Patents

Literature

47results about How to "Overcome the disadvantage of high energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amphipathic polymer resin as well as preparation and use thereof in production of intelligent breathing coating

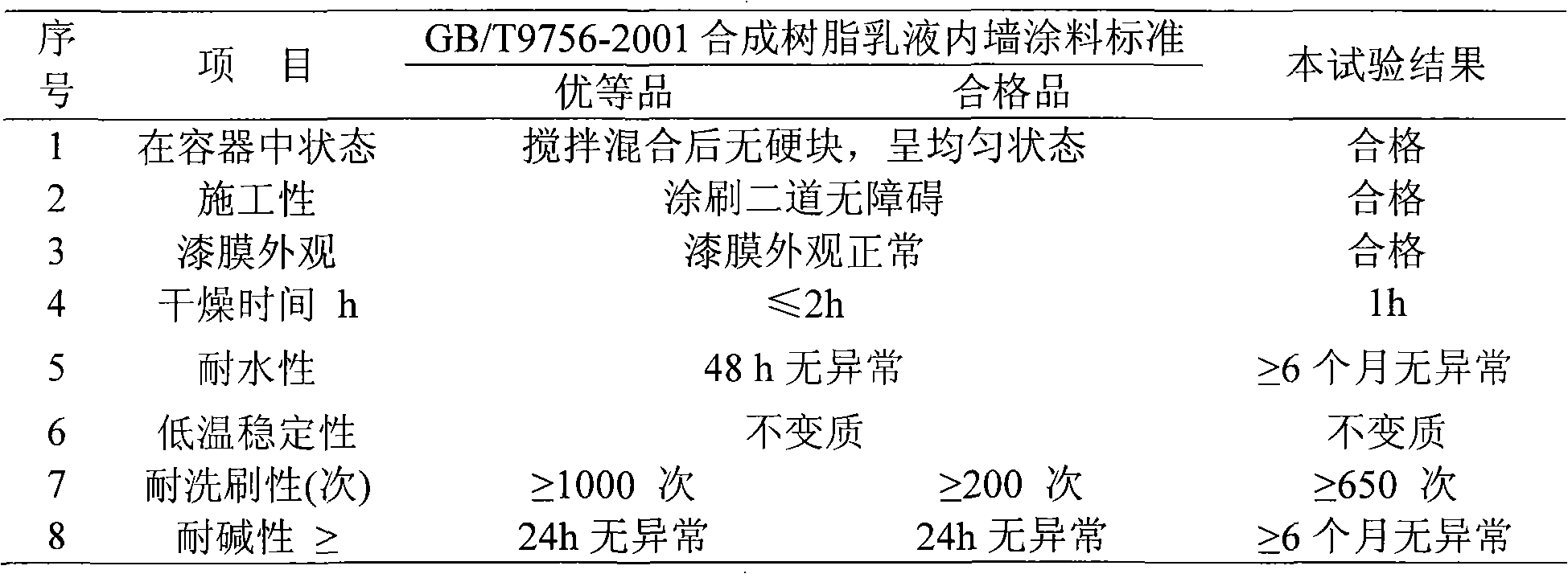

InactiveCN101250242AOvercome the disadvantage of high energy consumptionInhibit sheddingCoatingsPolymer resinThermal insulation

