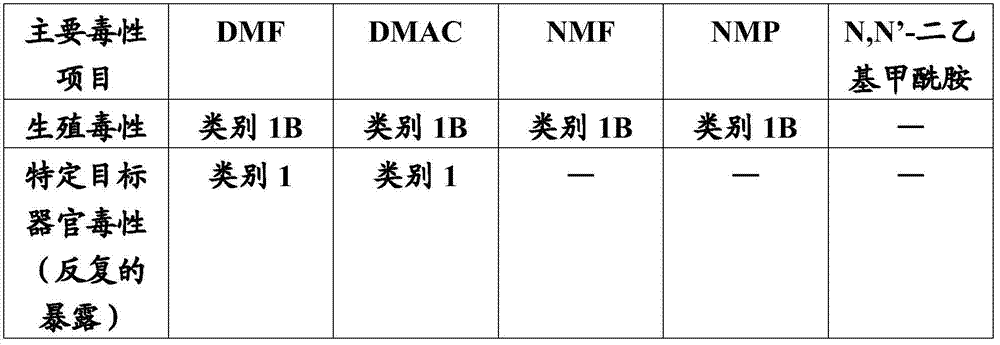

Photoresist-removing stripper composition and method for stripping photoresist using same

ActiveCN105143984AReduced copper/oxygen ratioSemiconductor/solid-state device manufacturingPhotosensitive material processingOrganic solventPhotoresist

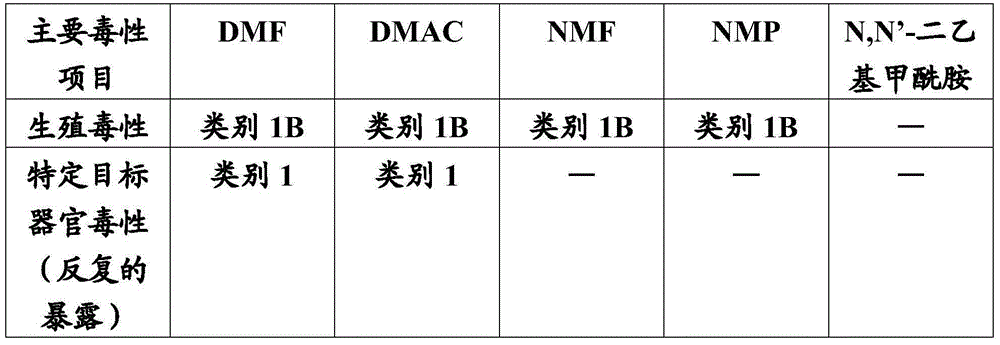

The present invention relates to: a photoresist removing stripper composition which does not comprise N-methylformamide, N,N′-dimethylcarboxamide, or the like, but which has outstanding stripping capacity and rinsing capacity, and which minimizes time-dependent deterioration of physical properties; and to a method for stripping a photoresist using the composition. The photoresist-removing stripper composition comprises: one or more types of amine compounds; N,N′-diethylcarboxamide; and a protic organic solvent of alkyleneglycol or alkyleneglycol monoalkylether.

Owner:LG CHEM LTD

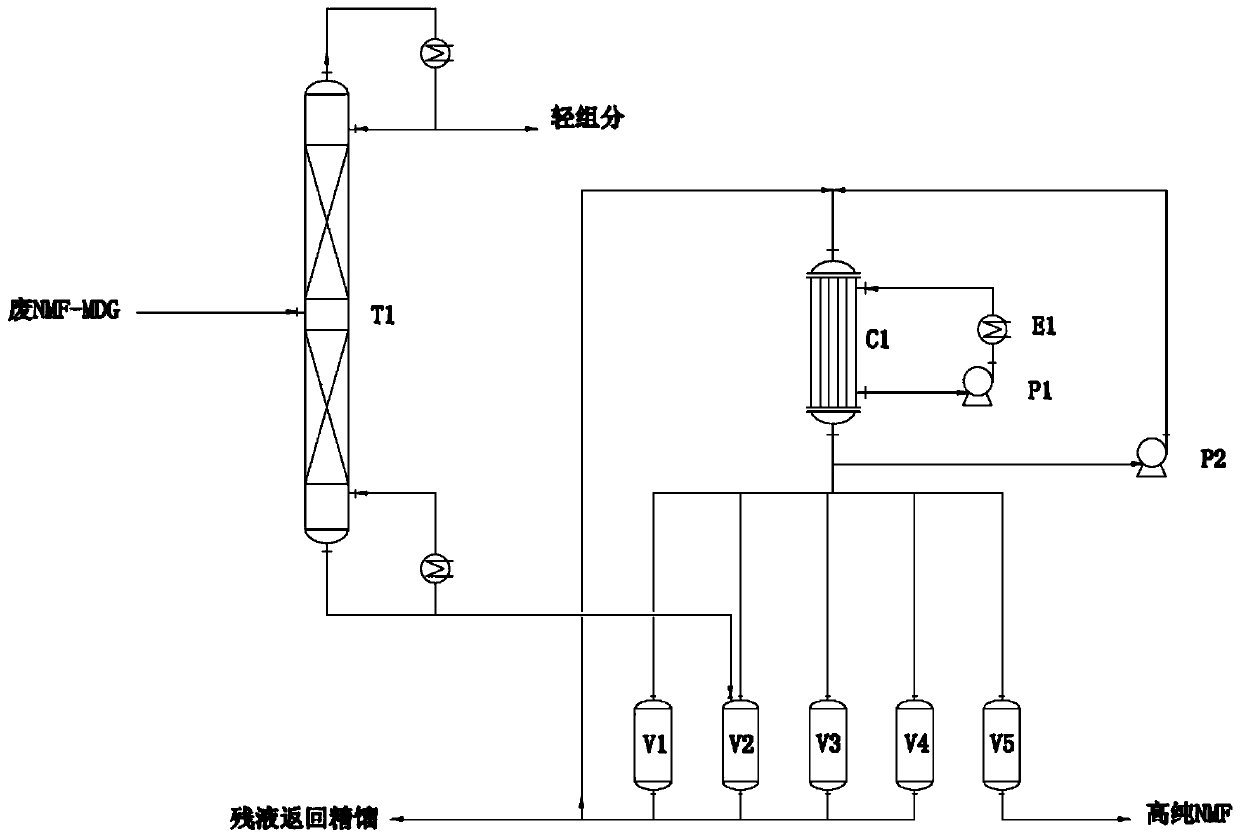

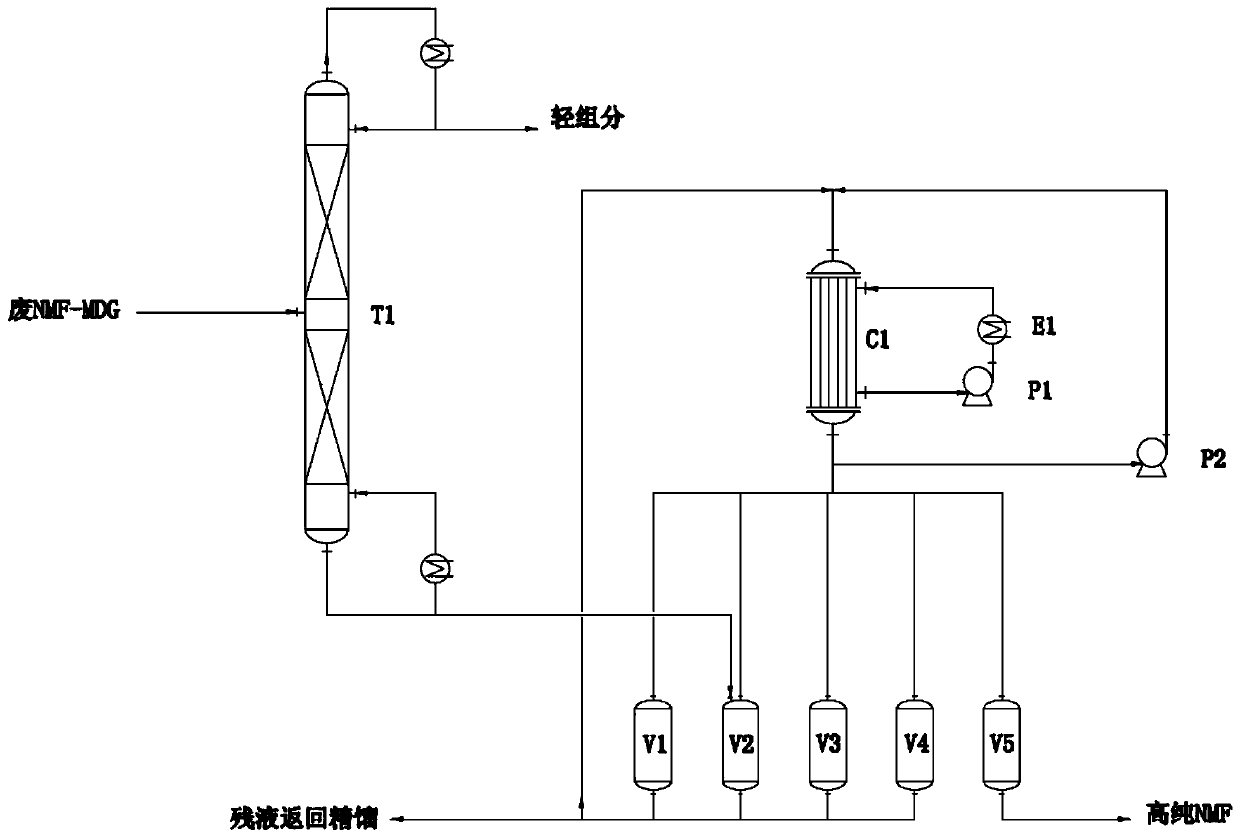

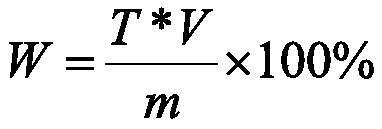

Process for recovering high-purity N-methyl formamide from waste stripping solution

