Forming method and forming catalyst of titanium silicon molecular sieve and its application and method for oxidation of cyclohexanone

A technology of titanium-silicon molecular sieve and molding method, which is applied in the field of cyclohexanone oxidation, can solve the problems of definite hydroxy acid selectivity, achieve high hydroxy acid selectivity, high pore volume and crush resistance, and overcome the production process complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] According to a preferred embodiment of the present invention, the aqueous mixture also contains Al element, preferably Al 2 o 3 The content of the calculated Al element is 0.05-10% by weight. The catalyst thus obtained is used in the oxidation reaction of cyclohexanone with higher hydroxy acid selectivity.

[0026] According to the method of the present invention, as long as the above-mentioned elements are contained in the mixture, the purpose of the present invention can be achieved. The present invention has no special requirements for the raw materials of each element, which can be determined according to the type of raw material of the crystallization mother liquor, for example, the provision of silicon element The silicon source can be an organic silicon source and / or an inorganic silicon source.

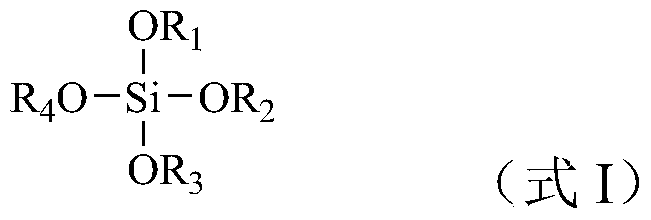

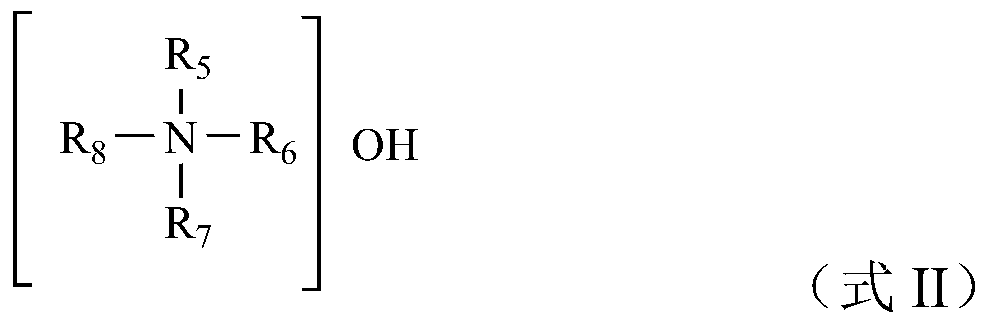

[0027] Specifically, the organosilicon source can be, for example, one or more selected from the silicon-containing compounds shown in formula I,

[0028]

[0029...

Embodiment 1

[0081] (1) Titanium-silicon molecular sieve TS-1 was prepared according to the method in Example 1 of US4410501, and the crystallization mother liquor was collected. The specific operation process is:

[0082] Place 455 g of tetraethyl orthosilicate in a CO-free 2 Then, 15 g of tetraethyl titanate and 800 g of aqueous solution of tetrapropylammonium hydroxide with a concentration of 25% by weight were successively added into the reactor in the atmosphere. After stirring for 1 hour, the temperature was raised to 80-90°C and stirring was continued for 5 hours. Then, deionized water was added to the reaction solution until the total volume of the reaction solution was 1.5 L. Next, the reaction solution was transferred to a high-pressure reactor equipped with a stirring device, and after hydrothermal crystallization at 175°C for 10 days under autogenous pressure, the resulting reaction mixture was filtered to collect the crystallization mother liquor, and the filtered solid was ...

Embodiment 2

[0096] The same method as in Example 1 is used to prepare the shaped titanium-silicon molecular sieve. The difference is that in step (1), the crystallization mother liquor is concentrated to the total amount of the crystallization mother liquor, and the SiO 2 The silicon element content is 3.5% by weight, based on TiO 2 The content of titanium element is 0.09% by weight, expressed as NH 3 The calculated nitrogen content is 8.6% by weight, and step (2) mixes 10 g of titanium-silicon molecular sieve TS-1 prepared in step (1) with 10 g of crystallization mother liquor obtained in step (1).

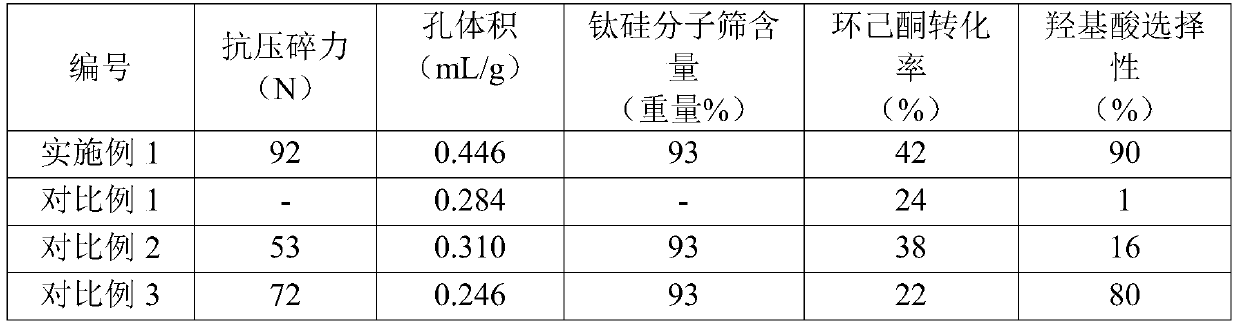

[0097] Table 1 lists the crush resistance, titanium-silicon molecular sieve content, cyclohexanone conversion, and hydroxy acid selectivity of the obtained shaped titanium-silicon molecular sieve (volume average particle diameter of 81 microns).

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing resistance | aaaaa | aaaaa |

| crushing resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com