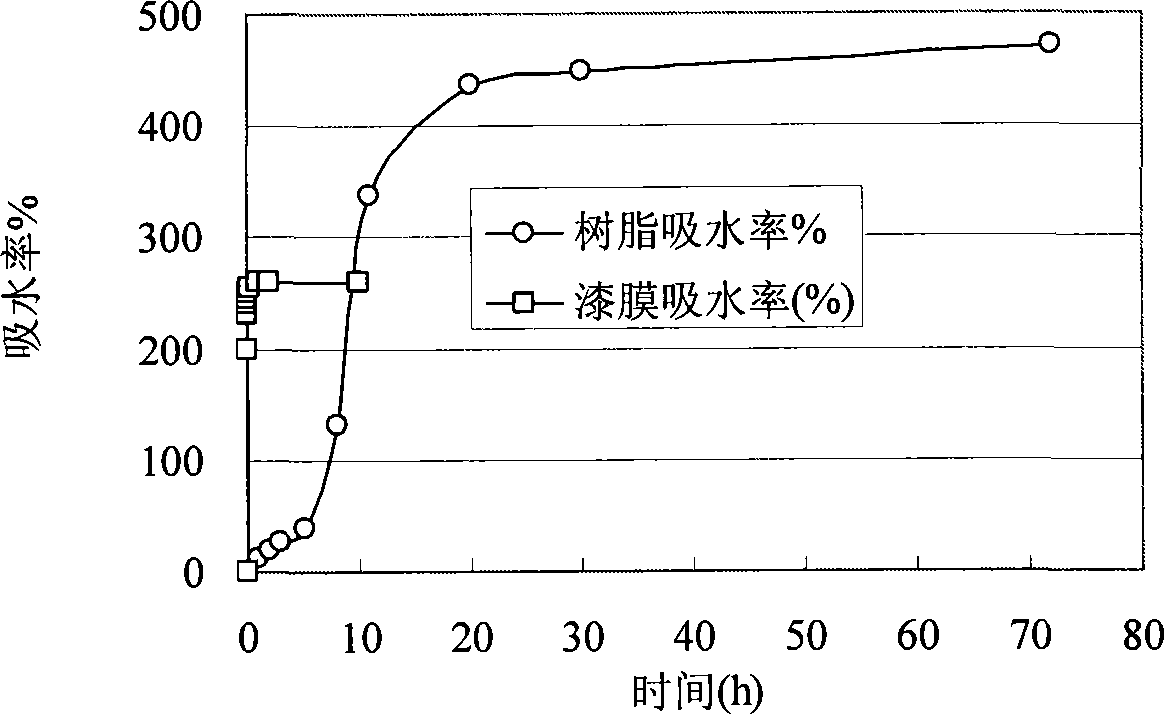

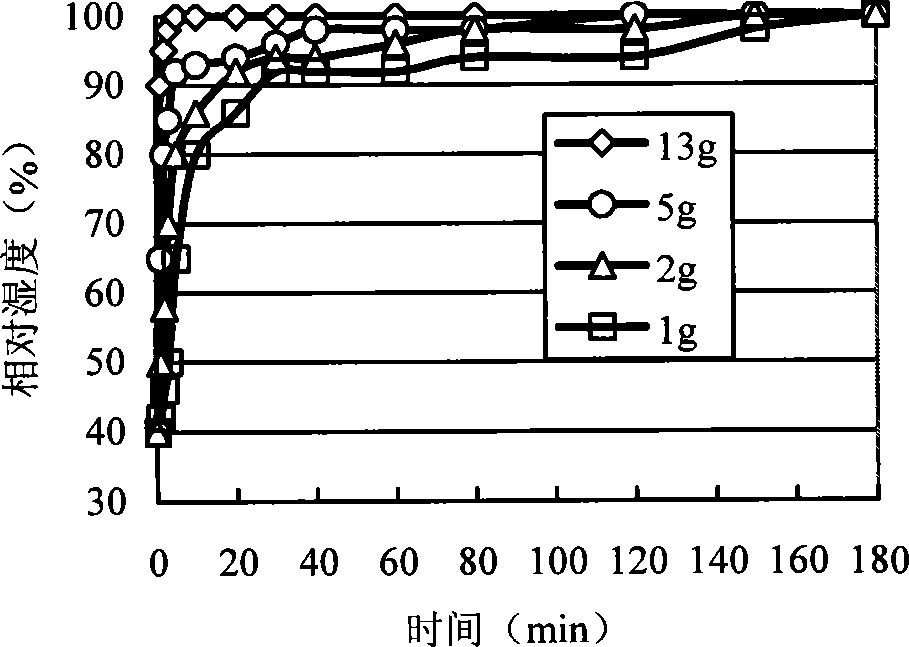

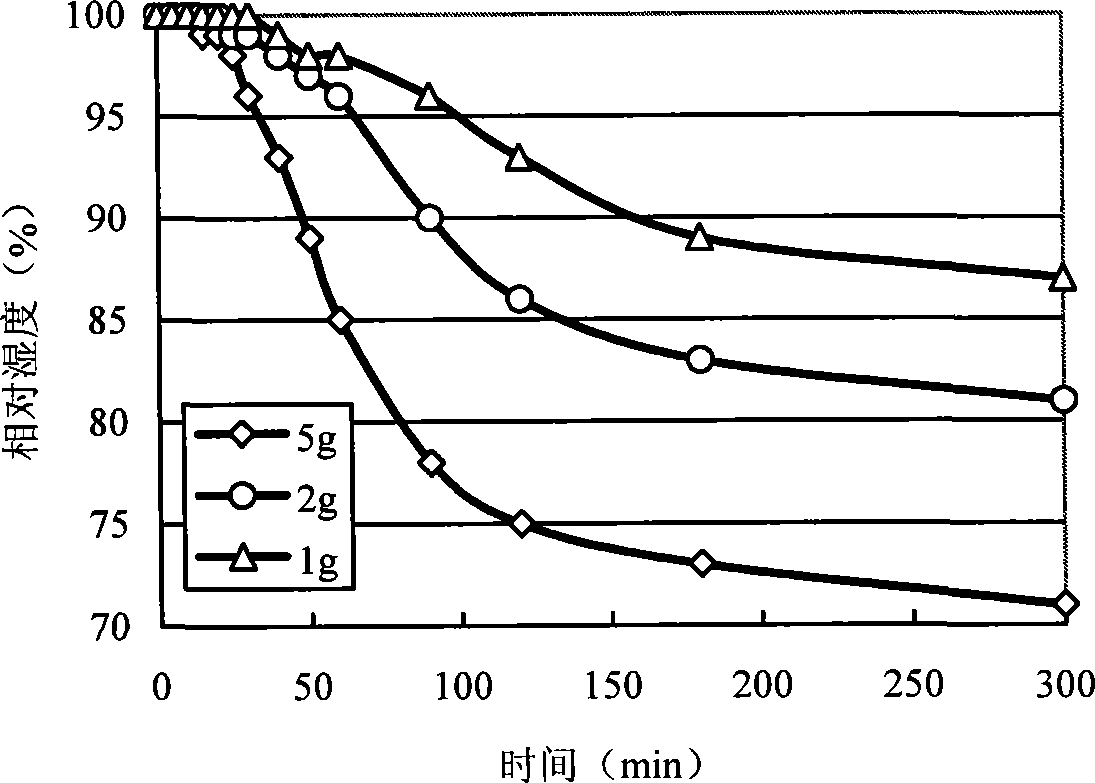

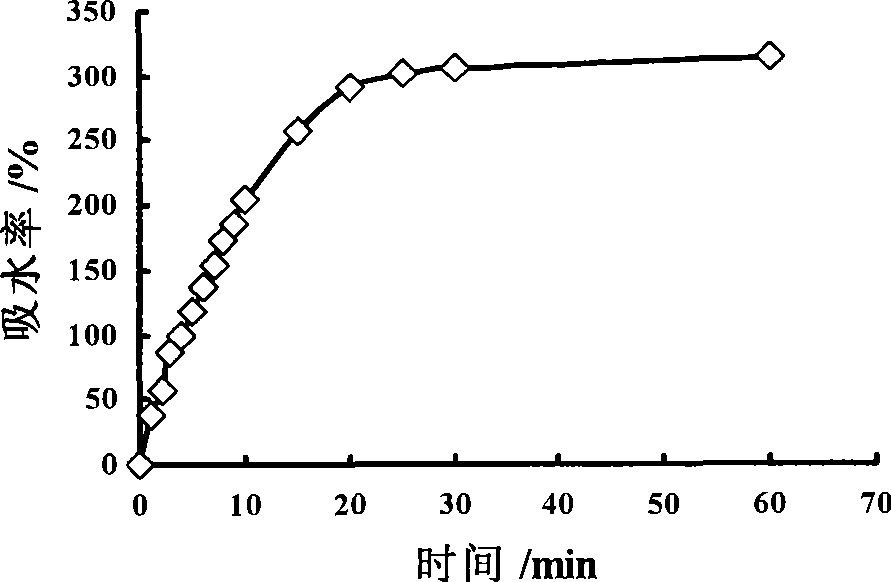

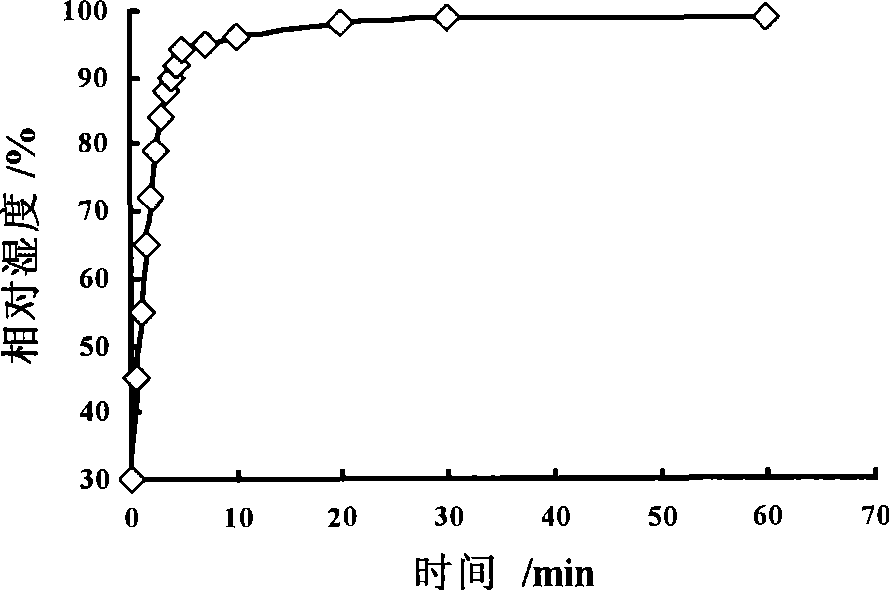

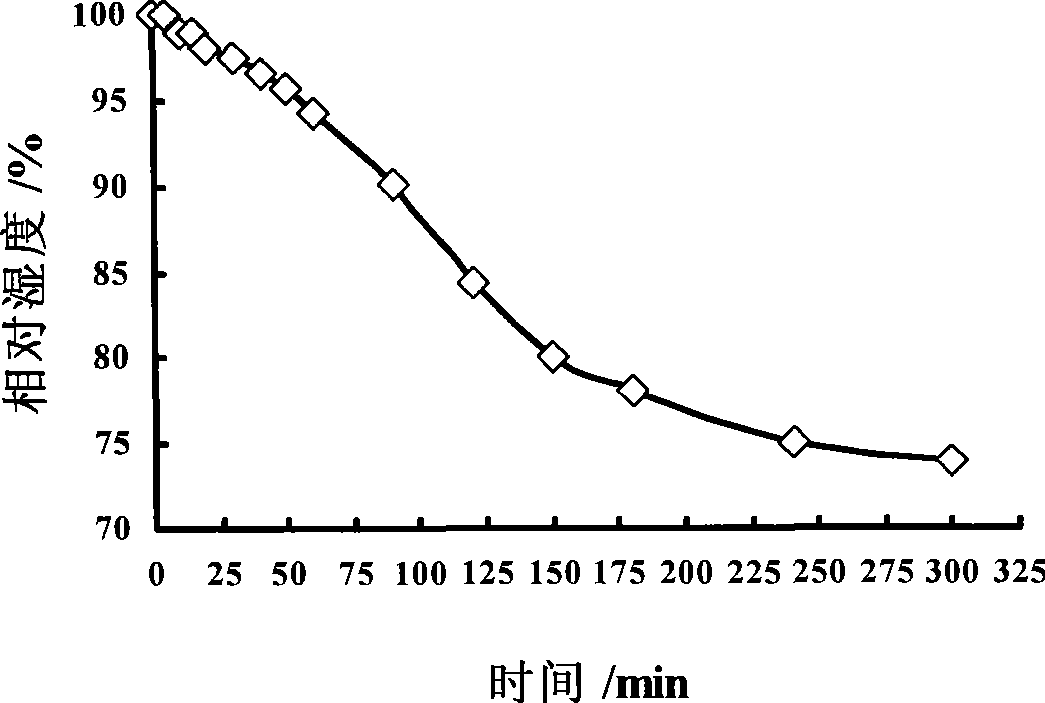

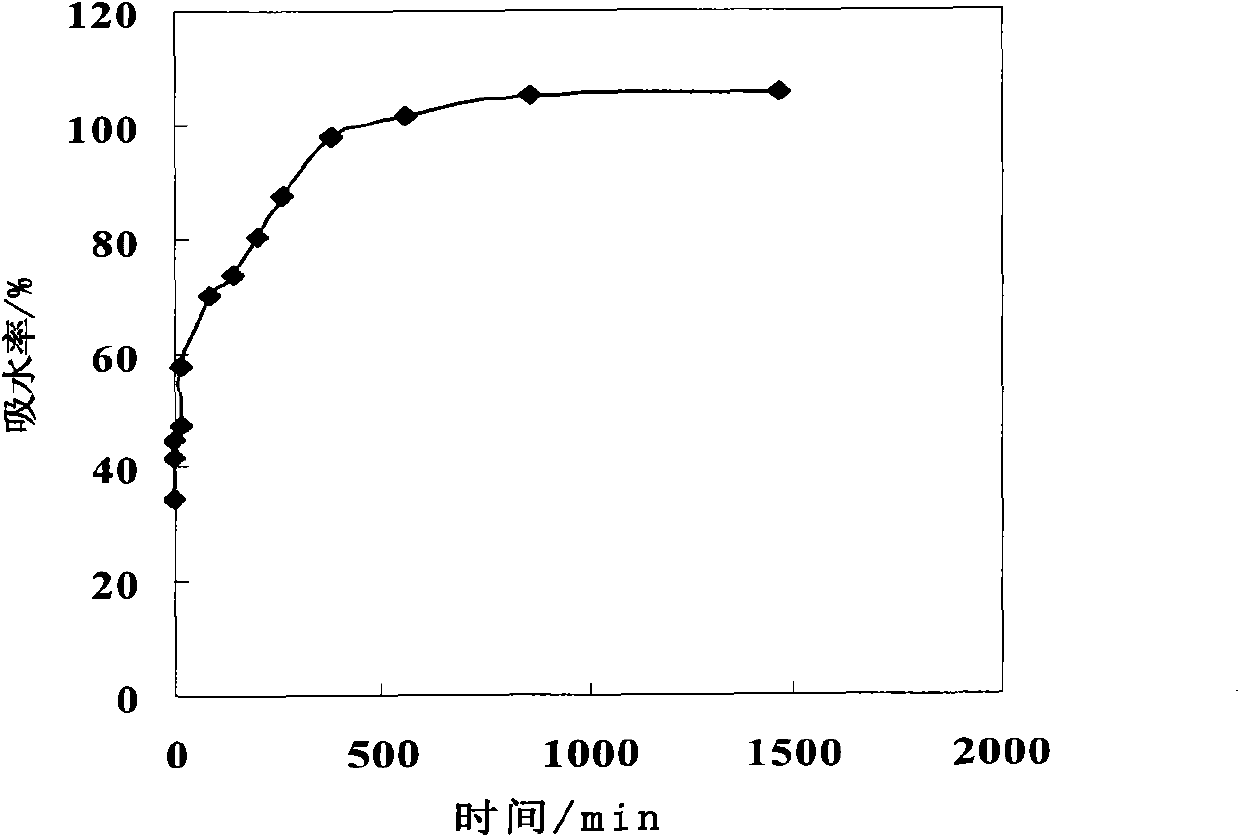

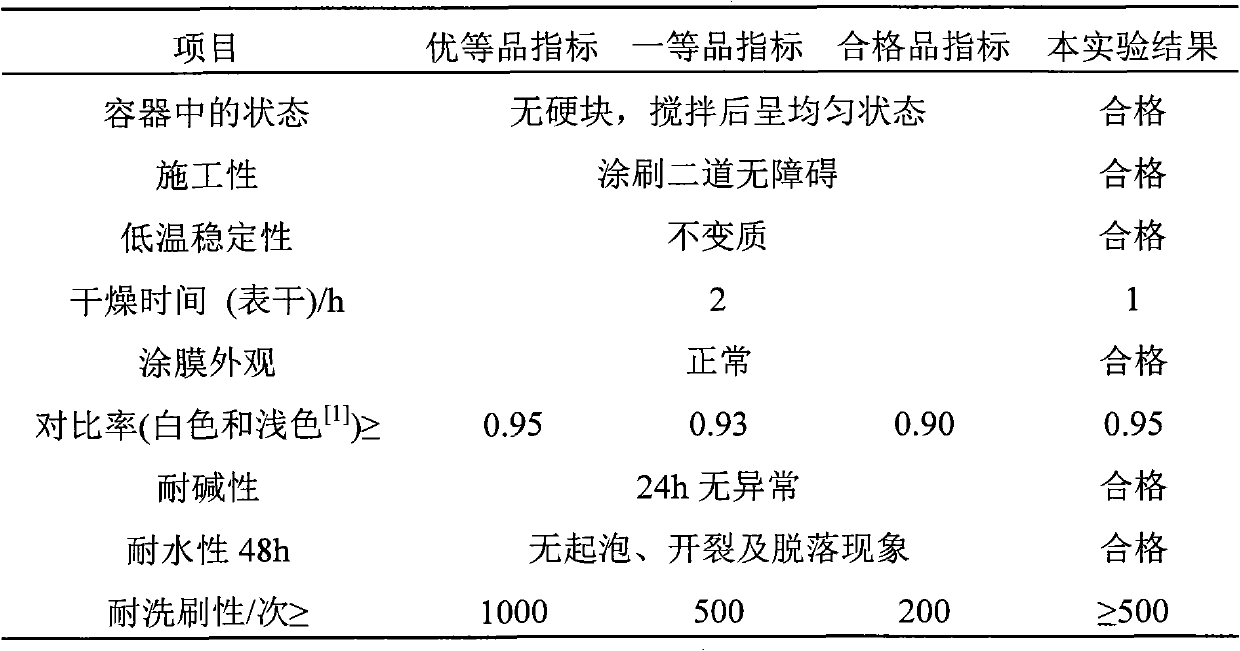

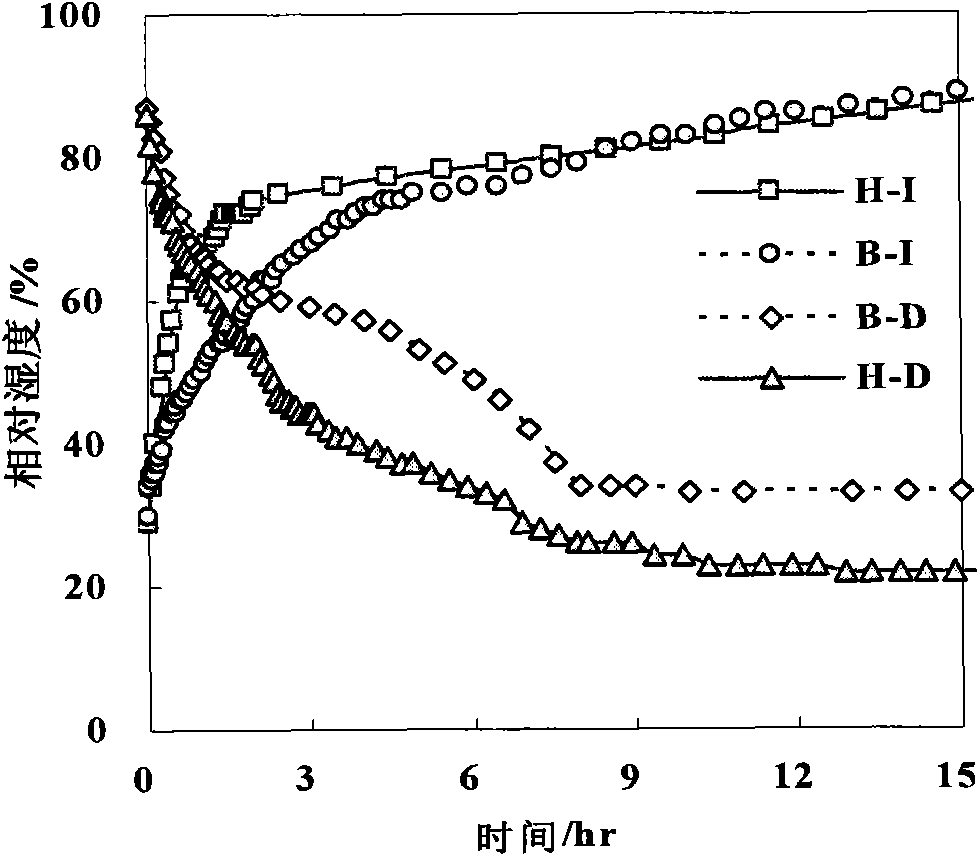

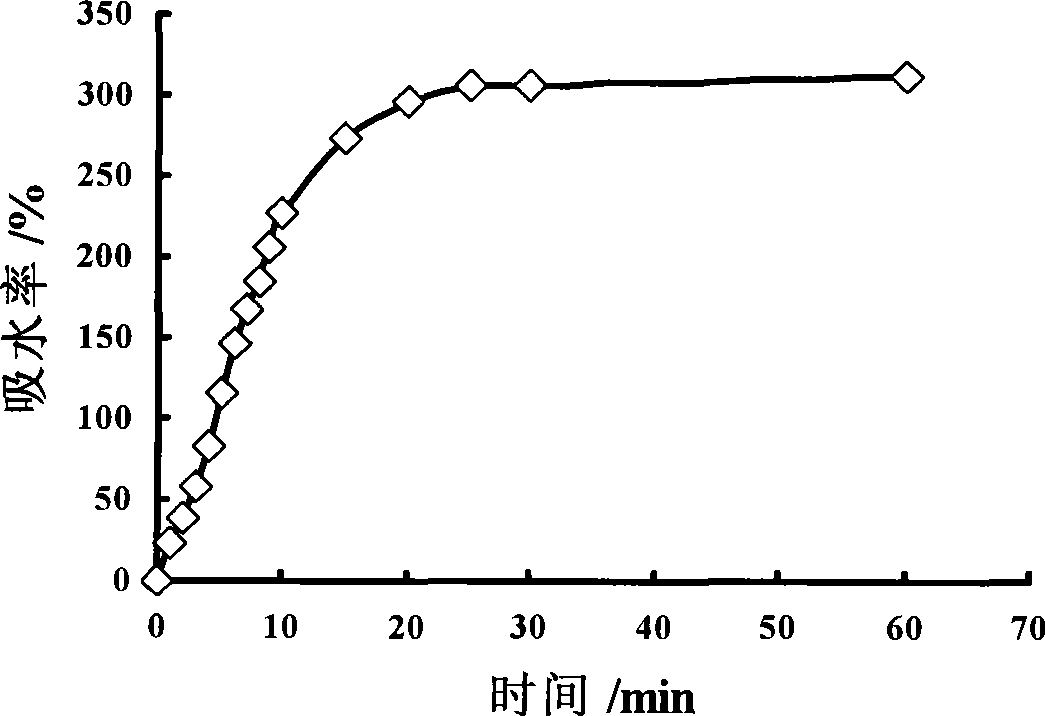

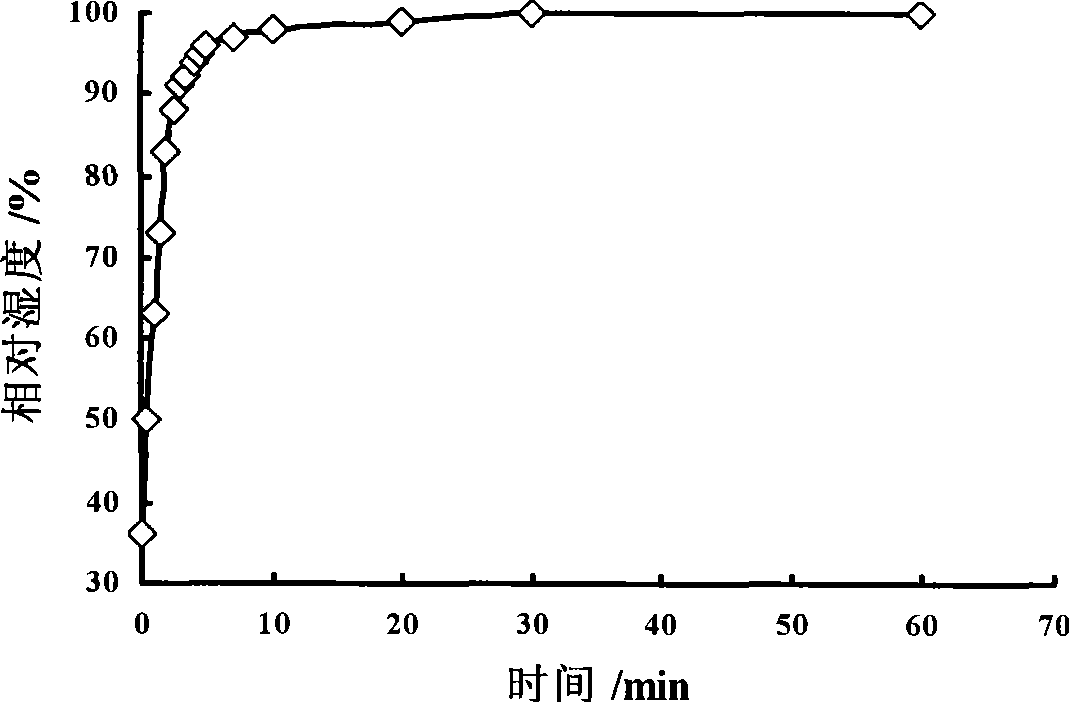

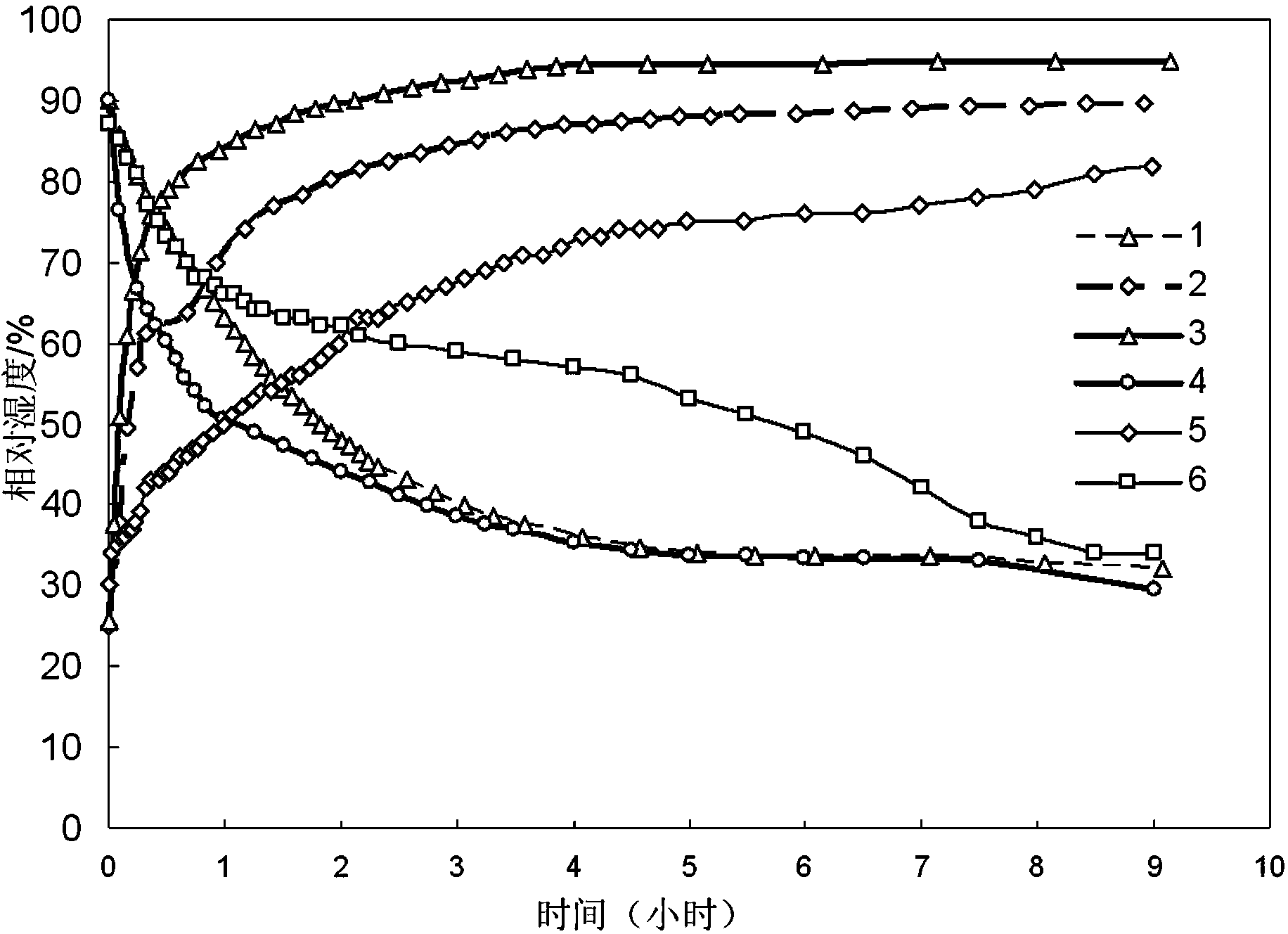

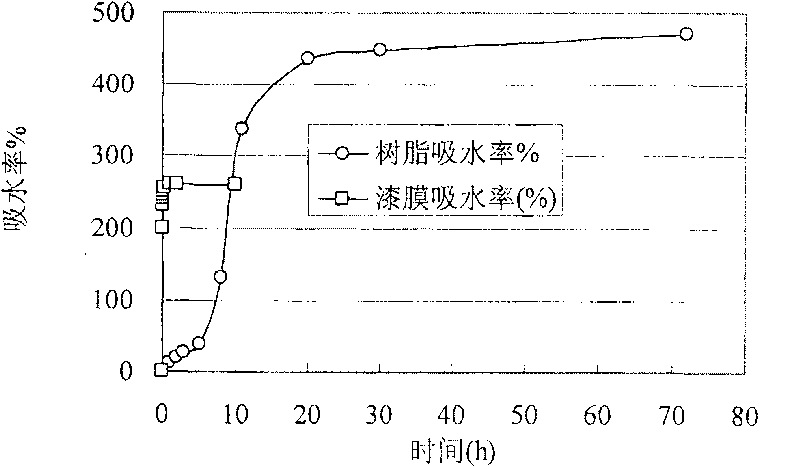

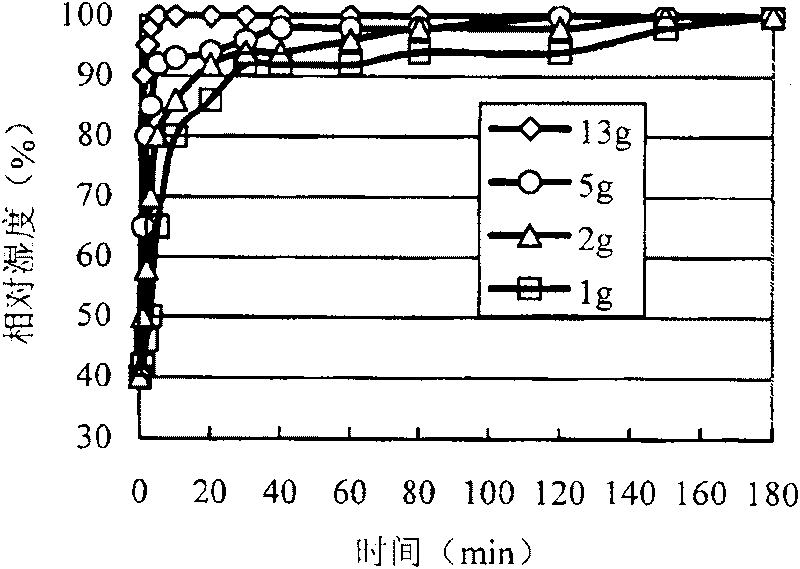

The invention provides an amphiphilic polymer resin with hydrophilicity and hydrophobicity, which is polymerized by methacrylic acid, methyl methacrylate, butyl acrylate, beta-hydroxypropyl methacrylate, acrylamide, diacetone acrylamide and adipic dihydrazide monomers or the like. The amphiphilic polymer resin can be used as main filming material of paint to combine various cell forming materials to prepare the paint with decorativeness, humidity adjustment, permeability, thermal insulation, dew prevention, water and alkali resistance and anti-bacterial property, as one multifunctional intelligent breath paint. The product can overcome the defects of traditional air conditioner as high energy consumption and can avoid paint from dropping off wall caused by leakage and water, thereby prolonging the service life of paint, and the invention has wide application.

Owner:NORTHWEST NORMAL UNIVERSITY

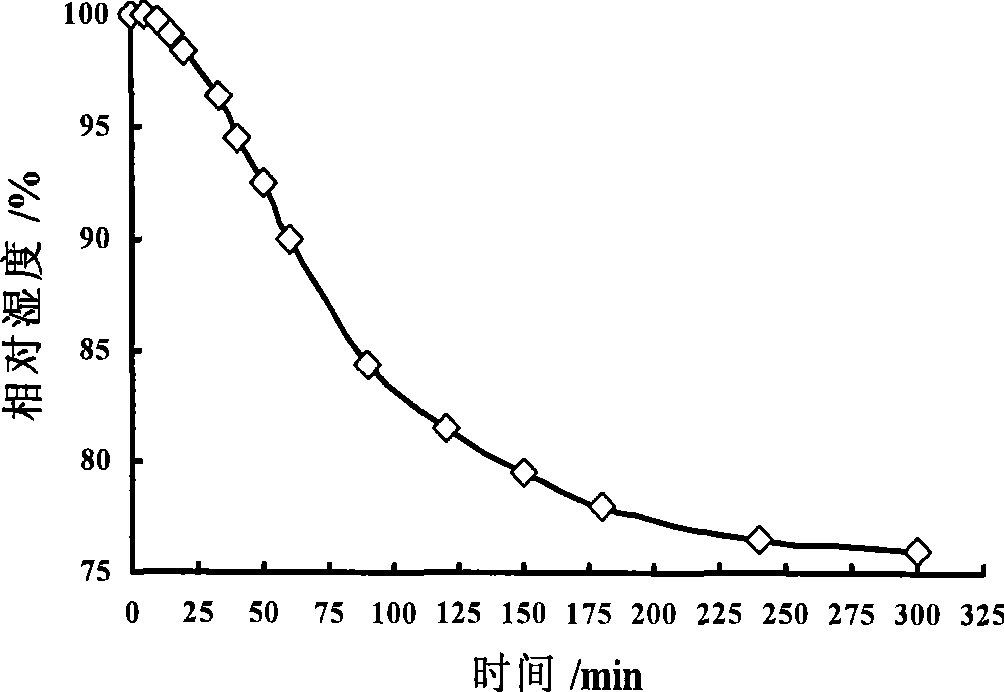

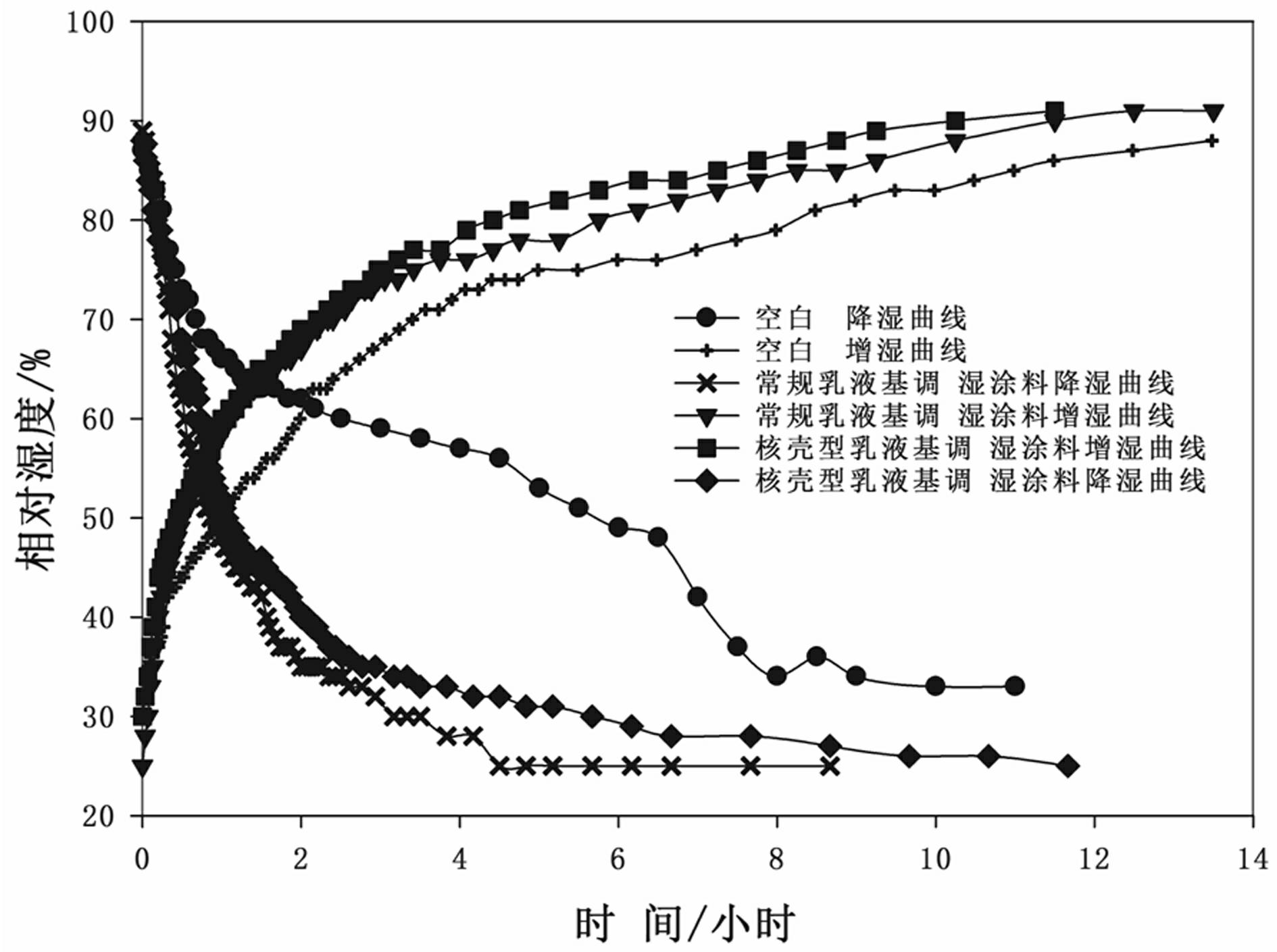

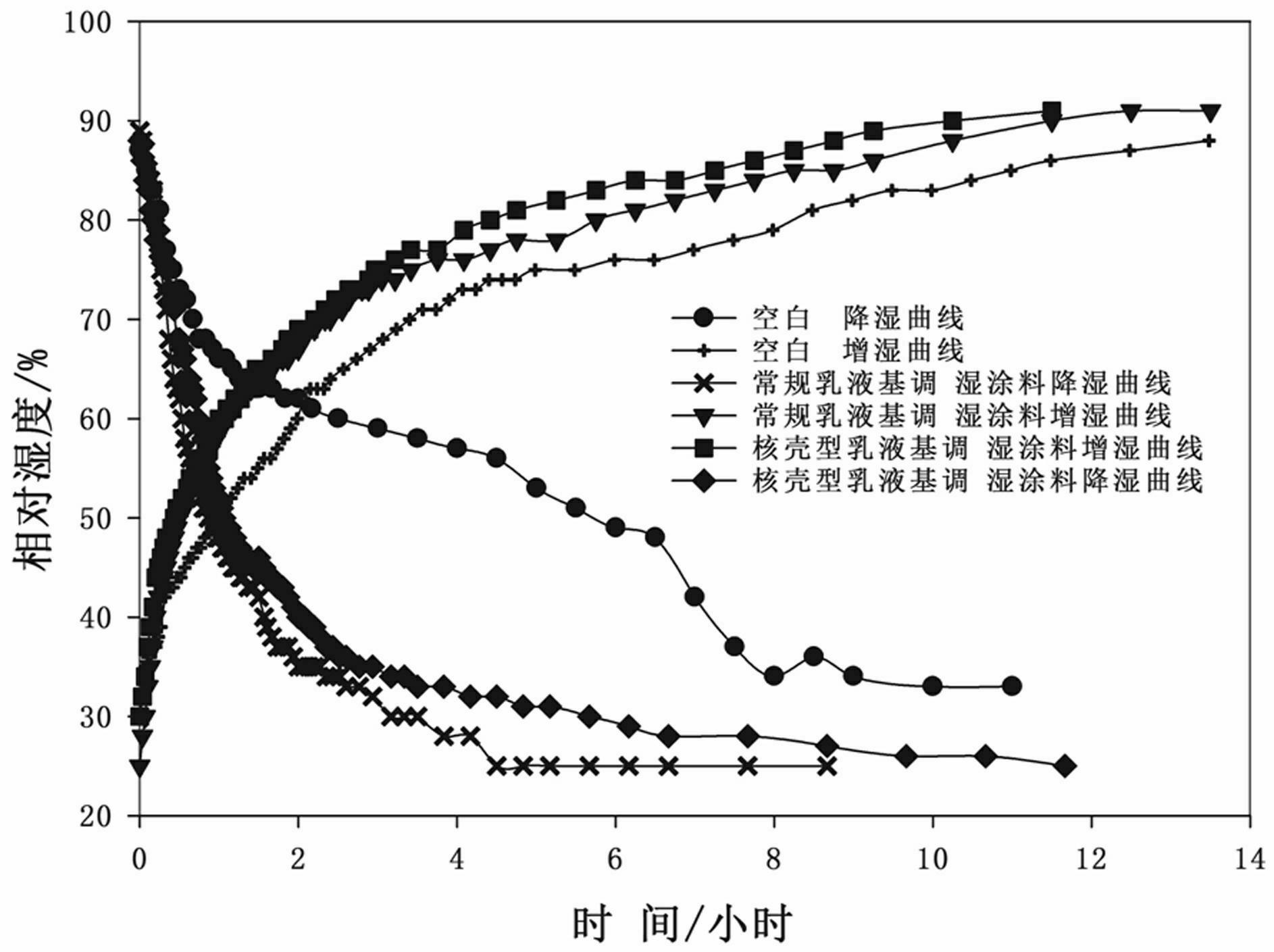

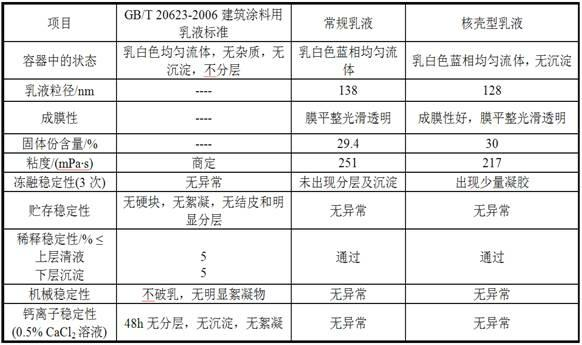

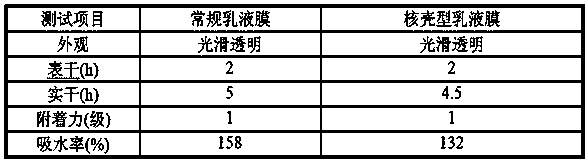

Soap-free core-shell emulsion type amphiphilic polymer resin and preparation and application thereof in preparation of function humidity controlling coating

InactiveCN101423581AGood lookingImprove water resistanceCoatingsPolymer science(Hydroxyethyl)methacrylate

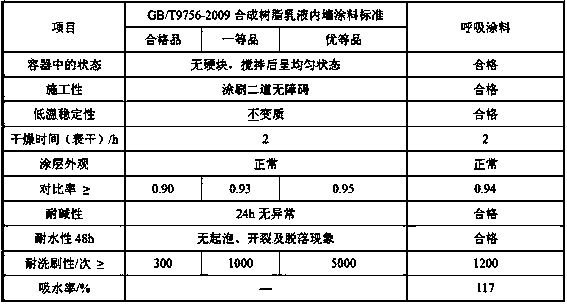

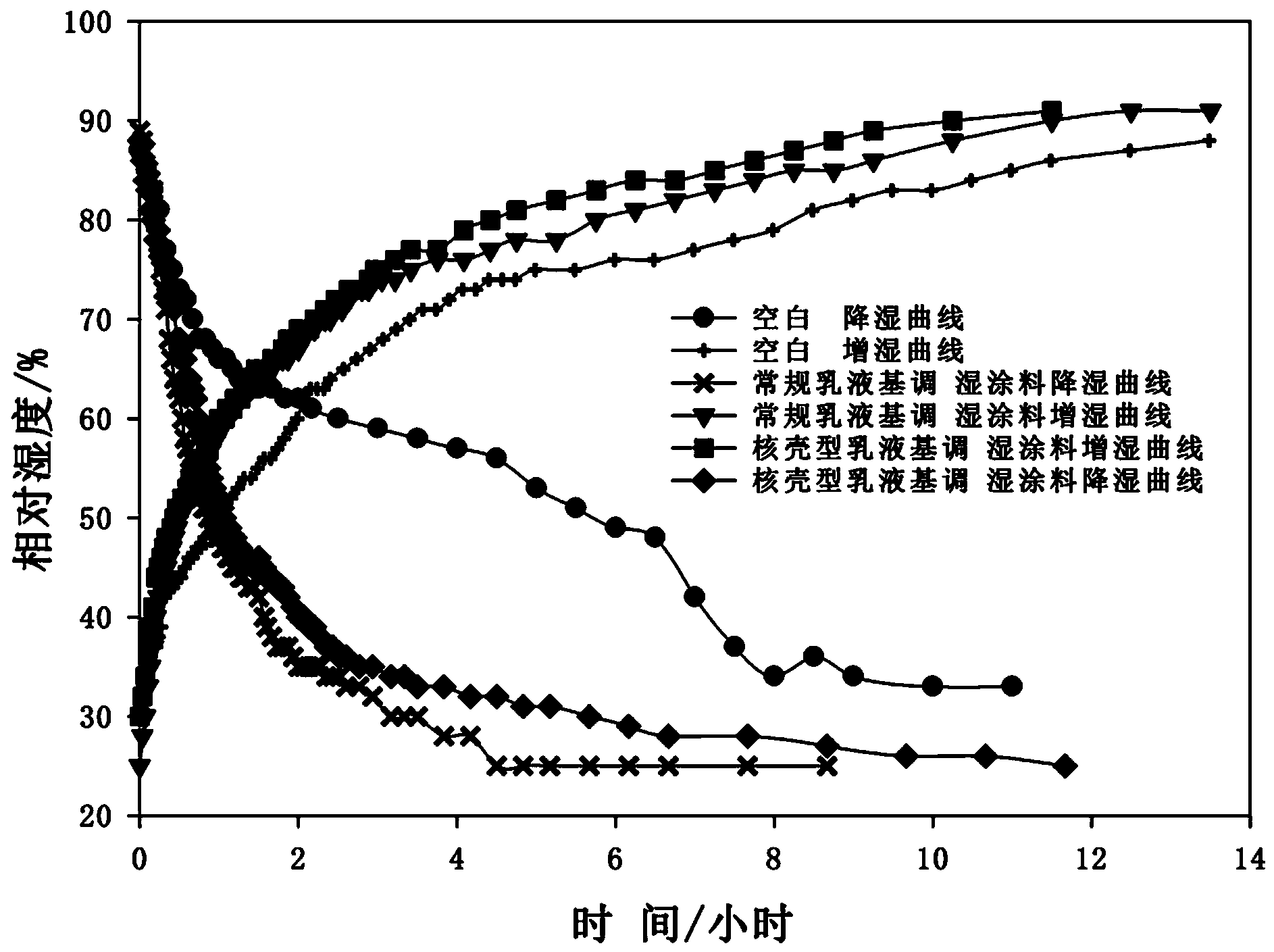

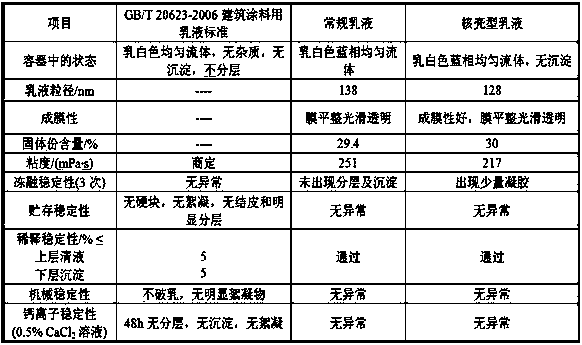

The invention provides a nonsoap nuclear shell latex type amphipathic polymer resin, which is polymerized from methyl methacrylate, styrene, methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, hydroxyethyl methacrylate, acrylamide, diacetone acrylamide and other monomers. The nonsoap nuclear shell latex type amphipathic polymer resin is used as a main film forming material for a paint and is combined with various inorganic macromolecular fillers to prepare the paint; the prepared paint integrates decoration, dampness regulation, permeability, heat insulation, dewing resistance, water and alkali resistance, antisepsis and the like, and can also prevent a coating film from falling off caused by various leakage and water condensation of a wall body so that the coating film is more lasting and durable; and the paint contains no organic solvent and no emulsifier, is safer and more environment-friendly, and has more superior coating property.