ActiveCN109970591AAvoid negative effectsSolve the problem of not being able to recover high-purity NMFCarboxylic acid amide separation/purificationPhysical chemistryEther

The invention relates to the technical field of waste stripping solution recovery, and provides a process for recovering high-purity N-methyl formamide from a waste stripping solution. The process includes rectifying the waste stripping solution containing N-methyl formamide and diethylene glycol methyl ether to obtain a NMF crude product having a mass concentration of 80-90%; repeating 1-3 timesof melting and crystallization; performing partial melting, melting, melt liquid collection and cooling for crystallization to obtain high-purity NMF. A technique combining melting and crystallizationwith rectification is adopted so that a problem that high-purity NMF cannot be obtained through recovery is solved, and the process has advantages of simple procedures, low investment, short period,a high yield and a low cost. The obtained high-purity NMF is high in purity which can be electronic chemical purity that is 99.99%, thus overcoming a problem that purity of a product of rectificationonly can reach 90%.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

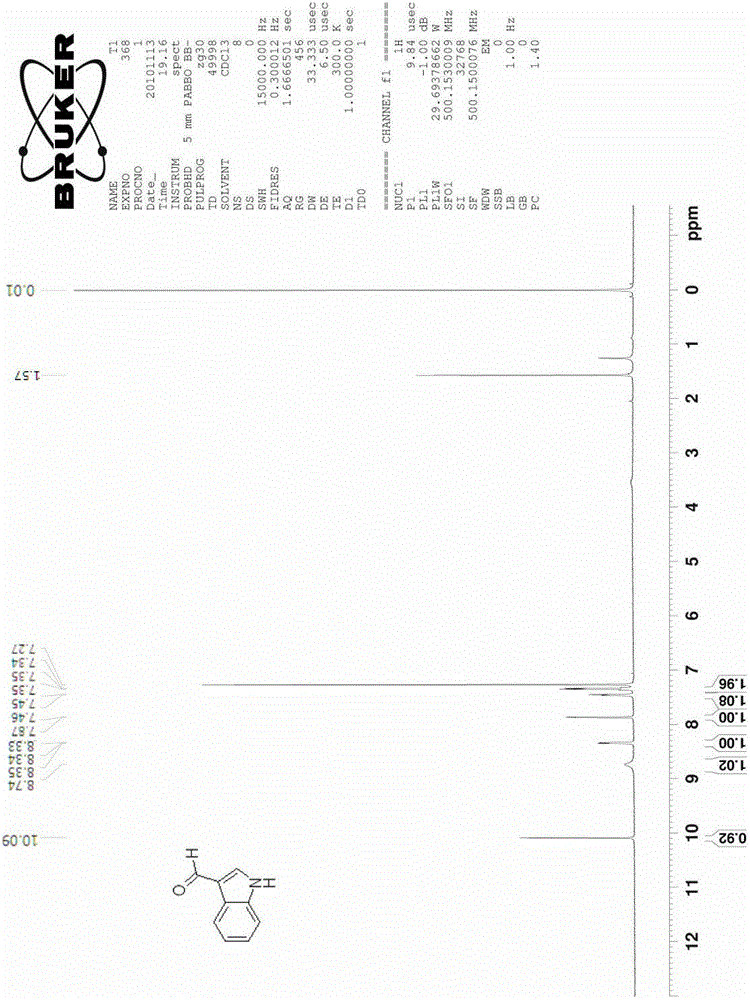

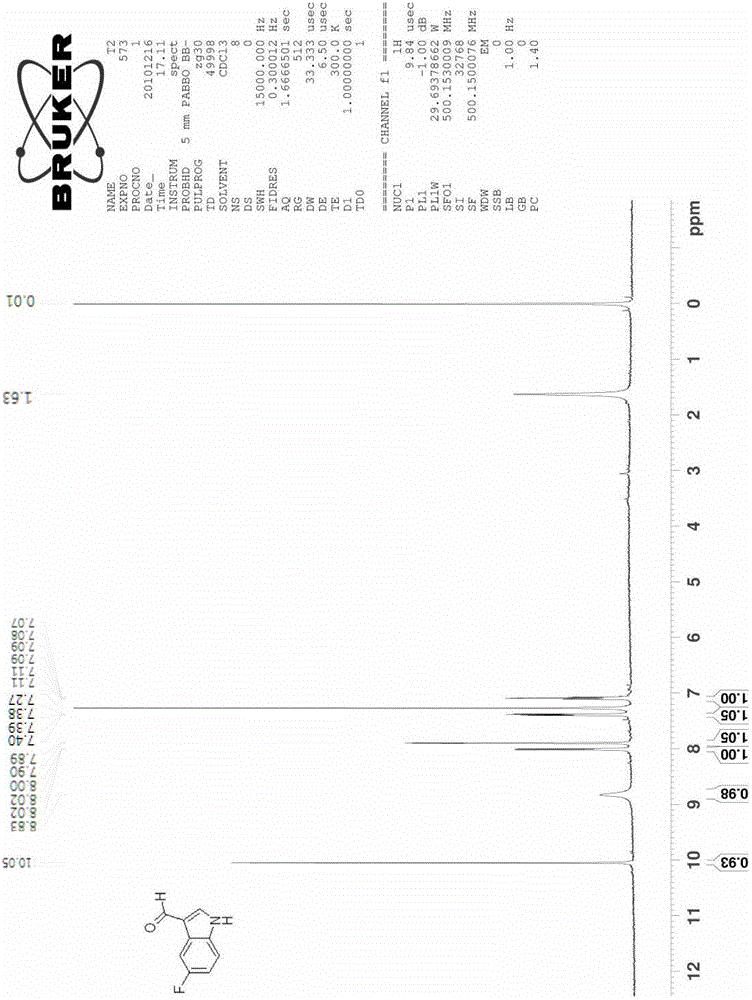

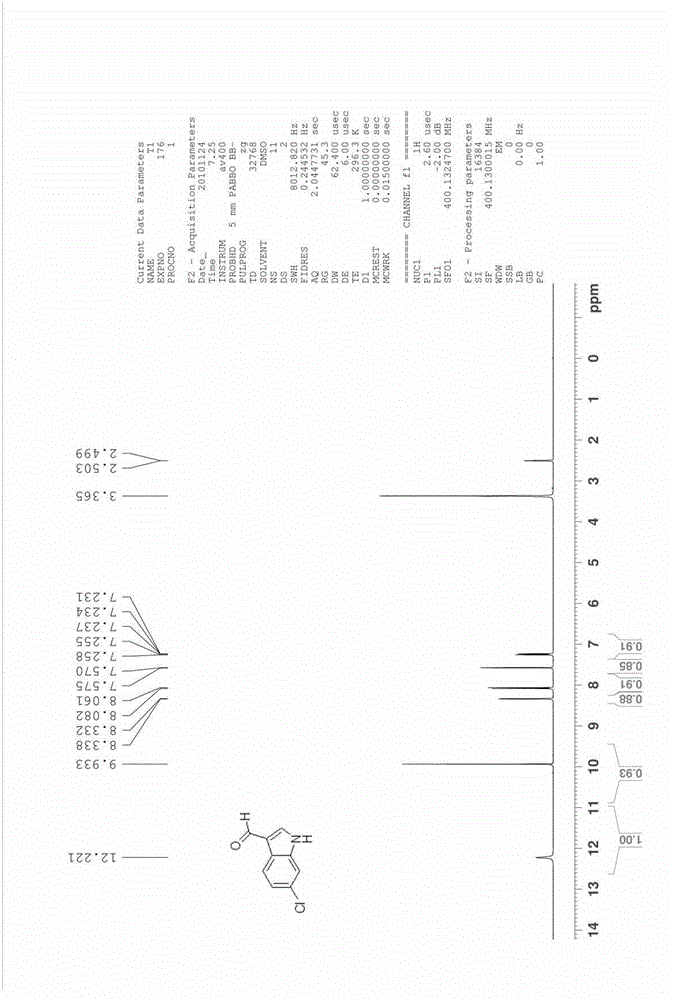

Method for preparing substituted indole-3-methanal compound

The invention relates to the field of organic synthesis and medical intermediate preparation and especially relates to a method for preparing a substituted indole-3-methanal compound. The method comprises the following steps that N,N-dimethylformamidodimethylacetal or N,N-methylformamidodiethylacetal and substituted 2-nitrotoluene undergo a reflux reaction to produce beta-dimethylamino-2-nitrostyrene; beta-dimethylamino-2-nitrostyrene and a mixed solution of hydrazine and alcohol undergo a reaction to produce a substituted indole; and the substituted indole, dimethylformamide (DMF) and phosphorus oxyhalogen undergo a reaction to produce the substituted indole-3-methanal compound. Yields of all processes of the method provided by the invention are more than 90%. A total yield of the method is more than 80%.

