Direct-writing preparation method of high-flexibility organic electrode

An organic electrode and highly flexible technology, applied in the direction of additive manufacturing, manufacturing tools, manufacturing auxiliary devices, etc., can solve the problems of affecting electrode stability, affecting conductivity, and complicated operation, so as to save raw material costs, not easy to peel off and loose, Electrode Dimensionally Precise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

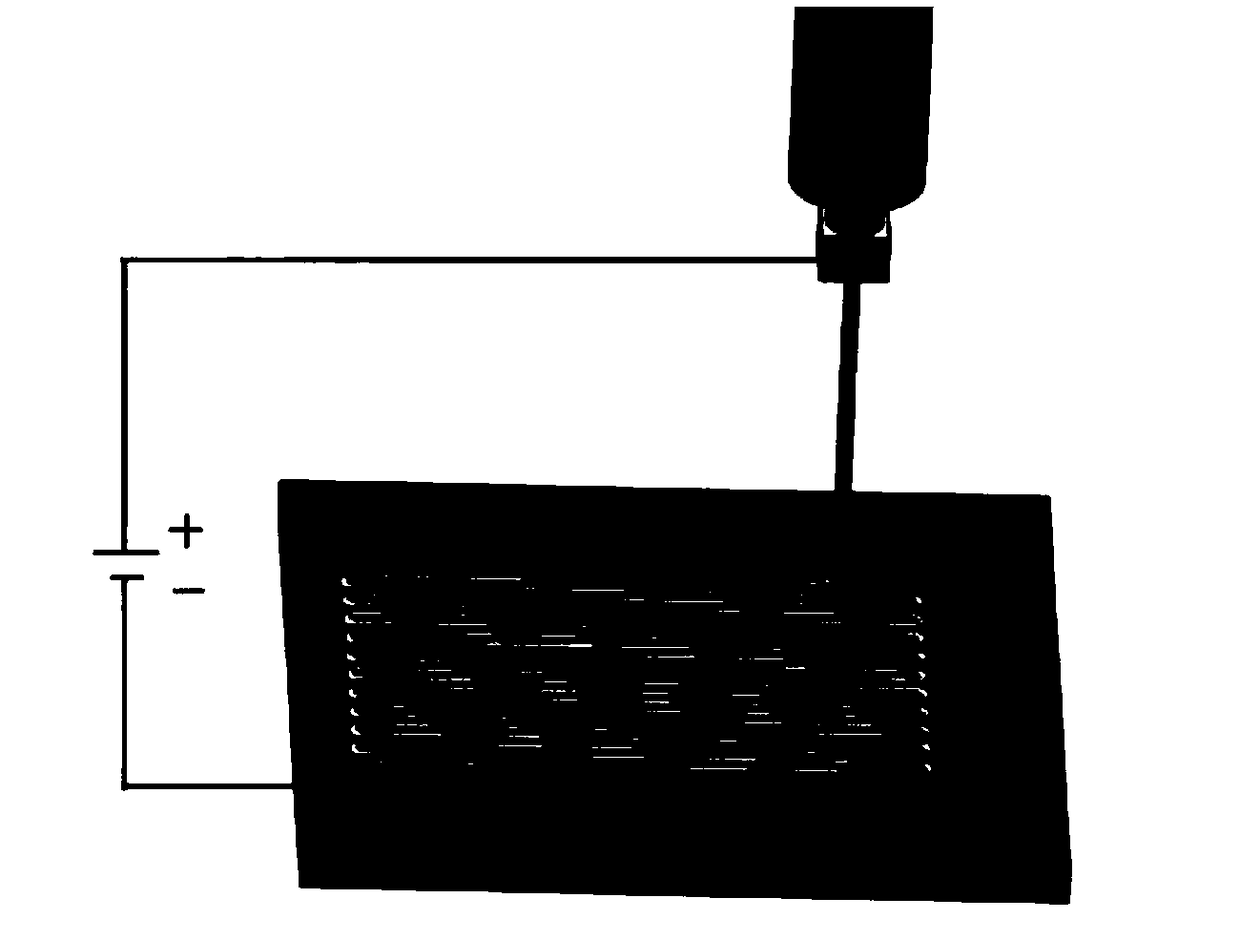

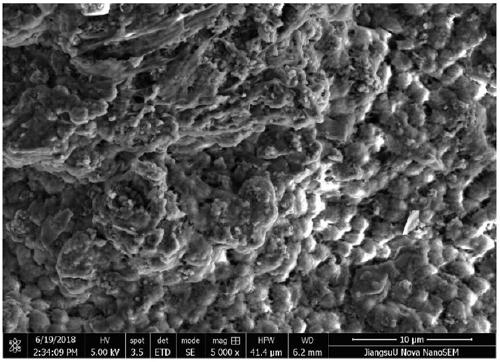

Embodiment 1

[0031] Use Soildworks software to build a 20mm×20mm×0.5mm film electrode 3D model, and use Cura software to slice the established 3D model. The slice parameters are: layer thickness 0.01 mm, number of printing layers is 50 layers, and the needle tip moving speed is set at 30 mm / s, the trajectory is woven with non-woven fabric. Weigh 0.6 g of conductive polyaniline and dissolve it in 8.1 g of N-methylformamide, seal and ultrasonically disperse for 3 h, weigh 0.4 g of polyvinylidene fluoride and 0.9 g of acetone, add to the above PANI solution and seal for 3 h to prepare a mixture containing 6wt%PANI, 4wt%PVDF and 9wt% acetone printing ink; draw 3 mL of printing ink with a syringe, and assemble the needle; connect the positive pole of the high-voltage DC power supply to the needle, connect the negative pole of the high-voltage DC power supply to the copper plate at the bottom of the base plate, and fix the needle tube , after adjusting the distance between the needle and the bo...

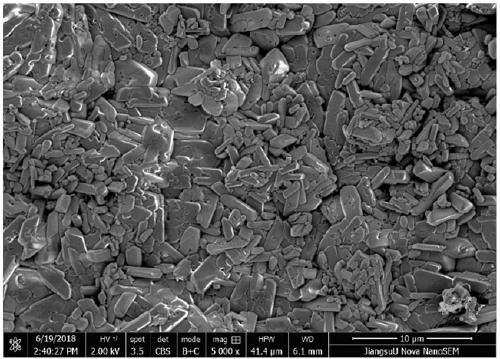

Embodiment 2