Owner:NORTHWEST NORMAL UNIVERSITY

Potato starch graft emulsion, preparation and application thereof

InactiveCN101906189AOvercome the disadvantage of high energy consumptionInhibit sheddingCoatings(Hydroxyethyl)methacrylatePotato starch

The invention provides a potato starch graft emulsion which is formed by carrying out monomer graft polymerization on potato starch, unsaturated alkyl acid, styrene, methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, hydroxy-ethyl methacrylate, acrylic amide, diacetone acrylamide and the like. The potato starch graft emulsion is taken as main film forming matter of paint and is added with conventional inorganic polymer filler which is adopted for preparing the paint, so that the prepared paint has the functions of decoration, humidity adjustment, permeability, heat preservation, moisture condensation prevention, water and alkali resistance, antibiosis and the like; meanwhile, the invention also can prevent a coating from falling off caused by various leakage and water condensation of a wall body, thus ensuring the coating to be more durable; and the potato starch graft emulsion does not contain organic solvent and is safer and more environment-friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

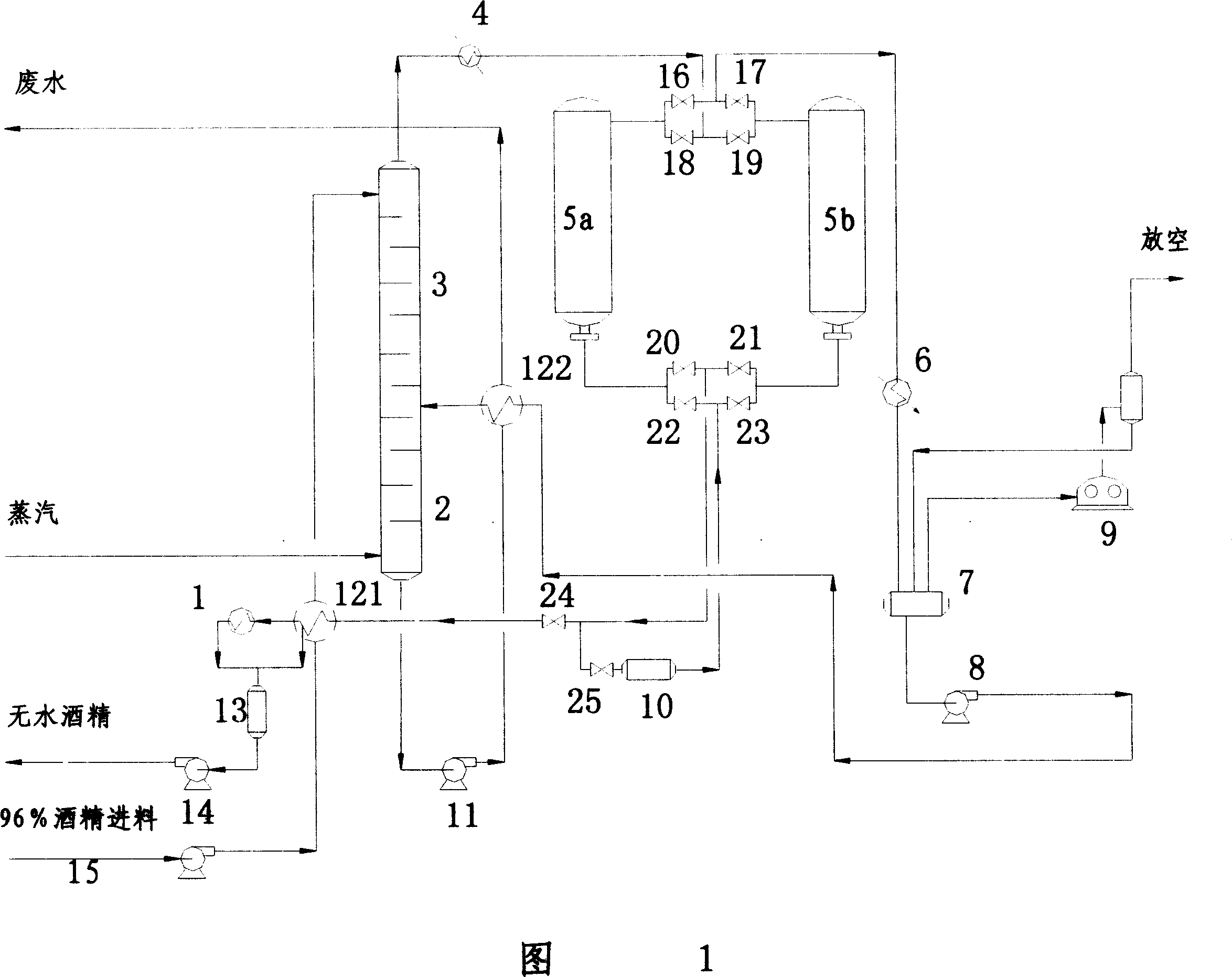

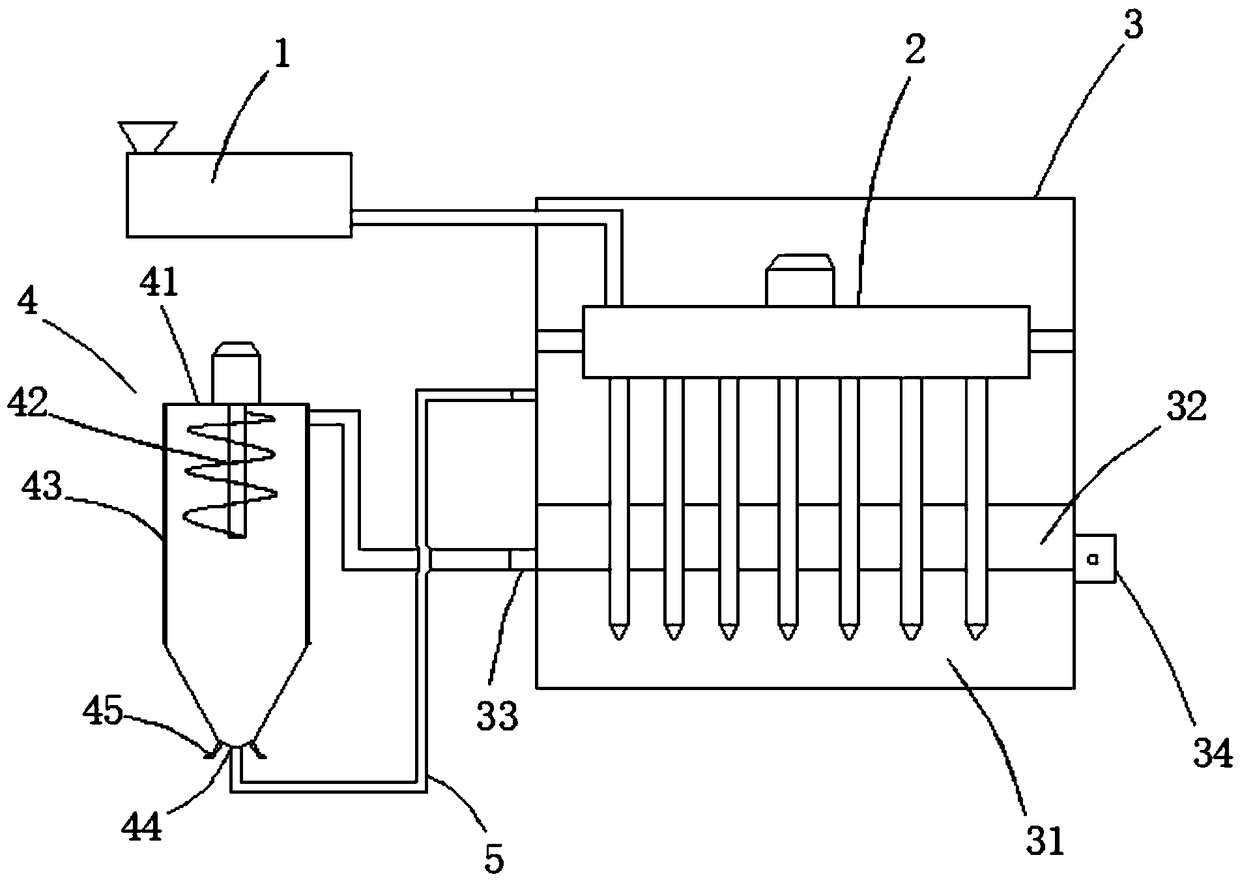

Fuel alcohol dewatering apparatus and process

InactiveCN101088975AReduce consumptionImprove recycling ratesOrganic compound preparationChemical industryMolecular sieveAlcohol

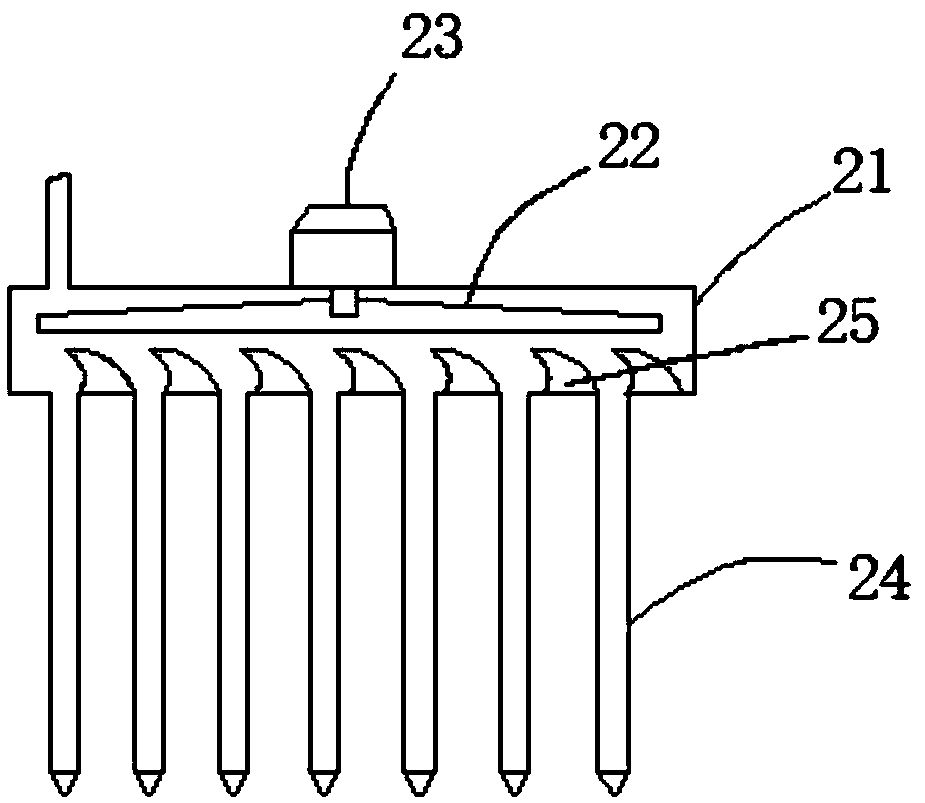

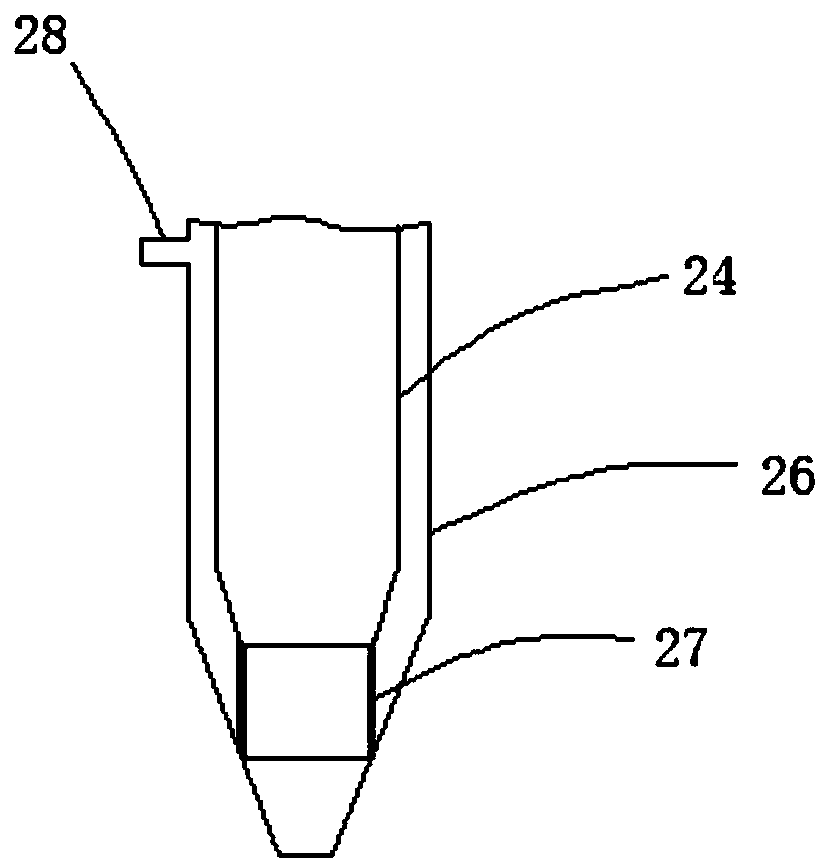

The fuel alcohol dewatering apparatus a rectification tower and a stripping tower connected serially, two parallel molecular sieves with valves in the inlets and the outlets, an overheater, a product cooler, a material preheater, a feeding pump, a waste water pump and a vacuum pump. The present invention has low power consumption, high energy recovering rate, no environmental pollution and high production efficiency.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Soap-free emulsion type amphiphilic polymer resin and preparation and application thereof in production of intelligent breathing coating

InactiveCN101423583AImprove humidity control performanceImprove performanceCoatings(Hydroxyethyl)methacrylateEthylene Glycol Methacrylate

The invention provides a soap free latex type amphiphilic polymer resin, which is formed by polymerizing unsaturated acid alkyl, styrene, methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, ethylene glycol methacrylate, acrylamide, diacetone-acryloamide and other monomers. The paint which takes the soap free latex type amphiphilic polymer resin as a main film forming material and combines with multiple kinds of inorganic polymer stuffing integrates with decorative property, humidifying property, permeability, heat preservation, condensation prevention, water and alkali resistance, bacterium resistance and so on, and can prevent the paint film from dropping off due to multiple kinds of seepage and water condensation of a wall body, so that the paint film is more durable; in addition, the paint has no organic solvent, and is more safe and environment friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

Organic silicon-acrylic ester copolymer emulsion and preparation and application thereof

The invention provides organic silicon-acrylic ester copolymer emulsion, which utilizes organic silicon, methyl methacrylate, butyl acrylate, unsaturated alkyl acid and methacrylic acid-beta-hydroxypropyl ester as comonomers, utilizes deionized water as solvent, utilizes potassium peroxydisulfate or ammonium persulfate as an initiator and utilizes sodium bicarbonate as a neutralizer, and is prepared by polymerization in the presence of an emulsifying agent. The emulsion introduces the organic silicon into polyacrylate, the rigidness of a copolymer is improved to a certain extent, and cohesion of the copolymer emulsion is improved due to the introduction of a polar group. Interior wall humidity-conditioning paint prepared by the copolymer emulsion serving as a film former integrates multiple functions of decoration, humidity conditioning performance, permeability, insulation and anti-condensation performance, water resistance, alkali resistance, alkali-resistant performance and antibiosis, the paint film is durable and long in service life, and the organic silicon-acrylic ester copolymer emulsion serving as the interior wall humidity-conditioning paint has application prospects.

Owner:NORTHWEST NORMAL UNIVERSITY

Method for changing sludge to organic fertilizer

InactiveCN1562904AOvercome the disadvantage of high energy consumptionOvercome the disadvantage of high consumptionClimate change adaptationExcrement fertilisersSludgeAnimal feces

The invention relates to a mud treatment technology, particularly to method transforming mud into organic fertilizer. In the invention, mud is stirred to pulp, then is screened, feces of birds and beasts is dried and fine grinder, then to be mixed and smelted with mud, cut and prilled, the grains are dried by drying machine, then to be packed.

Owner:陈茂铨

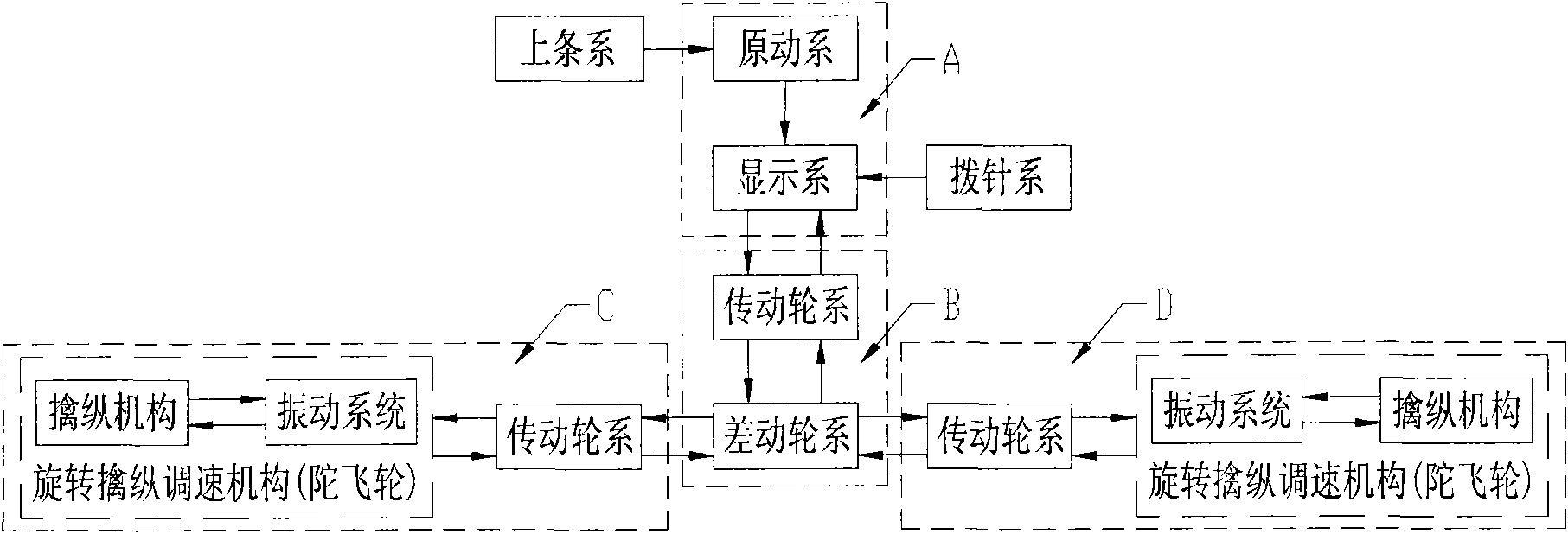

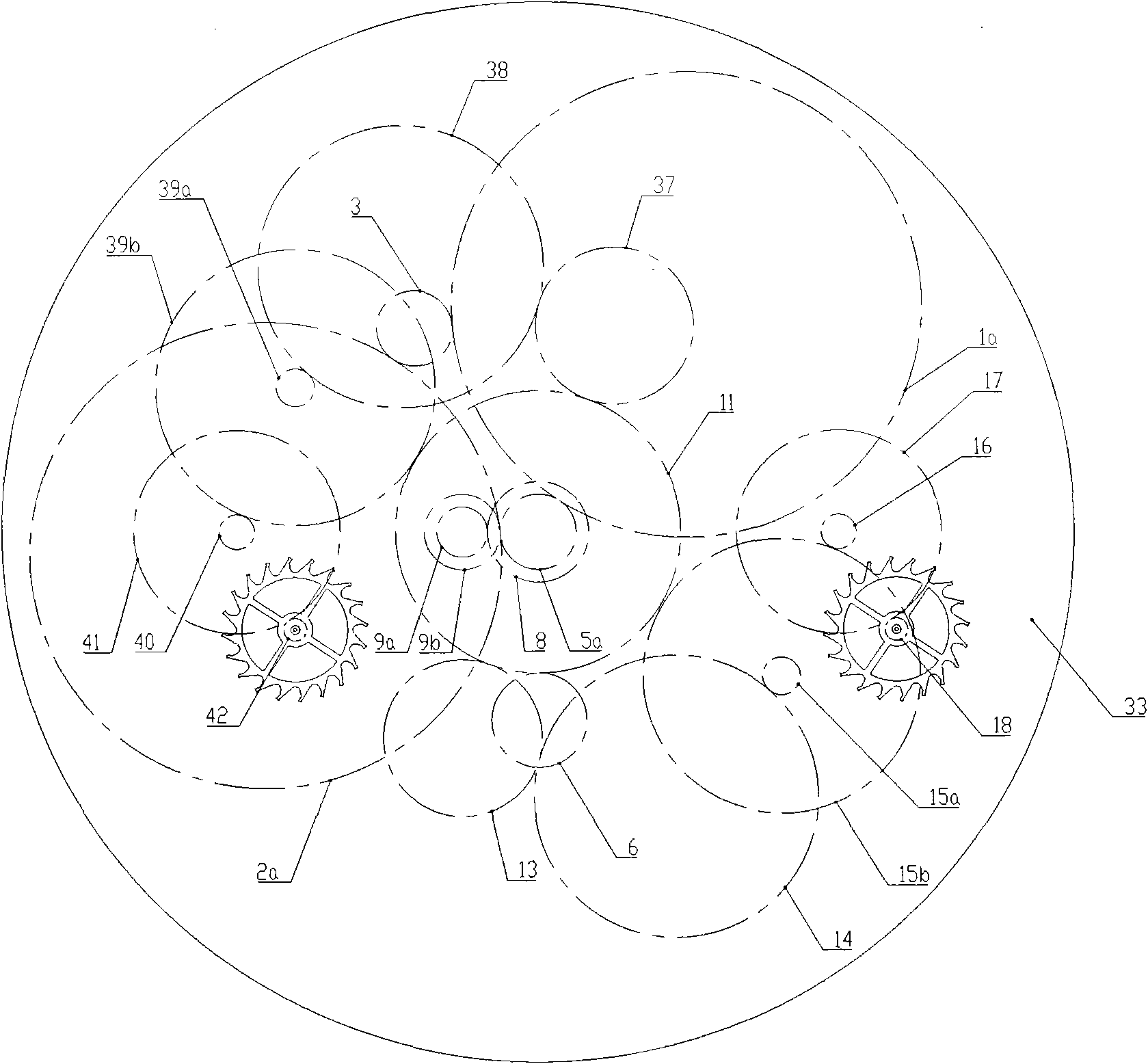

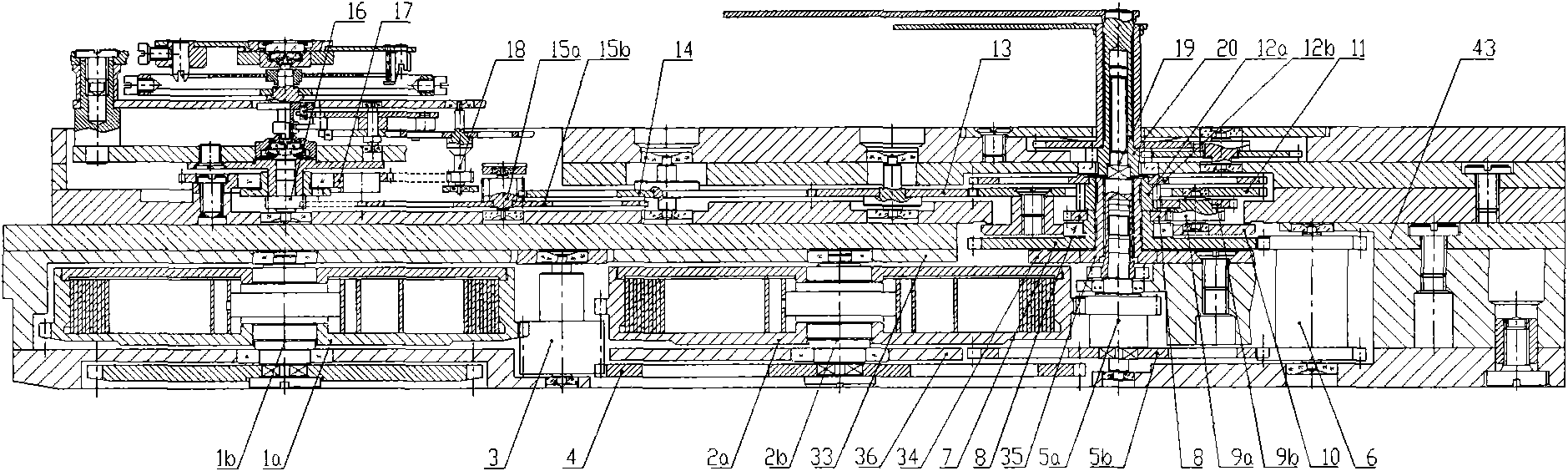

Mechanical watch with two tourbillons

InactiveCN101846961AExtended travel timeLong hair lengthFrequency stabilisation mechanismJewel bearingMoment of inertia

The invention discloses a mechanical watch with two tourbillons, which comprises a winding system, a drive system, a display system, a shifting needle system, a transmission gear train, a differential gear train and two tourbillon gear trains; a cover plate which is connected with a main clamping plate is adopted as a beachmark, the mechanical watch is divided into an upper layer and a lower layer; the winding system, the drive system, the shifting needle system and a drive part of the display system are arranged on the lower layer, and the tourbillon gear train, the transmission gear train and a display part of the display system are arranged on the upper layer; and the upper and the lower layers of the mechanical watch are connected with each other through the differential gear train into a whole. The mechanical watch has the advantages that: two identical driving gears on barrel which are serially connected with each other are divided by two coaxial tourbillons which are horizontally arranged into an upper and a lower layer, the two driving gears on barrel are connected with each other through a differential system which is provided with a jewel bearing, and the size of the two driving gears on barrel are maximized to obtain the maximum driving torque and the maximum winding length so as to provide energy to a balance and hair spring system and to prolong the time traveling length of the machine core. In addition, the size of an outer balance wheel is maximized, so the rotation inertia is increased, the time traveling precision of the watch is improved, and the time of the watch is more correct.