Owner:上海泰坦科技股份有限公司

Fluoroalkyl alcohol mixture and method for producing the same

InactiveUS20100288971A1Low bioaccumulation potentialEasy to useOther chemical processesOrganic compound preparationAlcoholIodide

Disclosed is a mixture of fluoroalkyl alcohols represented by the general formulae: CF3(CF2)n(CH═CF)a(CF2CF2)b(CH2CH2)cOH [Ia] and CF3(CF2)n-1(CF═CH)aCF2(CF2CF2)b(CH2CH2)cOH [Ib], wherein n is an integer of 1 to 5, a is an integer of 1 to 4, b is an integer of 0 to 3, and c is an integer of 1 to 3. This fluoroalkyl alcohol mixture is produced by the reaction of a fluoroalkyl iodide represented by the general formula: CF3(CF2)n(CH2CF2)a(CF2CF2)b(CH2CH2)cI [II], with N-methylformamide, followed by hydrolysis in the presence of a basic compound.

Owner:UNIMATEC CO LTD

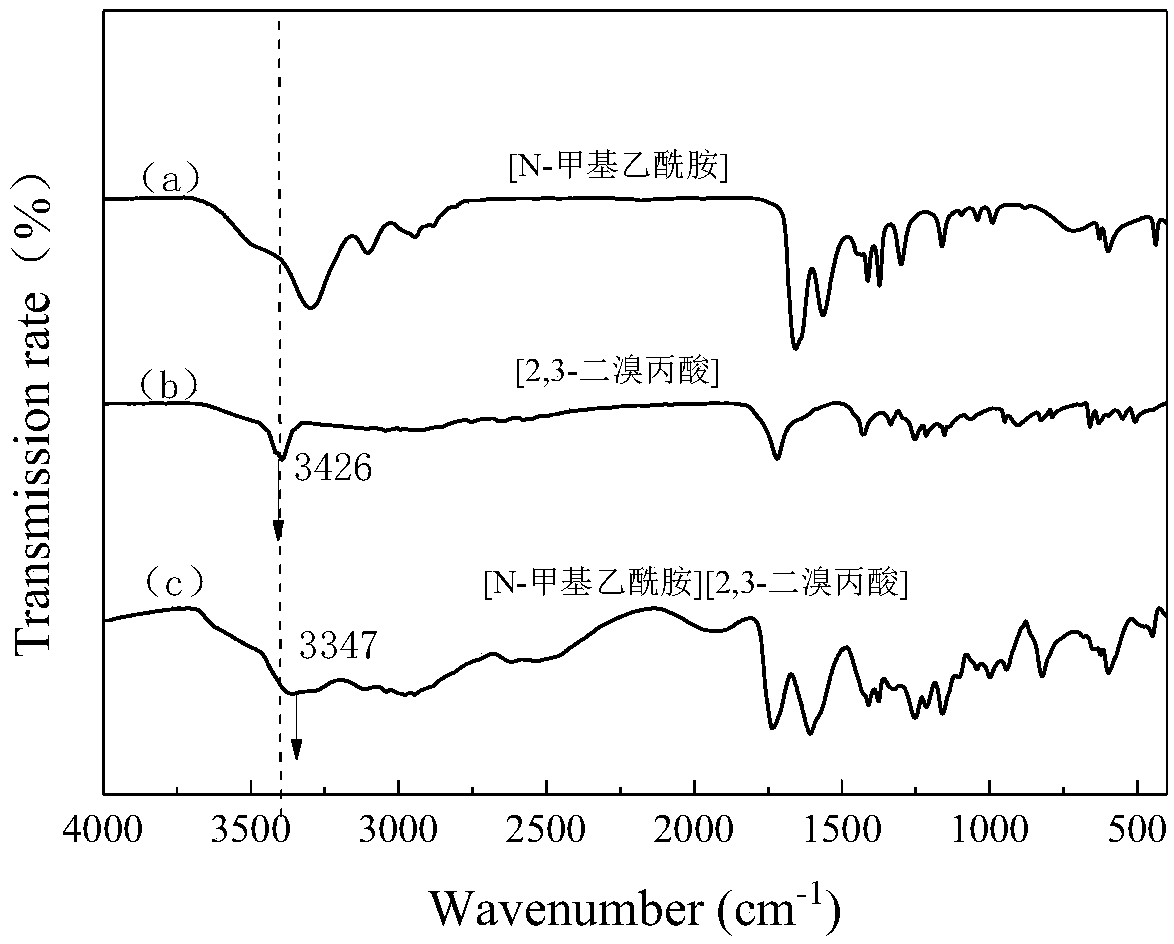

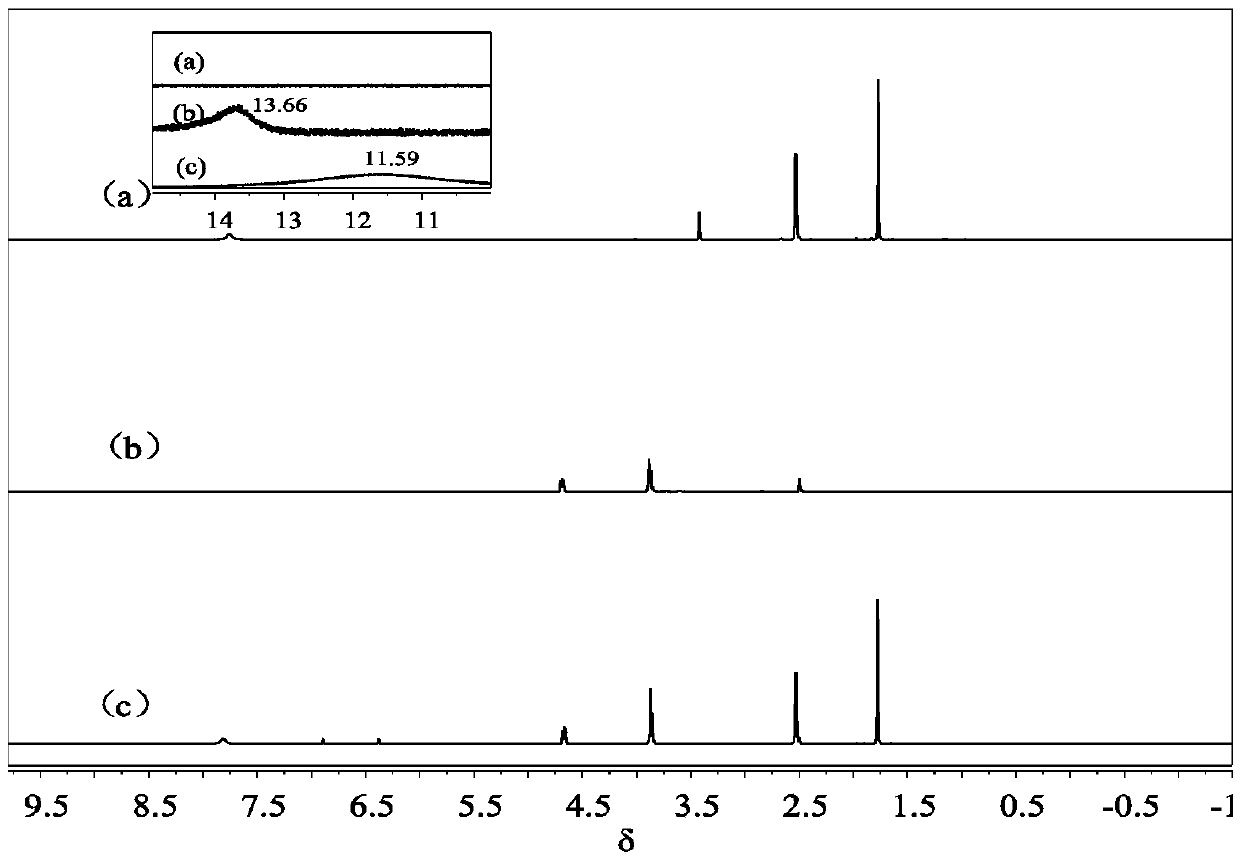

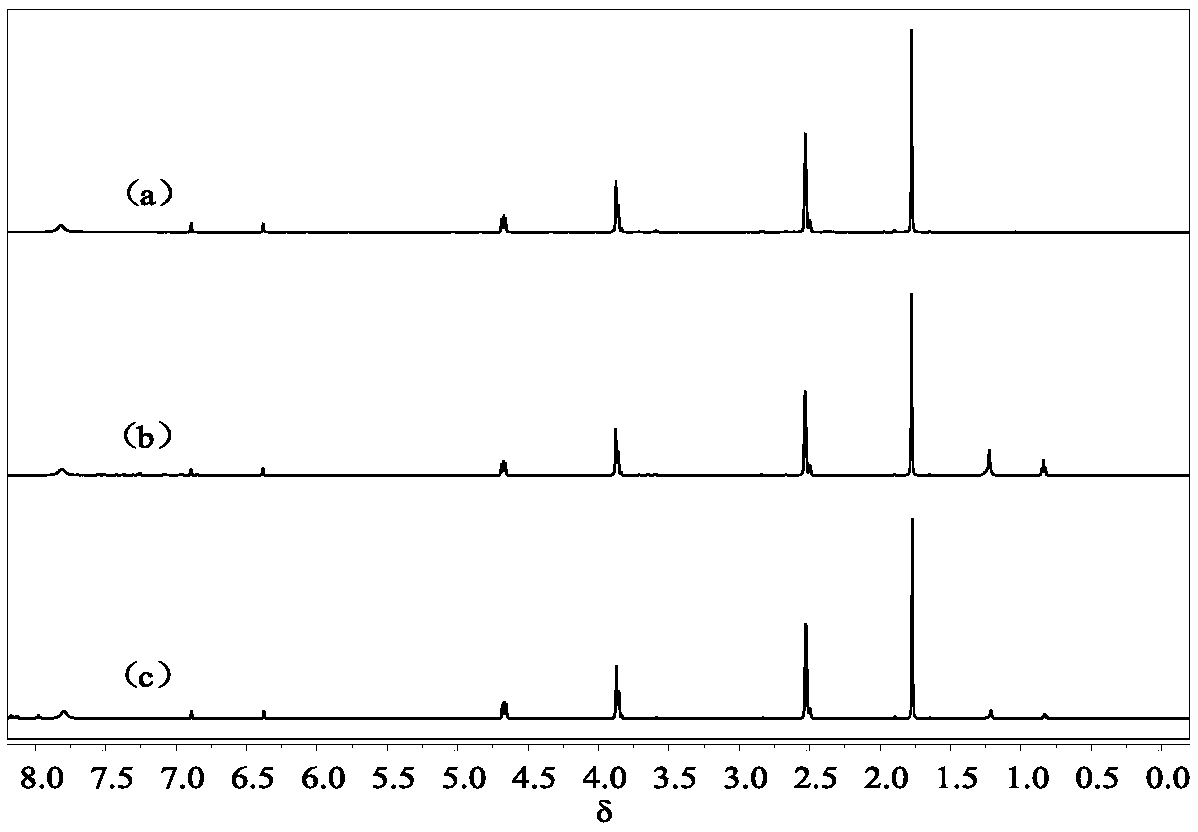

Low eutectic solvent and method for extracting alkaline/non-alkaline nitrogen from simulated gasoline

ActiveCN109679678AReduce usageStrong continuous extraction abilityRefining with acid-containing liquidsN-methylacetamideHydrogen

The invention relates to the technical field of extraction of alkaline / non-alkaline nitrogen from simulated gasoline, and discloses a low eutectic solvent and a method for extracting the alkaline / non-alkaline nitrogen from the simulated gasoline. The low eutectic solvent for extracting the alkaline / non-alkaline nitrogen from the simulated gasoline is prepared by heating a hydrogen bond receptor and a hydrogen bond donor according to a molar ratio of 1:1 while stirring, and performing a reaction, wherein the hydrogen bond receptor is N-methylacetamide or N-methylformamide and the hydrogen bonddonor is 2,3-dibromopropionic acid or 2,3-dichloropropionic acid. When the low eutectic solvent is used for extracting the alkaline / non-alkaline nitrogen from the simulated gasoline, the extracting efficiency is high and the using amount of an extracting agent is low, so that achievement of industrialization of extraction of the non-alkaline nitrogen from the gasoline through the low eutectic solvent becomes possible.

Owner:QINGDAO UNIV OF SCI & TECH

Multifunctional eraser composition