[0033] Use Soildworks software to build a 3D model of a circular thin-film electrode with a diameter of 20 mm and a thickness of 1 mm. Use Cura software to slice the established 3D model. The slice parameters are: layer thickness 0.01 mm, number of printing layers is 100 layers, and needle tip movement is set. The speed is 30mm / s, and the motion trajectory is set as concentric circles. Weigh 1.5 g conductive polyaniline and dissolve in 6.8 g N-methylformamide (DMF), seal and ultrasonically disperse for 3 h, weigh 0.8 g polyvinylidene fluoride and 0.9 g acetone into the above PANI solution and seal for 3 h, Prepare printing ink containing 15wt% PANI, 8wt% PVDF and 9wt% acetone; draw 3 mL of printing ink with a syringe, assemble a needle, connect the positive pole of the high-voltage DC power supply to the needle, and connect the negative pole of the high-voltage DC power supply to the copper plate at the bottom of the bottom plate. Fix the needle tube, adjust the distance betwe...

Embodiment 3

[0035] Use Soildworks software to build a 3D model of a circular thin-film electrode with a diameter of 20 mm and a thickness of 1 mm. Use Cura software to slice the established 3D model. The slice parameters are: layer thickness 0.01 mm, number of printing layers is 100 layers, and needle tip movement is set. The speed is 30mm / s, and the motion trajectory is set as concentric circles. Weigh 1.0 g of conductive polyaniline and dissolve it in 7.5 g of N-methylformamide (DMF), seal and ultrasonically disperse for 3 h, weigh 0.6 g of polyvinylidene fluoride and 0.9 g of acetone into the above PANI solution and seal for 3 h. , prepared as printing ink containing 10wt% PANI, 6wt% PVDF and 9wt% acetone; draw 3 mL of printing ink with a syringe, assemble a needle, connect the positive pole of the high-voltage DC power supply to the needle, and connect the negative pole of the high-voltage DC power supply to the copper plate at the bottom of the bottom plate . After fixing the needle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com