Process for recovering high-purity N-methyl formamide from waste stripping solution

A technology of methylformamide and stripping solution, applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problems of limited use, difficulty in recovering high-purity products, low product quality, etc., and achieve negative impact and considerable economic value , The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

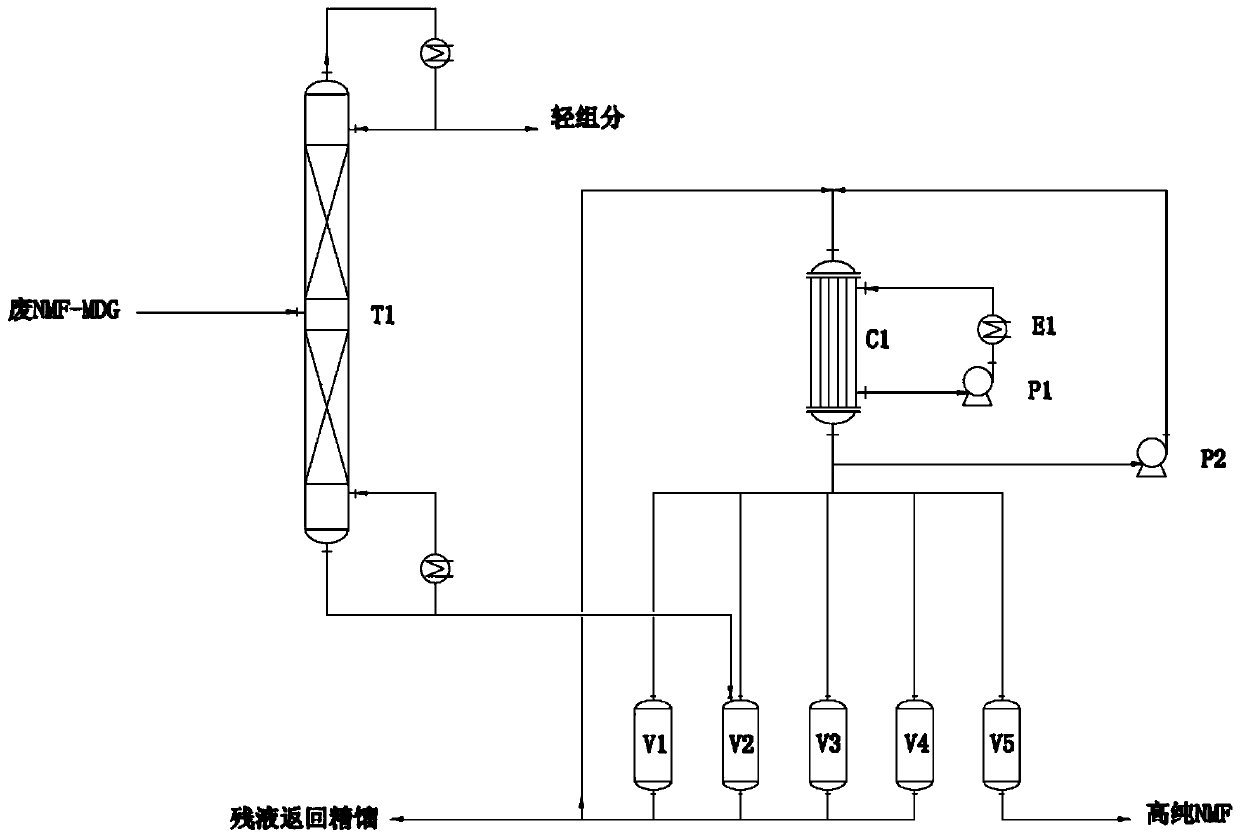

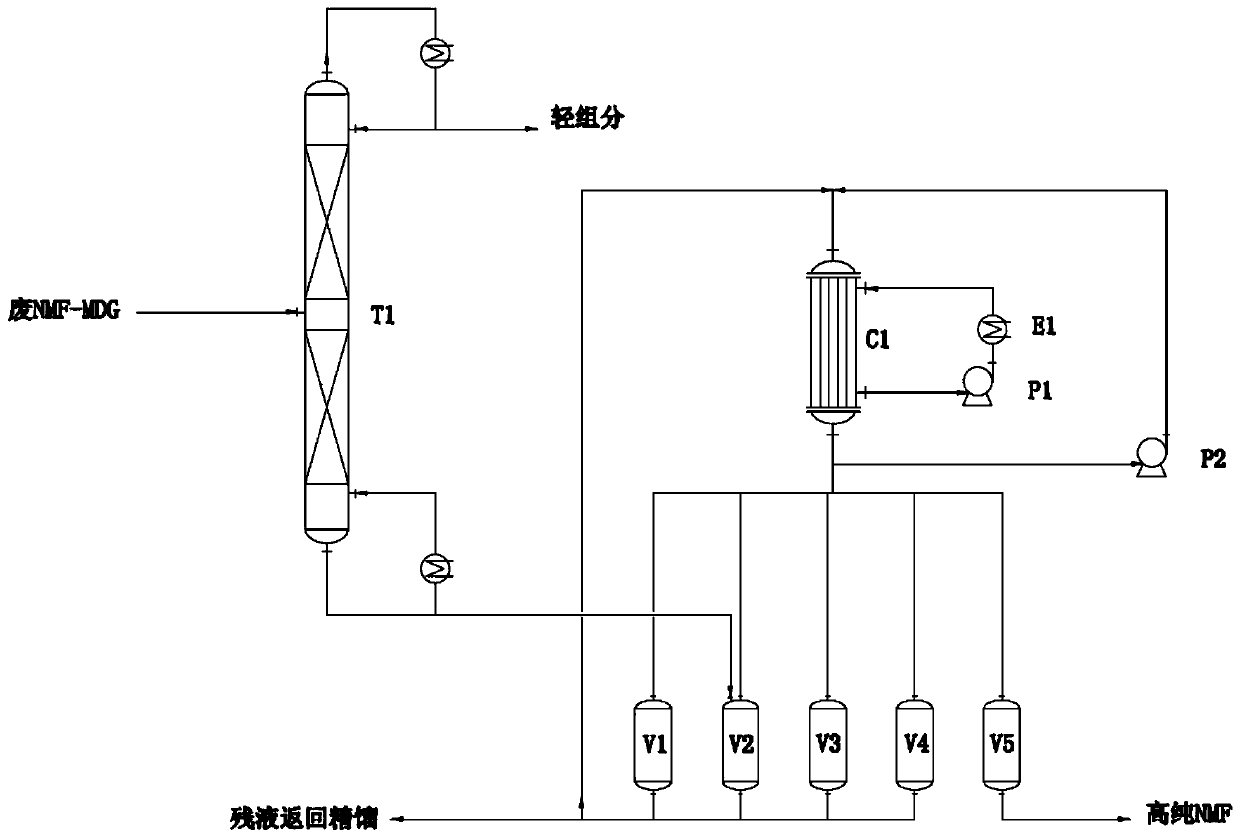

[0021] A kind of technique that reclaims high-purity N-methylformamide from waste stripping solution, its flow chart sees figure 1 shown, including the following steps:

[0022] (1) rectification: carry out rectification in the lightening rectification tower, the stripping liquid rectification of waste N-methylformamide and diethylene glycol methyl ether obtains the NMF crude product of mass concentration 80%;

[0023] (2) Melting crystallization: using a falling film crystallizer, use a chilled water control system to control the system temperature to -10°C~0°C, and distribute the molten NMF crude product at -10°C~-5°C from the feed liquid at the upper part of the crystallizer The device flows down along the inner wall of the crystallization tube, the frozen water and the molten material are kept circulating, and the temperature is lowered to -15~-10°C at a rate of 1°C / h to crystallize NMF, and the uncrystallized raffinate is collected and reused for rectification process; ...

Embodiment 2

[0029] A kind of technique that reclaims high-purity N-methylformamide from waste stripping solution, its flow chart sees figure 1 shown, including the following steps:

[0030] (1) rectification: carry out rectification in the lightening rectification tower, the stripping liquid rectification of waste N-methylformamide and diethylene glycol methyl ether obtains the NMF crude product of mass concentration 90%;

[0031] (2) Melting crystallization: using a falling film crystallizer, use a chilled water control system to control the system temperature to -10°C~0°C, and distribute the molten NMF crude product at -10°C~-5°C from the feed liquid at the upper part of the crystallizer The device flows down along the inner wall of the crystallization tube, the frozen water and the molten material are kept circulating, and the temperature is lowered to -15~-10°C at a rate of 5°C / h to crystallize NMF, and the uncrystallized raffinate is collected and reused for rectification process; ...

Embodiment 3

[0037] A kind of technique that reclaims high-purity N-methylformamide from waste stripping solution, its flow chart sees figure 1 shown, including the following steps:

[0038] (1) rectification: carry out rectification in the lightening rectification tower, the stripping liquid rectification of waste N-methylformamide and diethylene glycol methyl ether obtains the NMF crude product of mass concentration 85%;

[0039] (2) Melting crystallization: using a falling film crystallizer, use a chilled water control system to control the system temperature to -10°C~0°C, and distribute the molten NMF crude product at -10°C~-5°C from the feed liquid at the upper part of the crystallizer The device flows down along the inner wall of the crystallization tube, the frozen water and the molten material are kept circulating, and the temperature is lowered to -15~-10°C at a rate of 3°C / h to crystallize NMF, and the uncrystallized raffinate is collected and reused for rectification process; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com