The invention relates to a multifunctional eraser composition. The composition is prepared through using 25-35 parts by weight of a polyvinyl chloride resin slurry, 15-25 parts by weight of dioctyl phthalate, 4-8 parts by weight of calcium carbonate, 0.1-0.4 parts by weight of a stabilizing agent, 15-25 parts by weight of calcium stearate, 10-15 parts by weight of sodium silicate, 0.2-0.8 parts by weight of dichlorobenzene, 0.1-0.4 parts by weight of a nonionic surfactant, 15-25 parts by weight of N-methylformamide and 10-15 parts by weight of a foaming agent. The making method of the composition comprises the following steps: mixing the above components, uniformly stirring, pressurizing at 120DEG C, heating to 165DEG C, dumping the obtained mixture into a mold, and carrying out pressure forming to obtain the composition. The multifunctional eraser composition is convenient to use, and can eliminate a plurality of stains comprising pen and Chinese writing brush writings and pencil and ball pen writings.

Owner:王丽

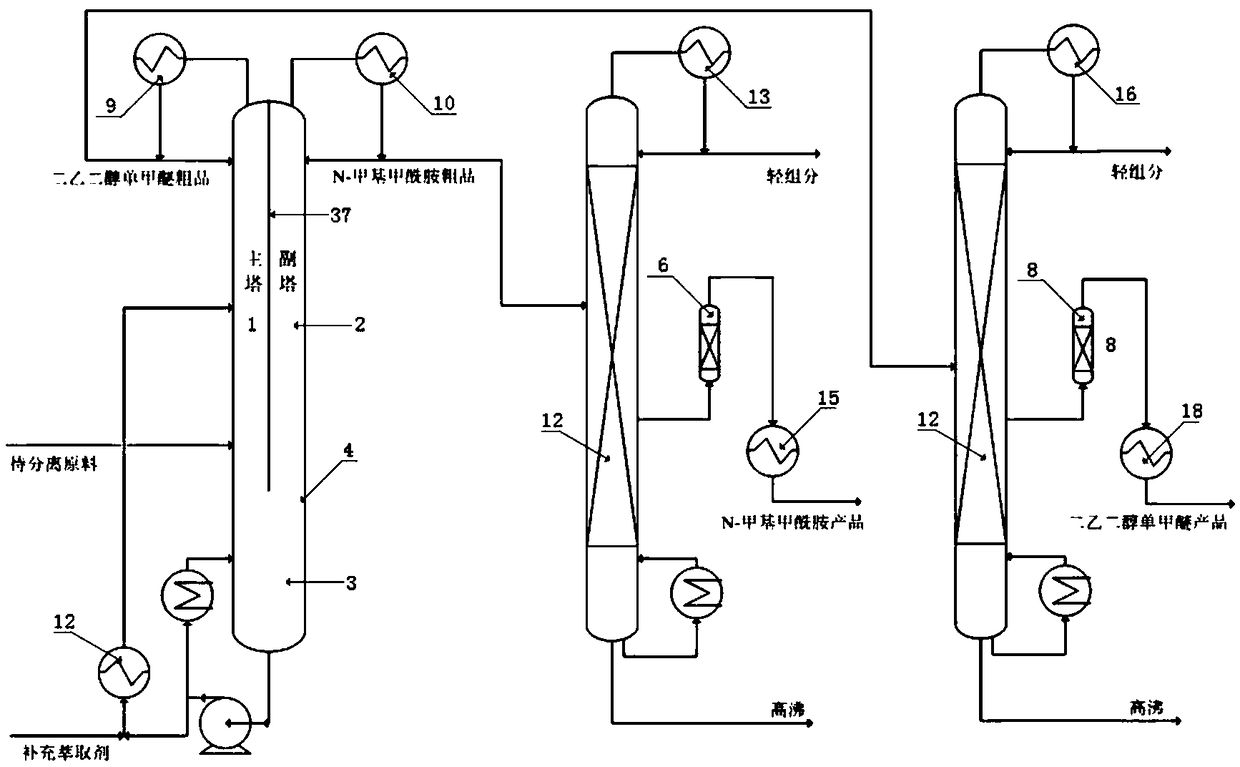

Method for recycling N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid

PendingCN109320431AAchieve separationReduce energy consumptionEther separation/purificationCarboxylic acid amide separation/purificationDiethylene glycolMetal

The invention relates to the field of solvent recycling, in particular to a method for recycling N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid. The method adopts an extraction dividing-wall rectifying method to recycle N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid; the paint remover waste liquid is rectified and separated through a main tower and an auxiliary tower of an extraction dividing-wall rectifying tower, and N-methylformamide crude product and diethylene glycol monomethyl ether crude product are obtainedrespectively; the N-methylformamide crude product passes through a N-methylformamide refining tower and a metal removing tower to obtain N-methylformamide, and the diethylene glycol monomethyl ethercrude product passes through a diethylene glycol monomethyl ether refining tower and the metal removing tower to obtain diethylene glycol monomethyl ether. The method can be adopted to conduct continuous production; the separation of the N-methylformamide and the diethylene glycol monomethyl ether is achieved; the method has the advantages that the purity of separated products is high; the technological procedure is simple; energy consumption and equipment investment in the separation process can be effectively lowered at the same time.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

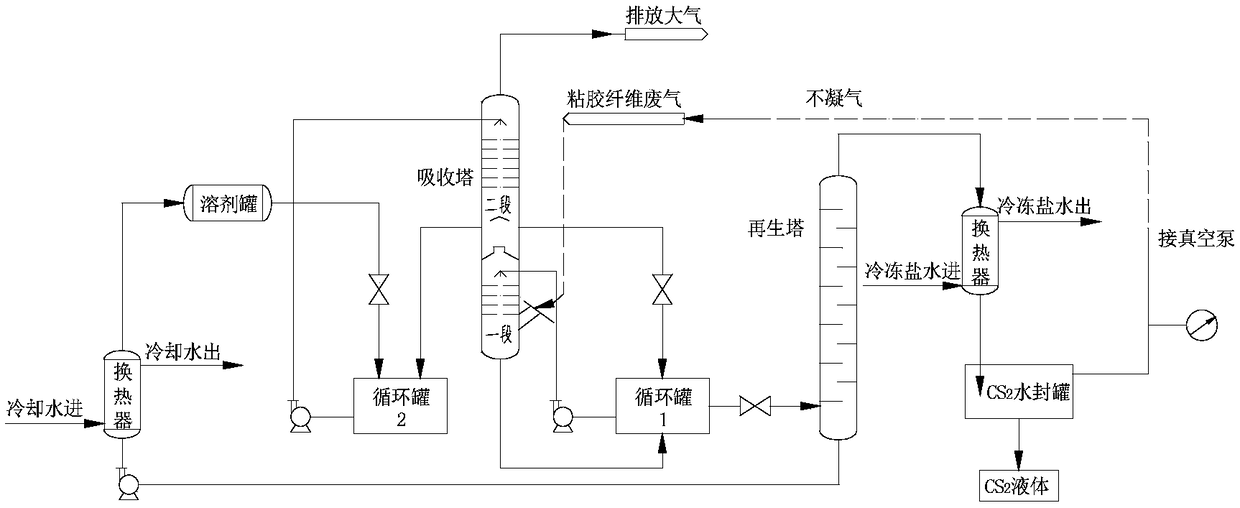

Composite solvent for recovering CS2 from viscose fiber waste gas by absorption process, and application thereof