Owner:TIANJIN SEAGULL WATCH CO LTD

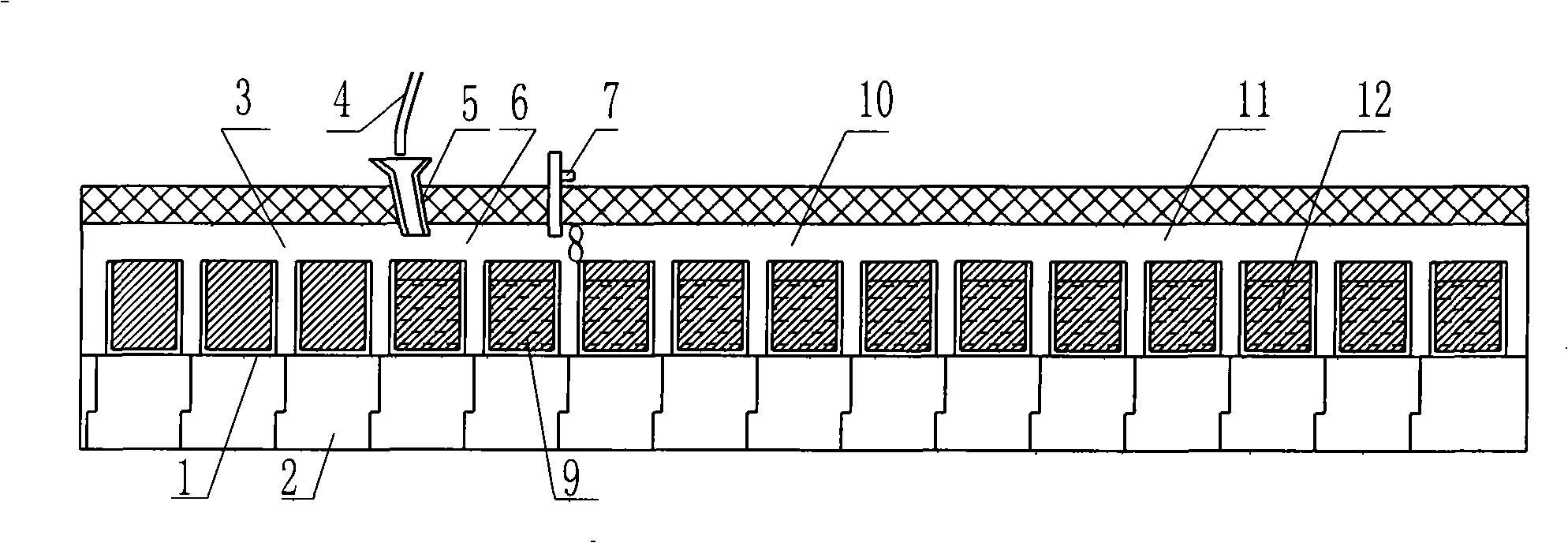

Directional solidification method and its device for continuous production for polycrystalline silicon ingot

InactiveCN101307487AEasy to replaceRealize job productionPolycrystalline material growthFrom frozen solutionsHearthPolycrystalline silicon

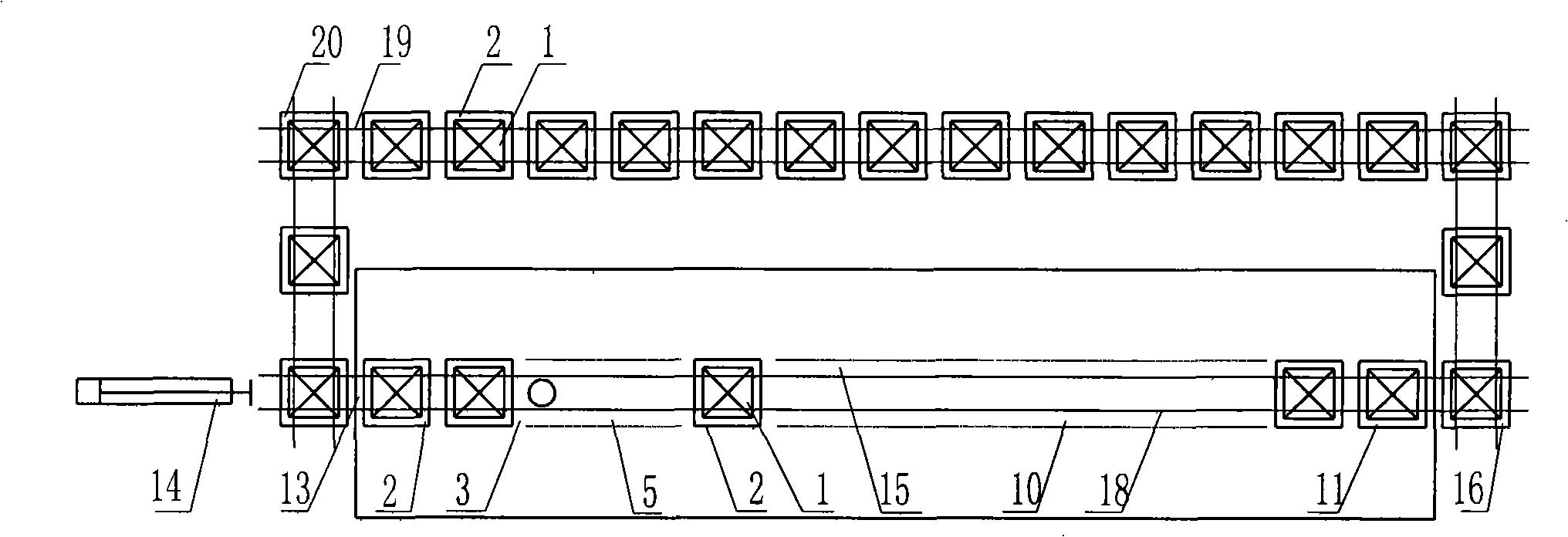

The invention provides a directional freezing method for continuously producing polysilicon ingots, relating to an uniform polycrystal material which takes material or shape as characteristics and possesses of a certain structure. The invention provides a directional freezing method for continuously mass production of polysilicon ingots in the process of producing solar energy-level polysilicon by metal silicon in the metallurgy process and a device adopting the method. Empty graphite molds are arranged according to the axial space order and driven to move forward by a furnace vehicle, and the empty graphite molds are preheated in the preheating area; liquid silicon undergoing melt refining is put in the empty graphite molds after preheating; the liquid silicon is kept warm in a high-temperature area of a hearth and enters an intermediate-temperature area; from the high-temperature area to the intermediate-temperature area, the liquid silicon are gradually directionally frozen in graphite molds; frozen silicon is cooled down to room temperature below a revolving track protective cover in the graphite molds to obtain directionally frozen polysilicon ingots. The directional freezing continuous track furnace for continuously producing polysilicon ingots is provided with a furnace body, a furnace hearth, a furnace vehicle track, a furnace vehicle, a front auxiliary cart, a back auxiliary cart, a revolving track, a propelling device and a power supply and temperature control system.

Owner:JACO SOLAR SILICON LONGYAN CO LTD +1

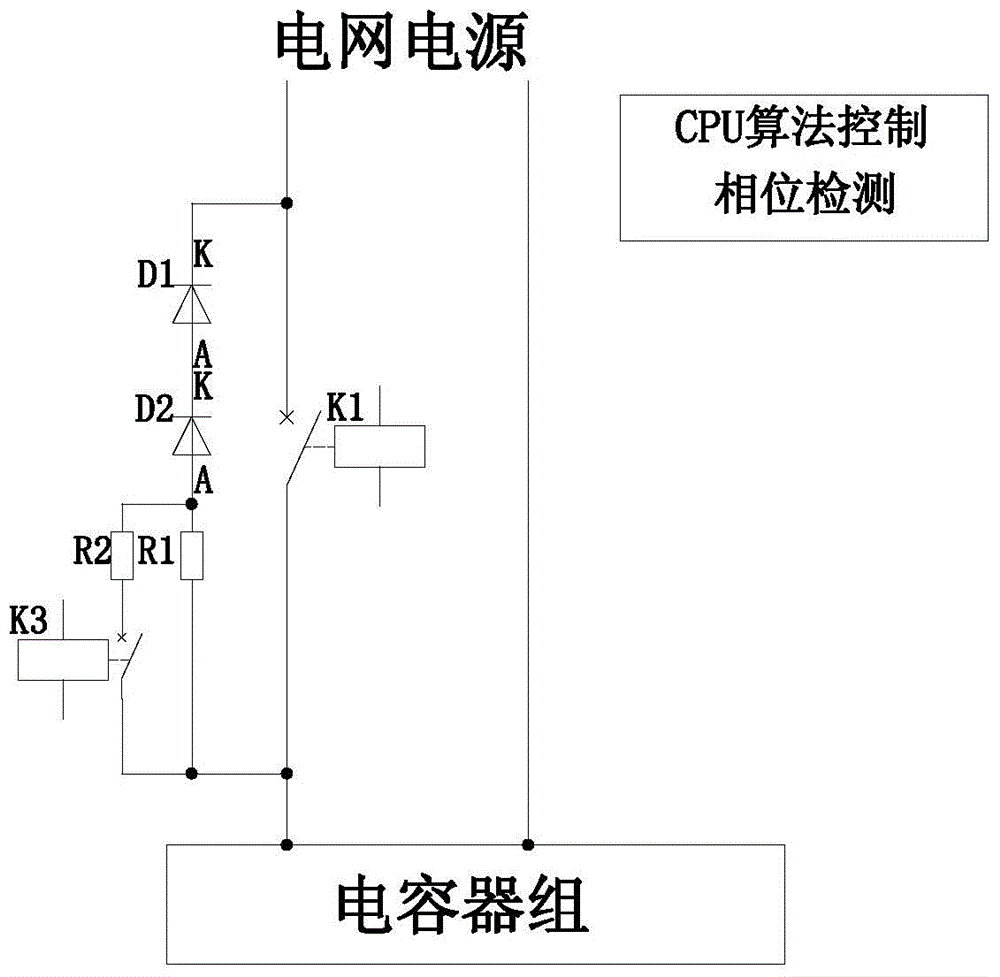

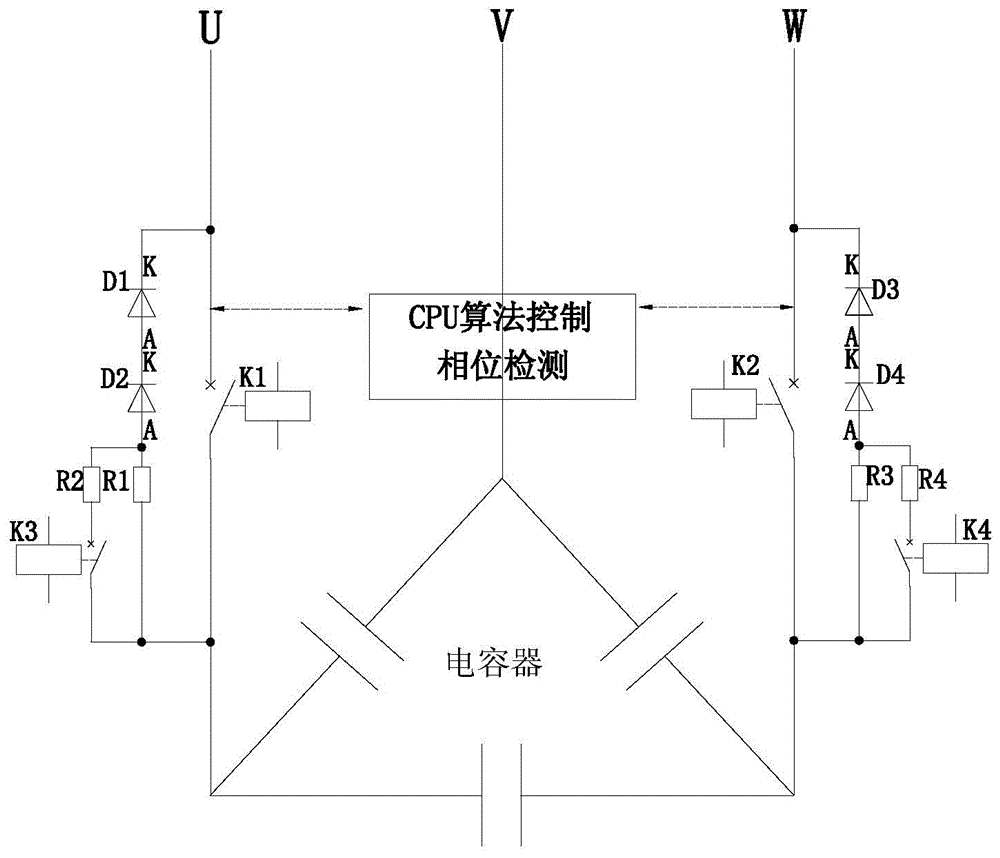

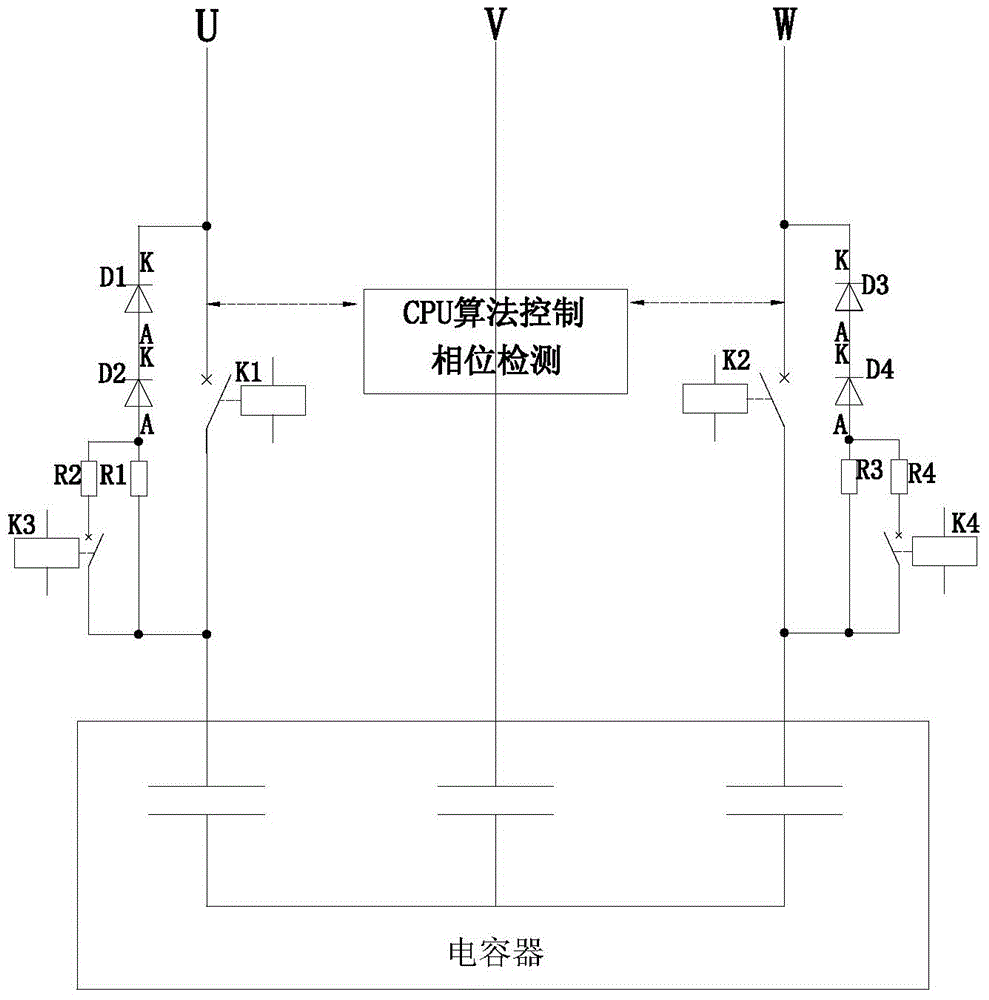

Phase-controlled switch peak zero-cross-switching inrush current control circuit and control method

ActiveCN104578093AWon't fuseSmall currentReactive power adjustment/elimination/compensationEmergency protective arrangements for limiting excess voltage/currentHigh resistanceElectric power system

The invention relates to a phase-controlled switch peak zero-cross-switching inrush current control circuit and a control method thereof, and belongs to the technical field of reactive compensation and harmonic filter of electric power systems. The control circuit comprises a control circuit which is provided with an intelligent control device and a magnetic latching relay switch which is used for controlling the connection and disconnection between a capacitor group and a network source, wherein a primary series circuit formed by a high-voltage diode and a high-resistance high-voltage current limiting resistor via series connection is connected beside the magnetic latching relay switch in parallel; a secondary series circuit formed by an auxiliary relay switch and a low-resistance high-voltage current limiting resistor via series connection is connected beside the high-voltage current limiting resistor in parallel; a zero-cross signal input end of the intelligent control device of the control circuit is connected with two ends of a contact of the magnetic latching relay switch; a detection end of a reference phase detection circuit is connected with the network source; a control output end is connected with controlled ends of a primary relay switch and a secondary relay switch. The phase-controlled switch peak zero-cross-switching inrush current control circuit and the control method can be used for solving the problem that the inrush current on the traditional pre-charging circuit is large and the capacitor group is easy to damage, and have the advantages of being energy-saving, environment-friendly, free of energy consumption and suitable for the switching control of multi-phase switched capacitor groups with various connection manners and different voltage classes.

