Composite solvent for recovering CS2 from viscose fiber waste gas by absorption process, and application thereof

A viscose fiber and compound solvent technology, applied in the field of industrial waste gas treatment, can solve the problems of high investment cost, difficult regeneration, low purification rate, etc., and achieve the effects of reducing process cost, solving solvent loss rate, and high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The waste gas to be treated in the present invention is derived from condensation recovery tail gas, containing 2100-2900mg / Nm 3 CS 2 , trace H 2 S and part of water vapor, due to the fact that under the existing experimental conditions, it is impossible to obtain the same CS as the actual composition of the factory 2 exhaust gas, so it is necessary for the CS used in the experiment 2 The exhaust gas is simulated, and the CS in the simulated exhaust gas 2 Content about 3000mg / m 3 , the water vapor content is about 1.0%.

[0030] Moisture content is measured using a trace moisture analyzer of the Karl Fischer method, and the calculation formula of moisture content W is:

[0031]

[0032] In the formula: W represents the water content, %; T represents the titer of Karl Fischer reagent to water, g / mL; V represents the injection volume, mL; m represents the mass of the sample, g.

[0033] Using TU-1900 double-beam ultraviolet spectrometer to CS 2 Measure the import ...

Embodiment 2

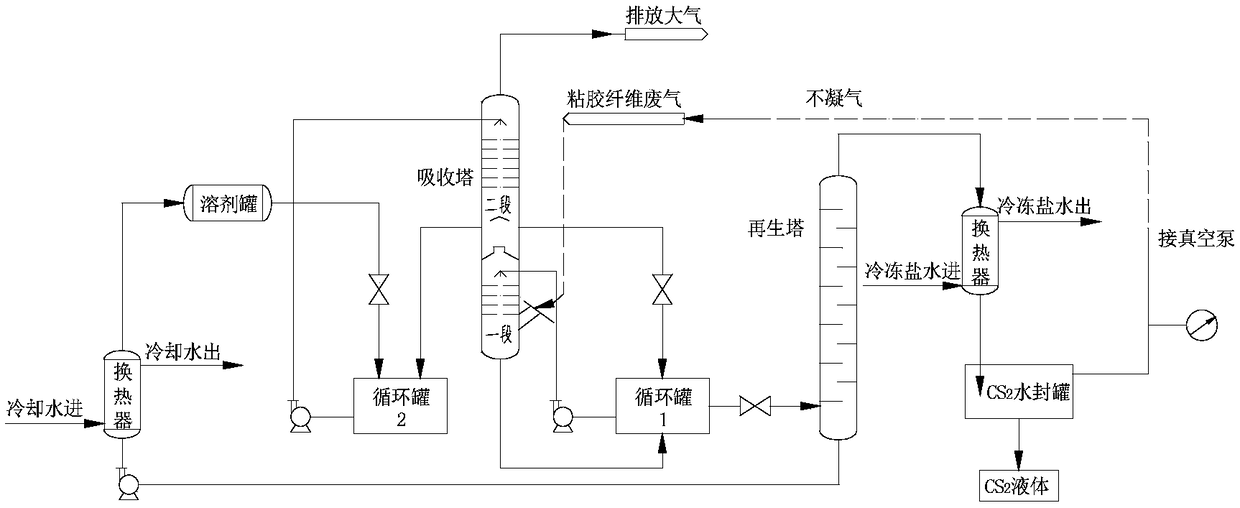

[0052] Adopt 80wt% NHD and 20wt% NMP to make composite solvent, absorb CS in viscose fiber 2 exhaust gas, which produces CS-containing 2 The absorbed rich liquid flows out from the outlet of the lower part of the absorption tower, enters the circulation tank 1, and then flows into the regeneration tower from the feed port of the lower part of the regeneration tower by the circulation tank 1 (the operating temperature of the regeneration tower is 120 ° C ~ 145 ° C, and the operating pressure is 10kPa~40kPa) under reduced pressure distillation, regenerated lean liquid (CS 2 The content is less than 0.5‰, and the water content is less than 0.5%) flows out from the outlet of the lower section of the regeneration tower, and is cooled to 18-20°C by the condenser (the cooling medium is cooling water), stored in the solvent tank, and regularly flows into the circulation tank 2 . The results are shown in Table 3.

[0053] Table 3 Repeated absorption effect

[0054]

[0055] It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com