ActiveCN109173598AReduce lossesReduce volatilityGas treatmentDispersed particle separationSolubilityPoly(ethylene glycol) dimethyl ether

The invention discloses a composite solvent for recovering CS2 from viscose fiber waste gas by an absorption process. The composite solvent comprises polyethylene glycol dimethyl ether (NHD), N-methylpyrrolidone (NMP) or N,N-methylformamide or ethylene glycol butyl ether or 1,2,4-trimethylbenzene. CS2 in the viscose fiber waste gas is absorbed by the composite solvent to obtain a purified gas andan absorption rich solution, and the rich solution can be recycled after undergoing reduced pressure distillation regeneration. The composite solvent can effectively improve the CS2 dissolving ability, and has a higher solubility and a higher purification rate than the pure NHD solvent when applied to CS2 waste gas recovery; and compared with activated carbon for adsorption treatment of CS2 wastegas, the composite solvent has the advantages of wide application range, low process cost, high operational stability, economical property, environmental protection and long service life.

Owner:NANJING FORESTRY UNIV

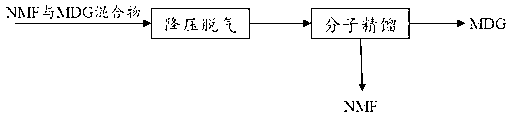

Industrial separation method of N-methylformamide and diethylene glycol monomethyl ether

InactiveCN109096142AEfficient purificationHigh purityEther separation/purificationCarboxylic acid amide separation/purificationMean free pathTower

The invention relates to an industrial separation method of main components N-methylformamide (NMF) and diethylene glycol monomethyl ether (MDG) in an electronic chemical stripper. A low-pressure molecular distillation method is adopted to efficiently recover the NMF and the MDG in the waste electronic chemical stripper, and has the advantages of energy saving and safety and environmental protection. A high-purity NMF and MDG separation refining process mainly comprises the following steps of 1) depressurization and degassing: decompressing and degassing the mixture of the NMF and the MDG to prevent entrainment splashing caused by sudden pressure drop after materials enter a molecular rectification tower; 2) molecular rectification of enabling the degassed materials to enter the molecularrectification tower achieve separation by utilizing the feature that molecular mean free paths of the two components are different. Compared with the conventional process, the method achieves the effect that the the purity of the finished NMF and the finished MDG is over 99%, and the rectified NMF and the rectified MDG reach the purity requirement of the electronic chemical stripper and achieve the separation and the purification of the NMF and the MDG.

Owner:福建钰融科技有限公司 +2

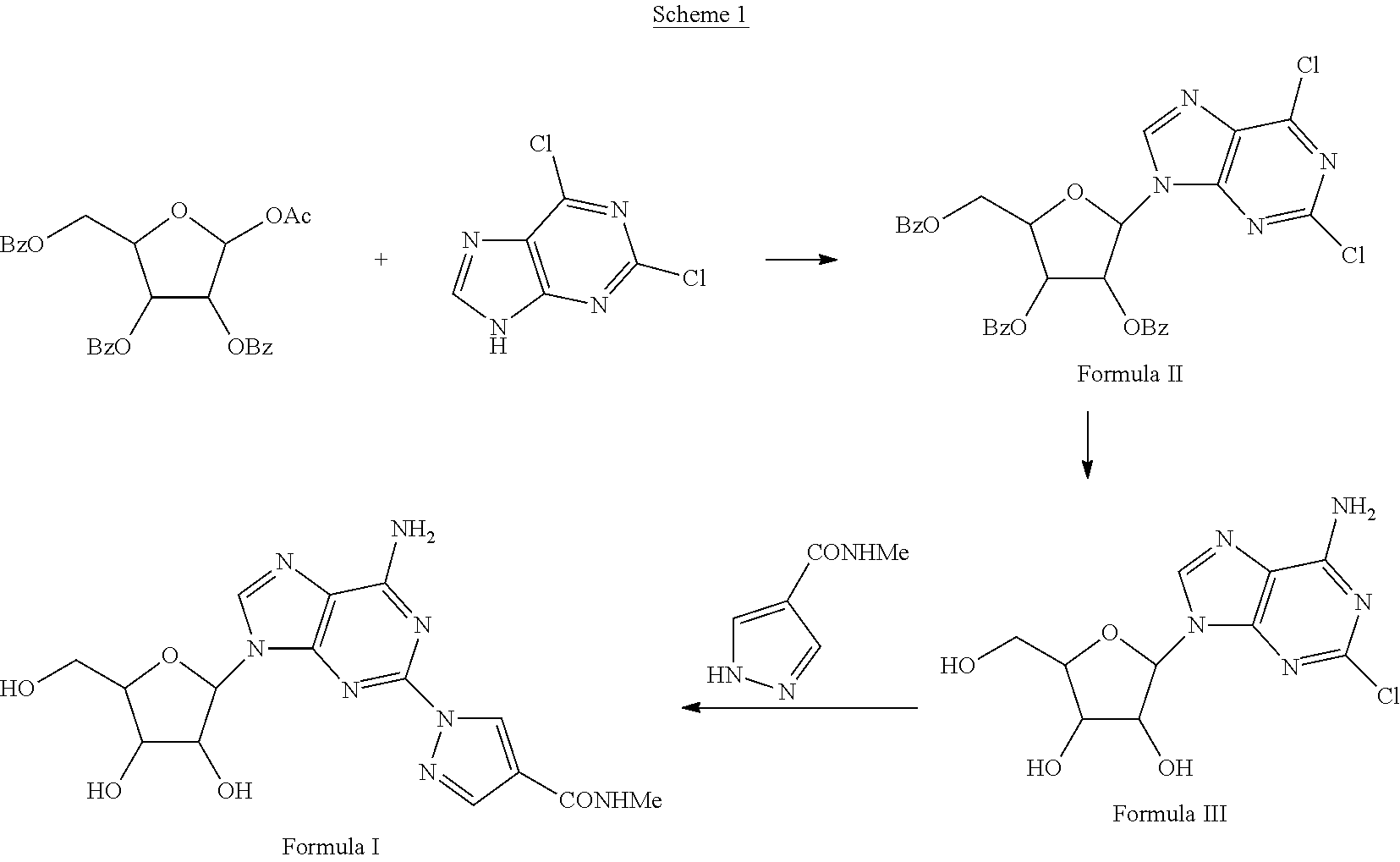

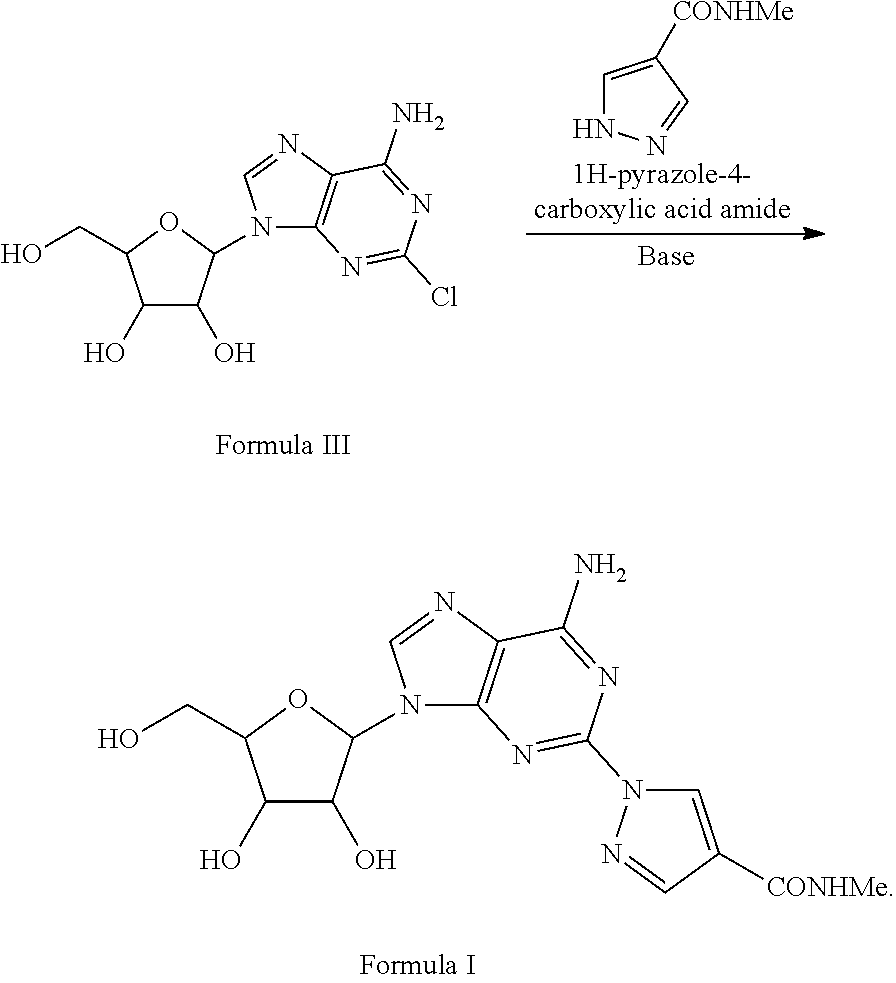

Process for the preparation of (1-{9-[(4S, 2R, 3R, 5R)-3, 4-dihydroxy-5-(hydroxymethyl)oxolan-2-yl)-6-aminopurin-2-yl}pyrazole-4-yl)-N-methylcarboxamide

The present invention relates to a novel process for the preparation of (1-{9-[(4S,2R,3R,5R)-3,4-dihydroxy-5-(hydroxymethyl)oxolan-2-yl)-6-aminopurin-2-yl}pyrazole-4-yl)-N-methylcarboxamide.

