Method for preparing Y-type molecular sieve by using kaolin

A kaolin, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, fajhedral crystalline aluminosilicate zeolite, etc., can solve problems such as consumption and high thermal energy, and achieve the effects of reducing energy consumption, low calcination temperature, and small crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Mix urea, raw kaolin powder and water in a mass ratio of 1.0:1.0:1.4 to form a slurry, and vigorously stir at 95° C. for 1.5 hours. After the reaction is finished, filter with suction and dry at 80° C. to obtain a kaolin-urea intercalation complex.

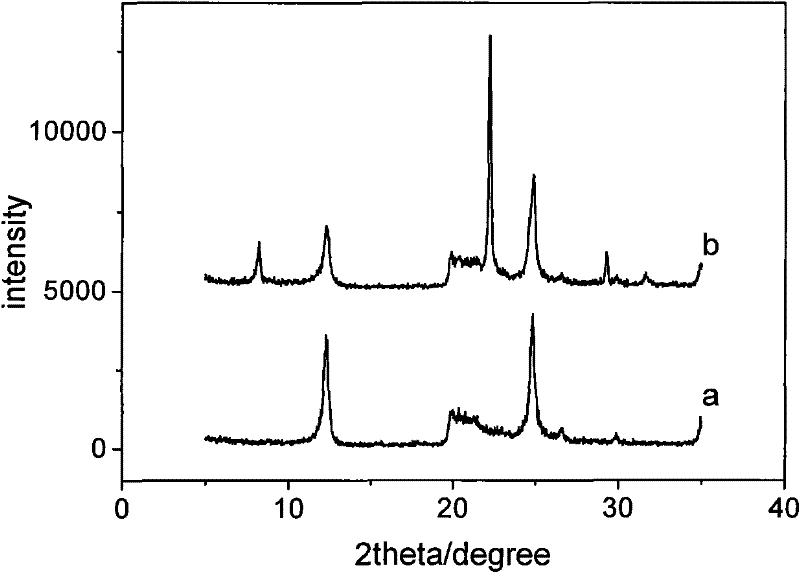

[0035] (2) directly calcining the intercalation compound obtained in step (1) at 600° C. for 2 hours to obtain metakaolin powder. NaY-3 was synthesized according to the method of Comparative Example 1. The relative crystallinity of NaY-3 determined by X-ray diffraction is 80.2%, and the silicon-aluminum ratio is 3.5. X-ray patterns such as image 3 (a) shown.

Embodiment 2

[0037] Prepare NaY-4 by the method for embodiment 1. The only difference is that the intercalation complex was fired at 830°C for 2 hours. The relative crystallinity in NaY-4 was determined to be 86.9% by X-ray diffraction, and the silicon-aluminum ratio was 3.3. X-ray patterns such as image 3 (b) shown.

Embodiment 3

[0039] Prepare NaY-5 by the method for embodiment 1. The only difference is that metakaolin calcined at 830°C and high-temperature calcined clay calcined at 950°C are mixed at a mass ratio of 3:7 for in-situ crystallization. The relative crystallinity in NaY-5 was determined by X-ray diffraction to be 20.0%, and the silicon-aluminum ratio was 4.66.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com