Owner:江苏南自通华智慧能源股份有限公司

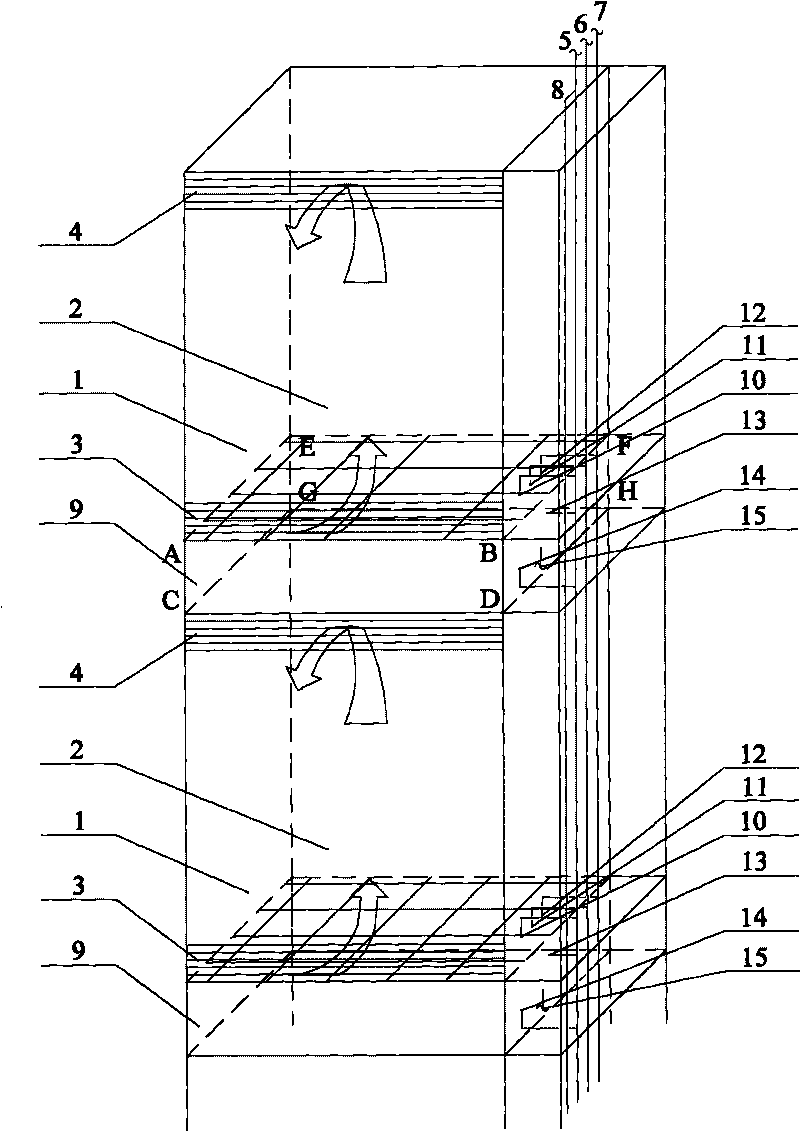

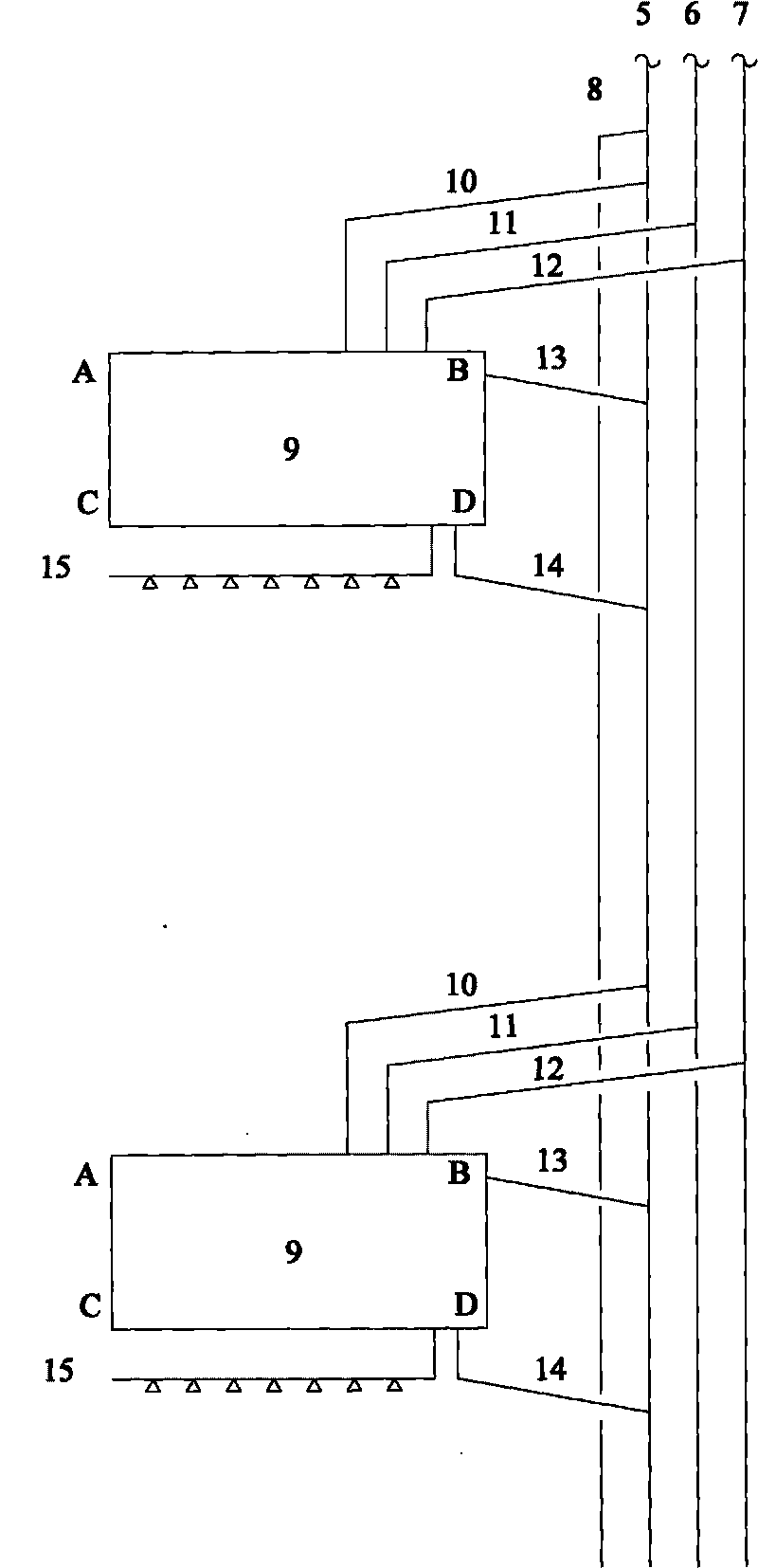

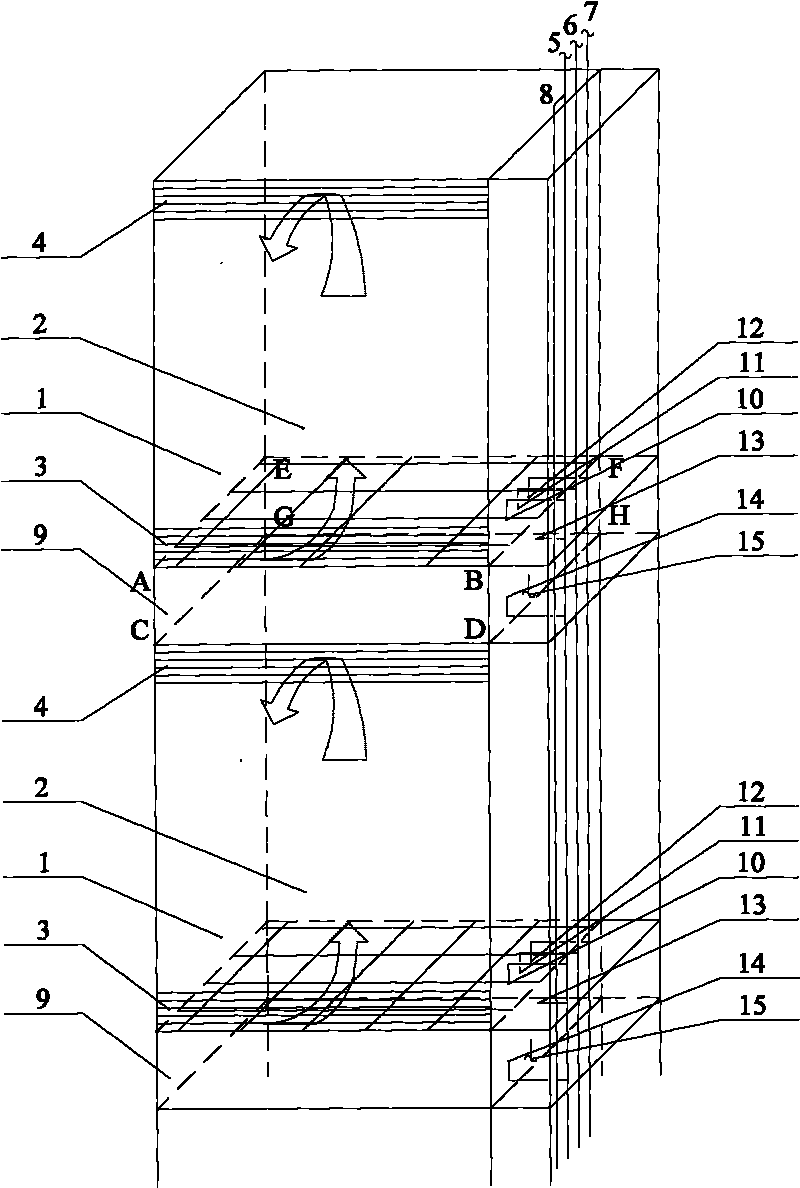

Box-type double-layer curtain wall using water storage tank for evaporative cooling

The invention relates to a box-type double-layer curtain wall using a water storage tank for evaporative cooling, in particular to a box-type ventilating double-layer curtain wall using the technology of evaporative cooling of the water storage tank, belonging to the technical fields of building energy conservation, etc. The box-type double-layer curtain wall using the water storage tank for evaporative cooling is provided with an external layer ventilating curtain wall and an internal layer ventilating curtain wall which are arranged in parallel, the upper ends and the lower ends of the external layer ventilating curtain wall and the internal layer ventilating curtain wall are respectively provided with an air inlet and an air outlet, and the lower end of the air outlet is provided with the water storage tank; the same side of all the box-type double-layer curtain walls is respectively provided with a rain water pipe, a condensate pipe, a water supplementing pipe and a rain water discharge pipe, wherein the rain water pipe is connected with the water storage tank by a rain water jointing pipe; the condensate pipe is connected with the water storage tank by a condensate jointing pipe; the water supplementing pipe is connected with the water storage tank by a water supplementing jointing pipe; the rain water discharge pipe is connected with the rain water pipe; and a gravity spraying pipeline is arranged under the water storage tank. The box-type double-layer curtain wall achieves the aims of good cooling effect of leading the indoor temperature to be lower than the outdoor air dry bulb temperature, and being simple in structure.

Owner:JIANGSU FOCUS NEW ENERGY TECH +1

Continuous production method of cotton fiber heat-insulating material by using molten yellow phosphorus slag

The invention relates to a production method of cotton fiber, comprising the following steps: 1. conveying molten phosphorus slag; 2. adjusting components of the phosphorus slag: selecting the following additives based on the weight percentage of the phosphorus slag: 1%-10% of borax, 0.1%-0.5% of albite, 0.01%-0.03% of sodium carbonate and 10%-30% of glass, evenly mixing the additives, placing in a storage container, heating and melting the additives by tail gas of a phosphorus furnace to form a molten mass, and directly adding the molten mass to the molten phosphorus slag; 3. making the phosphorus slag into cotton: transferring the phosphorus slag obtained in step 2 into a four-roll high-speed centrifugal cotton making machine, and adding a secondary adjuvant to positive-pressure airflow needed for cotton making to participate in the cotton-making procedure, wherein, the secondary adjuvant is mixed liquid composed of the following components in percentage by weight: 60%-80% of kerosene and 20%-40% of paraffin, and the secondary adjuvant accounts for 0.5%-1% of the weight of the phosphorus slag; and 4. collecting, curing and forming the cotton fiber.

Owner:YUNNAN WANFUYUAN IND & TRADE

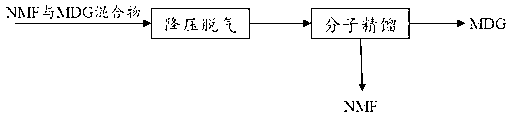

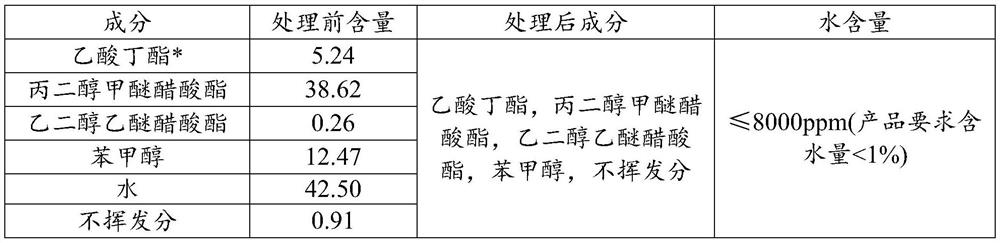

Industrial separation method of N-methylformamide and diethylene glycol monomethyl ether

InactiveCN109096142AEfficient purificationHigh purityEther separation/purificationCarboxylic acid amide separation/purificationMean free pathTower

The invention relates to an industrial separation method of main components N-methylformamide (NMF) and diethylene glycol monomethyl ether (MDG) in an electronic chemical stripper. A low-pressure molecular distillation method is adopted to efficiently recover the NMF and the MDG in the waste electronic chemical stripper, and has the advantages of energy saving and safety and environmental protection. A high-purity NMF and MDG separation refining process mainly comprises the following steps of 1) depressurization and degassing: decompressing and degassing the mixture of the NMF and the MDG to prevent entrainment splashing caused by sudden pressure drop after materials enter a molecular rectification tower; 2) molecular rectification of enabling the degassed materials to enter the molecularrectification tower achieve separation by utilizing the feature that molecular mean free paths of the two components are different. Compared with the conventional process, the method achieves the effect that the the purity of the finished NMF and the finished MDG is over 99%, and the rectified NMF and the rectified MDG reach the purity requirement of the electronic chemical stripper and achieve the separation and the purification of the NMF and the MDG.

Owner:福建钰融科技有限公司 +2

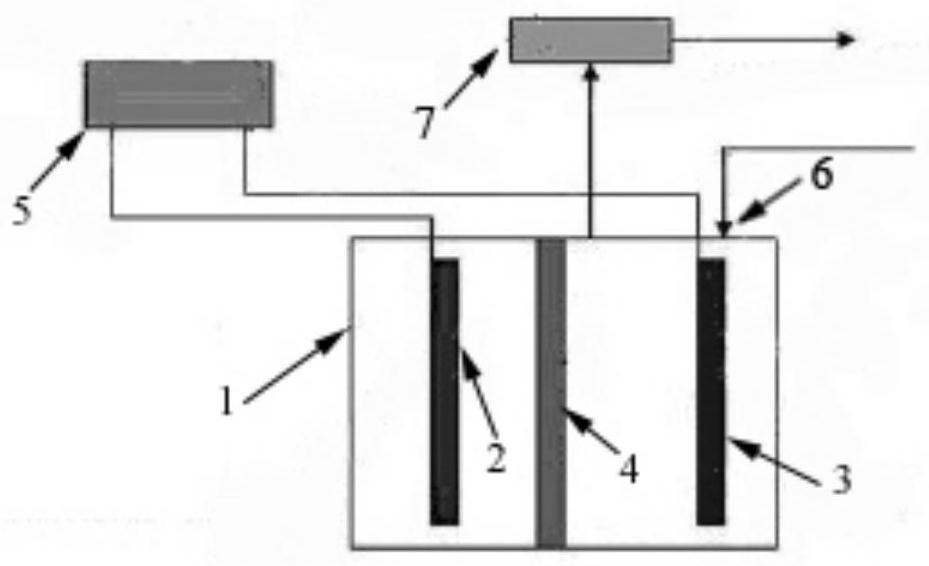

Electrochemical water removal method and system for stripping liquid waste liquid

ActiveCN112079418AAchieve self-sufficiencyOvercome the disadvantage of high energy consumptionDispersed particle separationWater/sewage treatmentLiquid wasteChemical reaction

The invention discloses an electrochemical water removal method and system for stripping liquid waste liquid, and belongs to the technical field of wastewater recycling in the electronic manufacturingindustry. According to the method, stripping liquid waste liquid enters an electrochemical water removal system through a liquid inlet and then flows through a metal anode, an air cathode and an insulating diaphragm, anode metal and water in the stripping liquid waste liquid are consumed in the reaction process, reactants in a precipitation state are formed at the same time, and the purpose of water removal is achieved while substance separation is achieved. An electrochemical reaction method is used, the defect of high energy consumption in the prior art is overcome, water participates in anelectrode reaction, water in waste liquid is consumed, energy consumption is zero, electric energy is generated, and high-purity fine chemical products are produced again.

Owner:南京博裕环境科技有限公司

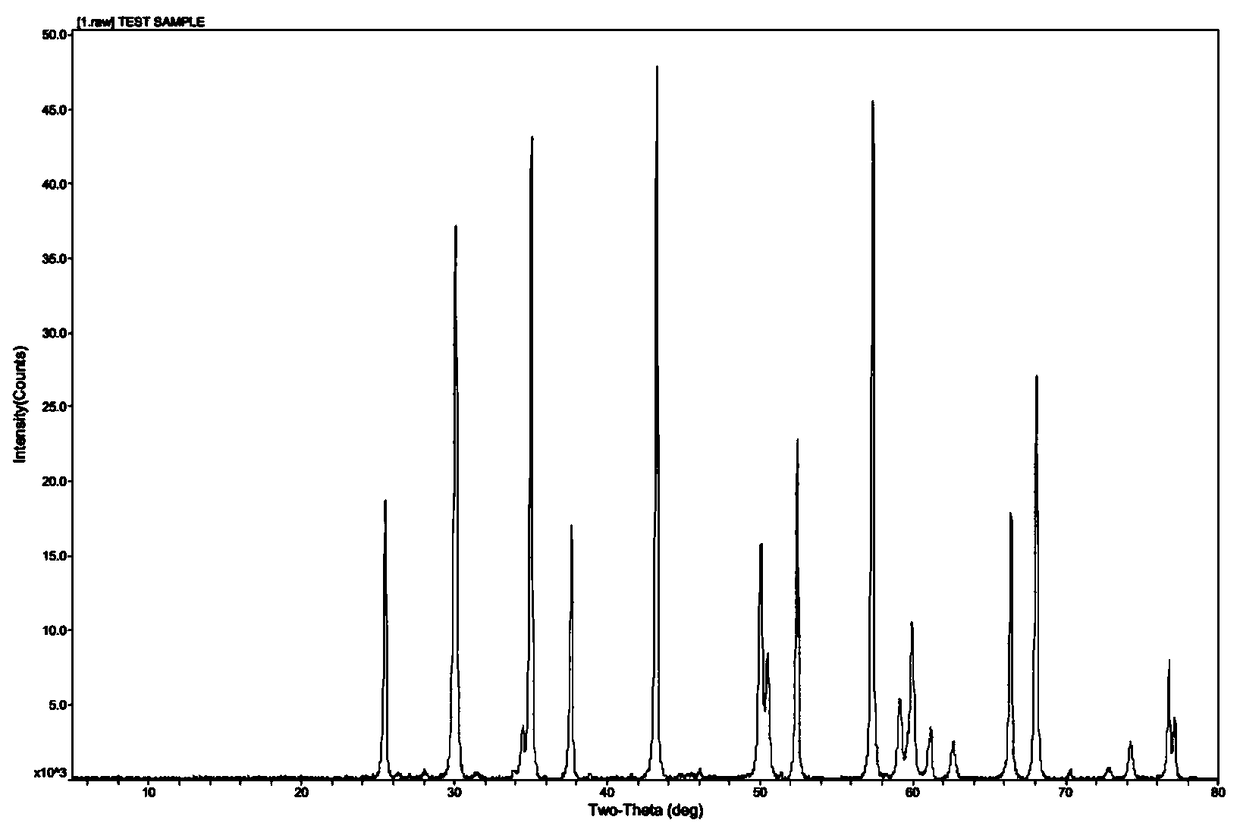

Hydrothermal preparation method of chromium-doped aluminum oxide photoluminescence material

ActiveCN108559501AOvercome the disadvantage of high energy consumptionLower sintering temperatureMaterial nanotechnologyNanoopticsChromium dopingFiltration

The invention belongs to the technical field of preparation of fluorescence light-harvesting solar photovoltaic device photoluminescence materials, and provides a hydrothermal preparation method of achromium-doped aluminum oxide photoluminescence material for solving the problems that an existing preparation method of the photoluminescence material cannot precisely control the doping ratio and islong in reaction time and high in energy consumption. The method comprises the steps that firstly, an aluminum source and a chromium source are dispersed into a KOH solution and stirred to obtain a solution A and a solution B; then, under the constant temperature environment of 30-40 DEG C, the solution B is added into the solution A, and stirring is performed to obtain a mixing solution; the mixing solution is put into a reaction kettle, the temperature is heated to 200-280 DEG C, and the hydrothermal reaction is performed for 0.5-6 h; finally, filtration, washing and drying are performed toobtain chromium-doped aluminum oxide powder. The preparation technology is simple, the sintering temperature is low, energy consumption is low, the yield is high, and the chromium doping proportion can be accurately controlled; the crystallinity of the obtained chromium-doped aluminum oxide photoluminescence material is good, the product purity is high, the particle size is small, the uniformityis good, and synthesis temperature is greatly lowered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

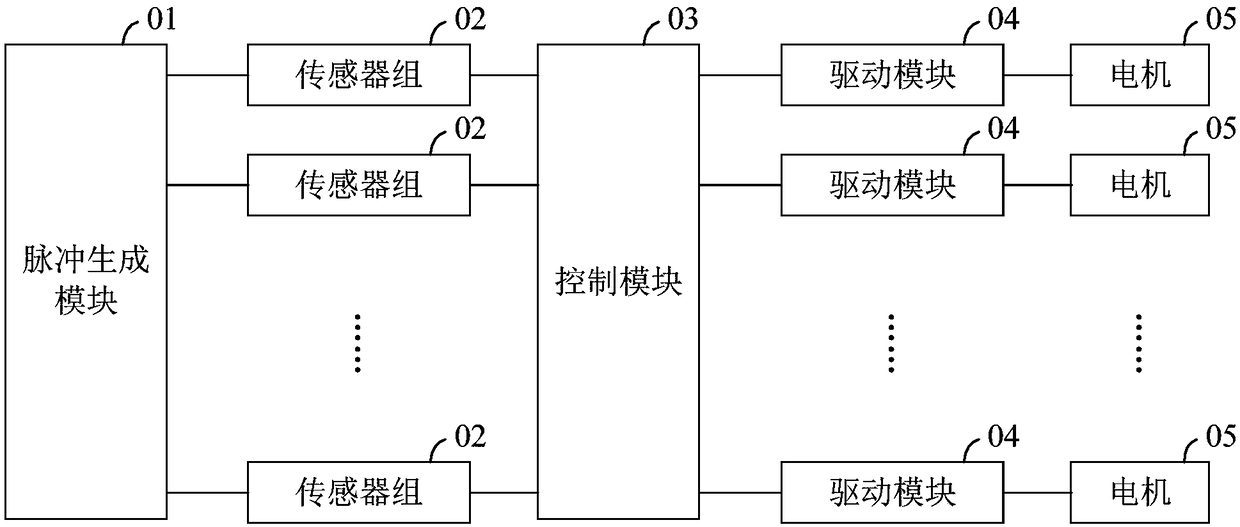

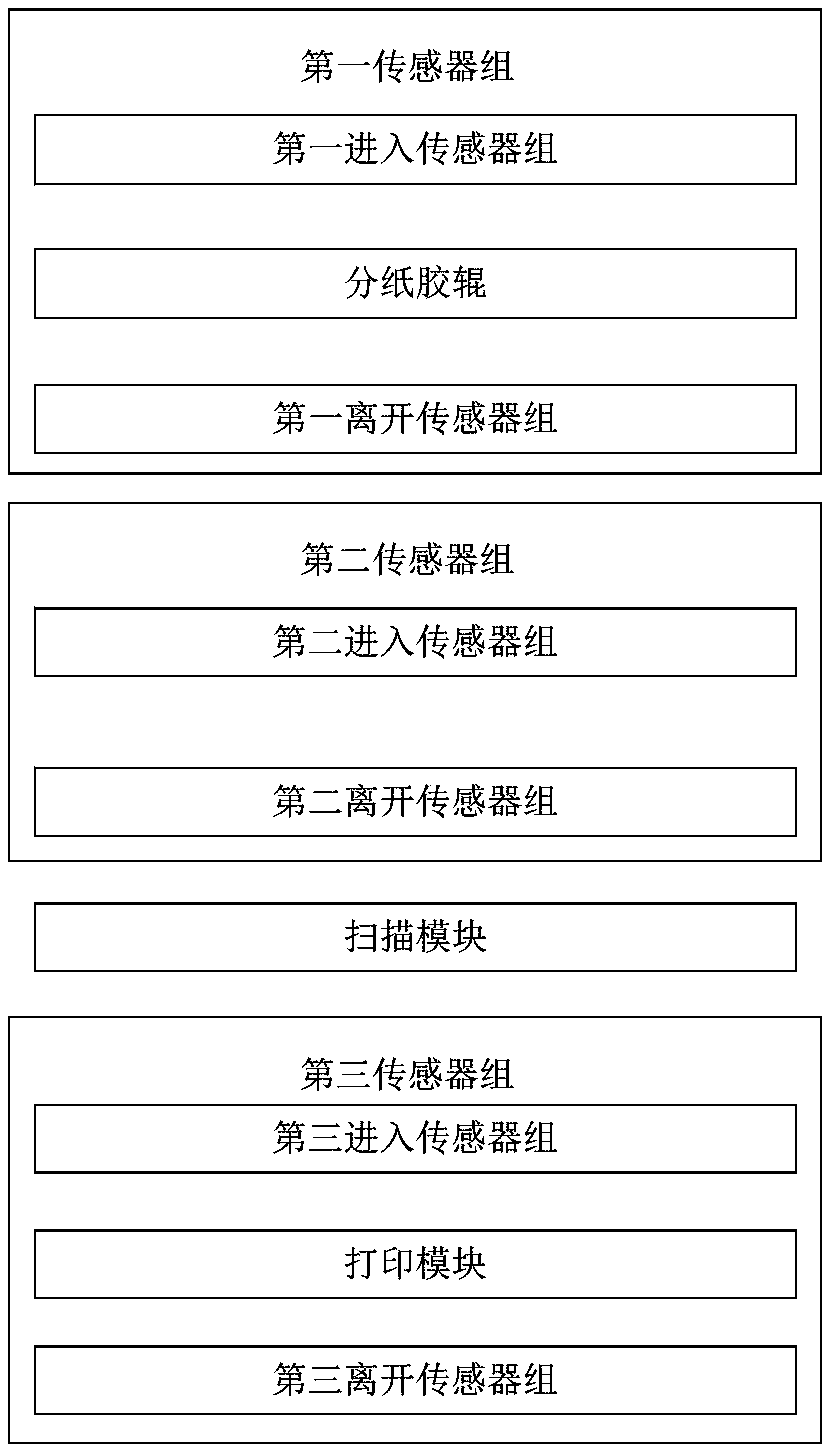

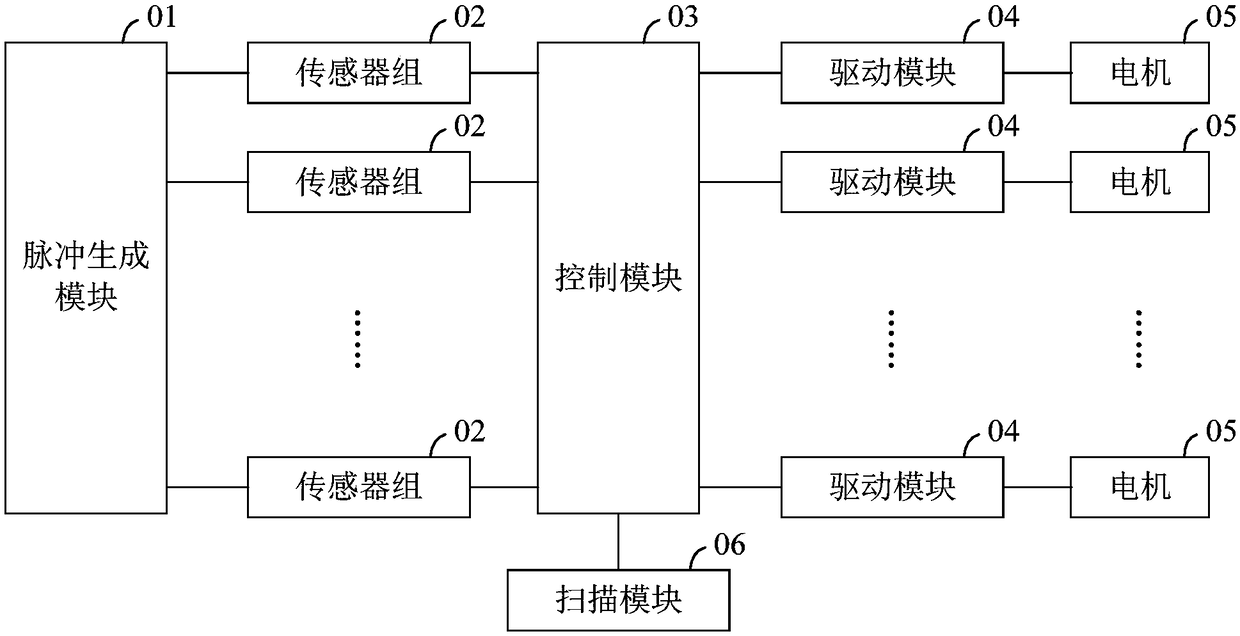

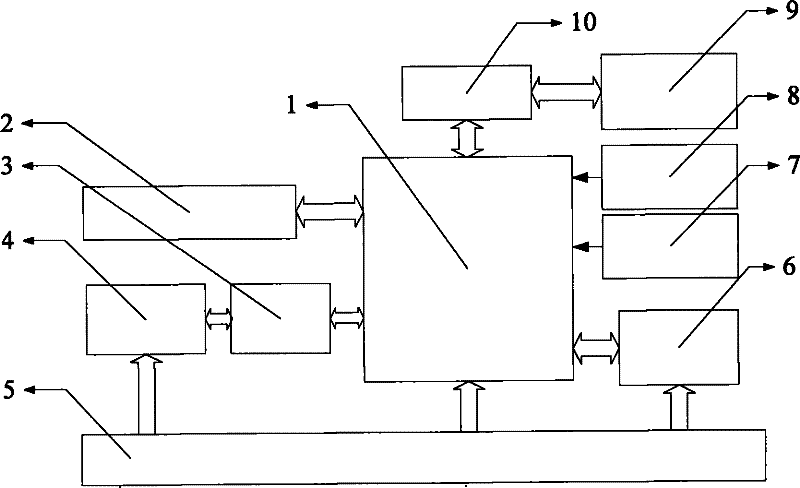

Printing control device, printer and reader

PendingCN109228699AOvercome the disadvantage of high energy consumptionSave electricityOther printing apparatusControl signalMultiple sensor

The invention belongs to the field of printers, and discloses a printing control device, a printer and a reader. An original pulse signal is generated through a pulse generation module; multiple sensor groups generate an entry state signal / an exit state signal indicating that a paper sheet enters / leaves the preset area according to the original pulse signal; a control module generates each start control signal according to each entry state signal and generates each stop control signal according to each exit state signal; multiple driving modules generate a driving signal according to the startcontrol signal and stop generation of the driving signal according to the stop control signal; and multiple motors work according to the driving signal. The corresponding motor is started / stopped according to the situation that the paper sheet enters / leaves the preset area formed by each sensor group so that the defects that the driving motors need to drive all the rotating shafts to rotate in the whole process of paper feeding, printing and paper delivery and the energy consumption is high can be overcome and the electric energy can be saved.