Owner:BIOPHORE INDIA PHARMA PVT LTD

Fluoroalkyl alcohol mixture and method for producing the same

InactiveUS8278361B2Low bioaccumulation potentialEasy to useOther chemical processesOrganic compound preparationAlcoholIodide

Disclosed is a mixture of fluoroalkyl alcohols represented by the general formulae: CF3(CF2)n(CH═CF)a(CF2CF2)b(CH2CH2)cOH [Ia] and CF3(CF2)n-1(CF═CH)aCF2(CF2CF2)b(CH2CH2)cOH [Ib], wherein n is an integer of 1 to 5, a is an integer of 1 to 4, b is an integer of 0 to 3, and c is an integer of 1 to 3. This fluoroalkyl alcohol mixture is produced by the reaction of a fluoroalkyl iodide represented by the general formula: CF3(CF2)n(CH2CF2)a(CF2CF2)b(CH2CH2)cI [II], with N-methylformamide, followed by hydrolysis in the presence of a basic compound.

Owner:UNIMATEC CO LTD

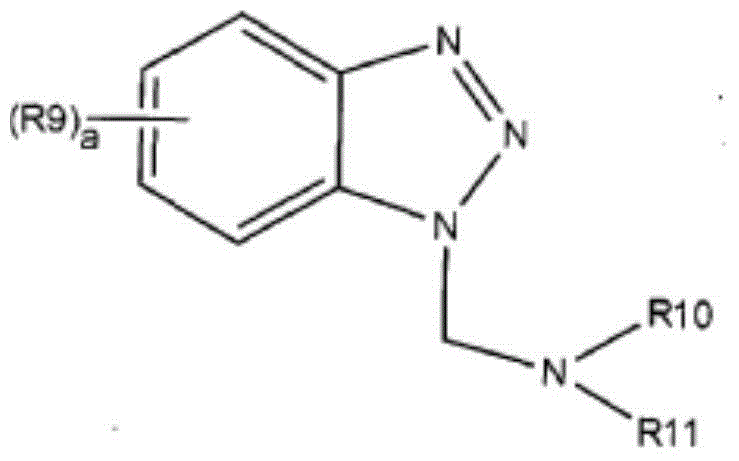

Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

An electrophotographic photosensitive member includes a support member, a charge generating layer, and a charge transport layer in that order. The charge generating layer contains a gallium phthalocyanine crystal containing therein at least one amide compound selected from the group consisting of N-methylformamide, N-propylformamide, and N-vinylformamide. The charge transport layer contains fluorine-containing resin particles and a fluorine-containing copolymer.

Owner:CANON KK

Polyfluoroalkyliodide and method of producing the same

Disclosed is a polyfluoroalkyliodide represented by the following general formula: CnF2n+1(CH2CF2)a(CF2CF2)b(CH2CH2)cOR (R: H, a (meth)acrylic acid group; n:1-6; a:1-4; b:1-3; c:1-3), or a (meth)acrylic acid derivative thereof. A polyfluoroalkyliodide can be produced by reacting a fluoroalkyl iodide represented by the following general formula: CnF2n+1(CH2CF2)a(CF2CF2)b(CH2CH2)cI with N-methylformamide, and then hydrolyzing the resulting in the presence of an acid catalyst. A (meth)acrylic acid derivative of such a polyfluoroalkyl alcohol (R: a (meth)acrylic acid group) can be produced by reacting a (meth)acrylic acid with the polyfluoroalkyl alcohol.

Owner:UNIMATEC CO LTD

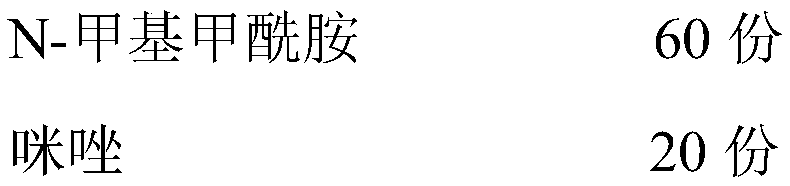

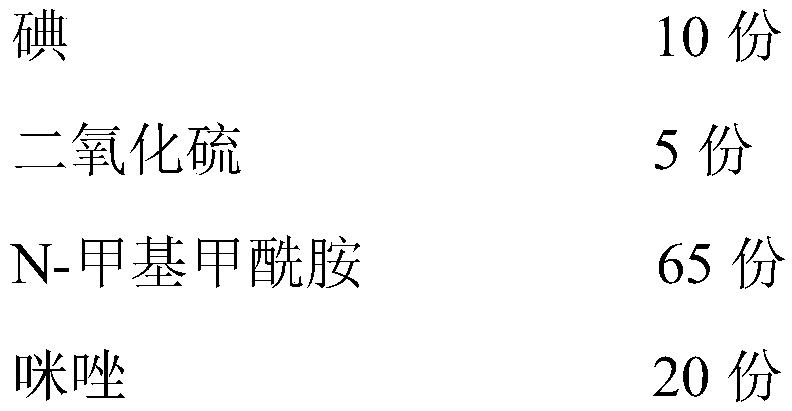

Reagent for Karl Fischer volumetric method, preparation method of reagent and application of reagent

InactiveCN109406713AReduced responseAchieving Moisture TitrationChemical analysis using titrationSide reactionMethanol

The invention discloses a reagent for a Karl Fischer volumetric method, a preparation method of the reagent and an application of the reagent. The reagent for the Karl Fischer volumetric method comprises a titrant and a solvent, wherein the titrant comprises iodine, sulfur dioxide, N-methylformamide and imidazole, and the solvent comprises ethylene glycol monomethyl ether, ethyl alcohol and imidazole. The titrant and the solvent in the reagent for the Karl Fischer volumetric method is free from methyl alcohol, the ethyl alcohol and the imidazole are added into a reactive solvent, hydroxy needed by Karl Fischer reaction can be ensured, reaction can be normal, reaction of ethylene sulfate and alcohol can be slowed down, even if slight reactant acid is generated, the reactant acid can be neutralized by a large amount of imidazole in the solvent, the PH (potential of hydrogen) value of volumetric solution is buffered, and side reaction is avoided, so that water titration of the ethylene sulfate is realized.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

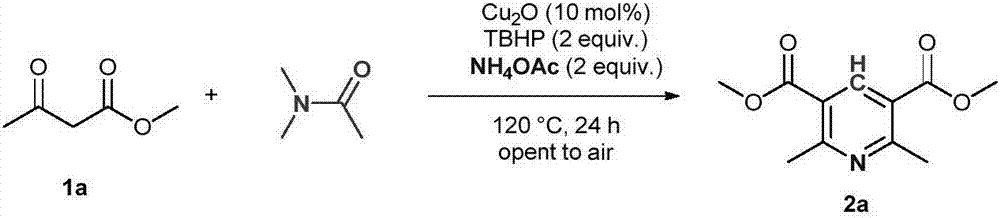

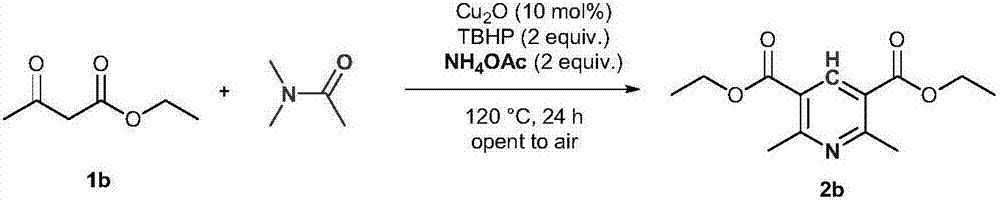

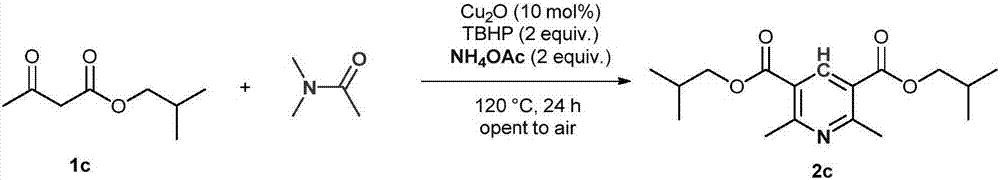

Preparation method of 2,3,5,6-tetra-substituted symmetric pyridine

The invention discloses a preparation method of 2,3,5,6-tetra-substituted symmetric pyridine. Specifically, the symmetric 2,3,5,6-tetra-substituted pyridine is prepared by taking beta-ketonic ester as a reaction substrate, a metal copper compound as a catalyst, a peroxide reagent as an oxidizing agent, inorganic ammonium salt as a nitrogen source and N-methylformamides as an organic solvent (also as a carbon source) and through carbon-hydrogen and carbon-nitrogen removal, dehydration condensation and an oxidation aromatization reaction. The preparation method disclosed by the invention has the characteristics of easily available raw materials, cheap and low-toxic catalyst, high catalytic efficiency, wide substrate range, simple and convenient operation, greenness and environmental friendliness and the like.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Preparation method of N-(4-ethoxycarbonylphenyl)-N'-methyl-N'-phenylformamidine

