Amphipathic polymer resin as well as preparation and use thereof in production of intelligent breathing coating

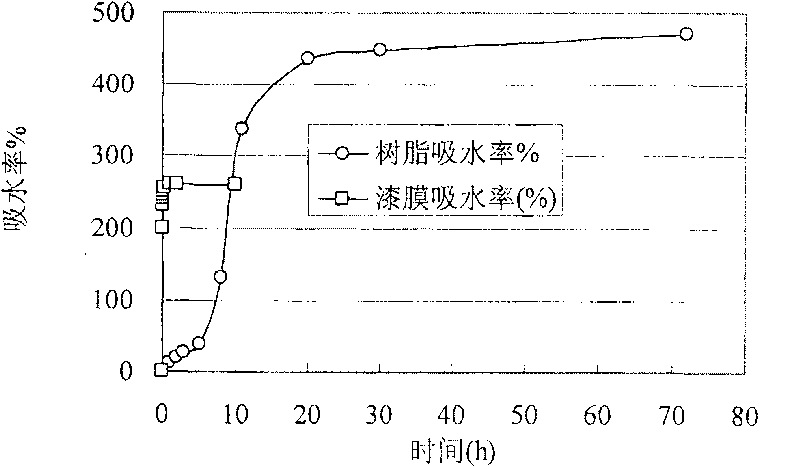

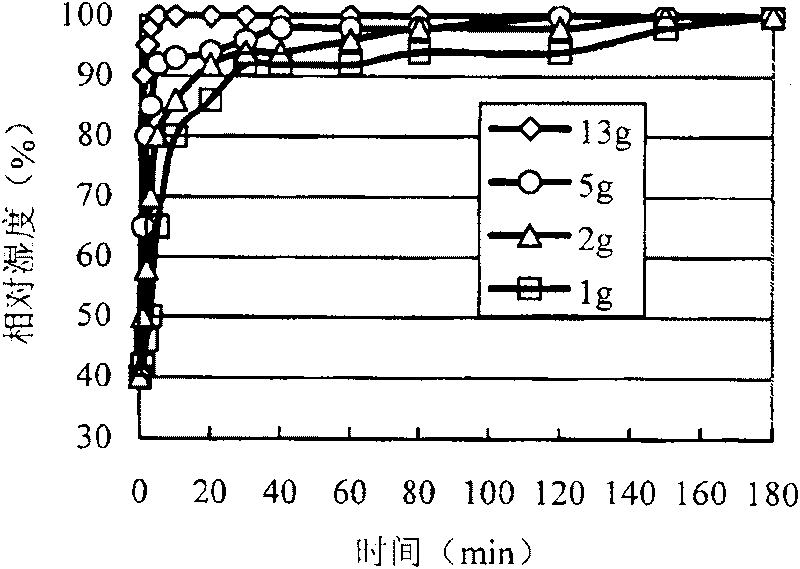

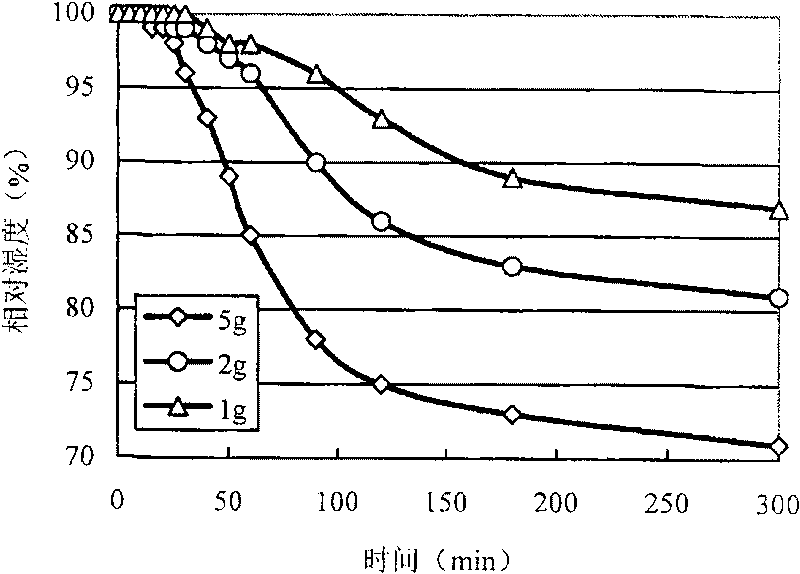

An amphiphilic polymer and intelligent technology, applied in the field of polymers, can solve problems such as foaming, poor water resistance of the coating film, and low responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: Preparation of amphiphilic polymer resin

[0063] Recipe: by weight

[0064] 50 parts of methacrylic acid, 80 parts of methyl methacrylate, 10 parts of butyl acrylate, 10 parts of hydroxypropyl methacrylate, 10 parts of diacetone acrylamide, 50 parts of adipic hydrazide, and 80 parts of isopropanol.

[0065] Preparation method: Dissolve methacrylic acid, methyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, diacetone acrylamide, and adipic hydrazide monomers in the solvent according to the above formula, and add the total mixed monomer The amount of benzoyl peroxide is 5%; the mixture is reacted at 95°C for 3 hours and then cooled to 60°C, the unreacted monomer and part of the solvent are evaporated under reduced pressure, and then neutralized with ammonia to pH=7-10, Then adjust the water to a viscosity of 15~150s (coating -6 Cup measurement), the solid content is 30-70%, and the transparent amphiphilic polymer resin solution is obtained.

[0066] After ...

Embodiment 2

[0069] Example 2: Preparation of amphiphilic polymer resin

[0070] Recipe: by weight

[0071] 25 parts of methacrylic acid, 40 parts of methyl methacrylate, 40 parts of butyl acrylate, 30 parts of hydroxypropyl methacrylate, 20 parts of acrylamide, 10 parts of diacetone acrylamide, 30 parts of adipic hydrazide, 40 parts of ethanol Copies.

[0072] Process: Dissolve methacrylic acid, methyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, acrylamide, diacetone acrylamide, and adipic hydrazide monomers in ethanol according to the above formula quantity, and add the mixing unit Azobisisobutyronitrile containing 1% of the total volume; the temperature is raised to 65°C for 4 hours, and the temperature is reduced to 25°C. The unreacted monomer and part of the solvent are evaporated under reduced pressure, and then neutralized with ammonia to pH=7~10 , Then adjust the water to a viscosity of 15~150s (paint -6 Cup measurement), the solid content is 30-70%, and the transparent am...

Embodiment 3

[0074] Example 3: Preparation of amphiphilic polymer resin

[0075] Recipe: by weight

[0076] 5 parts of methacrylic acid, 40 parts of methyl methacrylate, 50 parts of butyl acrylate, 10 parts of hydroxypropyl methacrylate, 5 parts of acrylamide, 25 parts of diacetone acrylamide, 5 parts of adipic hydrazide, 20 parts of water Copies.

[0077] Process: Dissolve methacrylic acid, methyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, acrylamide, diacetone acrylamide, and adipic hydrazide monomers in water according to the above formula amount, and add mixed monomers The total amount of 0.2% ammonium persulfate; the temperature is raised to 80°C for 1 hour, and then the temperature is lowered to 40°C, the unreacted monomer and part of the solvent are evaporated under reduced pressure, and then neutralized with ammonia water to pH=7~10, and then adjusted with water To viscosity 15~150s (coating -6 Cup measurement), the solid content is 30-70%, and the transparent amphiphilic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com