Owner:SHENZHEN SINODATA TECH

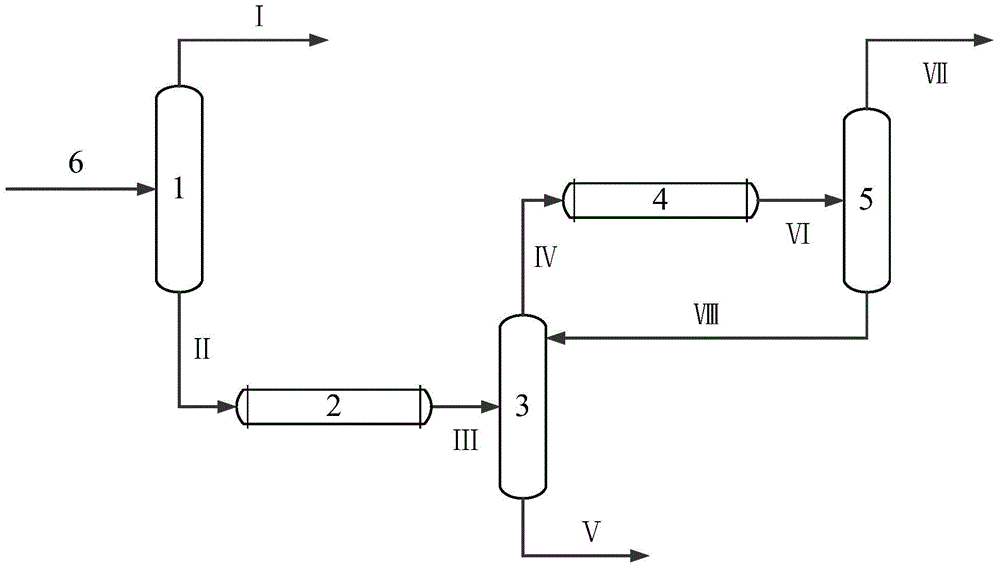

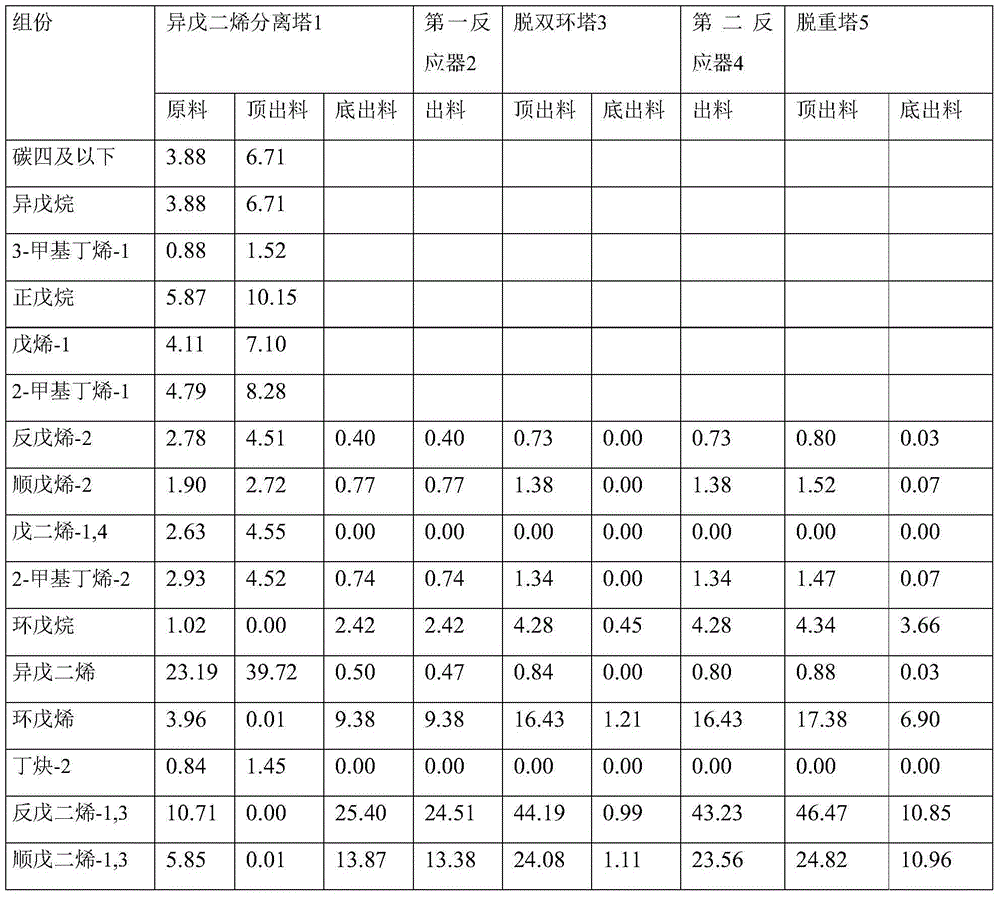

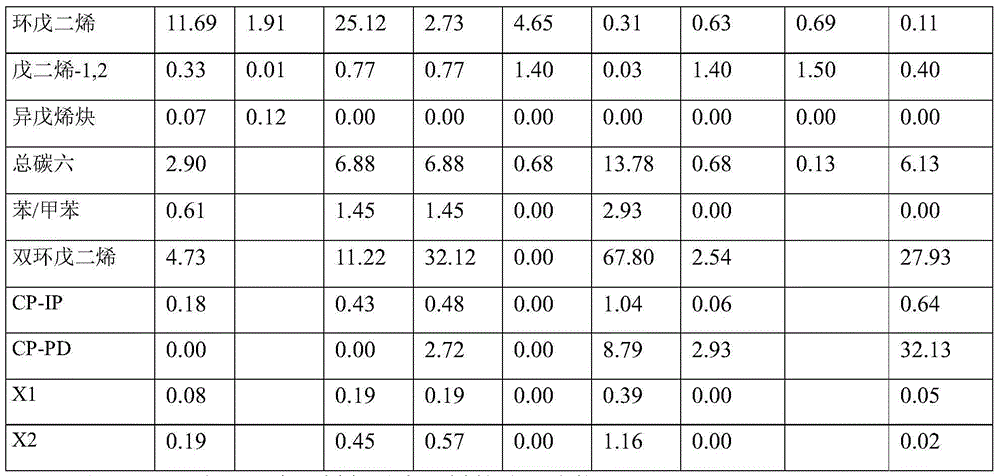

Method for separating piperylene from petroleum cracking C5 fraction

ActiveCN104591949AOvercome the disadvantage of high energy consumptionHigh purityDistillation purification/separationHydrocarbonsPetroleumEnergy consumption

The invention discloses a method for separating piperylene from a petroleum cracking C5 fraction. The method comprises the following steps: (a) the petroleum cracking C5 fraction is delivered into an isoprene separation tower (1) and is subjected to separation, such that a material flow (I) rich in isoprene is separated and is obtained from the tower top, and a material flow (II) rich in cyclopentadiene and piperylene is separated and is obtained from the tower bottom; (b) the material flow (II) is delivered into a first thermal dimerization reactor (2) and is subjected to a thermal dimerization reaction, such that a material flow (III) rich in dicyclopentadiene is produced; (c) the material flow (III) is delivered into a de-dicyclization tower (3) and is subjected to separation, such that a dicyclopentadiene material flow (V) is separated; the remaining material (IV) is delivered into a second thermal dimerization reactor (4) and is subjected to a thermal dimerization reaction, such that a material flow (VI) containing trace cyclopentadiene is obtained; and (d) the material flow (VI) is delivered into a de-heavy tower (5), and a piperylene product material flow (VII) is obtained from the tower top. With the method provided by the invention, energy consumption can be effectively reduced; the piperylene product with relatively high purity can be obtained; and the piperylene and dicyclopentadiene products can be obtained with relatively high yield.

Owner:SINOPEC SHANGHAI ENG +1

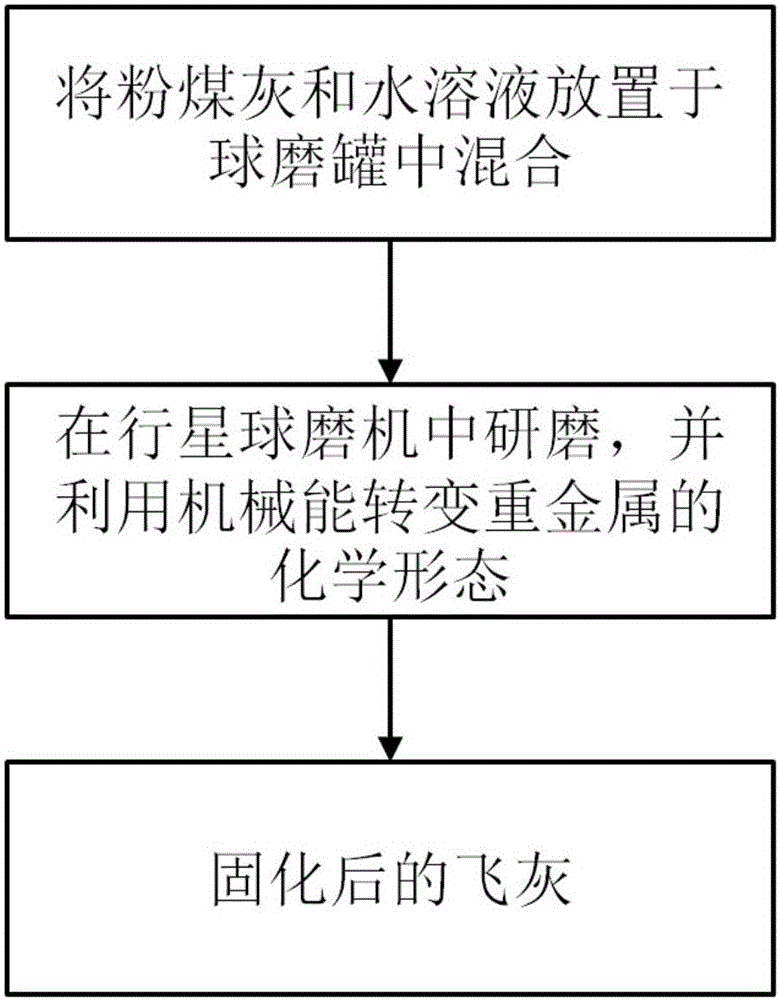

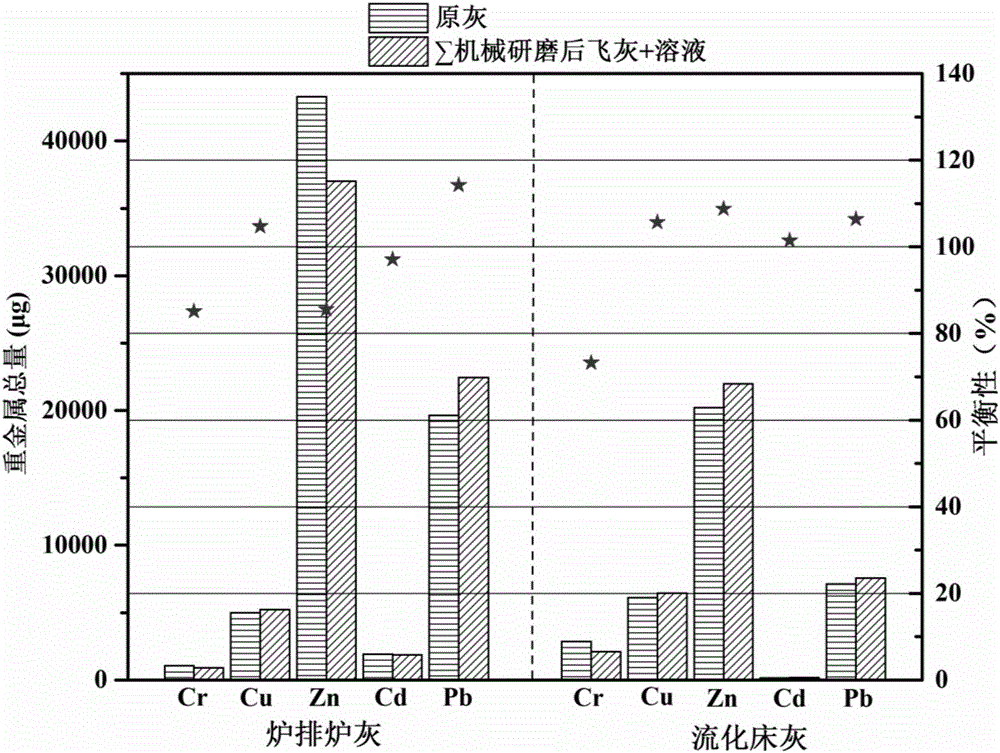

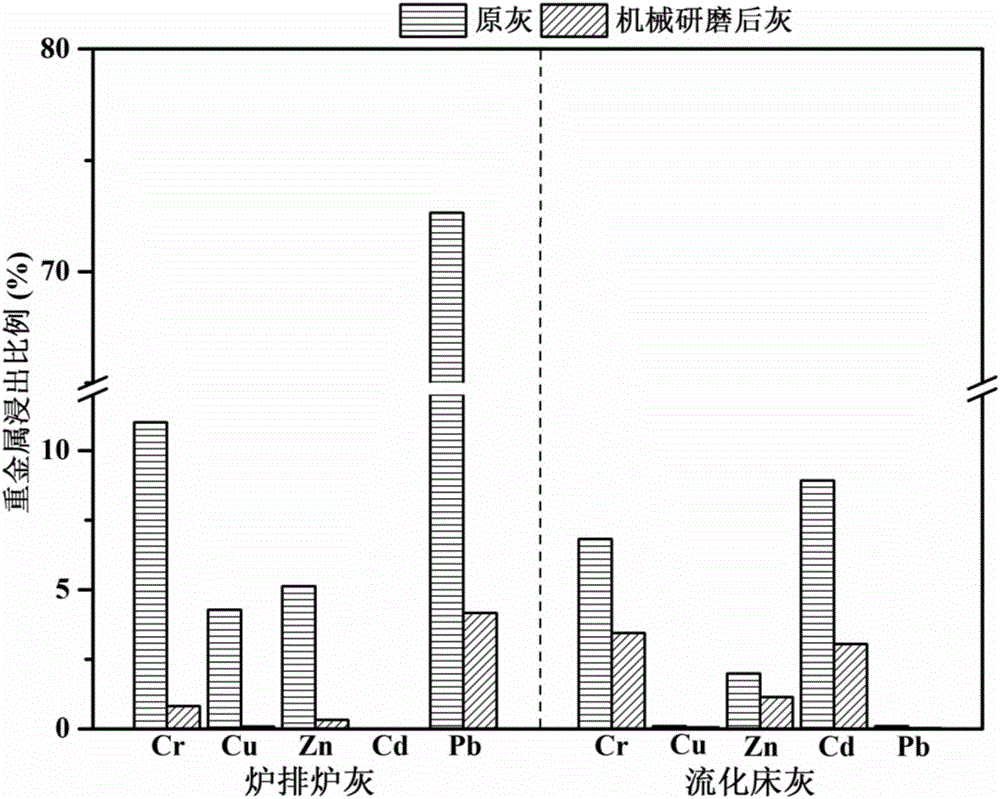

Curing method for heavy metals in waste incineration ash and application thereof

ActiveCN105964655AReduced capacityOvercome the disadvantage of high energy consumptionSolid waste disposalTransportation and packagingBall millIncineration

The invention discloses a curing method for heavy metals in waste incineration ash and application thereof. The curing method comprises the steps of (1) mixing waste incineration ash with water to form a mixture according to a certain proportion, putting the mixture in a ball milling pot, and then, adding grinding balls into the ball milling pot; and (2) sealing the ball milling pot, then, enabling the ball milling pot to perform ball milling treatment under the driving of a planetary ball mill, then, opening the ball milling pot, separating the grinding balls to obtain a ball milling product, then, filtering the ball milling product, and drying filter residues for 4 h to 24 h at the temperature of 60 DEG C to 85 DEG C, so as to obtain waste incineration ash with cured heavy metals. According to the curing method, key ball milling technologies such as the proportion of the mixture, the mass and diameter specifications of the grinding balls and the reaction conditions of the follow-up treatment technologies are improved, the harmful heavy metals in original waste incineration ash are cured, the leaching is reduced, and the environmental protection application approach of waste incineration ash is expanded.

Owner:HUAZHONG UNIV OF SCI & TECH

Soap-free core-shell emulsion type amphiphilic polymer resin and preparation and application thereof in preparation of function humidity controlling coating

InactiveCN101423581BImprove humidity control performanceImprove permeabilityCoatings(Hydroxyethyl)methacrylatePolymer chemistry

The invention provides a nonsoap nuclear shell latex type amphipathic polymer resin, which is polymerized from methyl methacrylate, styrene, methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, hydroxyethyl methacrylate, acrylamide, diacetone acrylamide and other monomers. The nonsoap nuclear shell latex type amphipathic polymer resin is used as a main film formingmaterial for a paint and is combined with various inorganic macromolecular fillers to prepare the paint; the prepared paint integrates decoration, dampness regulation, permeability, heat insulation, dewing resistance, water and alkali resistance, antisepsis and the like, and can also prevent a coating film from falling off caused by various leakage and water condensation of a wall body so that the coating film is more lasting and durable; and the paint contains no organic solvent and no emulsifier, is safer and more environment-friendly, and has more superior coating property.

Owner:NORTHWEST NORMAL UNIVERSITY

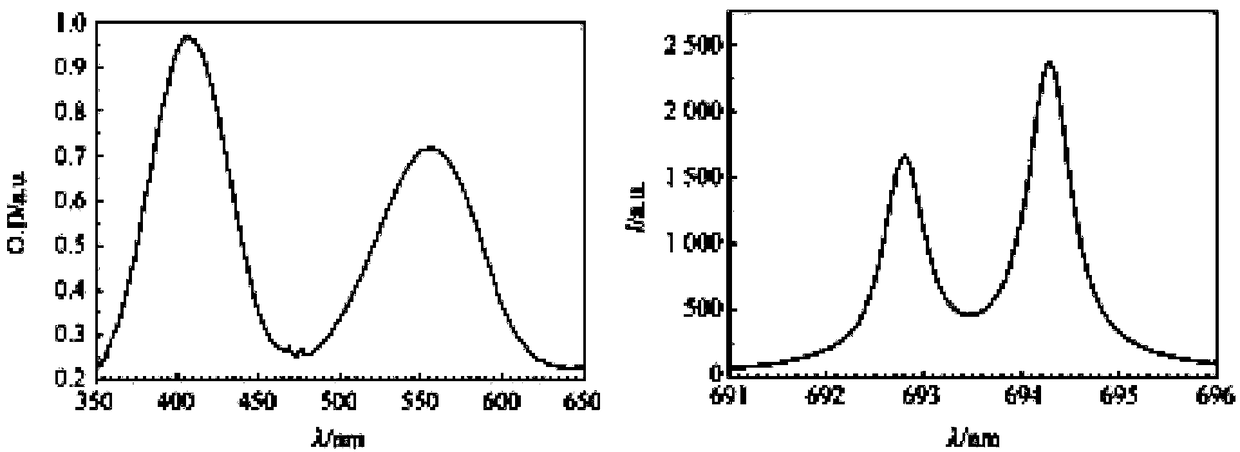

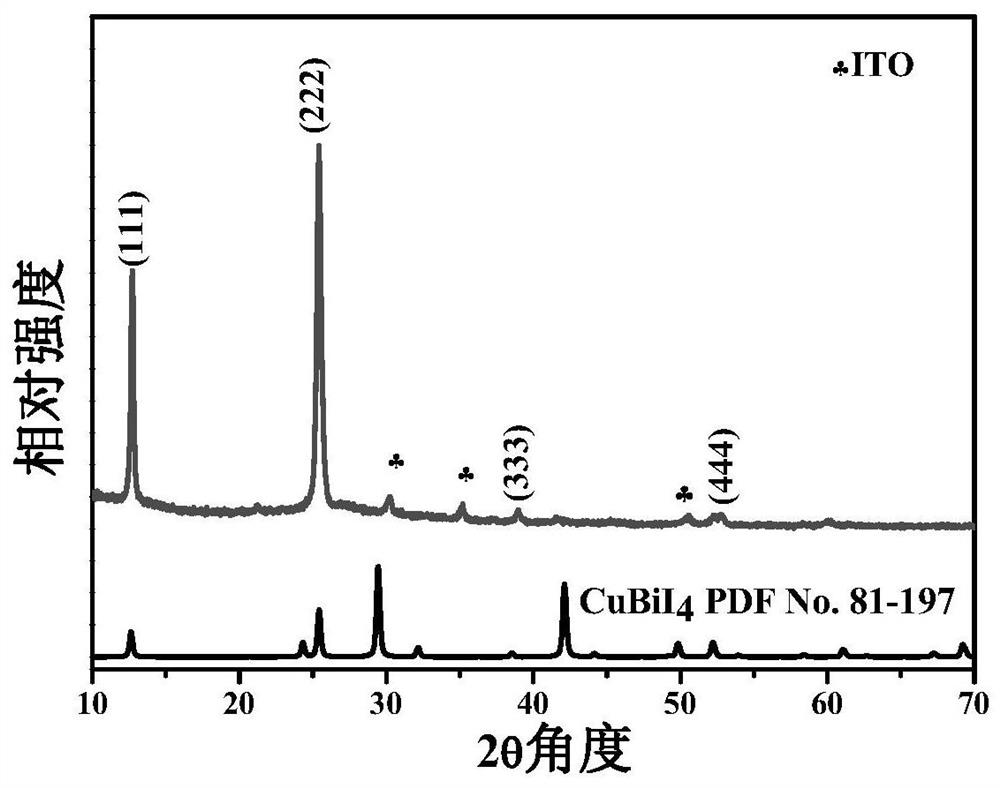

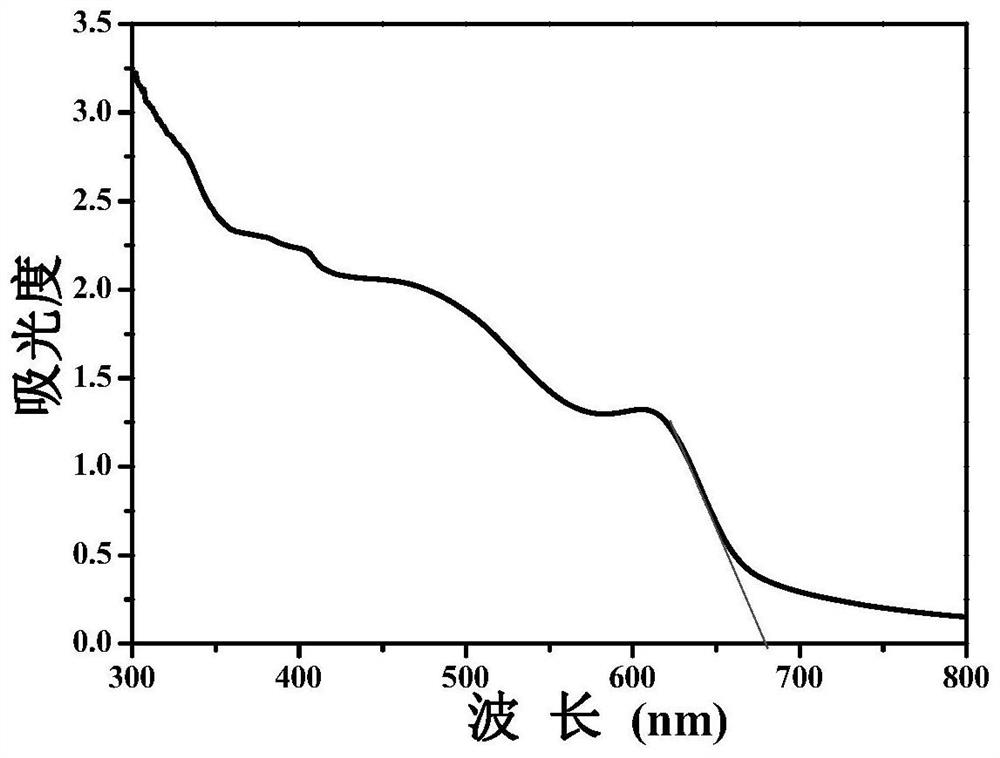

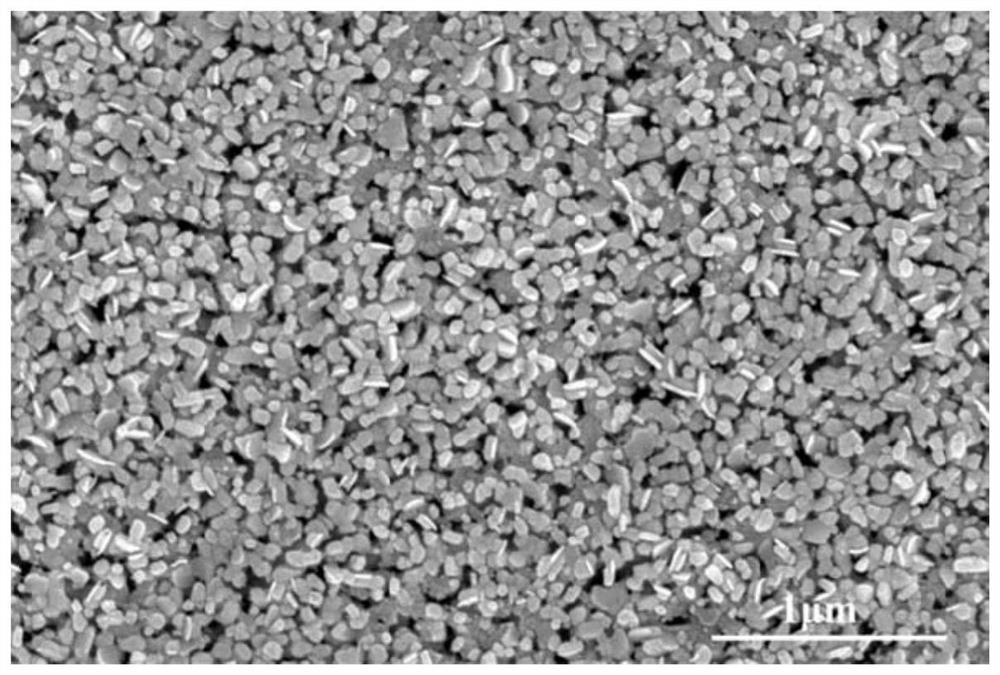

Chemical method for preparing CuBiI4 photoelectric thin film material through wet-process elementary substance powder room-temperature reaction