PendingCN110437105ALow costHigh purityOrganic chemistryTrifluoromethanesulfonic anhydrideUltraviolet lights

The invention discloses a preparation method of an ultraviolet light absorber UV-1. The ultraviolet light absorber UV-1 is prepared by condensation of ethyl p-aminobenzoate and N-methylformanilide inthe presence of thionyl chloride or trifluoromethanesulfonic anhydride. The condensation reaction comprises the following steps: performing a reaction at room temperature for 12-24 hours, heating thereactants to 45-60 DEG C, and performing a reaction for 5-10 hours. The molar ratio of the ethyl p-aminobenzoate to the N-methylformanilide is (1:0.5)-(1:1.5). The molar ratio of thionyl chloride or trifluoromethanesulfonic anhydride to N-methylformamide is 1:1-10:1. According to the method, trimethyl orthoformate / triethyl orthoformate can be prevented from being used as a main raw material, so that the cost for preparing the UV-1 is greatly reduced; thionyl chloride / trifluoromethanesulfonic anhydride is used as a reaction reagent of ethyl p-aminobenzoate and N-methylformyl aniline, so that the method is not only environment-friendly, but also can obtain higher reaction yield and product purity.

Owner:CHANGZHOU YONGHE FINE CHEM

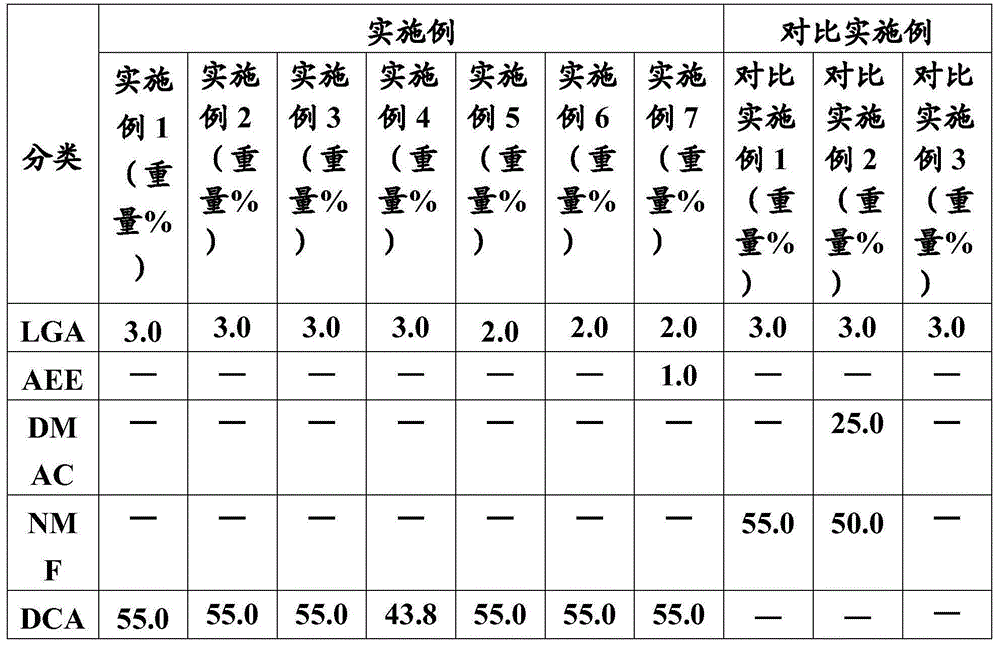

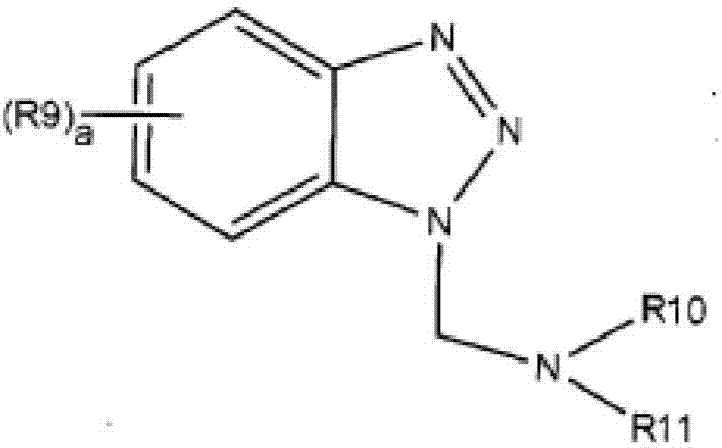

Stripping agent containing alkylamide mixture

ActiveCN103019049AImprove protectionReduce manufacturing costSemiconductor/solid-state device manufacturingPhotosensitive material processingAdditive ingredientPhysical chemistry

The invention relates to a stripping agent containing an alkylamide mixture. The stripping agent containing an alkylamide mixture comprises 50-70wt% of N-methylformamide, 30-50wt% of N,N-dimethylacetamide, and the balance water. The stripping agent containing an alkylamide mixture has water intersolubility, no corrosivity to copper or a copper alloy, and no toxicity to human and the environment. Because the stripping agent containing an alkylamide mixture only comprises the two main ingredients, the used stripping agent can be easily recovered by fractionation and is restructured into an original formula for recycle in the manufacturing process, thus the effects of reducing a cost and protecting the environment are achieved. The invention further provides a method for removing light resistance by the stripping agent containing an alkylamide mixture.

Owner:THE CHEMOURS CO FC LLC

Dimethrin microcapsules, preparation method therefor and insectproof preparation

InactiveCN109953021AReduce decompositionNormal temperature is goodBiocideAnimal repellantsN dimethylformamideSolvent

The invention discloses dimethrin microcapsules, a preparation method therefor and an insectproof preparation prepared from the dimethrin microcapsules. The microcapsules comprise capsule shells and capsule cores, wherein the capsule shells are prepared from polydopamine, the capsule cores are prepared from dimethrin, the dimethrin comprises one or more of lambda-cyhalothrin, beta-cyfluthrin, biphenthrin and cis-cypermethrin, and the capsule cores are wrapped in the capsule shells. The preparation method disclosed by the invention comprises the steps: (1) providing hollow polydopamine capsuleshells; and (2) providing a dimethrin solution, and enabling the dimethrin solution to enter the capsule shells to form the capsule cores, wherein N,N-dimethylformamide or N-methylformamide serves asa solvent of the solution. According to the dimethrin microcapsules, the preparation method therefor and the insectproof preparation, the chemical stability and released control of dimethrin pesticides are improved, the effect duration is prolonged, toxic or side effects are lowered, and the bioavailability is improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of cyclodextrin/photocatalyst composite modified carbon-based water purifying agent

InactiveCN108751319AWide variety of sourcesLow costWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionModified carbonChloroacetic acids

The invention relates to the technical field of water purifying agents, in particular to a preparation method of a cyclodextrin / photocatalyst composite modified carbon-based water purifying agent. Thepreparation method of the cyclodextrin / photocatalyst composite modified carbon-based water purifying agent comprises the following steps: annealing orange peel to obtain porous charcoal powder; sequentially performing a reaction on beta-cyclodextrin, chloroacetic acid and N-methylformamide to obtain graft-modified beta-cyclodextrin; performing a reaction on organic titanate, soluble metal salt and the porous charcoal powder in a sealed environment to obtain modified porous charcoal; compounding the modified beta-cyclodextrin, the modified porous charcoal and a silane coupling agent to obtainthe cyclodextrin / photocatalyst composite modified carbon-based water purifying agent. Through compounding of the porous charcoal, grafted amphoteric chitosan and modified titanium dioxide, the water purifying agent integrates the functions of adsorption, flocculation, catalytic degradation and the like, so that the effect of purifying a water body in multiple aspects is achieved.

Owner:ANHUI LEJIN ENVIRONMENT TECH CO LTD

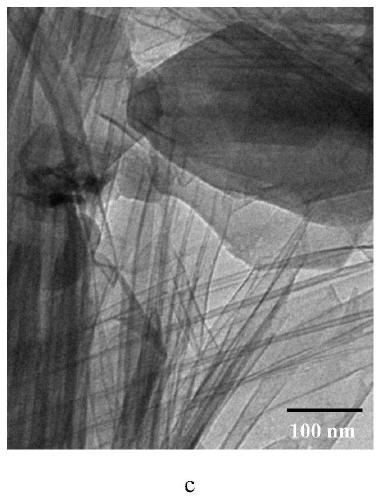

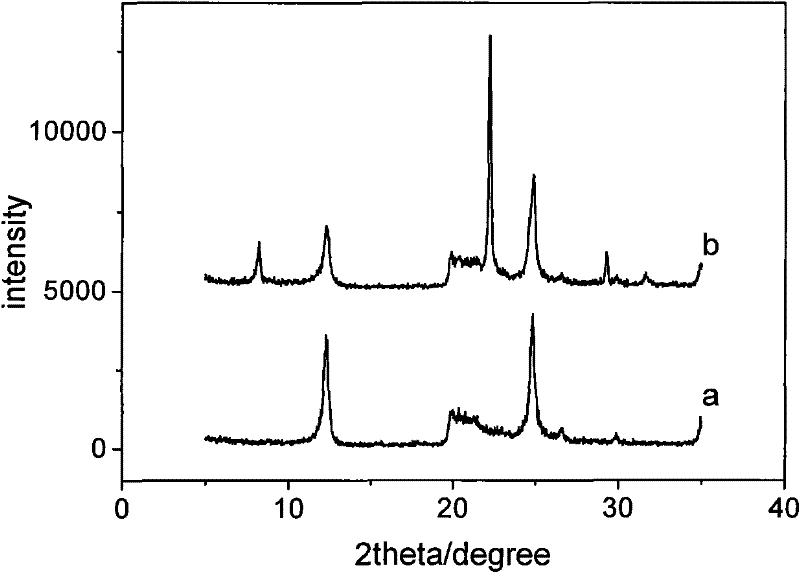

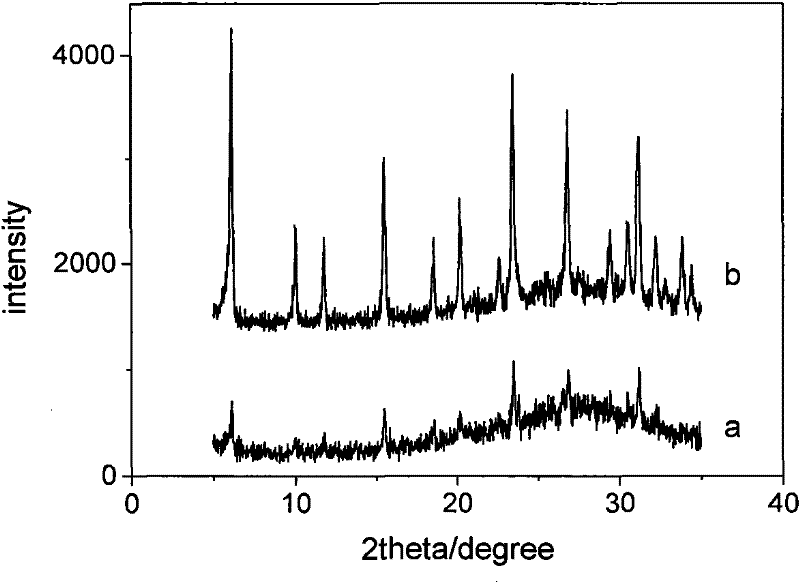

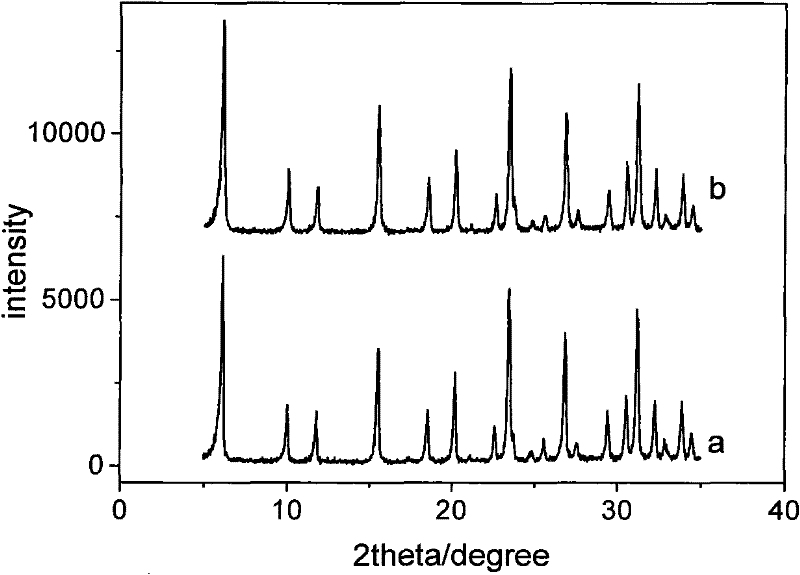

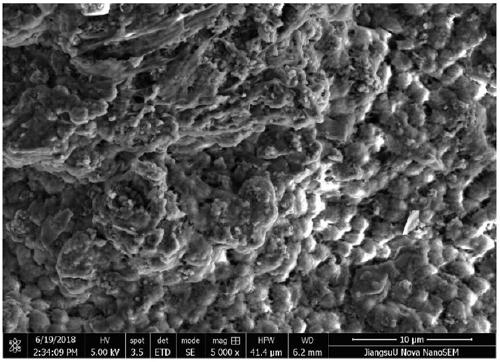

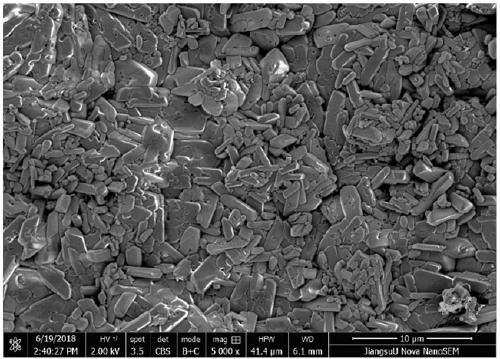

Preparation method of kaolin nanotubes

InactiveCN110156035AHigh yieldHigh economic valueMaterial nanotechnologySilicon compoundsHigh energyGraft reaction

The invention discloses a preparation method of kaolin nanotubes. The preparation method comprises the following steps: flaky kaolin and an intercalating agent (such as N-methylformamide) are mixed, then are ball-milled in a high-energy ball mill for 1 min to 24 h, and are dried; the obtained mixture and a solvent (such as methanol) are mixed, and then are ball-milled in the high-energy ball millfor 1 min to 24 h to carry out a surface grafting reaction; the obtained reaction product and a structure inducing agent (such as a quaternary ammonium salt surfactant) are mixed, and are ball-milledin the high-energy ball mill for 1 min to 24 h; and finally the obtained mixture is dried and calcined to obtain the kaolin nanotubes. The preparation method converts kaolin with a flaky crystal structure into kaolin with a tubular crystal structure in a short time and a high efficiency, breaks the bottleneck restricting a processing and preparation technology of a kaolin-based catalyst carrier material, and achieves the purposes of high efficiency and low energy consumption.

Owner:NANJING UNIV

Method for preparing Y-type molecular sieve by using kaolin

InactiveCN101857242BHigh molecular sieve contentHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMicrosphereSodium hydroxide

The invention discloses a method for preparing a Y-type molecular sieve by using kaolin, which comprises the following steps of: (1) introducing an intercalation reagent into the kaolin to prepare kaolin intercalation composite powder; (2) modifying the kaolin intercalation composite powder with silicon or directly roasting the kaolin intercalation composite powder at the temperature of between 450 and 1,030 DEG C; or modifying the kaolin intercalation composite powder with silicon or directly adding the kaolin intercalation composite powder into inorganic binder and water, uniformly mixing the three, spraying the mixture to obtain microspheres and then roasting the microspheres at the temperature of between 450 and 1,030 DEG C; and (3) mixing the roasted powder or microspheres and inorganic silicon source, sodium hydroxide solution, directing agent and water, and crystallizing the mixture to obtain powder or microspheres containing the NaY molecular sieve. The method is characterizedin that: the intercalation modified kaolin is used for synthesizing the NaY molecular sieve; the intercalation reagent is one or more of urea, dimethyl sulfoxide, potassium acetate, potassium propionate, formamide, long-chain amine with carbon atom number of 8 to 12 and N-methylformamide; and the NaY content of the synthesized powder or microspheres of the NaY molecular sieve is 40 to 100 percent.

Owner:EAST CHINA NORMAL UNIVERSITY

Direct-writing preparation method of high-flexibility organic electrode

ActiveCN109130168AImprove conductivityGood flexibilityAdditive manufacturing apparatusInksCarbon nanotubeDirect writing

The invention belongs to the field of preparation of piezoelectric thin film materials and relates to a direct-writing preparation method of a high-flexibility organic electrode. The method comprisesthe specific steps that firstly, a piezoelectric thin film 3D model is established and cut into a slice; then, multi-wall carbon nanotubes are weighed and mixed with an N-methylformamide solution, themixed solution is subjected to ultrasonic dispersion to be uniform, and a precursor solution is obtained; polyaniline, polyvinylidene fluoride and acetone are added, sealing and ultrasonic dissolvingare conducted until complete dissolution is achieved, and writing ink is obtained; finally, a writing process and technology are set, a writing program is started, and the organic electrode is obtained. According to the direct-writing preparation method of the organic electrode, on the basis of guaranteeing smooth printing, the high-conductivity and high-flexibility organic electrode can be obtained; through flexible design for a writing trajectory, shapes and patterns which cannot be obtained by a traditional technology are directly written, the writing trajectory program is controllable, the electrode size is more accurate, and the application prospect is wide.

Owner:JIANGSU UNIV

Stripper composition for removing photoresist and method of stripping photoresist using the same

ActiveCN105143984BReduced copper/oxygen ratioSemiconductor/solid-state device manufacturingPhotosensitive material processingOrganic solventPhotoresist

The present invention relates to a photoresist-removing stripper composition which does not comprise N-methylformamide, N, N'-dimethylcarboxamide, or the like, showing reproductive toxicity, but is capable of showing excellent stripping capacity and rinsing capacity and is capable of minimizing time-dependent deterioration of physical properties; and a method for stripping a photoresist using the composition. The photoresist-removing stripper composition comprises: one or more types of amine compounds; N, N'-diethylcarboxamide; and a protic organic solvent of alkyleneglycol monoalkylether or alkyleneglycol.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com