ActiveCN112993078AExtensive researchBroad industrial application prospectsFinal product manufacturePhotovoltaic energy generationAcetic acidPhysical chemistry

The invention belongs to the technical field of material chemistry, and relates to a chemical method for preparing an iodine bismuth copper photoelectric thin film material through wet-process elementary substance powder room-temperature reaction. The method comprises the following steps: putting copper powder, bismuth powder and elemental iodine in a closed container, stirring the mixture for a period of time at the room temperature of 20-40 DEG C, adding a solvent and glacial acetic acid, continuously stirring and reacting for a period of time to generate CuBiI4, spin-coating a substrate material with a reaction liquid, and performing annealing to obtain the CuBiI4 film. According to the method, metal and nonmetal elementary substance powder directly reacts at room temperature, and glacial acetic acid is added, so that the generation of BiOI is effectively inhibited, and the high-purity CuBiI4 film is obtained. The method has the advantages of no special requirements on reaction equipment, mild conditions, simple process and good repeatability, and can be used for unlimited large-scale industrial production.

Owner:XUCHANG UNIV

Emulsion type amphiphilic polymer resin and preparation and application thereof in preparation of coating

InactiveCN101423582BAvoid disadvantagesImprove humidity control performanceCoatings(Hydroxyethyl)methacrylateEthylene Glycol Methacrylate

The invention provides a latex type amphiphilic polymer resin, which is formed by polymerizing unsaturated acid alkyl, methyl methacrylate, styrene, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, ethylene glycol methacrylate, acrylamide, diacetone-acryloamide and other monomers. The paint which takes the latex type amphiphilic polymer resin as a main film forming material and combines with inorganic polymer stuffing integrates with decorative property, humidifying property, permeability, heat preservation, condensation prevention, water and alkali resistance, bacterium resistance and so on, and can prevent the paint film from dropping off due to multiple kinds of seepage and water condensation of a wall body, so that the paint film is more durable; in addition, the paint has no organic solvent, and is safe and environment friendly.

Owner:NORTHWEST NORMAL UNIVERSITY

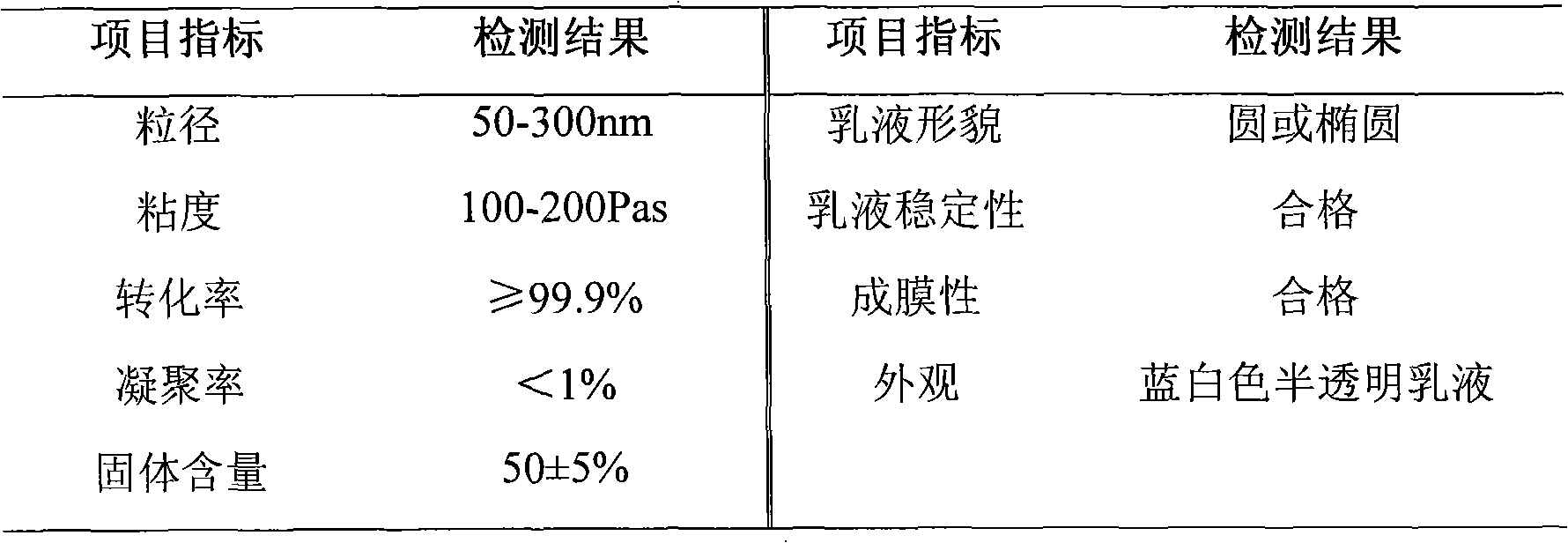

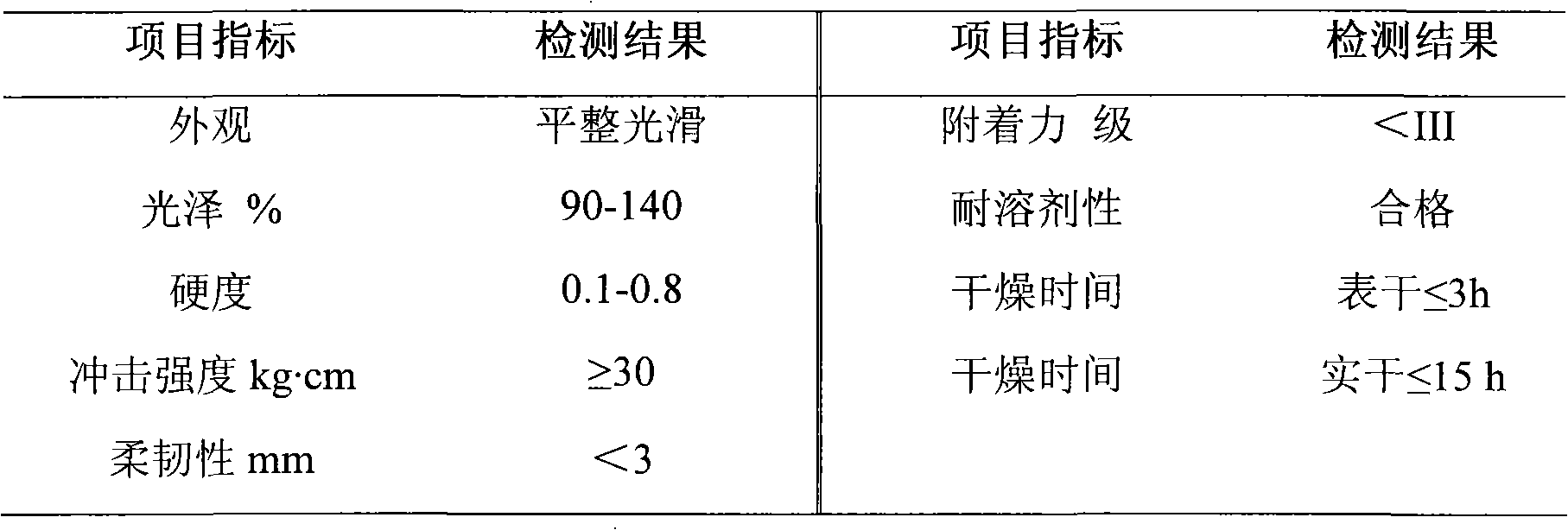

Preparation and application of water-borne polyurethane polyacrylate compound emulsion

InactiveCN102675798BOvercome the disadvantage of high energy consumptionInhibit sheddingPolyurea/polyurethane coatingsPolymer scienceMeth-

Owner:NORTHWEST NORMAL UNIVERSITY

Organic silicon-acrylic ester copolymer emulsion and preparation and application thereof

The invention provides organic silicon-acrylic ester copolymer emulsion, which utilizes organic silicon, methyl methacrylate, butyl acrylate, unsaturated alkyl acid and methacrylic acid-beta-hydroxypropyl ester as comonomers, utilizes deionized water as solvent, utilizes potassium peroxydisulfate or ammonium persulfate as an initiator and utilizes sodium bicarbonate as a neutralizer, and is prepared by polymerization in the presence of an emulsifying agent. The emulsion introduces the organic silicon into polyacrylate, the rigidness of a copolymer is improved to a certain extent, and cohesion of the copolymer emulsion is improved due to the introduction of a polar group. Interior wall humidity-conditioning paint prepared by the copolymer emulsion serving as a film former integrates multiple functions of decoration, humidity conditioning performance, permeability, insulation and anti-condensation performance, water resistance, alkali resistance, alkali-resistant performance and antibiosis, the paint film is durable and long in service life, and the organic silicon-acrylic ester copolymer emulsion serving as the interior wall humidity-conditioning paint has application prospects.

Owner:NORTHWEST NORMAL UNIVERSITY

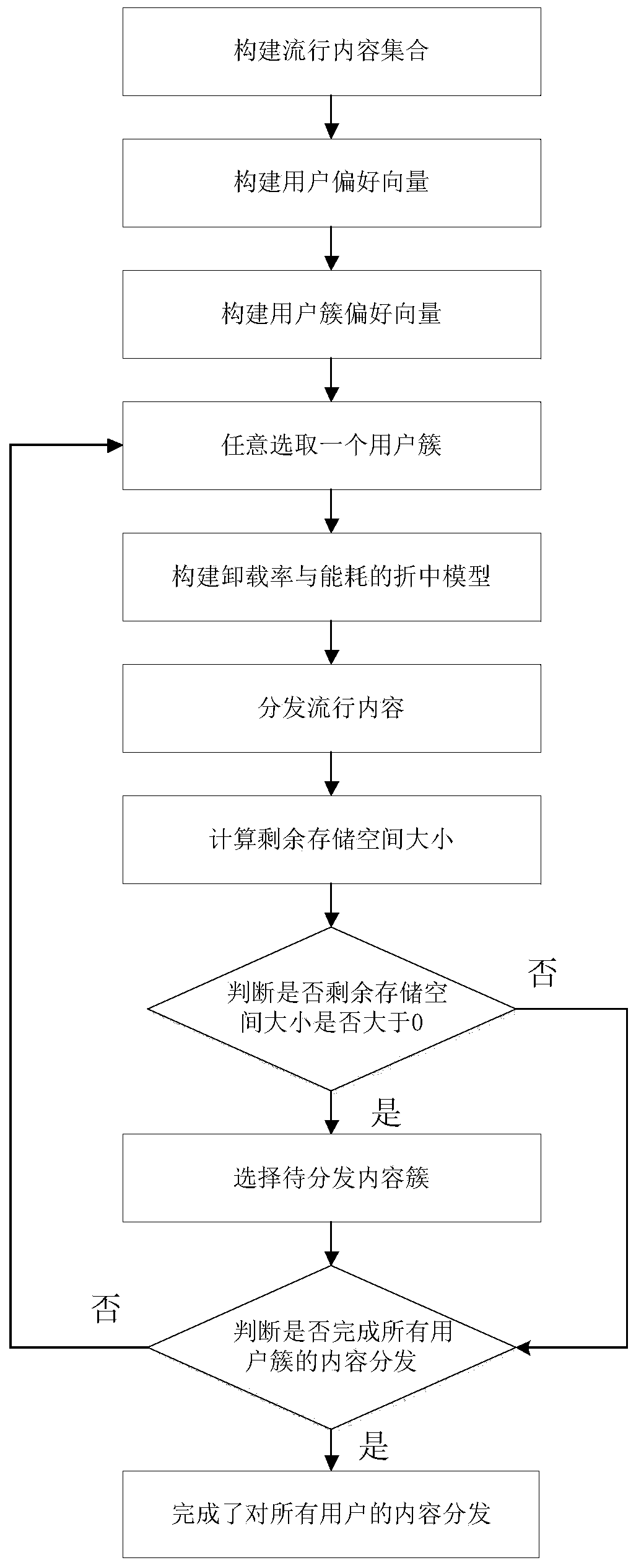

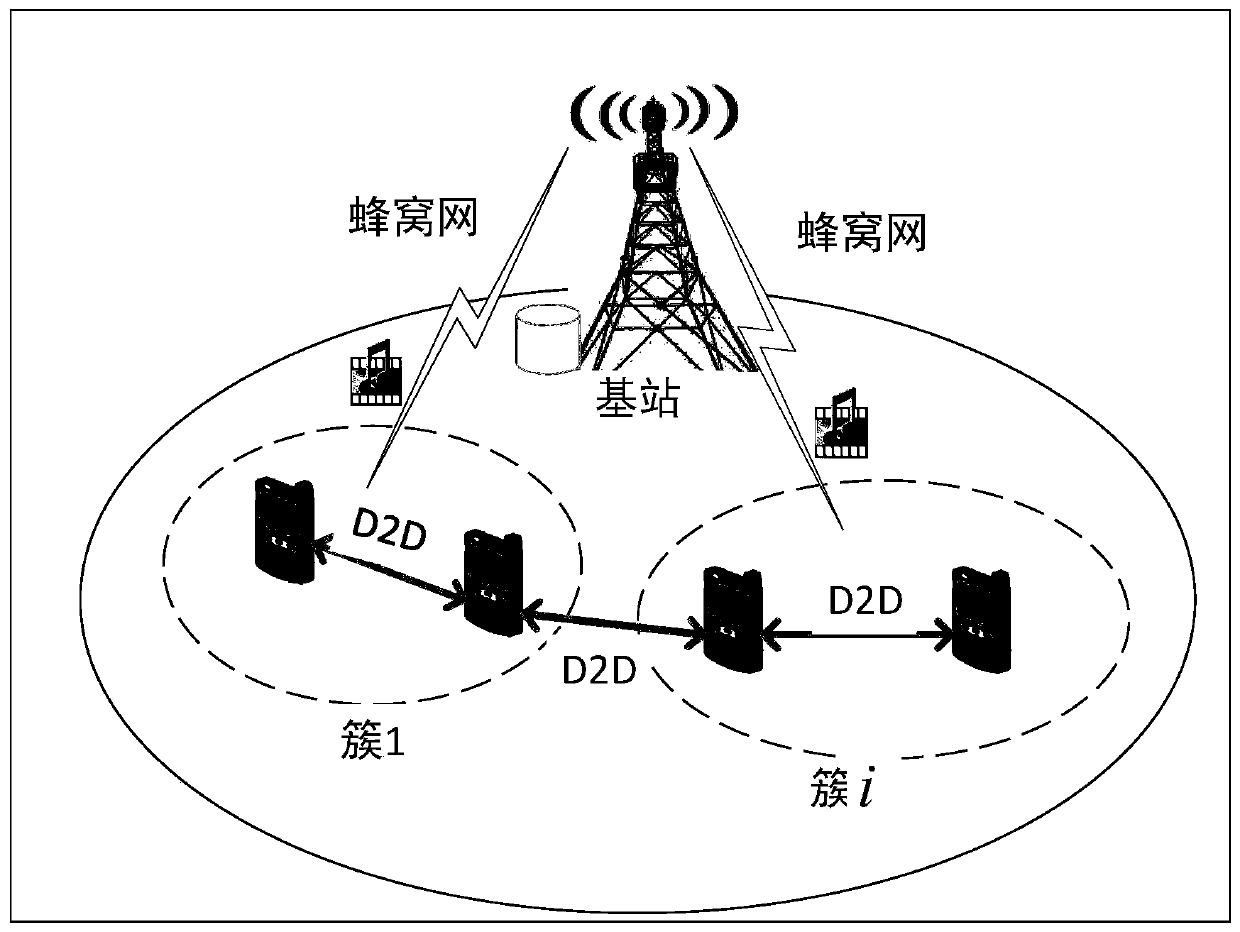

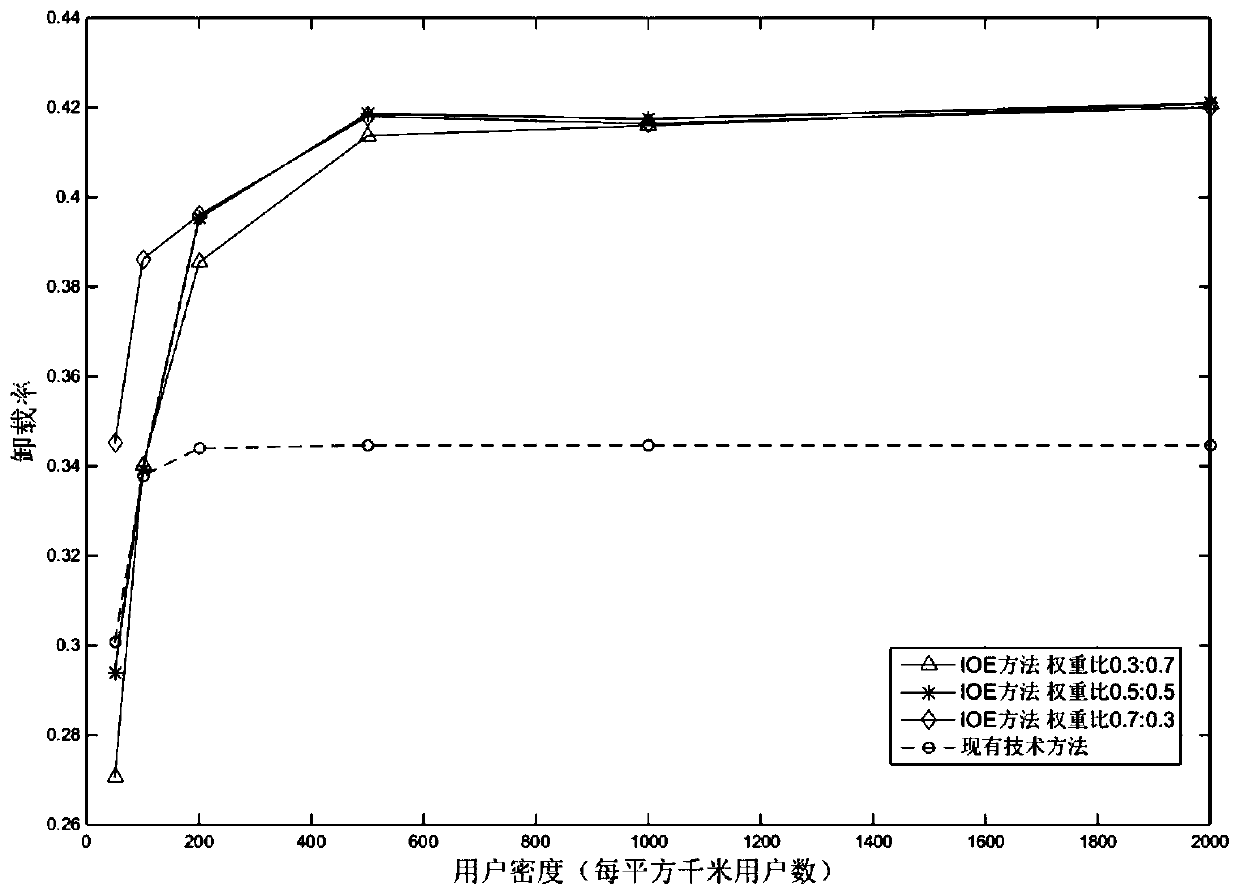

A content distribution method based on d2d and business offloading

ActiveCN107734482BImprove quality of experienceOvercome the disadvantage of high energy consumptionPower managementNetwork traffic/resource managementContent distributionCommunications system

The invention discloses a content distribution method based on D2D and service unloading, which is applied to a fifth-generation mobile communication system, and belongs to the field of wireless communication. The method comprises the following steps of (1) constructing a popular content set; (2) constructing a user preference vector; (3) constructing a user cluster preference vector; (4) randomlyselecting a user cluster; (5) constructing a trade-off model of an unloading rate and energy consumption; (6) distributing popular contents; (7) calculating remaining storage space size; (8) judgingwhether the remaining storage space size is larger than 0 or not; (9) selecting a to-be-distributed content cluster; (10) judging whether the content distribution of all user clusters is completed ornot; and (11) completing the content distribution of all users. Compared with the traditional content distribution method, the method has the advantages that the high service unloading rate of a basestation is guaranteed while the energy consumption is considered, and the user experience quality is improved.

Owner:XIDIAN UNIV

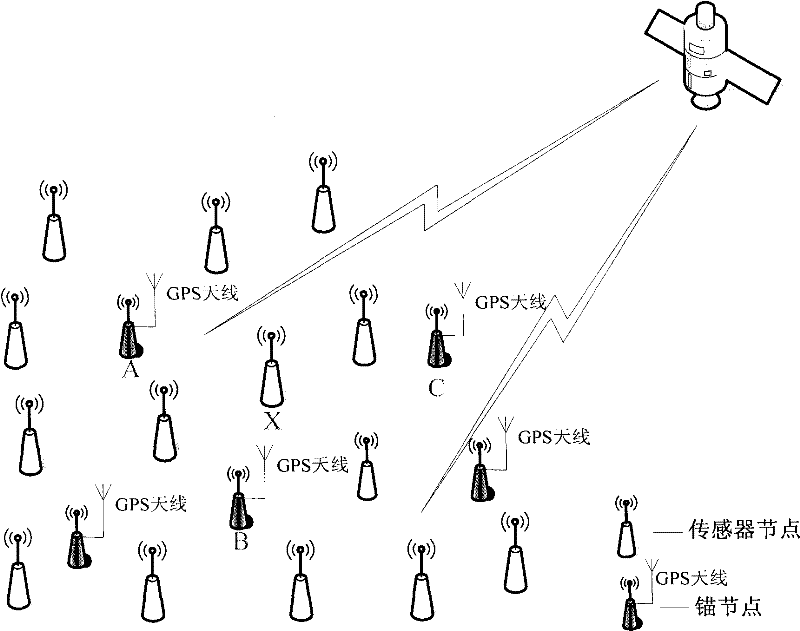

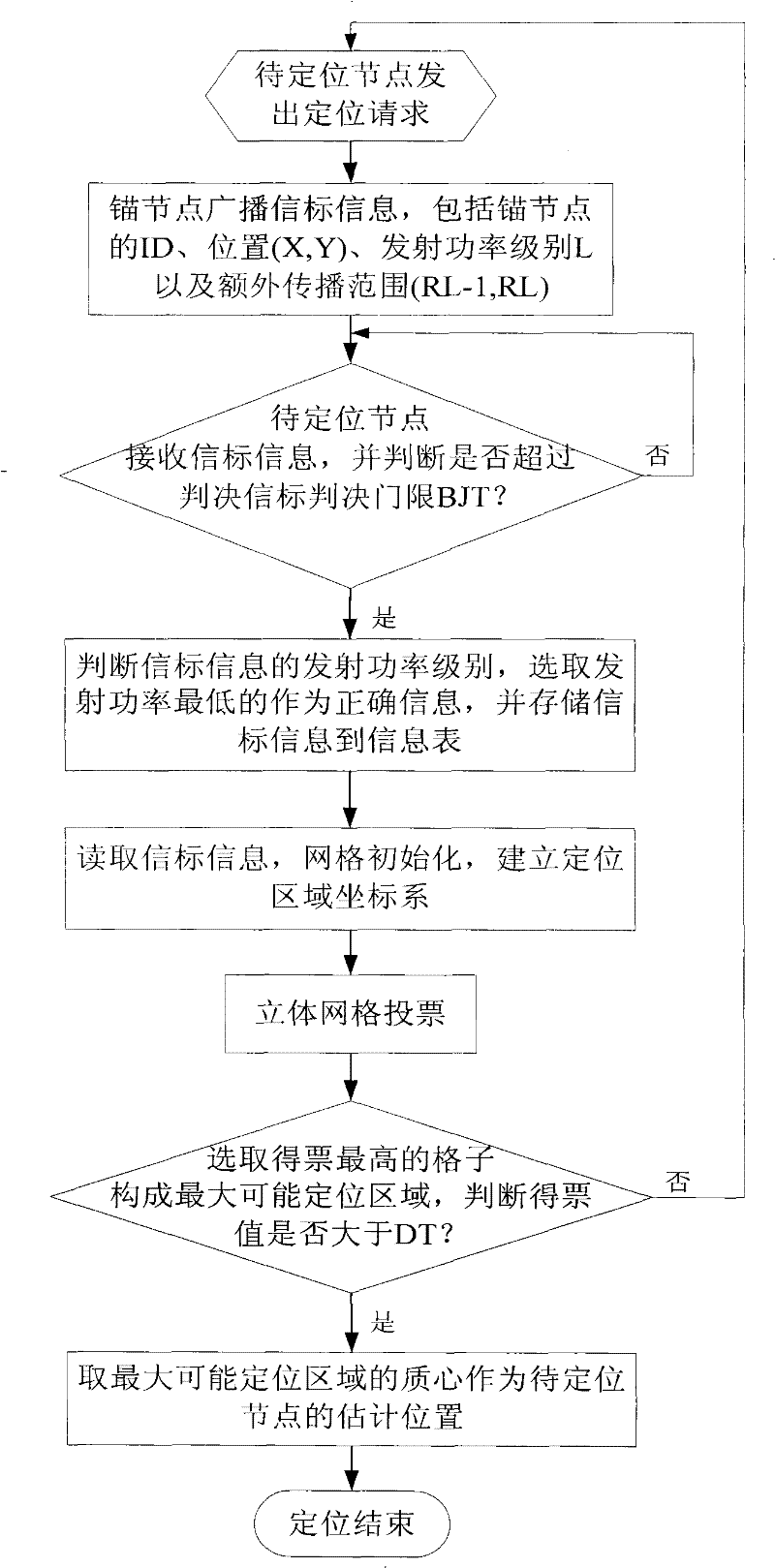

Three-dimensional space wireless sensor network non-range positioning system and method thereof

The invention relates to a system and a method for positioning nonmeasured distance of a wireless sensor network in a three-dimensional space. The system comprises a sensor node and an anchor node; the sensor node is provided with a microprocessor; the microprocessor is connected with a Zigbee radio-frequency communication module, a memorizer, a power module and a sensor acquisition module respectively through a bus and a data wire; the microprocessor is provided with an expanded serial port, a clock circuit, and a resetting circuit which are connected with the microprocessor; and the anchor node is provided with a microprocessor and a GPS positioning device, a GPS antenna, the memorizer and a power supply connected with the microprocessor. The method receives beaconing information from the anchor node by the sensor node, carries out the positioning of the nonmesured distance of the wireless sensor network in the three-dimensional space, does not need any information exchange between the wireless sensor nodes, reduces communication expense, does not need to measure the information of distance between nodes, does not need to add extra distance measuring equipment, reduces cost, adopts simple and effective algorithm, reduces calculation amount, and is easy to realize.

Owner:SHANDONG UNIV

High-purity compact micropore aluminum oxide processing equipment

PendingCN109231246AHigh purityOvercome the disadvantage of high energy consumptionAluminium oxide/hydroxide preparationHigh energyAqueous solution

The invention discloses high-purity compact micropore aluminum oxide processing equipment which comprises an aluminum block smashing device, an aluminum powder dissolving out device, an aluminum powder adding device and a centrifugal device, wherein a gallium solution area and a water solution area are arranged in the aluminum powder dissolving out device from bottom to top, a solution outlet andan ultrasonic oscillator are arranged on a lateral wall of the aluminum powder dissolving out device, and the solution outlet is arranged at the adjacent position between the gallium solution area andthe water solution area; the aluminum powder adding device is arranged in the aluminum powder dissolving out device and is used for adding aluminum powder smashed by the aluminum block smashing device into the aluminum powder dissolving out device, and a powder outlet of the aluminum powder adding device extends into the gallium solution area; the centrifugal device is communicated with the solution outlet of the aluminum powder dissolving out device and is used for separating aluminum oxide from an output aluminum oxide water solution. According to the equipment, the characteristic that aluminum blocks can permeate to the surface of the gallium solution from the outside of an inner core of the gallium solution is utilized, compact micropore aluminum oxide can be formed under the water layer existence condition, and high energy consumption disadvantage of traditional aluminum oxide preparation is overcome.

Owner:YIKANG TECH CO LTD

Amphipathic polymer resin as well as preparation and use thereof in production of intelligent breathing coating

InactiveCN101250242BOvercome the disadvantage of high energy consumptionInhibit sheddingCoatingsPolymer sciencePolymer resin

The invention provides an amphiphilic polymer resin with hydrophilicity and hydrophobicity, which is polymerized by methacrylic acid, methyl methacrylate, butyl acrylate, beta-hydroxypropyl methacrylate, acrylamide, diacetone acrylamide and adipic dihydrazide monomers or the like. The amphiphilic polymer resin can be used as main filming material of paint to combine various cell forming materialsto prepare the paint with decorativeness, humidity adjustment, permeability, thermal insulation, dew prevention, water and alkali resistance and anti-bacterial property, as one multifunctional intelligent breath paint. The product can overcome the defects of traditional air conditioner as high energy consumption and can avoid paint from dropping off wall caused by leakage and water, thereby prolonging the service life of paint, and the invention has wide application.

Owner:NORTHWEST NORMAL UNIVERSITY

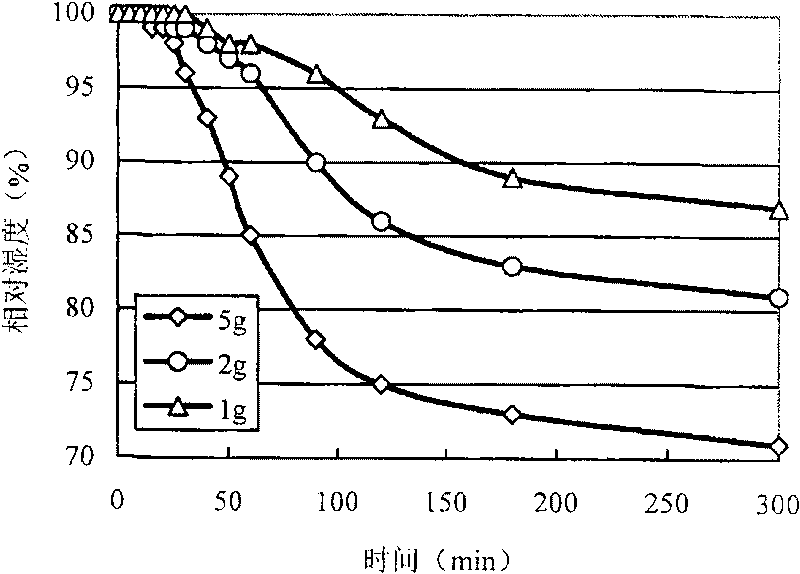

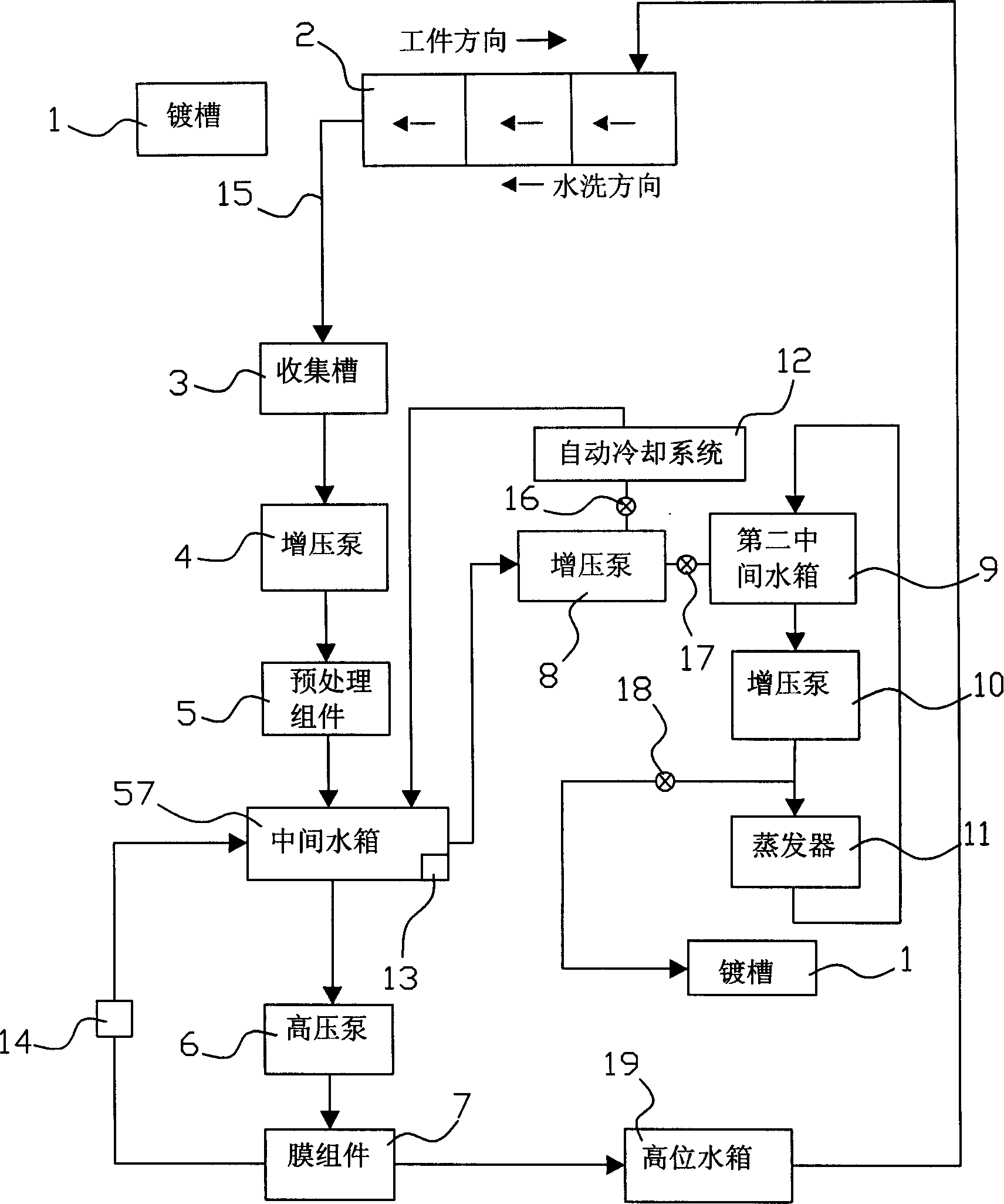

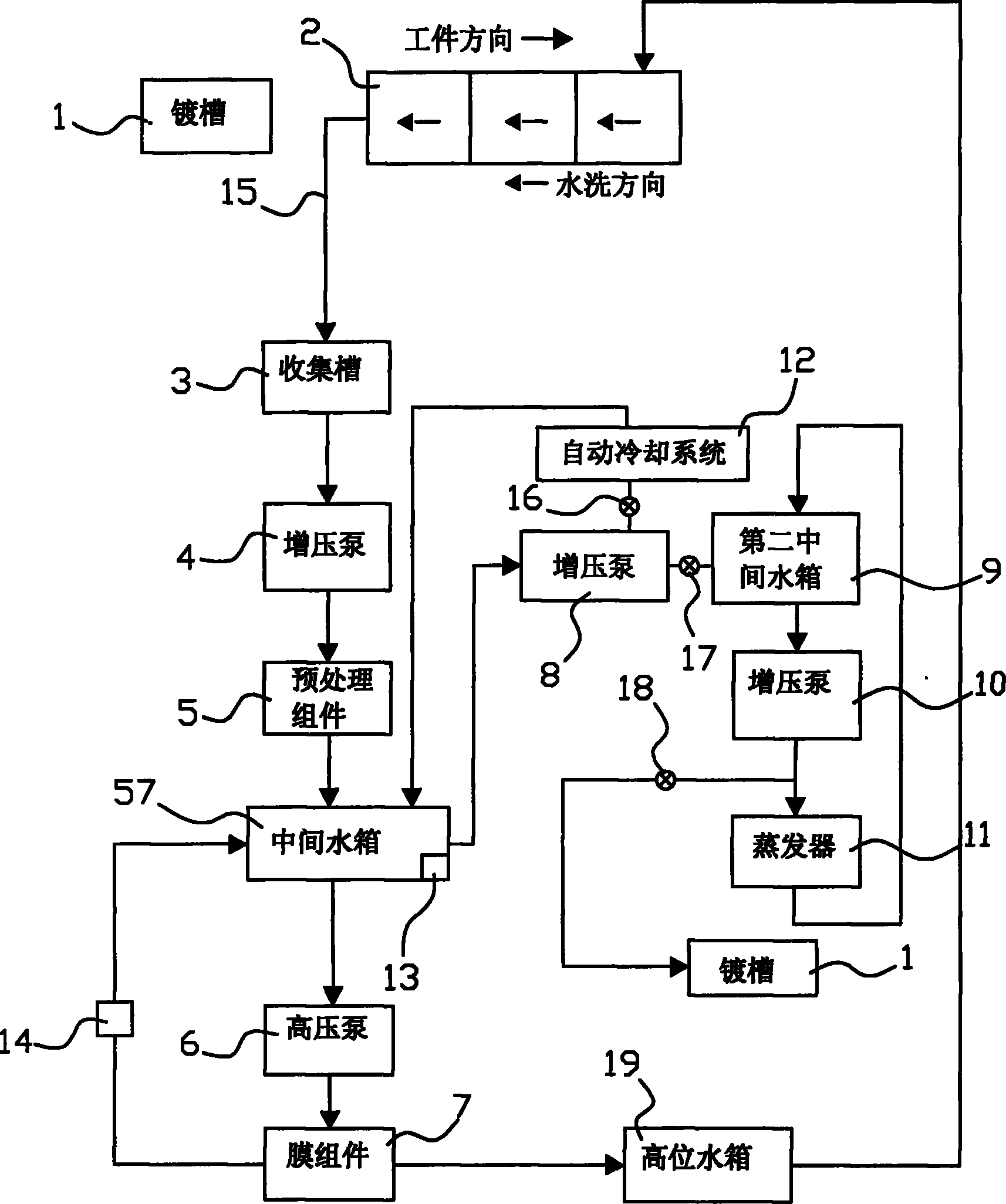

Zero drainage circulation ultilization process and equipment of electroplate waste water

InactiveCN1869289BAchieving zero emissionsOvercome the disadvantage of high energy consumptionCellsEngineeringPre treatment

The invention relates to electroplating waste water zero discharging recycling technology that includes the following steps: pre-treating to the electroplating waste water; separating the heavy metal; vaporizing and condensing to make the liquid achieve the thickness needed by electroplating. The device includes collecting groove, pre-treating component and evaporator. The invention could realizethe zero discharging of heavy metal and have saving and environment protecting effects.

Owner:王俊川

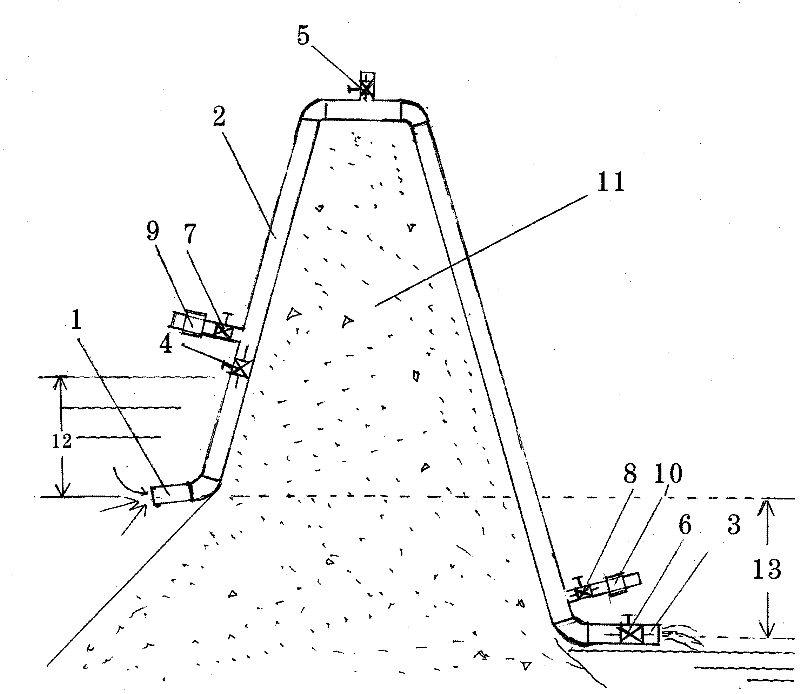

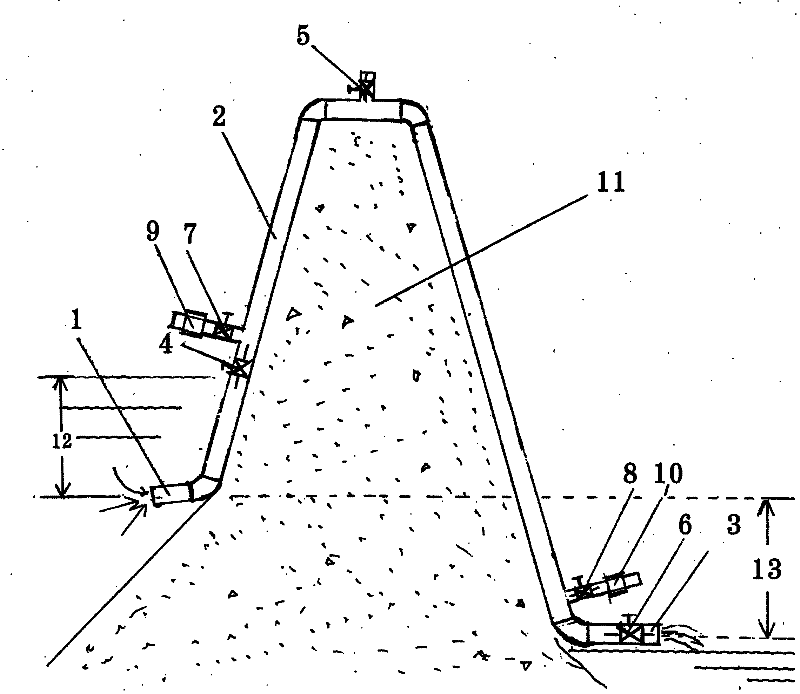

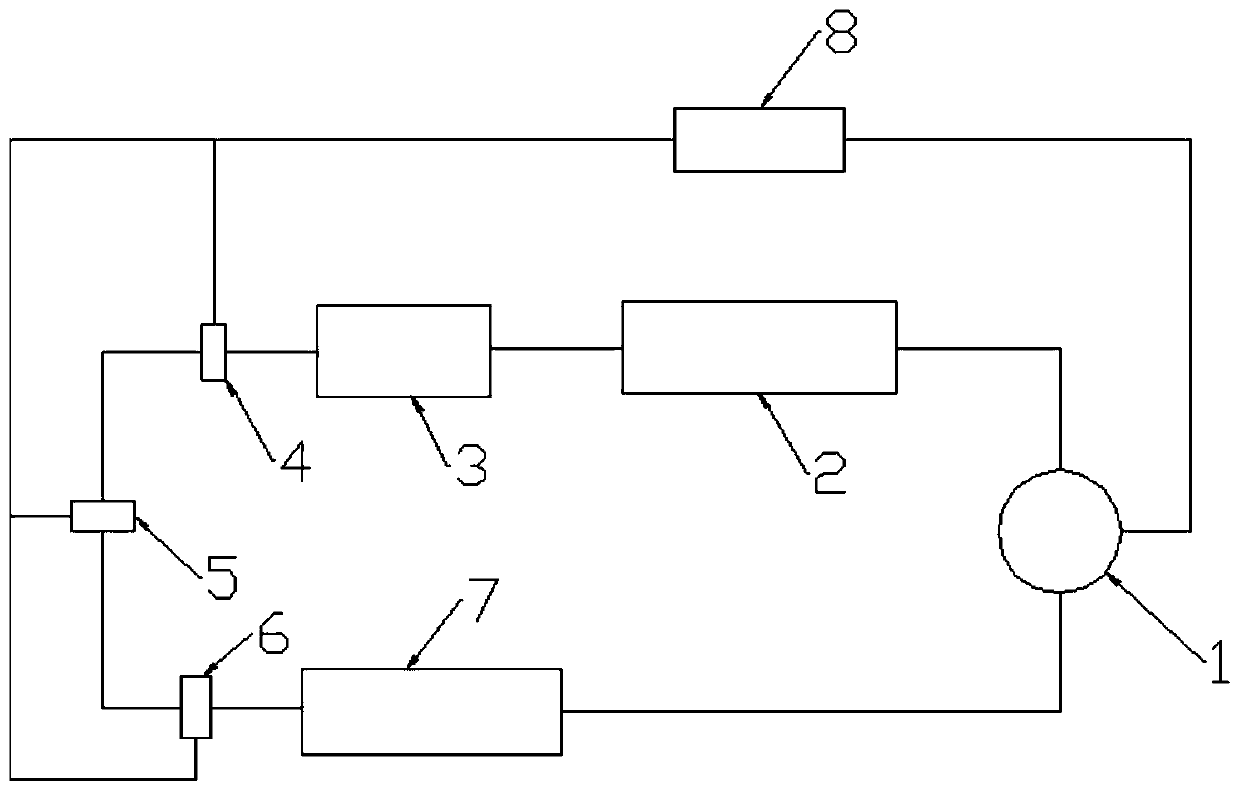

Automatically-flowing water conveyer capable of spanning mountains

InactiveCN102305350ASolve the problem of high energy consumptionSolve environmental problemsPipeline systemsEngineeringEnergy conservation

The invention discloses an automatically-flowing water conveyer capable of spanning mountains and aims to provide an energy-saving and environment-friendly water conveyer capable of flowing automatically without irrigating through machines and digging tunnels. According to the scheme of the invention, the water conveyer comprises a pipeline, a valve and a water pump; the valve is arranged on the water behind a water inlet of the pipeline; a branch pipe is arranged behind the valve, and the valve and the water pump are arranged on the branch pipe; a discharge valve is arranged on the pipeline where the pipeline spans the highest part of the mountain; a water outlet is arranged on the pipeline where the pipeline spans the highest part of the mountain and then extends to the foot of the mountain, wherein the water outlet is lower than the water inlet; the valve is arranged in front of the water outlet; the branch pipe is arranged in front of the valve; and the valve and the water pump are arranged on the branch pipe. The automatically-flowing water conveyer capable of spanning mountains has the advantages of unique design, convenience for implementation, energy conservation and environment protection and is suitable for water conveyance projects with barriers for spanning mountains.

Owner:周润泽 +2

Refrigerating air conditioner system of liquefied natural gas automobile

InactiveCN109780753AOvercome the disadvantage of high energy consumptionMechanical apparatusFluid circulation arrangementControl systemEvaporation

The invention discloses a refrigerating air conditioner system of a liquefied natural gas automobile. A compressor, a condenser, a heat exchanger, a temperature sensor, a pressure sensor, an expandingvalve, an evaporator and a controller system are included; the heat exchanger is connected with the condenser and a liquefied natural gas pipeline; the temperature sensor and the pressure sensor areconnected with the heat exchanger; the control system is connected with the compressor, the temperature sensor, the pressure sensor and the expanding valve; and the expanding valve is connected with the evaporator. The refrigerating air conditioner system of the liquefied natural gas automobile combines the advantages of a compressed steam refrigerating manner and a refrigerating manner utilizingliquefied natural gas evaporation heat absorbing, and has the beneficial effects that influences on the refrigerating capacity by engine loads are small, and energy is saved. The system overcomes thedefect that the energy consumption of the compressed steam refrigerating manner is large, and can also overcome the defect that the refrigerating capacity is affected by the engine loads during liquefied natural gas evaporation refrigerating.

Owner:CHANGZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com